Solid-liquid phase change material normal pressure thermal expansion rate and work volume digital measuring device

A thermal expansion rate and digital measurement technology, applied in the field of physical measurement, can solve problems such as the inability to guarantee the measurement accuracy, and the inability and inability of the digital acquisition system to provide digital information, achieving obvious scientific value and social benefits, low cost, and convenient production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] specific implementation plan

[0019] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

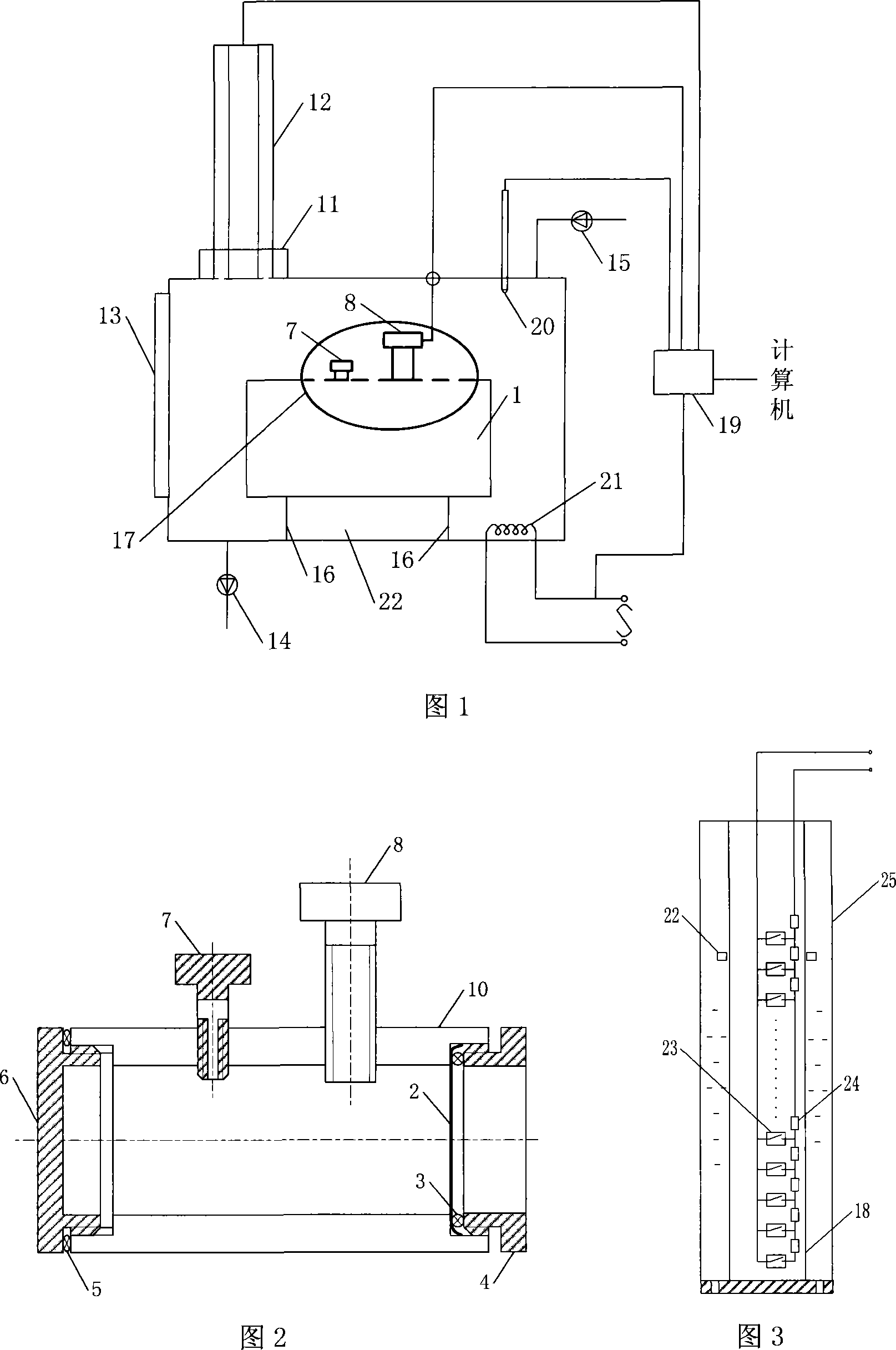

[0020] As shown in Fig. 1, Fig. 2 and Fig. 3, the present invention includes an inner tank 1, an outer tank 9, a vent plug 7, a pressure sensor 8, a water level gauge sealing seat 11, a water level gauge 12, a drain valve 14, and a replenishment valve 15 , sampling control unit 19, thermocouple 20 and automatic electric heater 21.

[0021] The liner 1 includes a gland 6 , a pressure ring 4 , a liner cylinder 10 and a latex film 2 . The inner tank cylinder 10 is a cylinder made of stainless steel with inner shoulders at both ends. The gland 6 is threadedly connected to one end of the inner tank body 10 through the rubber sealing ring 5, the latex film 2 is placed on the inner shoulder of the other end of the inner tank body 10, and the pressure ring 4 is screwed to the other end of the inner tank bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com