Hollow hole burn cut three-time blasting method

A hollow, blasting area technology, applied in blasting, earth-moving, mining equipment, etc., can solve the problems of low utilization rate of blasting holes, limited number of detonator segments used, and small circulation footage, so as to ensure the utilization rate of blasting holes and improve the The utilization rate of the blast hole and the effect of ensuring the cycle footage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

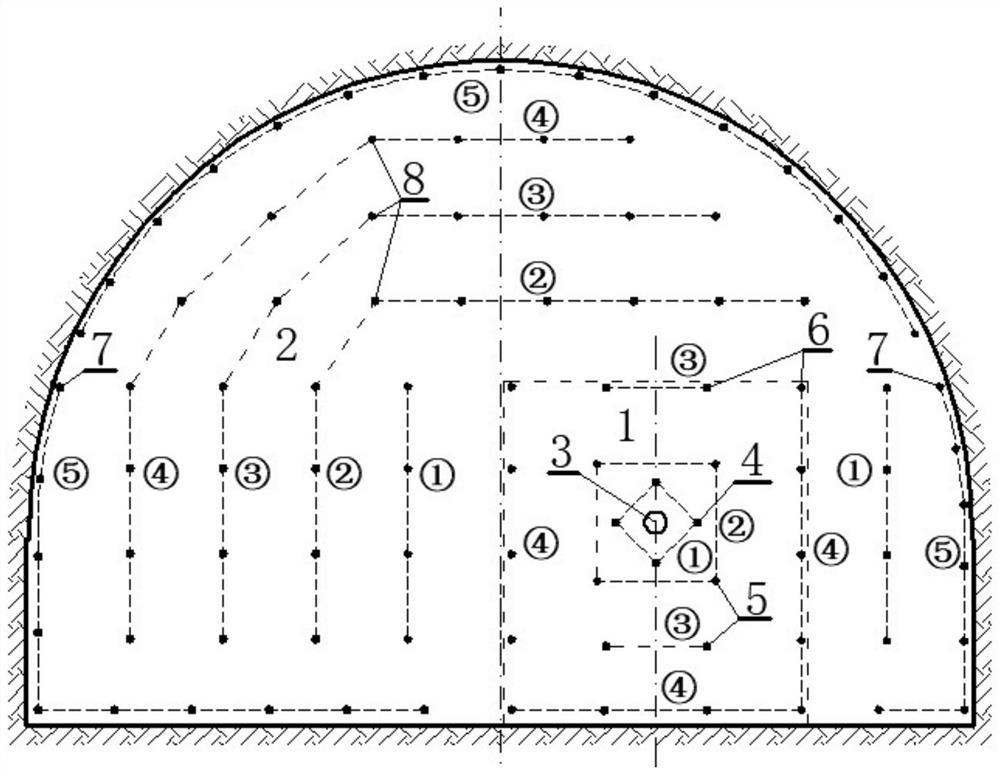

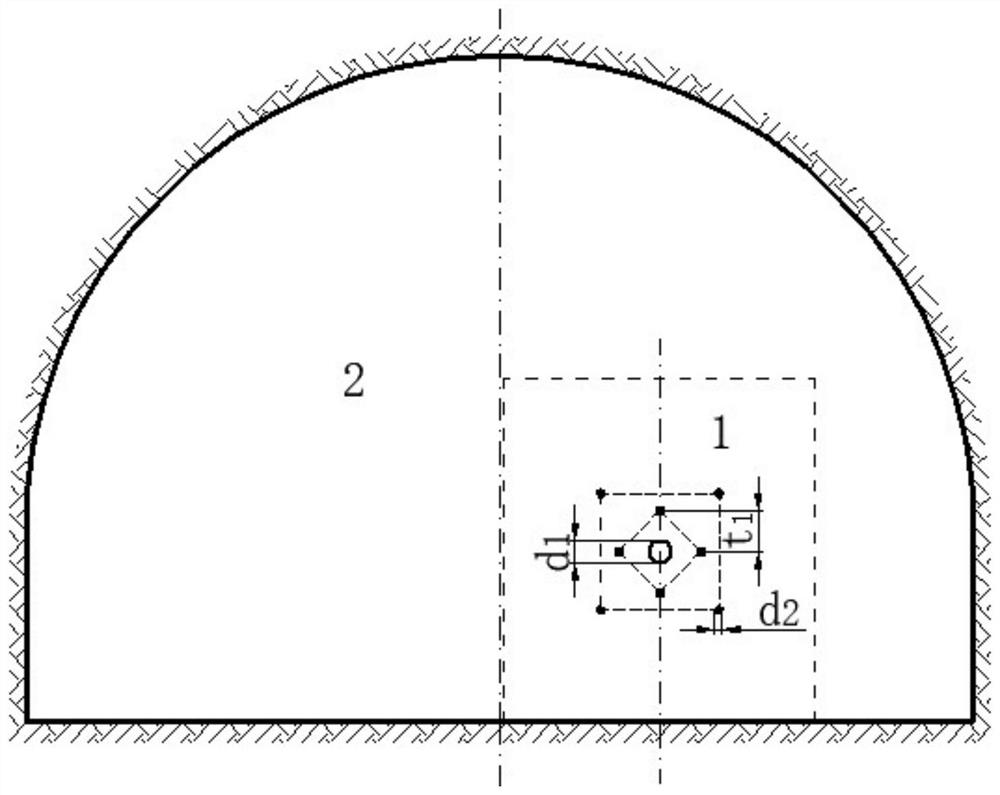

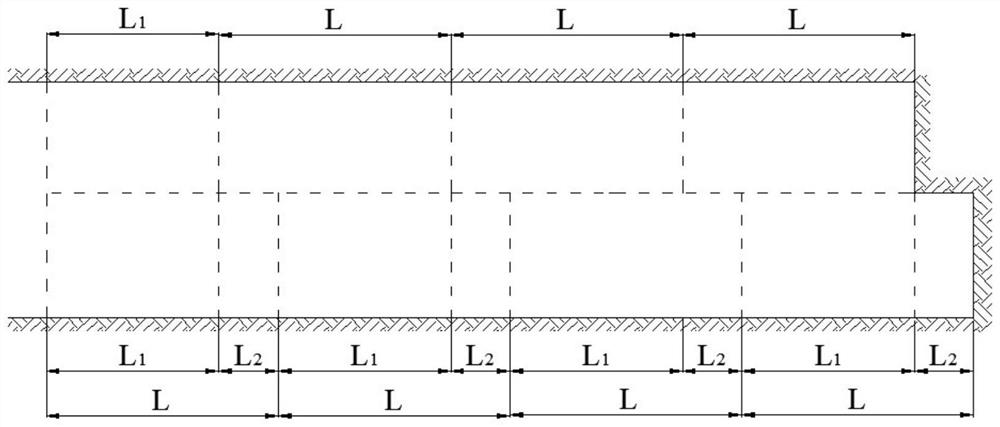

[0052] combine Figure 1 to Figure 6 As shown, the specific implementation of a three-time blasting method for hollow hole straight hole cut provided by the present invention will be described.

[0053] Taking the auxiliary transportation roadway of a certain coal mine as an example, a three-time blasting method of hollow hole straight hole cutting is described. The roadway is a straight wall semi-circular arch section, the excavation width is 5.40m, the height is 3.75m, and the section area is 15.53m 2 . Its working capacity is 220ml, the detonation velocity is 3000m / s, the force is 0.01m, the diameter of the drug roll is 0.035m, the length is 0.40m, and the mass is 400g / roll. Use the permissible electric detonator for coal mines in the 1st to 5th section. The hole diameter is 0.133m, and the charge hole diameter is 0.042m. Before the blasting, the drilling, loading and transporting integrated machine was withdrawn to a distance of 15.0m from the excavation working face, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com