Small-hole reinforced fracturing grain and single-surface hoop slit grain combined cutting undermine method

A charge and cutting technology, which is applied in earth drilling, mining equipment, offensive equipment, etc., can solve the problems of low blasthole utilization rate, low energy utilization rate of explosives, poor cutting effect of expansion space, and increased sandwiching effect of surrounding rocks, etc. , to achieve the effects of improving blasthole utilization and explosive energy, increasing damage range, and reducing blasting vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] In the deep underground -800m hard sandstone roadway, the combined cutting method of small hole reinforced fracturing charge and single-sided circumferential slit charge is adopted, including the following steps:

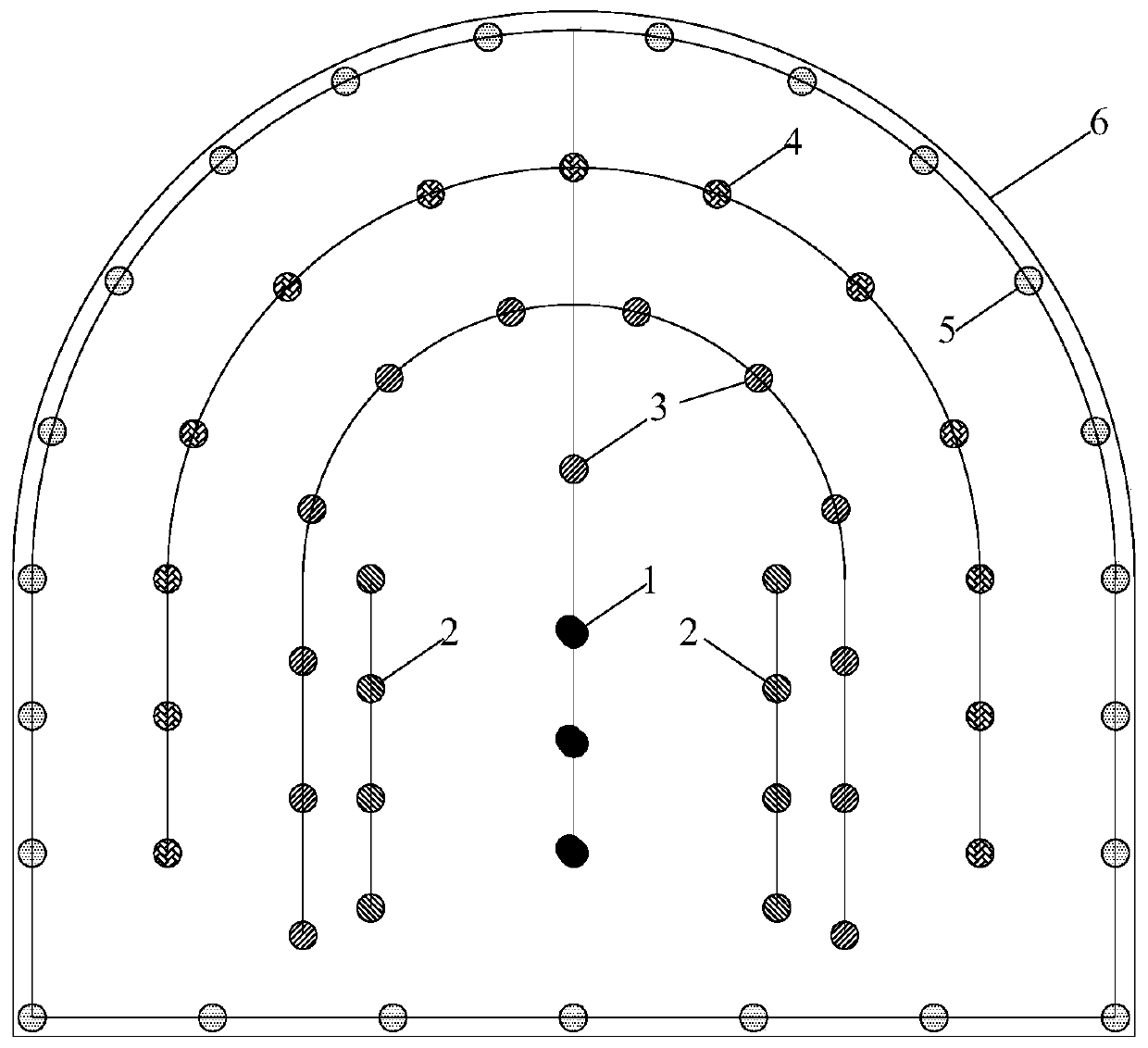

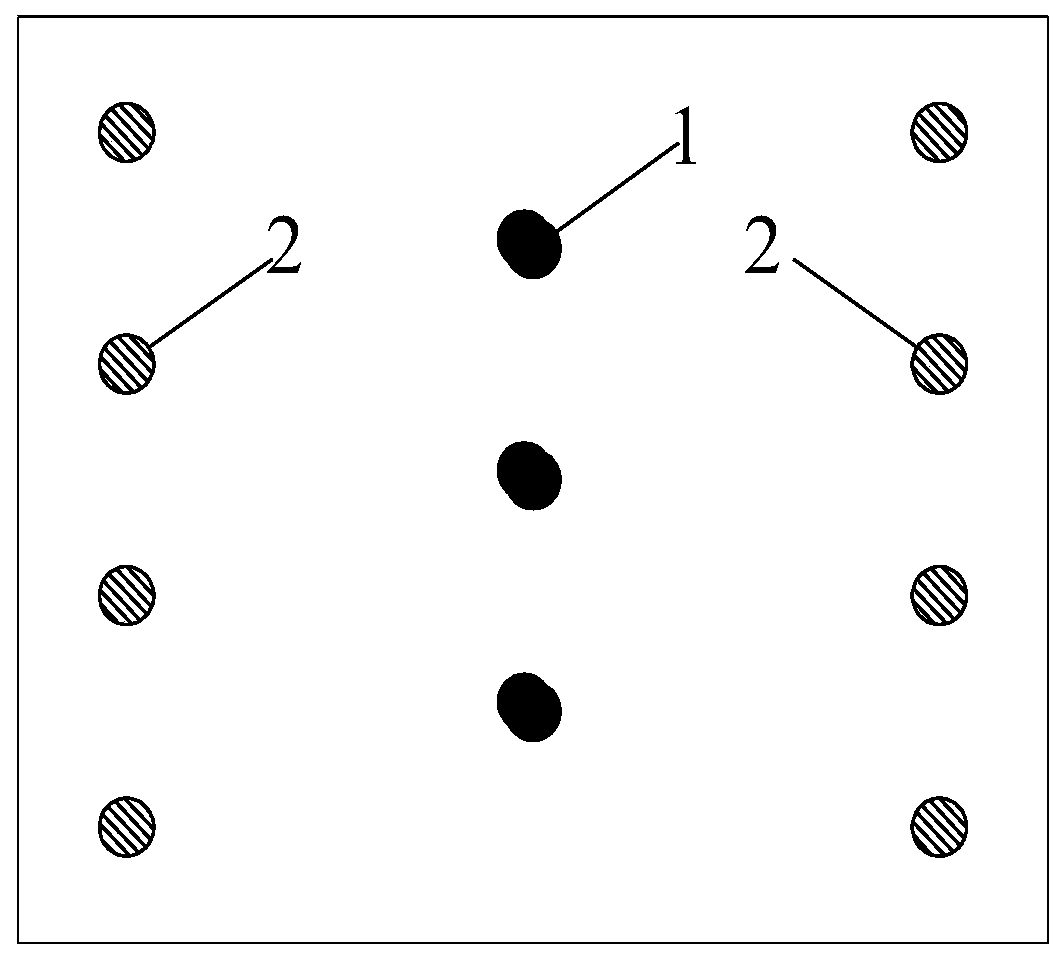

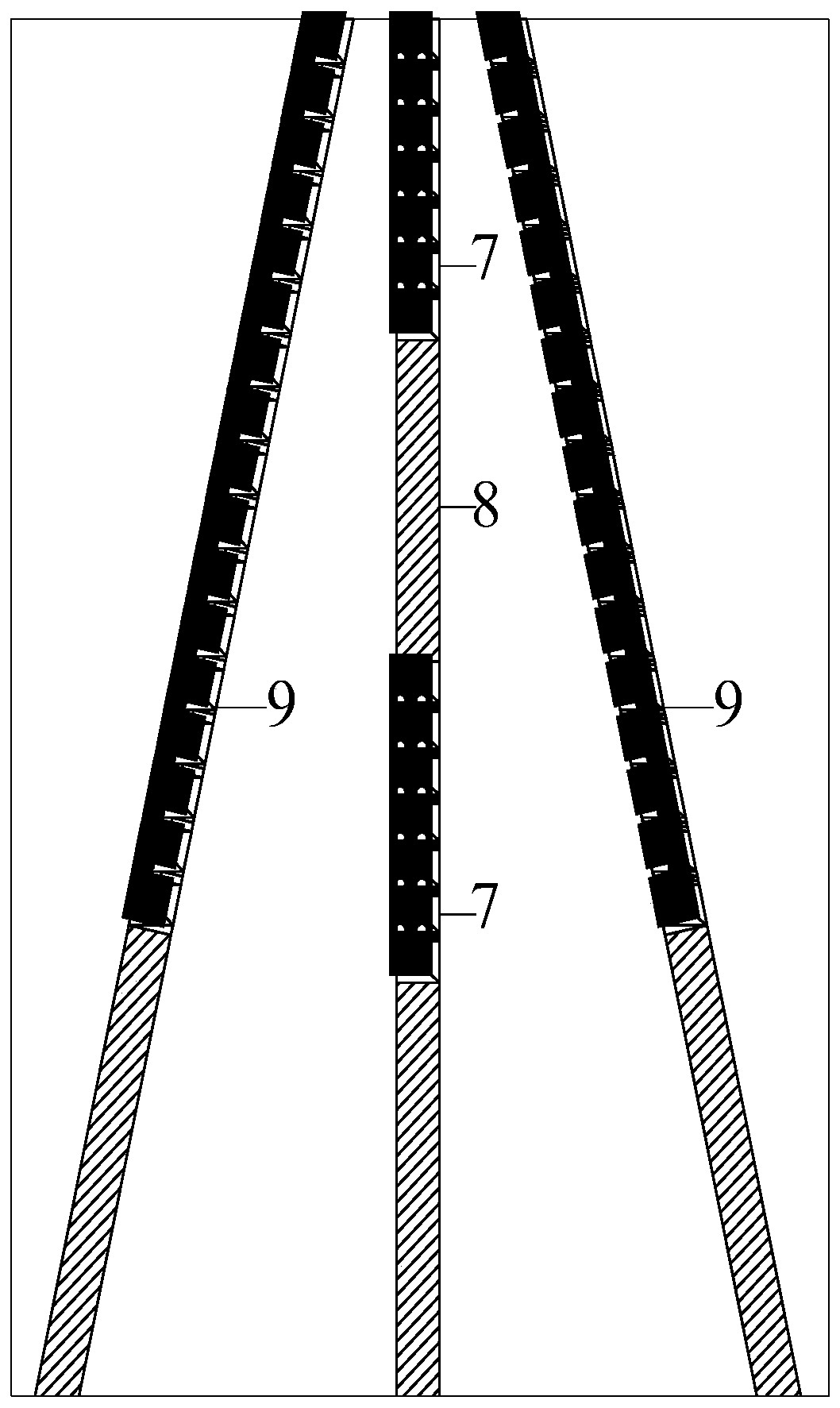

[0064] 1) Drilling: Using a hydraulic drilling rig, a 2.6m long rock drill rod, and a drill bit with a diameter of 42mm, drill a central cut hole 1, wedge cut hole 2, auxiliary hole 3, and caving hole 4 on the roadway section 6 and peripheral holes 5, the central cut hole 1 is located in the middle area of the roadway section 6, the wedge-shaped cut hole 2 is located on the left and right sides of the central cut hole 1, and the auxiliary hole 3 is located on the outside of the wedge-shaped cut hole 2. The above-mentioned caving hole 4 is located outside the auxiliary hole 3, the peripheral hole 5 is located on the outline of the roadway section 6, the depth of the central cut hole 1 and the depth of the wedge-shaped cut hole 2 are 2.5m, and the depth of oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com