Battery system with improved exhaust system

A battery system, battery cell technology, applied in the direction of batteries, exhaust plug devices, battery pack components, etc., can solve the problems of impact, shell damage to the environment, hazards, etc., achieve low temperature, save space, and reduce rigid components Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

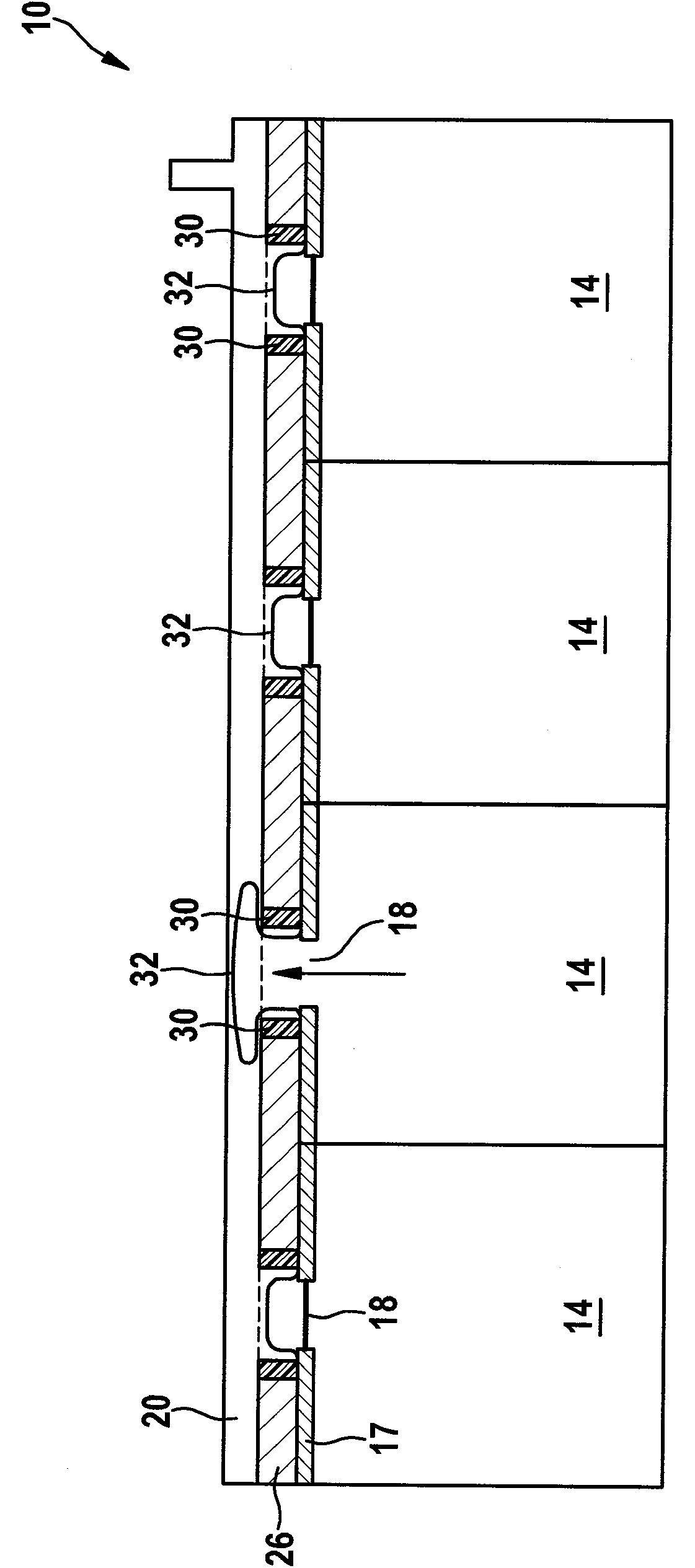

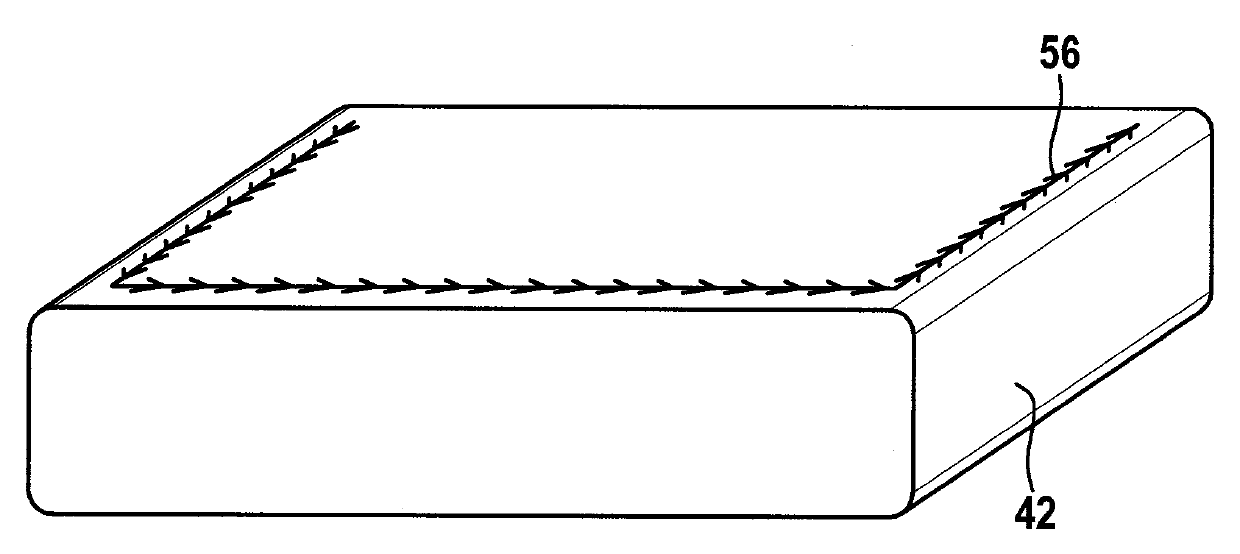

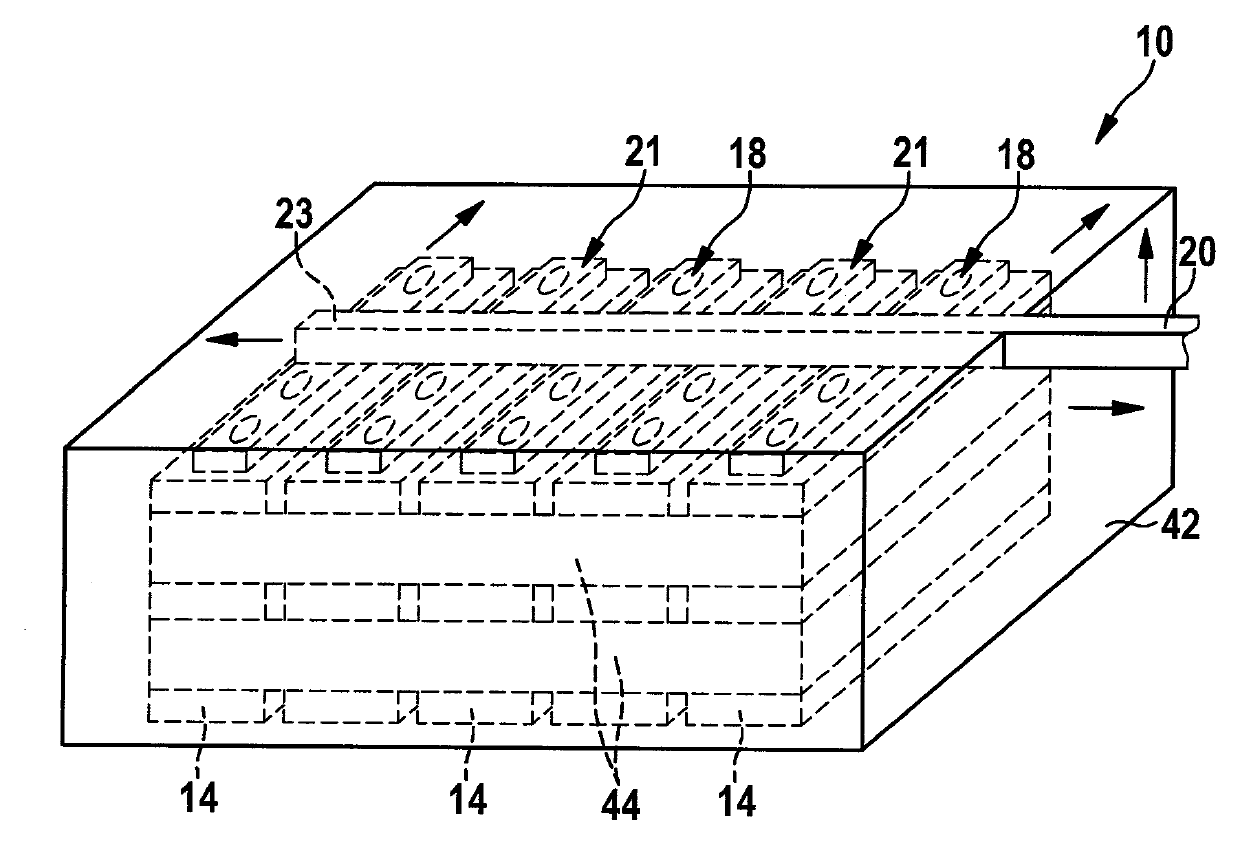

[0073] The following figures each show an embodiment of a battery system 10 , which can, for example, be a component of an electrically driven vehicle. The features shown in the different figures can form part of the invention individually or in any combination and are not discussed individually. In addition, the same reference numerals denote the same or corresponding components, so that detailed descriptions thereof are not specifically made for each drawing.

[0074] as in figure 1 The battery system 10 shown in a has a battery module 12 with a plurality of battery cells 14 . The battery cells 14 here each have at least one cell unit arranged in a cell housing 16 , wherein the cell housing 16 each has a device for draining the emissions formed in the cell housing 16 in the event of a fault. An exhaust valve 18 for the gas, and an exhaust collector 20 is provided therein for guiding exhaust from the battery system 10 . The exhaust gas collector 20 here comprises openings,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com