Method for acquisition of continuous profile image of polyphase material

A cross-sectional image and multi-phase material technology, applied in the field of cross-sectional image acquisition of multi-phase materials, can solve the problems of 3D reconstruction error, large distance between adjacent sections, and limit the promotion and application of CT scanning technology, so as to prevent dust and noise pollution , to ensure the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

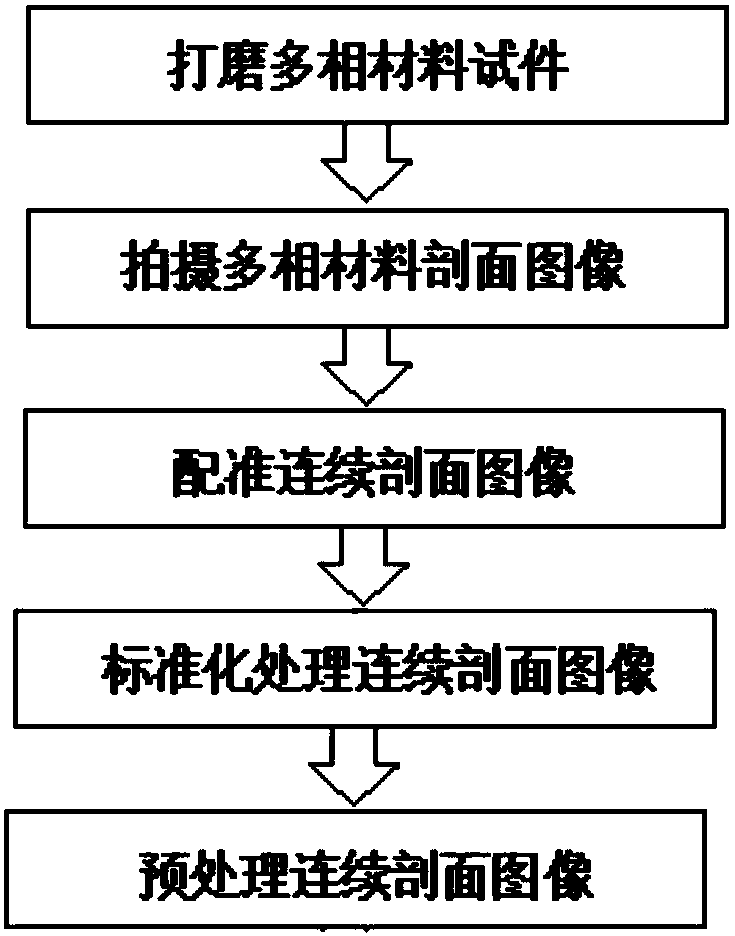

[0045] The specific process of the multiphase material continuous section image acquisition method involved in this embodiment includes grinding the multiphase material specimen, taking multiphase material section images, registering continuous section images, standardizing the continuous section images and preprocessing the continuous section images together. Five steps:

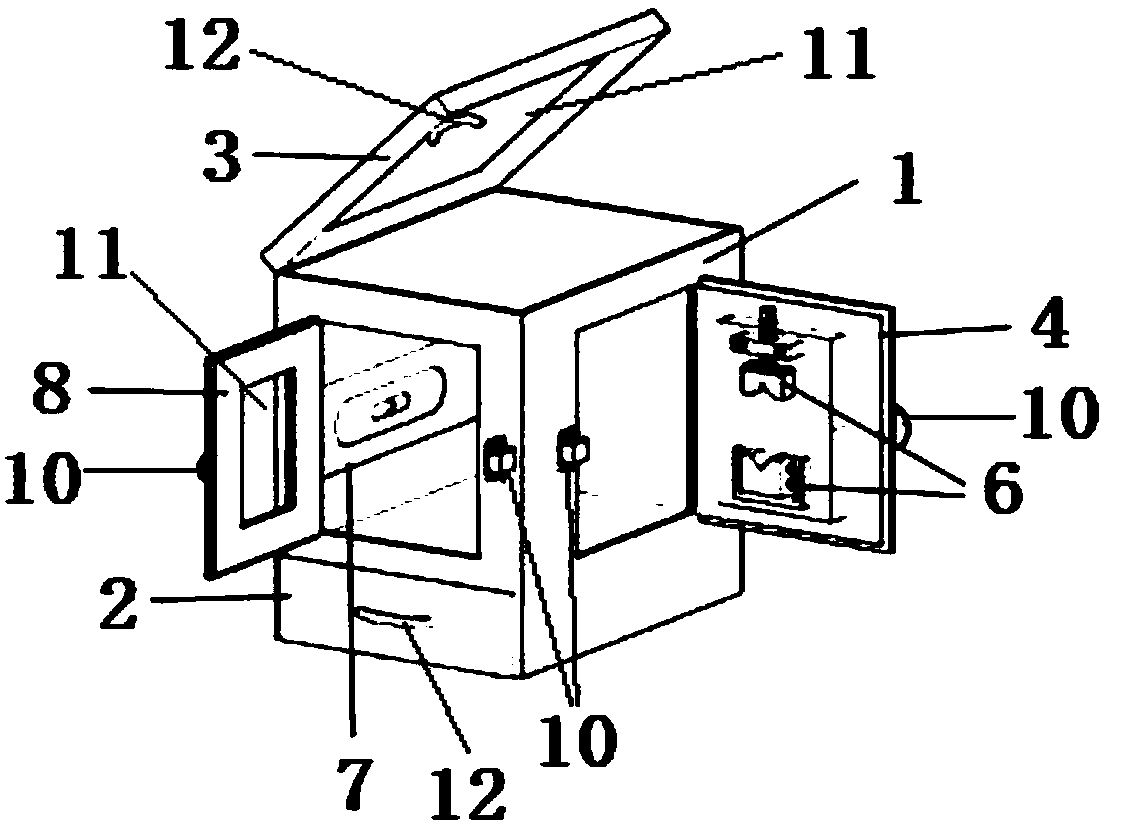

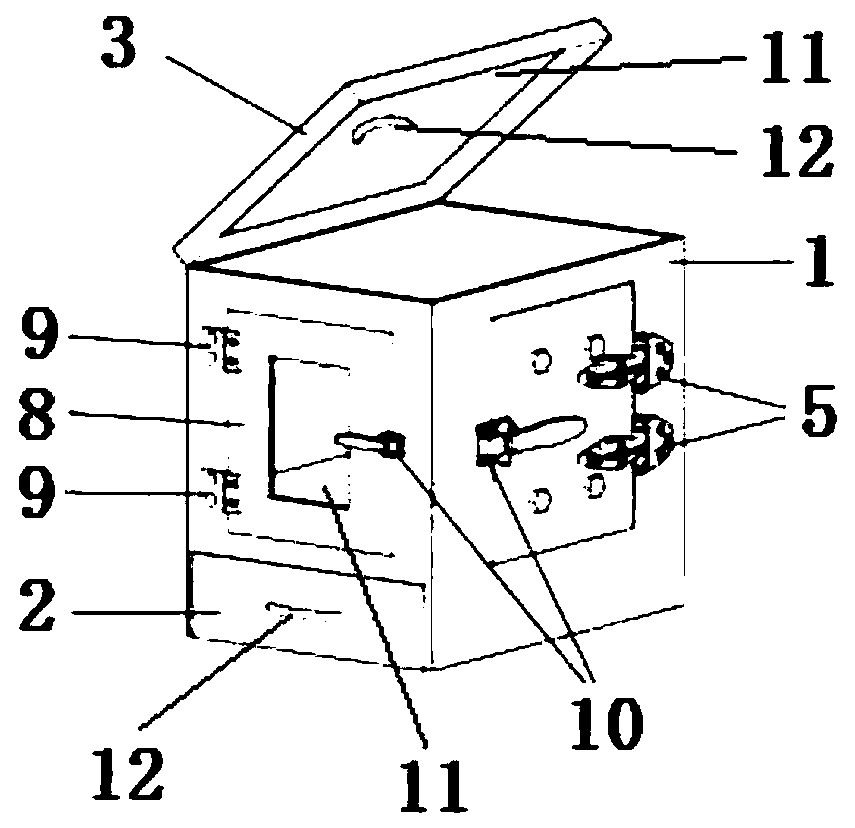

[0046] (1) Grinding multi-phase material specimens: the grinding tool is fixedly connected with the brittle material section grinding chamber, and the prefabricated 100mm×100mm×100mm concrete specimen is installed and fixed in the brittle material section grinding chamber. On the specimen clamping mechanism 6, the horizontal screw rod of the grinding tool controls the reciprocating movement of the fine-grained diamond particle grinding head, and the longitudinal screw rod of the grinding tool controls the depth and spacing of the grinding head, and the precision screw of the vertical screw rod rotates once ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com