Phase change material for solar energy storage

A phase change energy storage material and solar energy technology, which is applied in the field of phase change energy storage materials, can solve the problems of reducing heat transfer and enthalpy value of thickener, system deterioration, and heat storage capacity, etc., so as to improve thermal conductivity and enthalpy. The effect of small value change and strong thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

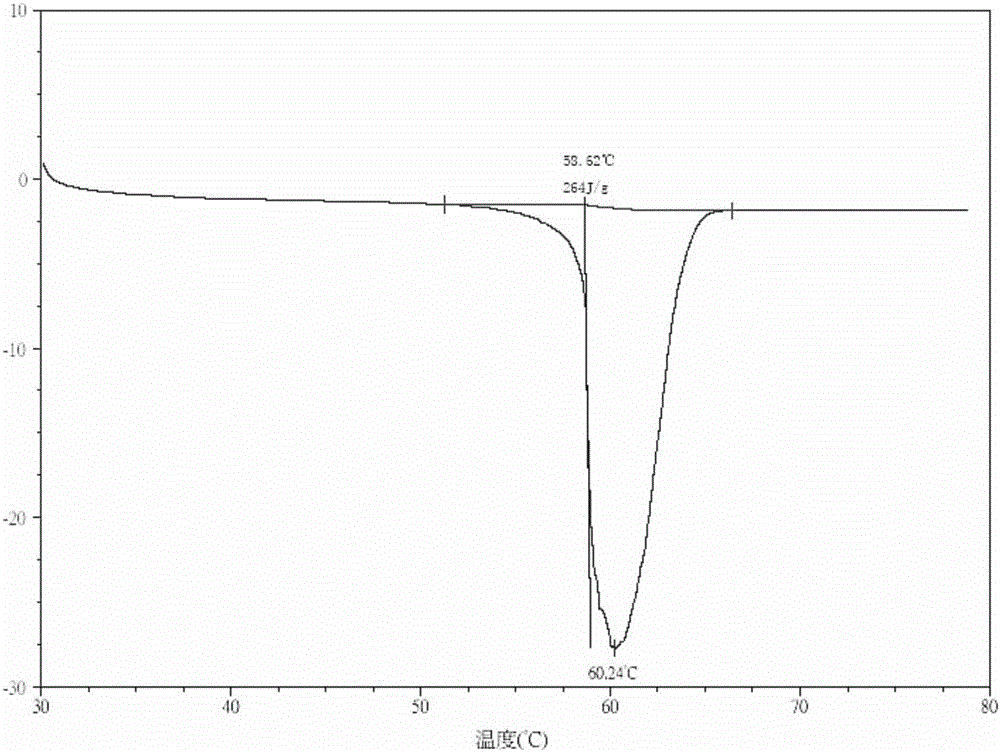

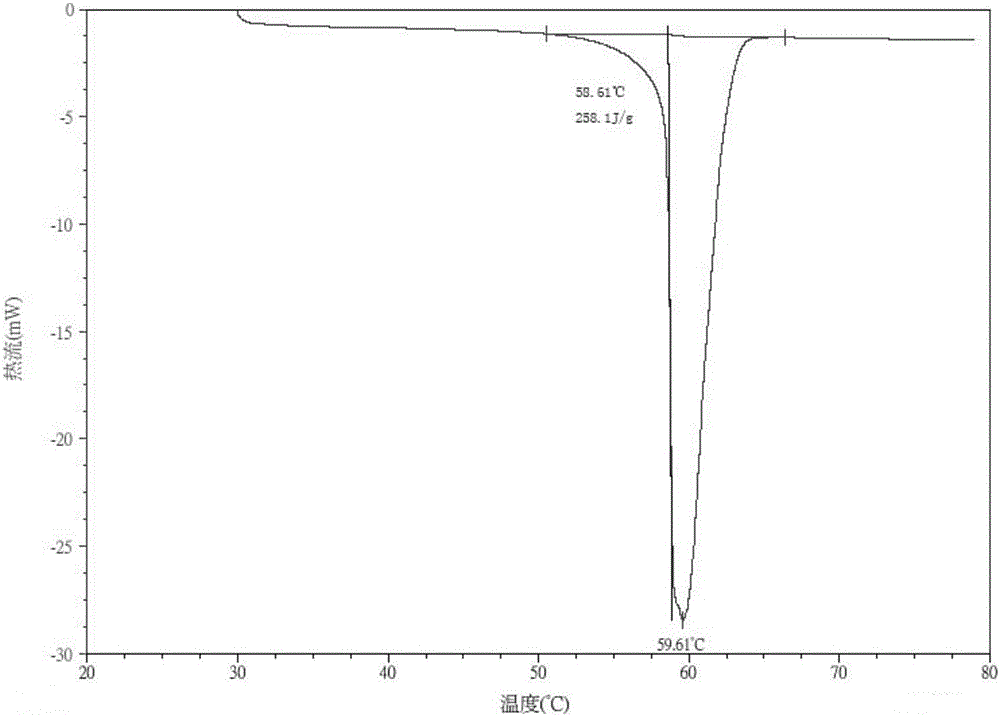

[0026] With 800g of sodium acetate trihydrate as the main raw material, after heating and melting at 70°C, add 80g of nucleating agent (64g of ethanol, 16g of potassium fluoroborate), after stirring, add 200g of 300-mesh expanded graphite, after stirring evenly, The phase change material obtained by cooling is 58.6°C, and after 5000 cycles, the enthalpy value is 258.1J / g (see figure 2 ) and blank test results 264J / g ( figure 1 ) compared to the attenuation of 2.2%.

Embodiment 2

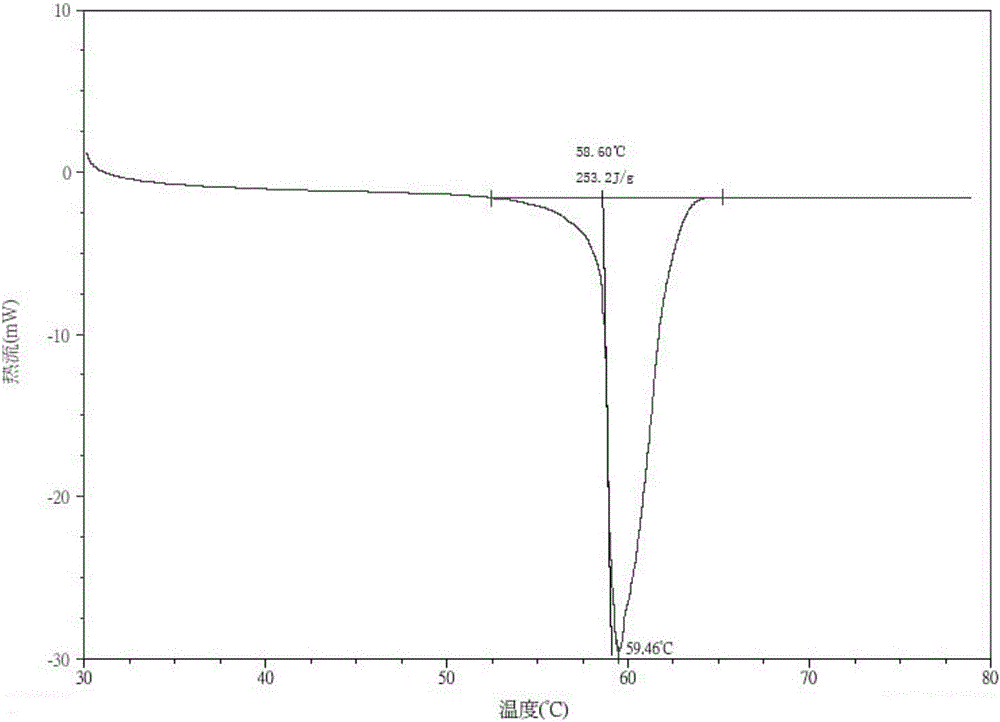

[0028] Use 850g of sodium acetate trihydrate as the main raw material, heat and melt at 70°C, add 50g of nucleating agent (45g of ethanol, 5g of potassium fluorosilicate), after stirring, add 70g of 100-mesh expanded graphite, stir evenly , the phase change material obtained by cooling is 58.6°C, and after 5000 cycles, the enthalpy value is 253.2J / g (see image 3 ), and the blank test result 264J / g ( figure 1 ) compared to attenuation of 4%.

Embodiment 3

[0030] Use 820g of sodium acetate trihydrate as the main raw material, heat and melt at 70°C, add 60g of nucleating agent (51g of ethanol, 9g of potassium fluoroaluminate), stir and add 120g of 200-mesh expanded graphite, stir well , the phase change material obtained by cooling is 58.63°C, and after 5000 cycles, the enthalpy value is 248.4J / g (see Figure 4 ). And blank test result 264J / g ( figure 1 ) compared to 5.9% attenuation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com