Low-phase-transition-temperature heat storage material and preparation method thereof

A technology of phase change temperature and heat storage materials, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of limited heat storage density and high price, and achieve the effect of high heat storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A thermal storage material with a low phase transition temperature is prepared using the following quality material-grade steps: 92g sodium acetate trihydrate, 2g potassium chloride, 3g deionized water, 1g starch, and 2g sodium pyrophosphate.

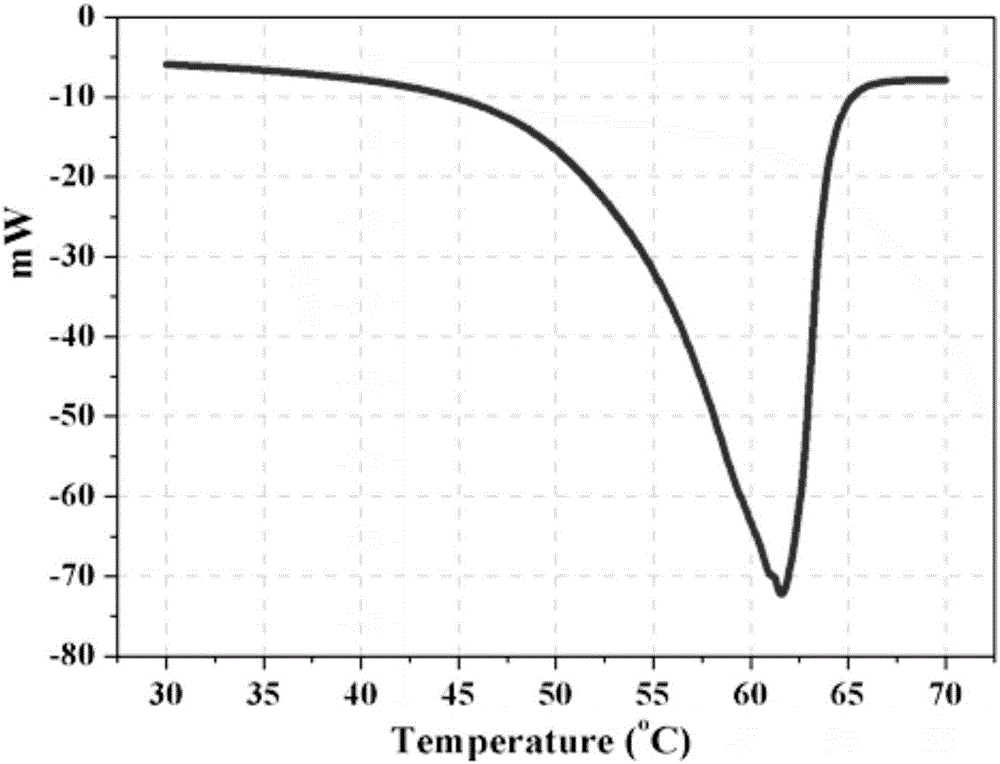

[0026] When preparing, first heat and melt sodium acetate trihydrate and potassium chloride, then replenish 3g of water, after complete clarification, add starch and stir to thicken, then add sodium pyrophosphate, after stirring evenly, take out the sample, and make it after cooling to solidify Differential scanning calorimetry analysis and T-t curve, use differential calorimetry scanner (DSC) to test its phase transition temperature, obtain as figure 1 The phase change material is measured to have a phase change latent heat of 275kJ / kg, a phase change temperature of 55°C, and a heat storage density (45-75°C) of 390kJ / L, which can be used in hand warmers and other fields.

Embodiment 2

[0028] A heat storage material with a low phase transition temperature, prepared using the following quality material-level steps: 83.8g sodium acetate trihydrate, 8g magnesium nitrate, 4g deionized water, 1.2g carboxymethyl cellulose, and 3g expanded graphite.

[0029] When preparing, first heat and melt sodium acetate trihydrate and magnesium nitrate, then replenish 4g of water, after complete clarification, add carboxymethyl cellulose to stir and thicken, then add expanded graphite, after stirring evenly, take out the sample, and wait for cooling and solidification Doing differential scanning calorimetry analysis and T-t curve, it is determined that the latent heat of phase transition is 250kJ / kg, the phase transition temperature is 48°C, and the heat storage density (40-70°C) is 370kJ / kg, which can be obtained in the field of small kitchen treasures. application.

Embodiment 3

[0031] A heat storage material with a low phase transition temperature, prepared using the following quality material-level steps: 75g of sodium acetate trihydrate, 17g of lithium chloride, 4g of deionized water, 1g of polyacrylamide, and 3g of carbon nanotubes.

[0032] When preparing, first heat and melt sodium acetate trihydrate and lithium chloride, then replenish 4g of water, after complete clarification, add polyacrylamide and stir to thicken, then add carbon nanotubes, after stirring evenly, take out the sample, wait for cooling and solidification Doing differential scanning calorimetry and T-t curves, it is determined that the latent heat of phase transition is 230kJ / kg, the phase transition temperature is 44°C, and the heat storage density (30-65°C) is 350kJ / kg, which can be used in small kitchen treasures and other fields .

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com