A self-regulating temperature phase change energy storage material and its preparation method

A phase-change energy storage and inorganic phase-change material technology, which is applied in the field of self-temperature-regulating phase-change energy storage materials and their preparation, can solve problems such as complex construction processes, and achieve the effects of reducing environmental pollution and achieving good construction performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Mix 0.4 parts by weight of paraffin, 0.2 parts by weight of butyl palmitate and 0.4 parts by weight of sodium acetate trihydrate for use; add 1 part by weight of expanded porous perlite to a vacuum reaction kettle, evacuate the air in the kettle, and then slowly add the compound After stirring for 3-5 minutes, slowly pressurize the kettle to normal pressure to infiltrate the mixture into the expanded porous perlite until the mixture is completely infiltrated into the expanded perlite phase-change material component; After mixing and stirring 1 part by weight of the thermal insulation component and 0.2 part by weight of the polymer macromolecule, the thermal insulation and energy-saving material is obtained.

Embodiment 2

[0032] Mix 0.3 parts by weight of paraffin wax, 0.3 parts by weight of butyl palmitate and 0.4 parts by weight of sodium acetate trihydrate for use; add 1 part by weight of expanded porous perlite to the vacuum reaction kettle, evacuate the air in the kettle, and then slowly add the compound After stirring for 3-5 minutes, slowly pressurize the kettle to normal pressure to infiltrate the mixture into the expanded porous perlite until the mixture is completely infiltrated into the expanded perlite phase-change material component; After mixing and stirring 1 part by weight of the thermal insulation component and 0.2 part by weight of the polymer macromolecule, the thermal insulation and energy-saving material is obtained.

Embodiment 3

[0034] Mix 0.4 parts by weight of paraffin wax, 0.3 parts by weight of butyl palmitate and 0.3 parts by weight of sodium acetate trihydrate for use; add 1 part by weight of expanded porous perlite to a vacuum reaction kettle, evacuate the air in the kettle, and then slowly add the compound After stirring for 3-5 minutes, slowly pressurize the kettle to normal pressure to make the mixture infiltrate into the expanded porous perlite, and the mixture is completely infiltrated into the expanded perlite phase change material component to complete; mix the obtained substance with 2 parts by weight of the coagulation material After mixing and stirring with 1 weight part of the thermal insulation component and 0.2 weight part of the polymer macromolecule, the thermal insulation and energy-saving material can be obtained.

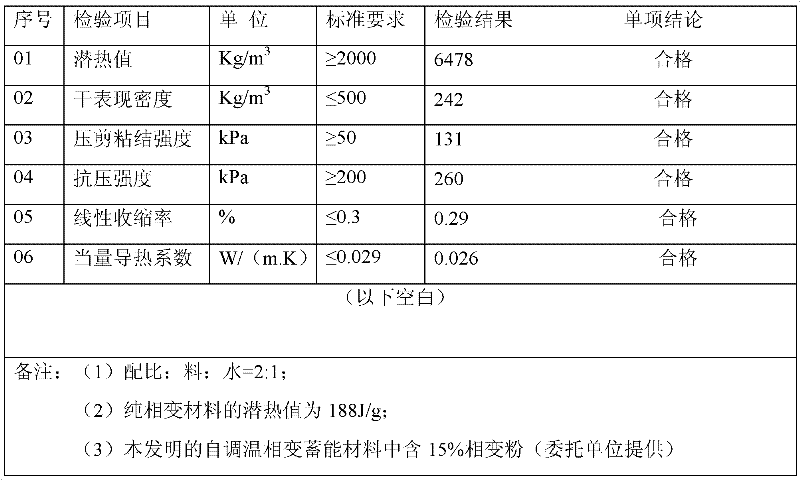

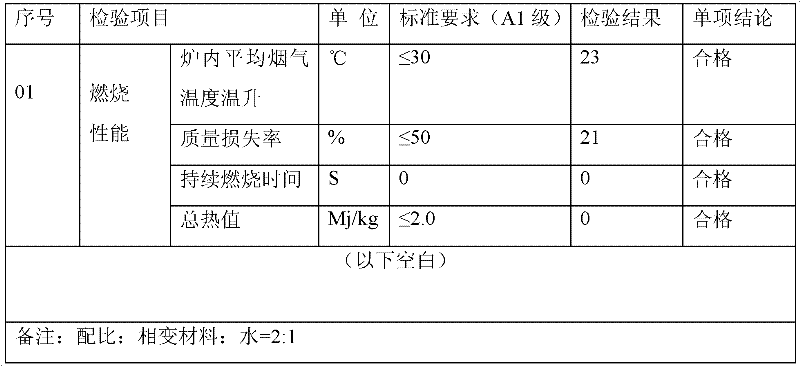

[0035] Table 1 Inspection report of the National Building Materials Industry Building Materials Quality Supervision, Inspection and Testing Center

[0036]

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com