Sodium acetate trihydrate phase change energy storage material compositions

A material composition, phase change energy storage technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., to achieve the effects of high heat storage density, high phase change stability, and best temperature adjustment ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

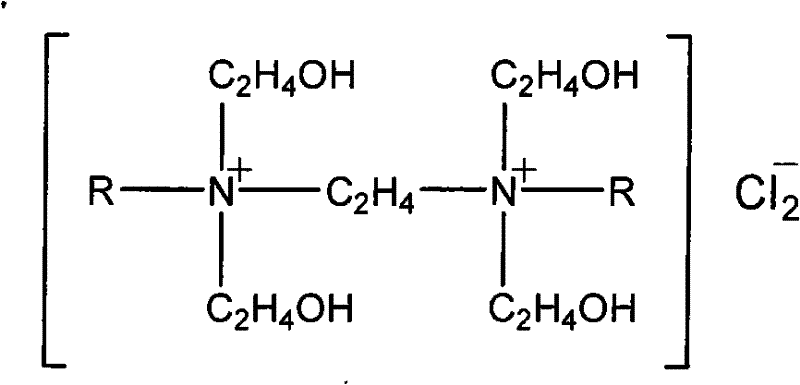

[0019] Heat 540g of water to 60-70°C, add 820g of anhydrous sodium acetate under stirring condition, keep the system temperature above 60°C, add Na 2 SO 4 10H 2 O 27.2g, CaSO 4 68g, carboxymethyl cellulose 13.6g, sodium polyacrylate 0.68g, ethylene bis (dodecyl dihydroxyethyl ammonium chloride) 0.14g, after mixing uniformly, test its phase transition temperature to be 57.6 ℃, pass The coldness is 2.5°C, and the latent heat value of phase change is 253kJ / kg. After 3000 times of cold and heat cycle tests, no obvious solid-liquid separation phenomenon appeared in the phase change system.

Embodiment 2

[0021] Heat 54kg of water to 60-70°C, add 82kg of anhydrous sodium acetate under stirring condition, keep the system temperature above 60°C, add Na 2 SO 4 10H 2 O 4.76g, CaSO 4 8.16kg, carboxymethyl cellulose 4.08kg, sodium polyacrylate 136g, ethylene bis(octadecyldihydroxyethylammonium chloride) 68g, after mixing evenly, test its phase transition temperature is 56.9 ℃, supercooled The temperature is 2.1°C, and the latent heat value of phase change is 248.2kJ / kg. After 3000 times of cold and heat cycle tests, no obvious solid-liquid separation phenomenon appeared in the phase change system.

Embodiment 3

[0023] Heat 1.08kg of water to 60-70°C, add 1.64kg of anhydrous sodium acetate under stirring condition, keep the system temperature above 60°C, add Na 2 SO 4 10H 2 O 136g, CaSO 4 108.8g, carboxymethyl cellulose 40.8g, sodium polyacrylate 8.16g, ethylene bis(hexadecyl dihydroxyethyl ammonium chloride) 2.18g, after mixing evenly, test its phase transition temperature is 57.8 ℃, The degree of subcooling is 1.9°C, and the latent heat value of phase change is 243kJ / kg. After 3000 times of cold and heat cycle tests, no obvious solid-liquid separation phenomenon appeared in the phase change system.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com