Preparation method of silicon aluminum phosphate molecular sieve of multilevel porous structure, prepared molecular sieve and application of molecular sieve

A silicoaluminophosphate, pore structure technology, applied in molecular sieve and alkali-exchanged phosphate, molecular sieve catalyst, chemical instruments and methods, etc., can solve the problems of high cost, cumbersome operation process, etc. The effect of good catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] To prepare SAPO-34 molecular sieve with hierarchical pore structure, the raw material is taken from the conventional SAPO-34 molecular sieve A prepared according to [Comparative Example 1], which only contains micropores.

[0037] Weigh 30g of molecular sieve A and place it in 0.05M citric acid solution, wherein the amount of citric acid solution is 0.9L, stir at 75°C for 3 hours, filter, wash, dry and roast to obtain product B.

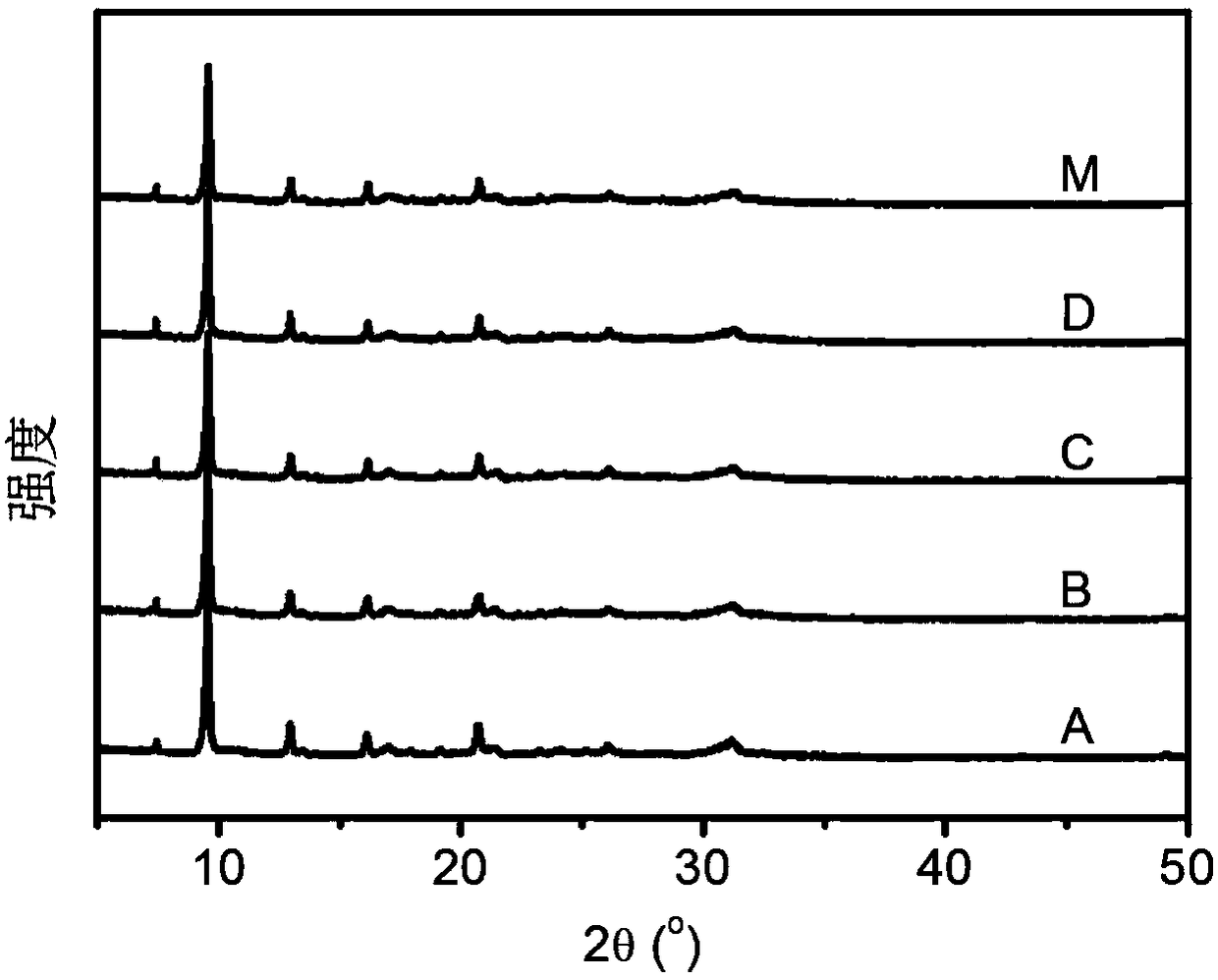

[0038] The XRD spectrum of B is as figure 1 shown, from figure 1 It can be seen that the synthesized molecular sieve has the characteristic diffraction peaks of SAPO-34 molecular sieve, indicating that the synthesized product is pure SAPO-34 molecular sieve with a relative crystallinity of 95%.

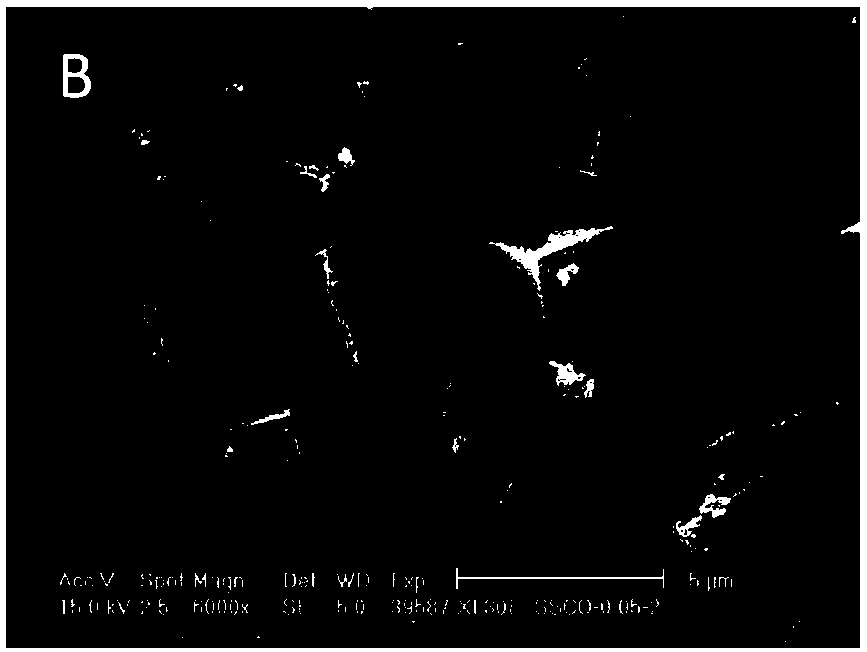

[0039] The SEM photograph of B is as image 3 As shown, obvious pore structure appeared on the surface of molecular sieve.

[0040] The micropore diameter of B is distributed in 0.3-0.5nm, the mesopore diameter is distributed in 5-18nm, and the mac...

Embodiment 2

[0043] Same as [Example 1], except that the raw material used is the conventional SAPO-34 molecular sieve A roasted product prepared according to the method of [Comparative Example 1], which only contains micropores. The final obtained SAPO-34 molecular sieve with hierarchical pore structure is denoted as C.

[0044] The XRD spectrum of C is as figure 1 shown, from figure 1 It can be seen that the synthesized molecular sieve has the characteristic diffraction peaks of SAPO-34 molecular sieve, indicating that the synthesized product is pure SAPO-34 molecular sieve with a relative crystallinity of 92%.

[0045] SEM photographs of C with image 3 similar.

[0046] C The micropore diameter is distributed in 0.3-0.5nm, the mesopore diameter is distributed in 8-28nm, and the macropore diameter is distributed in 50-250nm; the pore volume contributed by the micropore is 0.21cm 3 / g, the pore volume contributed by mesopores is 0.25cm 3 / g, the pore volume contributed by macropores...

Embodiment 3

[0049] Same as [Example 1], except that the concentration of citric acid is 0.1M, the consumption of citric acid is 0.6L, the reaction temperature is 65°C, and the reaction time is 6 hours, and the obtained product is marked as D.

[0050] The XRD spectrum of D is as figure 1 shown, from figure 1 It can be seen that the synthesized molecular sieve has the characteristic diffraction peaks of SAPO-34 molecular sieve, indicating that the synthesized product is pure SAPO-34 molecular sieve with a relative crystallinity of 89%.

[0051] The SEM photograph of D with image 3 similar.

[0052] D The micropore diameter is distributed in 0.3-0.5nm, the mesopore diameter is distributed in 5-30nm, and the macropore diameter is distributed in 50-250nm; the pore volume contributed by the micropore is 0.20cm 3 / g, the pore volume contributed by mesopores is 0.25cm 3 / g, the pore volume contributed by macropores is 0.19cm 3 / g.

[0053] According to the SEM photographs and the pore vol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com