Method for producing propylene, ethylene light olefin hydrocarbon

A technology of light olefins and ethylene, which is applied in the field of preparation of propylene and ethylene light olefins, can solve the problems of poor catalyst reaction stability and low propylene/ethylene ratio, and achieve improved hydrothermal stability, increased propylene selectivity, and delayed shedding speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 100 grams of Φ1.6 cylindrical binder-free NaZSM-5 molecular sieve (molar silicon-aluminum ratio 200) catalyst precursor was first roasted under nitrogen flow at 600 ° C for 4 hours to release templates and other volatiles, and then with 0.1M hydrochloric acid 1000 ml was exchanged at 80°C, and repeated four times, then washed with deionized water until no chlorine radicals were present, and dried at 120°C for later use.

[0041] 50 grams of the above catalyst and La 2 o 3 100 milliliters of lanthanum nitrate solution of 0.5 grams was heated and concentrated to dryness under stirring, then dried at 120° C. for 10 hours, then added to a solution made of 1.62 grams of 85% phosphoric acid and 50 grams of water, mixed evenly, and then evaporated to dryness. Dry at 120°C for 10 hours, and bake at 550°C for 2 hours. Obtain catalyst A, containing La in weight percent 2 o 3 1.0%, P 2 o 5 2.0%.

[0042] Install 3 grams of catalyst A in a fixed-bed reactor of Φ15 mm, add ...

Embodiment 2~11

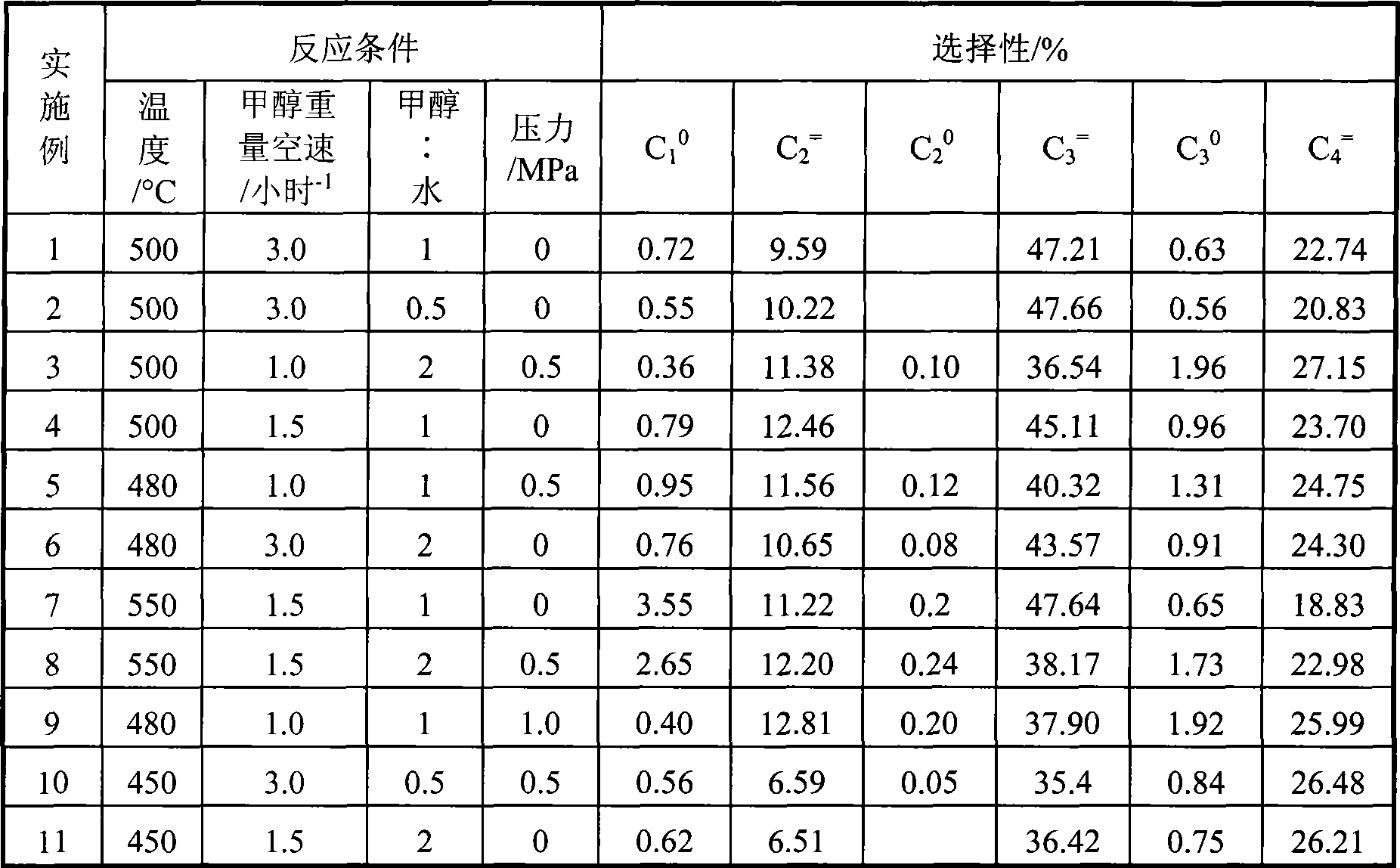

[0044] With the catalyst of Example 1, the reaction conditions were changed to obtain the evaluation result list 1.

[0045] Table 1 Reactivity of catalysts under different reaction conditions

[0046]

Embodiment 12

[0048] Carry out catalyst service life test under embodiment 5 catalyst and reaction condition, its result is as follows:

[0049] Response time (hours) Raw material conversion rate / % Propylene yield / % Ethylene yield% 50 100.00 39.17 11.06 100 100.00 40.08 11.63 200 100.00 38.48 10.97 500 99.8 37.88 9.34

[0050] Catalyst deactivation is mainly caused by carbon formation, and the catalyst can be regenerated by simple air scorching the catalyst and its reactivity can be basically restored.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com