Method for preparing super-long multi-walled carbon nanotube from biomass through two-step microwave treatment

A technology of multi-walled carbon nanotubes and microwave treatment, which is applied in the direction of multi-walled carbon nanotubes, carbon nanotubes, nanocarbons, etc., can solve the complex preparation process, many structural defects of carbon nanotubes, and the difficulty of separating catalysts and carbon nanotubes and other problems, to achieve the effect of low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

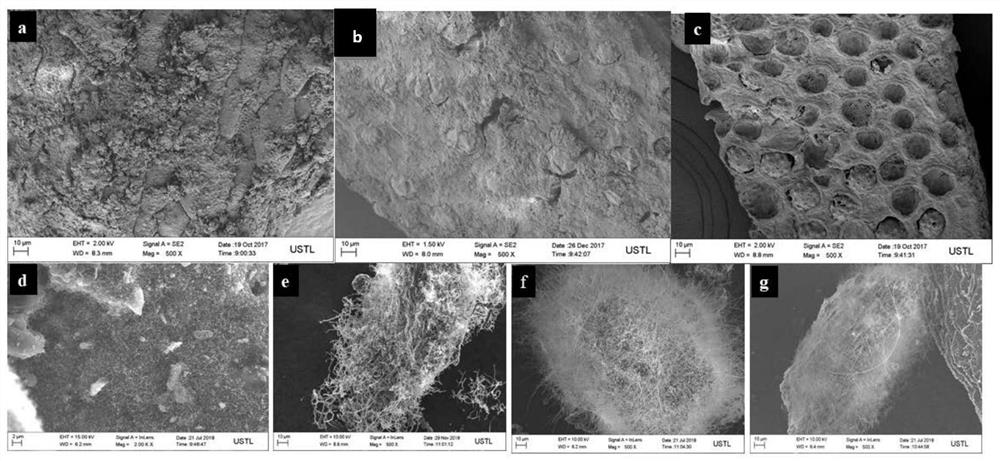

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention, and are all used to explain the content of the present invention within the scope of reasonable changes.

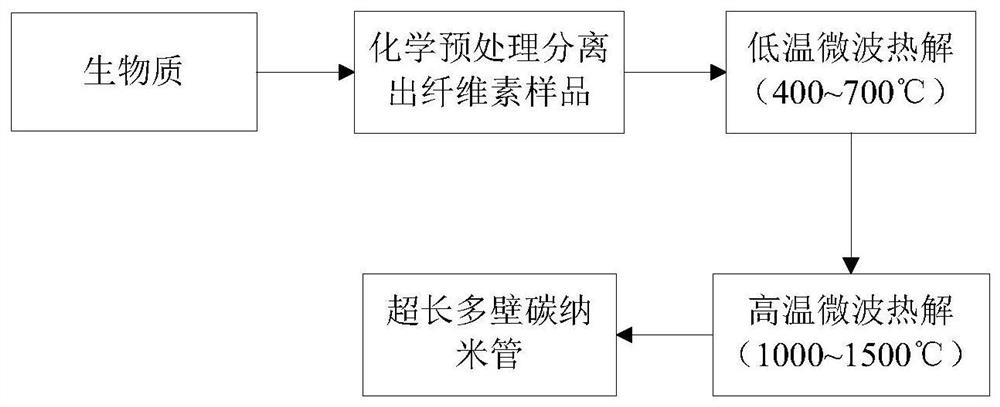

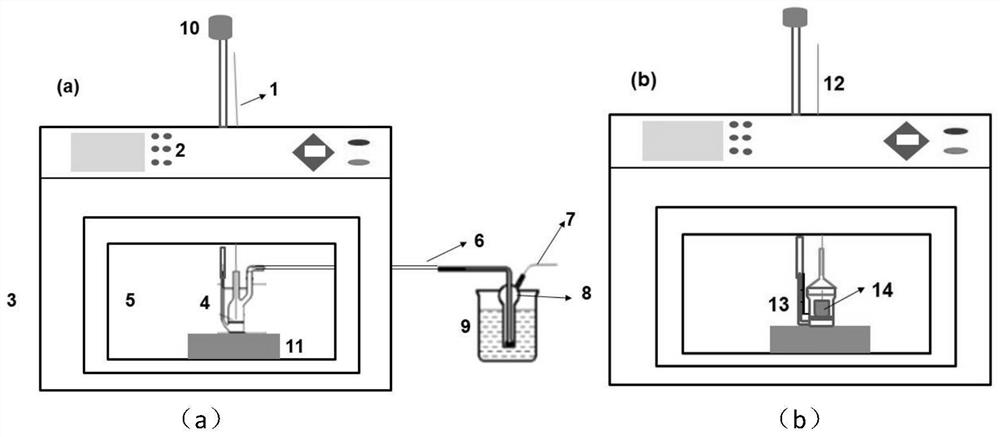

[0029] The process flow diagram for preparing ultra-long carbon nanotubes with Malaysian palm kernel shell (PKS) biomass is shown in 1, figure 2 It is the structure diagram of microwave equipment.

[0030] (1) Separation of cellulose samples from biomass by chemical pretreatment

[0031] Put the PKS sample with a particle size of 150 μm to 280 μm in a vacuum drying oven, and dry it at 105 ° C for 12 h to remove moisture; add 250 ml of NaOH (0.5 mol / L) to 10 g of the dried PKS sample, stir cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com