Method for recycling alkali liquor in aluminum alloy section alkali corrosion production procedure

A technology for recycling aluminum alloy profiles and lye, applied in the direction of improving process efficiency, etc., can solve the problems of large water consumption, high temperature concentration of alkaline etching solution, and reducing the quality of profiles, and achieves reduction of environmental protection pressure, great economic benefits, The effect of long process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

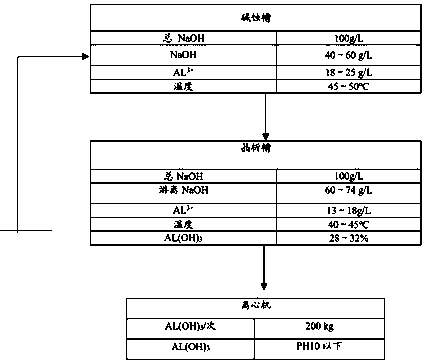

[0028] Embodiment one: if figure 1 Shown, a kind of method for the recovery and reuse of lye in the alkaline corrosion production process of aluminum alloy profile, it comprises the following steps:

[0029] S1. Alkaline corrosion of aluminum alloy profiles, specifically including the following steps:

[0030] S11. Put the bath liquid composed of NaOH solution and organic acid sodium salt solution into the alkali etching tank, and raise the bath liquid temperature to 45~50°C;

[0031] S12. Put the aluminum alloy profiles to be alkali-etched into the alkali-etch tank, and NaOH solution removes the natural oxide film on the surface of the aluminum alloy profiles and slight scratches on the surface of the aluminum alloy profiles, so that the aluminum alloy profiles are exposed uniformly, freshly and ideally. surface, while producing a large amount of high value-added Al in the bath 3 + , organic acid sodium salt and Al 3 + Complexation reaction occurs to generate NaAlO 2 , ...

Embodiment 2

[0042] Embodiment two: if figure 1 Shown, a kind of method for the recovery and reuse of lye in the alkaline corrosion production process of aluminum alloy profile, it comprises the following steps:

[0043] S1. Alkaline corrosion of aluminum alloy profiles, specifically including the following steps:

[0044] S11. Put the bath liquid composed of NaOH solution and organic acid sodium salt solution into the alkali etching tank, and raise the bath liquid temperature to 45~50°C;

[0045] S12. Put the aluminum alloy profiles to be alkali-etched into the alkali-etch tank, and NaOH solution removes the natural oxide film on the surface of the aluminum alloy profiles and slight scratches on the surface of the aluminum alloy profiles, so that the aluminum alloy profiles are exposed uniformly, freshly and ideally. surface, while producing a large amount of high value-added Al in the bath 3 + , organic acid sodium salt and Al 3 + Complexation reaction occurs to generate NaAlO 2 , ...

Embodiment 3

[0055] Embodiment three: as figure 1 Shown, a kind of method for the recovery and reuse of lye in the alkaline corrosion production process of aluminum alloy profile, it comprises the following steps:

[0056] S1. Alkaline corrosion of aluminum alloy profiles, specifically including the following steps:

[0057] S11. Put the bath liquid composed of NaOH solution and organic acid sodium salt solution into the alkali etching tank, and raise the bath liquid temperature to 45~50°C;

[0058] S12. Put the aluminum alloy profiles to be alkali-etched into the alkali-etch tank, and NaOH solution removes the natural oxide film on the surface of the aluminum alloy profiles and slight scratches on the surface of the aluminum alloy profiles, so that the aluminum alloy profiles are exposed uniformly, freshly and ideally. surface, while producing a large amount of high value-added Al in the bath 3 + , organic acid sodium salt and Al 3 + Complexation reaction occurs to generate NaAlO 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com