Polypropylene corrugated pipe sizing die and corrugated pipe forming machine head containing the sizing die

A technology for forming machine heads and corrugated pipes, which is applied to tubular articles, other household appliances, household appliances, etc., can solve the problems of insignificant effects and increase costs, and achieve the effects of no pollution, high production efficiency, and easy processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

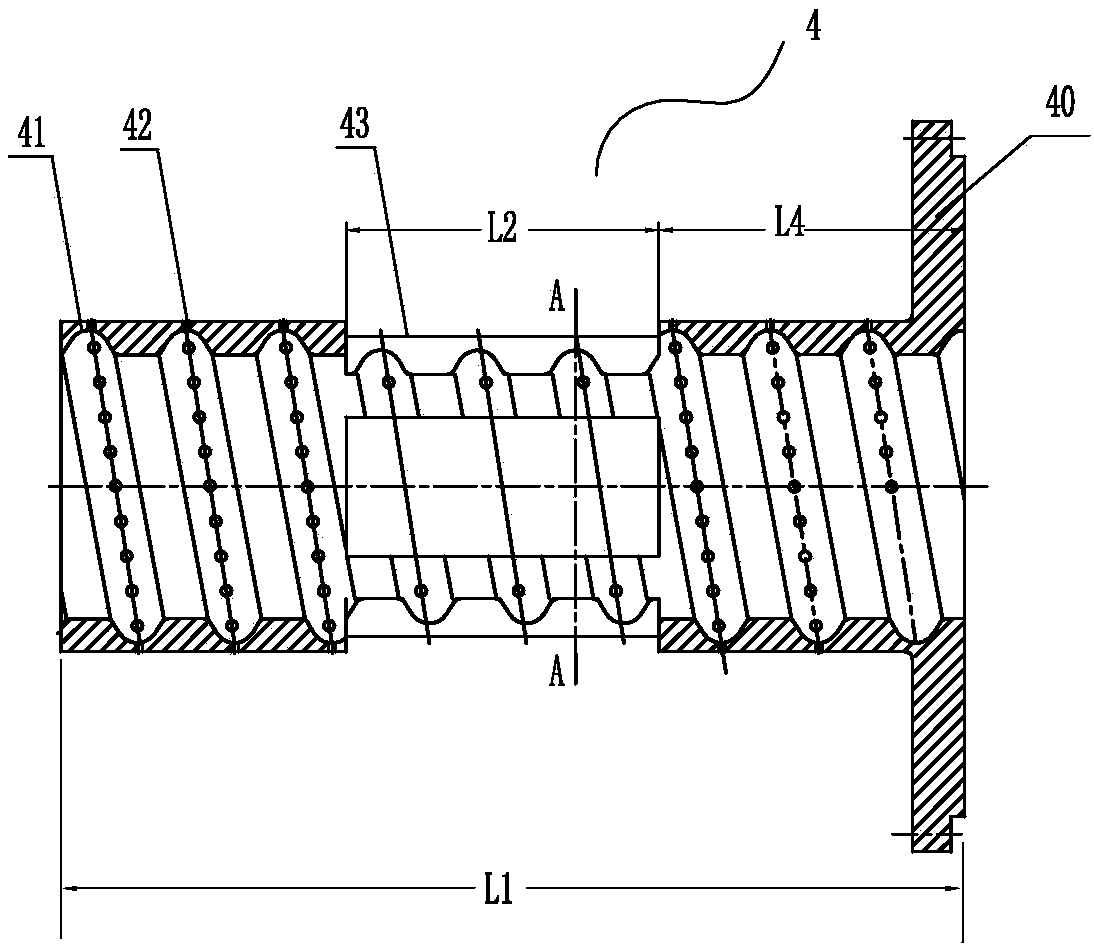

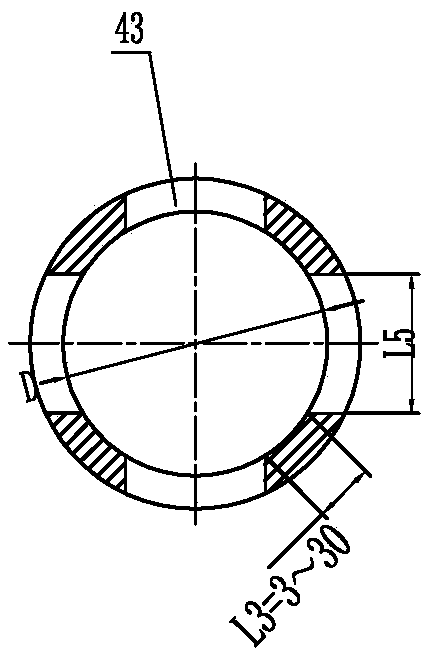

[0038] A polypropylene bellows sizing die, the length L1 of the bellows sizing die 4 is greater than or equal to 250 mm, and the middle section of the bellows sizing die 4 is provided with four long grooves 41 parallel to the central axis of the bellows sizing die, The length L2 of the long groove is 50-100mm, and the width L3 between two adjacent long grooves is 3-30mm. The distance between the long groove and the installation end face of the bellows sizing die 4 is L4=D×(0.5-1.5), where D is the inner diameter of corrugated sizing die;

[0039] A plurality of small holes 43 are evenly distributed on the top of each corrugated crest 42 of the bellows sizing die 4;

[0040] As a conversion, the value of the number N of long grooves opened in the middle section of the corrugated pipe sizing die can also be increased or decreased, and its value is any integer between 2 and 32. Generally, 4 to 8 are better, and the width of the long groove is L5 It is determined according to the...

Embodiment 2

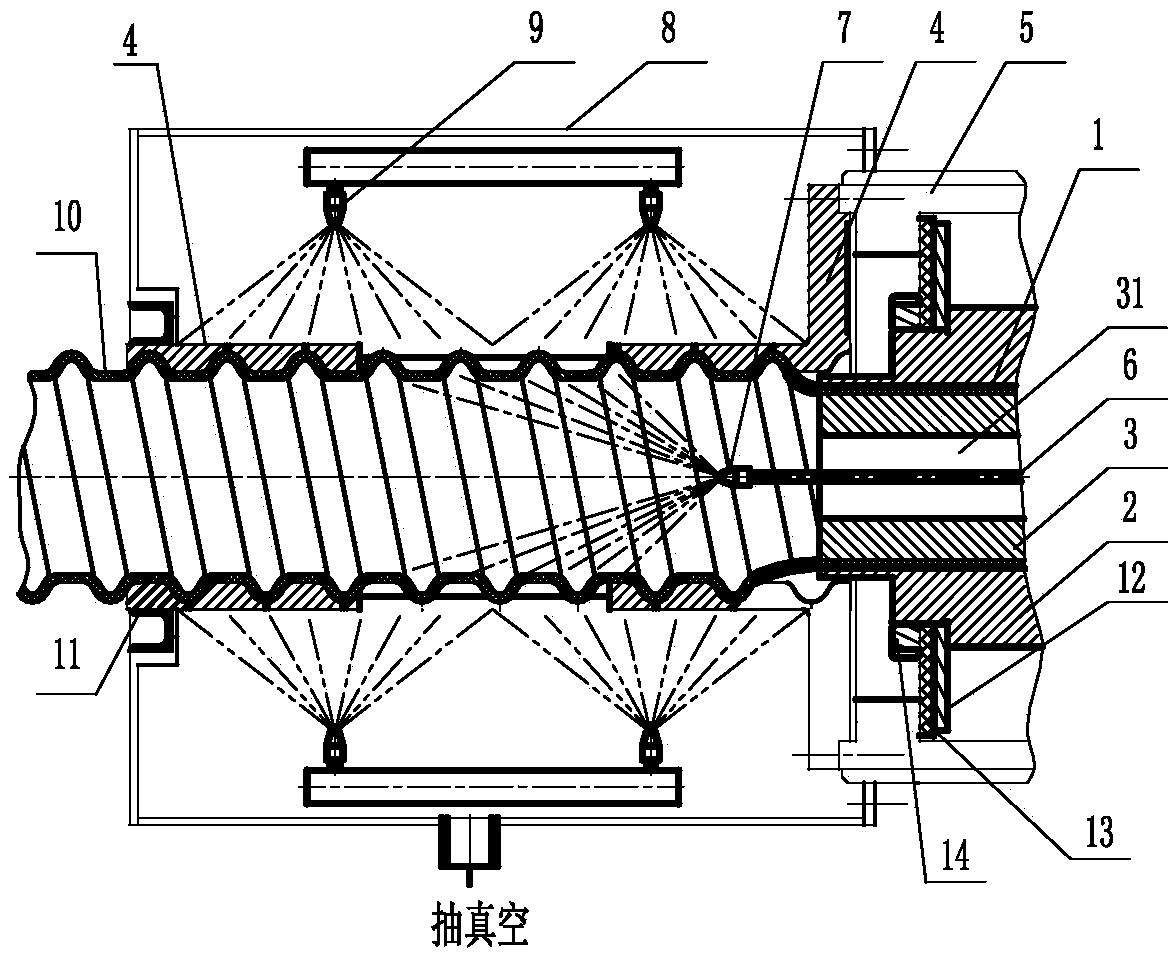

[0042] A bellows forming machine head, the bellows forming machine head is a bellows forming machine head containing a polypropylene bellows sizing die, comprising a machine head mold body, a vacuum box 8, a die 2, a core Die 3, bellows sizing die 4 and cooling device;

[0043] The vacuum box 8 is a sealed cavity with a volume greater than that of the bellows sizing die 4 and accommodates the bellows sizing die. The center of the front end of the vacuum box 8 is provided with a front mounting hole, and the center of the inlet end of the vacuum box is There is a rear mounting hole, the front end of the bellows sizing die is connected to the front mounting hole through the front sealing ring 11, the rear end of the bellows sizing die is connected to the rotating flange 5 through the connecting seat, and the rotating flange is connected to the rear mounting hole in rotation. A rear sealing ring is provided between the rotating flange and the rear mounting hole for dynamic sealing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com