Ceramic glass with lanthanum disilicate as principal crystalline phase, preparation method and application

A technology of lanthanum disilicate and glass-ceramics, which is applied in the field of material science, can solve problems such as preparation difficulties, and achieve the effects of simple preparation process, high crystal phase content, and lower melting temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

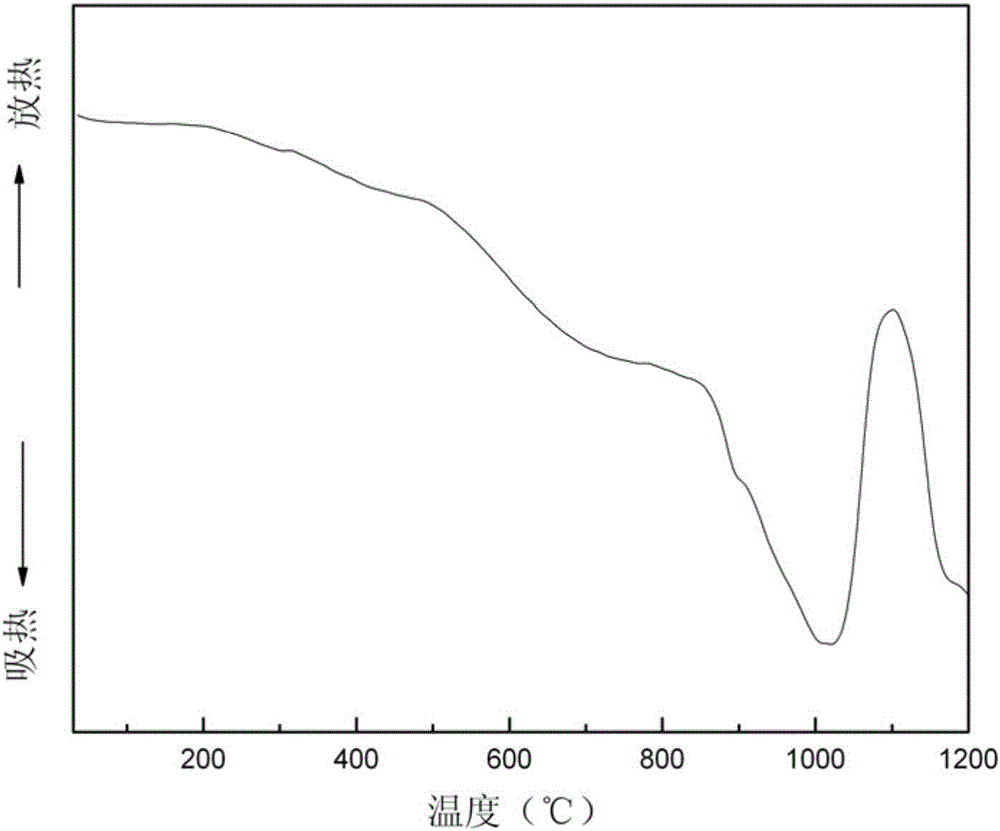

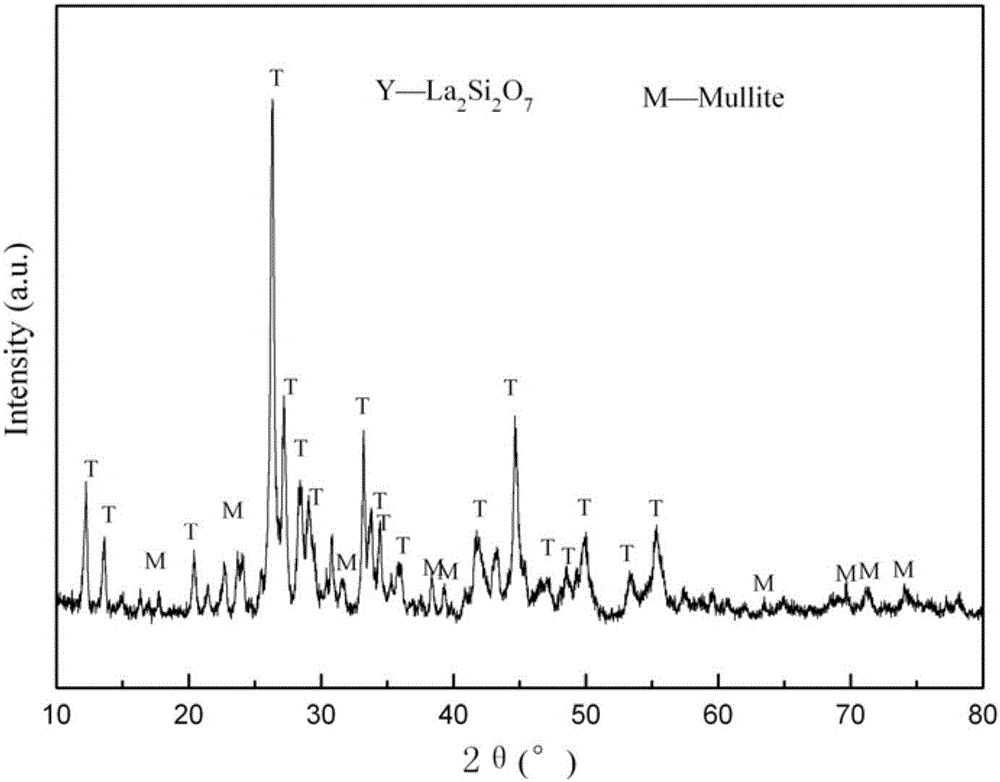

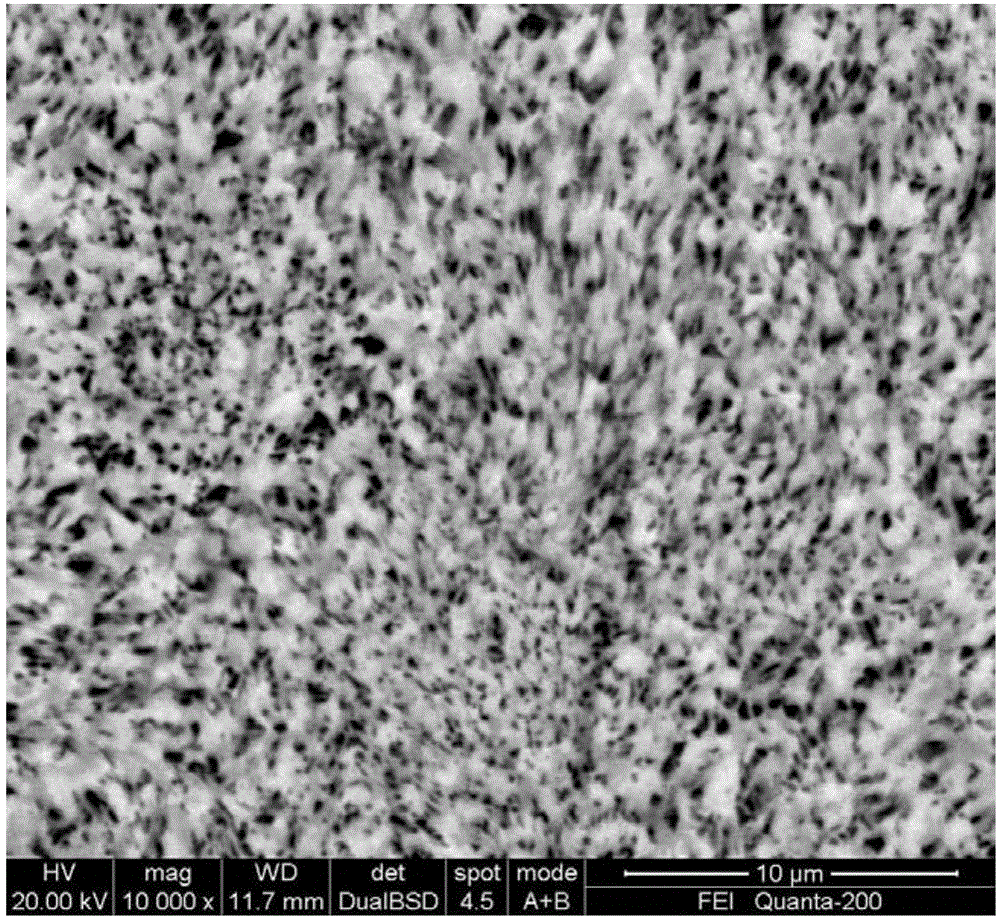

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1: the preparation main crystal phase that the present invention relates to is the glass-ceramic material of lanthanum disilicate, and the molar percentage (mol%) of each oxide in its base glass is composed of: La 2 o 3 : 22.0%, MgO: 3.0%, Al 2 o 3 : 13.0%, SiO 2 : 62.0%.

Embodiment 2

[0051] Embodiment 2: preparation of the main crystal phase involved in the present invention is a glass-ceramic material of lanthanum disilicate, and the mole percentage (mol%) of each oxide in its basic glass is composed of: La 2 o 3 : 26.0%, MgO: 5.0%, Al 2 o 3 : 11.0%, SiO 2 : 58.0%.

Embodiment 3

[0052] Embodiment 3: preparation main crystal phase involved in the present invention is the glass-ceramic material of lanthanum disilicate, and the molar percentage (mol%) of each oxide in its base glass is composed of: La 2 o 3 : 24.0%, MgO: 4.0%, Al 2 o 3 : 12.0%, SiO 2 : 60.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com