Laser transfer paper based on combination of water-based materials and preparation method of laser transfer paper

A technology of laser transfer paper and water-based materials, which is applied in papermaking, paper coatings, textiles and papermaking, and can solve the problems of short research period, slow progress, leveling, continuous moldability of nickel plates, and anti-reflection of holographic water-based transfer coatings. Can not meet the industry requirements and other problems, to achieve the effect of excellent transparency, good film formation smoothness, excellent anti-reflection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

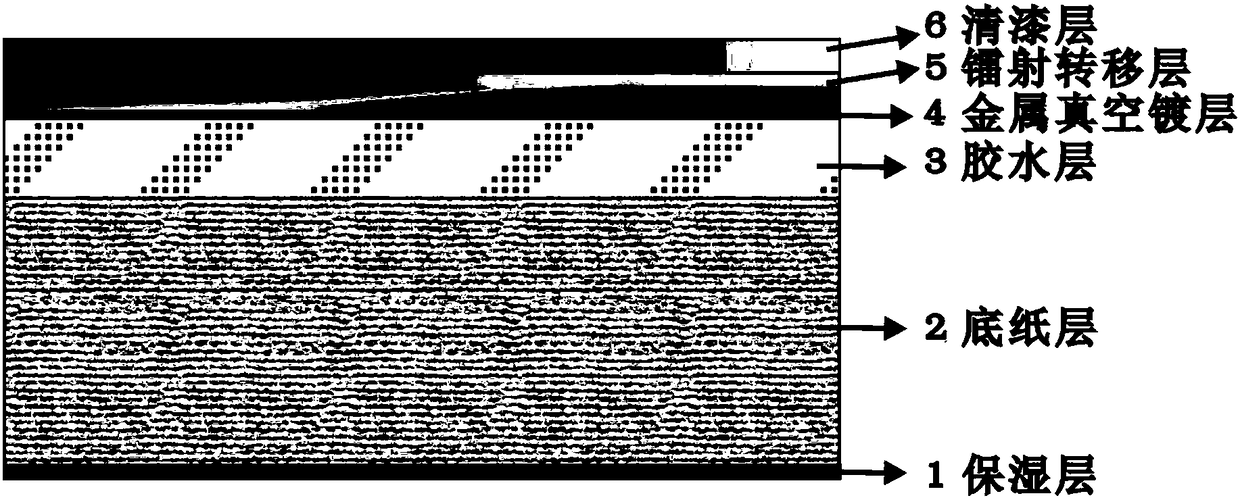

[0035] Such as figure 1 As shown, a water-based material combination laser transfer paper includes: a moisturizing layer 1, a backing paper layer 2, a glue layer 3, a metal vacuum coating 4, a laser transfer layer 5 and a varnish layer 6 that are sequentially stacked, and the glue layer 3 It is a self-crosslinking modified acrylate layer, the laser transfer layer 5 is a modified polyurethane layer, and the moisturizing layer 1, glue layer 3, laser transfer layer 5 and varnish layer 6 are all made of water-based resin. The thickness of each layer is as follows: moisturizing layer 1: 3-4 μm; backing paper layer 2: 70-300 μm; glue layer 3: 2-3 μm; metal vacuum coating 30-50nm; laser transfer layer 5: 1-2 μm; varnish layer 6: 0.8~1.6μm.

[0036] The modified polyurethane layer described in this example is prepared from the paint prepared by Xinrui DFW-09 and water and alcohol solvents at a mass ratio of 85:5:2. The preparation process is as follows:

[0037] (1) Prepare the lase...

Embodiment 2

[0047] Such as figure 1 As shown, a water-based material combination laser transfer paper includes: a moisturizing layer 1, a backing paper layer 2, a glue layer 3, a metal vacuum coating 4, a laser transfer layer 5 and a varnish layer 6 that are sequentially stacked, and the glue layer 3 It is a self-crosslinking modified acrylate layer, the laser transfer layer 5 is a modified polyurethane layer, and the moisturizing layer 1, glue layer 3, laser transfer layer 5 and varnish layer 6 are all made of water-based resin. The thickness of each layer is as follows: moisturizing layer 1: 3-4 μm; backing paper layer 2: 70-300 μm; glue layer 3: 2-3 μm; metal vacuum coating 30-50nm; laser transfer layer 5: 1-2 μm; varnish layer 6: 0.8~1.6μm.

[0048] The modified polyurethane layer described in this example is prepared from the coating prepared by Xinrui DFW-09 and water and alcohol solvents at a mass ratio of 80:5:2. The preparation process is as follows:

[0049] (1) Preparation of...

Embodiment 3

[0054] Such as figure 1 As shown, a water-based material combination laser transfer paper includes: a moisturizing layer 1, a backing paper layer 2, a glue layer 3, a metal vacuum coating 4, a laser transfer layer 5 and a varnish layer 6 that are sequentially stacked, and the glue layer 3 It is a self-crosslinking modified acrylate layer, the laser transfer layer 5 is a modified polyurethane layer, and the moisturizing layer 1, glue layer 3, laser transfer layer 5 and varnish layer 6 are all made of water-based resin. The thickness of each layer is as follows: moisturizing layer 1: 3-4 μm; backing paper layer 2: 70-300 μm; glue layer 3: 2-3 μm; metal vacuum coating 30-50nm; laser transfer layer 5: 1-2 μm; varnish layer 6: 0.8~1.6μm.

[0055] The modified polyurethane layer described in this example is prepared from the coating prepared by Xinrui DFW-09 and water and alcohol solvents at a mass ratio of 80:5:2. The preparation process is as follows:

[0056] (1) Prepare the la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com