White graphene modified polybutylene terephthalate composite material and preparation method thereof

A technology of polybutylene terephthalate and white graphene, which is applied in the field of white graphene modified polybutylene terephthalate composite materials and its preparation, can solve the problem of large amount of addition and poor thermal stability , a large number of problems, etc., to meet the needs of industrial applications and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

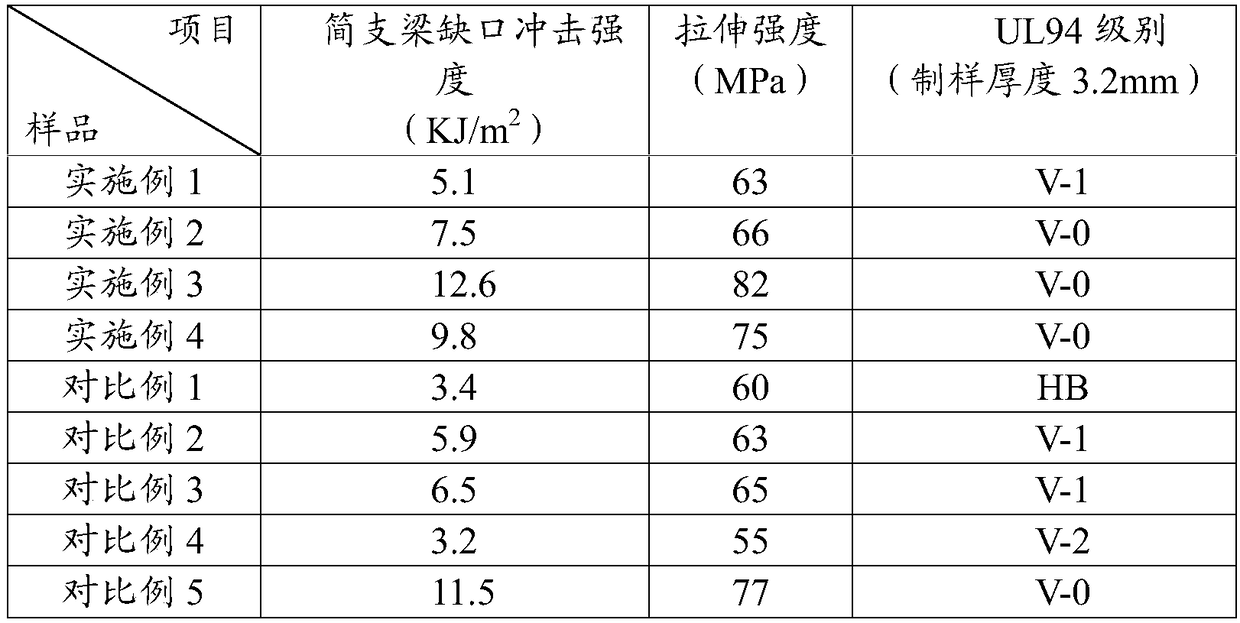

Examples

preparation example Construction

[0050] In addition, the preparation method of the white graphene modified by the polymer comprises the following steps:

[0051] (1) in parts by weight, white graphene is placed in a solvent for ultrasonic dispersion, and then a stabilizer is added for processing to obtain a lipophilic modified white graphene dispersion;

[0052] (2) Mix the lipophilic modified white graphene dispersion with polymerized monomers and initiators evenly, and react at 60°C-100°C for 0.5-3h, then add a neutralizer to adjust the pH to 7-8, cooling, filtering and drying to obtain the polymer-modified white graphene.

[0053] The above method first puts the white graphene in the dispersion liquid for ultrasonic dispersion; after ultrasonication, a stabilizer is added to modify the surface of the white graphene to improve its surface activity, and then it is mixed with the polymerized monomer under the action of the initiator. Polymerization occurs to form a coating on the surface of the white graphen...

Embodiment 1

[0068] Step 1) Preparation of the white graphene modified by polymer: get 0.5 part of white graphene powder and join in the round bottom flask, and add 100 parts of distilled water in the round bottom flask, then ultrasonic dispersion, add 0.1 part in the round bottom flask Parts of sodium lauryl sulfate, ultrasonically stirred at high speed to obtain a lipophilic modified white graphene dispersion; after heating the lipophilic modified white graphene dispersion to 60°C, add 0.5 parts of initiator ammonium persulfate, and stir After 10 minutes, 0.05 parts of methyl methacrylate was added dropwise, and the drops were completed after 0.5 hours. After the dropwise addition, keep warm for 0.5h until the reaction is complete. After the reaction is completed, adjust the pH value to 7 with ammonia water, quickly cool to room temperature, filter under reduced pressure, wash the filter cake with distilled water for 3 to 4 times, then wash with alcohol once, and vacuum dry and grind at ...

Embodiment 2

[0073] Step 1) Preparation of high polymer modified white graphene: get 1 part of white graphene powder and add it to a round bottom flask, and add 100 parts of ethanol to the round bottom flask, then ultrasonically disperse, add 0.2 parts to the round bottom flask One part of sodium lauryl sulfate, ultrasonically stirred at high speed to obtain a lipophilic modified white graphene dispersion; after heating the lipophilic modified white graphene dispersion to 90°C, add 1 part of initiator ammonium persulfate, and stir After 15 minutes, 0.5 parts of methyl acrylate were added dropwise, and the drops were completed after 0.6 hours. After the dropwise addition, keep warm for 1 h until the reaction is complete. After the reaction is completed, adjust the pH value to 7 with ammonia water, quickly cool to room temperature, filter under reduced pressure, wash the filter cake with distilled water for 3 to 4 times, then wash with alcohol once, and vacuum dry and grind at 70°C to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com