Apparatus and method for producing oil by means of coal pyrolysis

A technology of coal pyrolysis and pyrolysis chamber, which is applied in the petroleum industry, the manufacture of combustible gas, and the preparation of liquid hydrocarbon mixtures. It can solve the problems of reduced production capacity, complicated process, and low oil production rate, and achieve stable operation. , conducive to the effect of large-scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

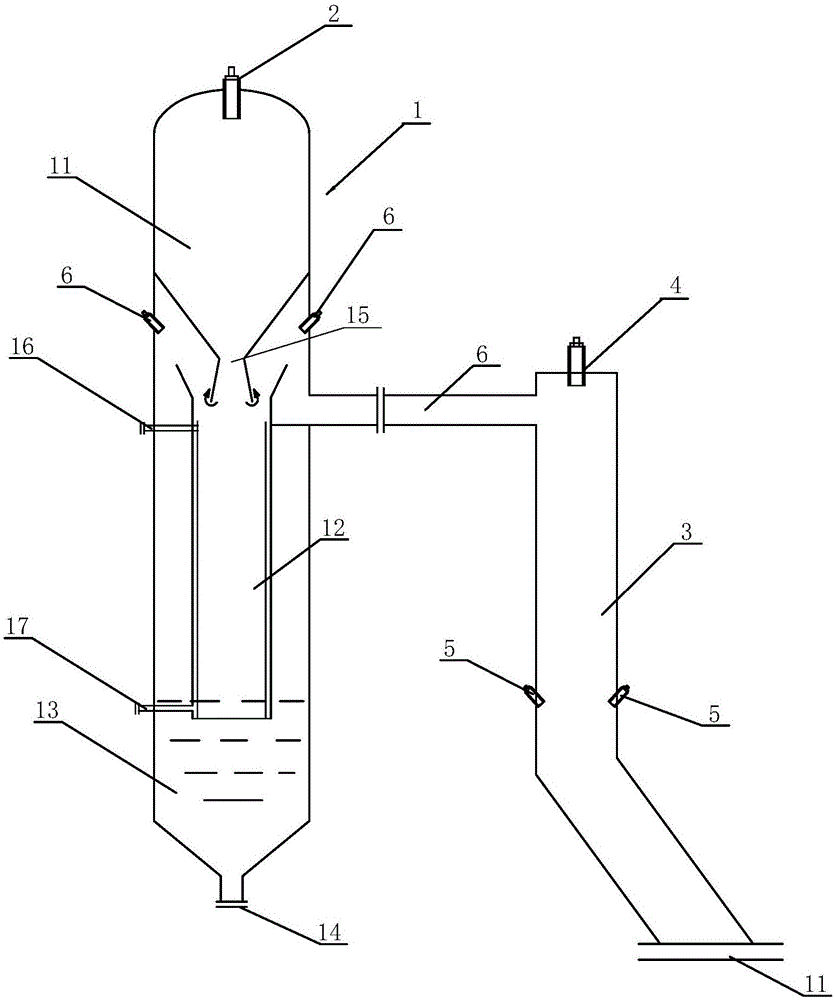

[0032] like Figure 1 to Figure 3 As shown, the coal pyrolysis oil production device includes a gasifier 1 and a pyrolysis chamber 3 that are connected to each other.

[0033] The gasification furnace 1 includes a gasification chamber 11 , a downcomer 12 and a quenching chamber 13 sequentially from top to bottom. The gasification chamber 11 is a hot-wall reactor structure, with a gasification nozzle 2 at the top and a conical structure at the bottom, and the outlet 15 at the bottom communicates with the inlet of the downcomer 12 .

[0034] The downcomer 12 is connected with a cooling water pipe 16 through which quenching water is passed into the surface of the downcomer 12 to form a water film on the inner wall of the downcomer to protect the downcomer. The entrance of the downcomer 12 is a flared bell mouth to facilitate the receiving of ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com