Patents

Literature

67results about How to "Reaction does not affect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

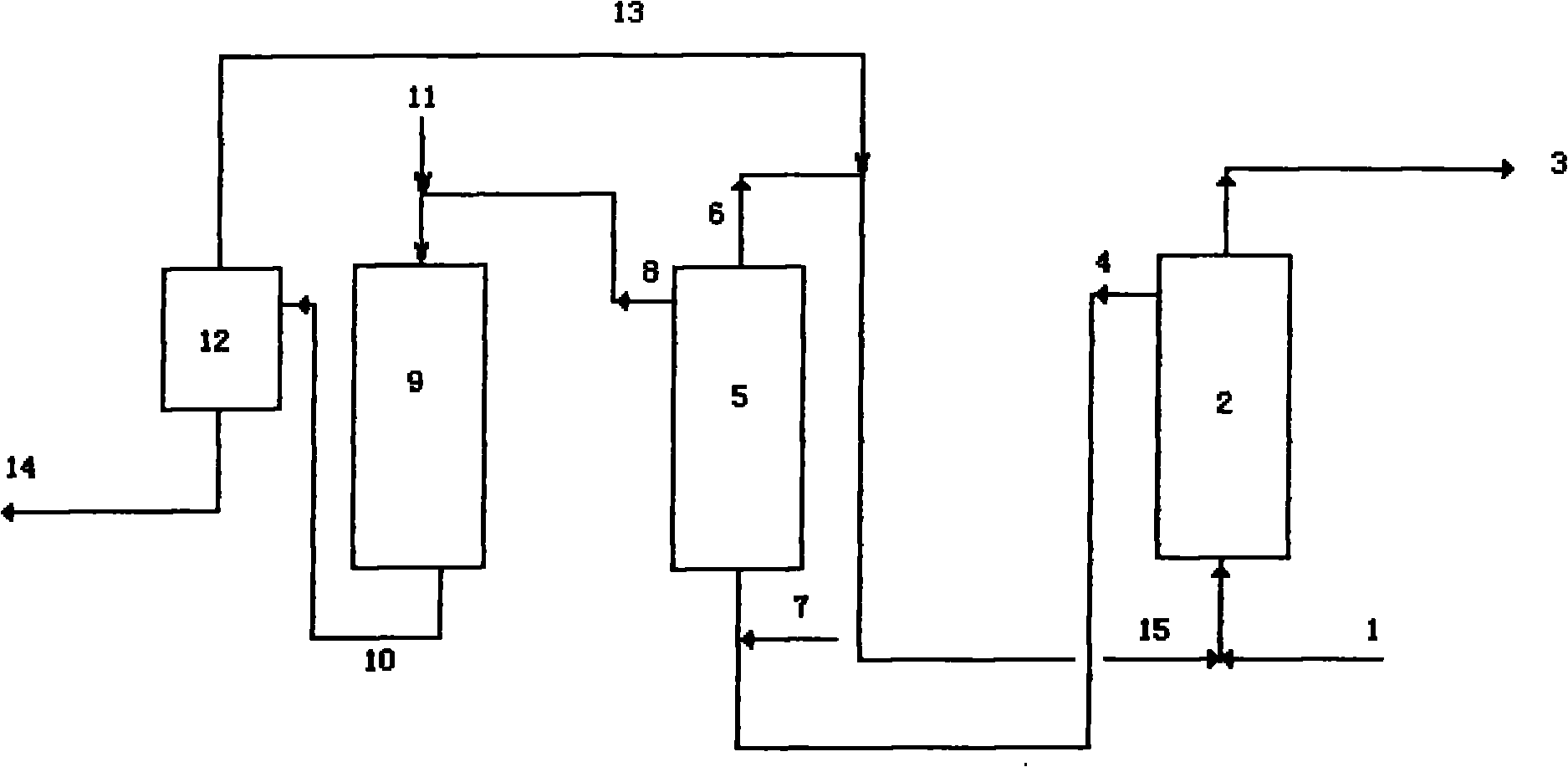

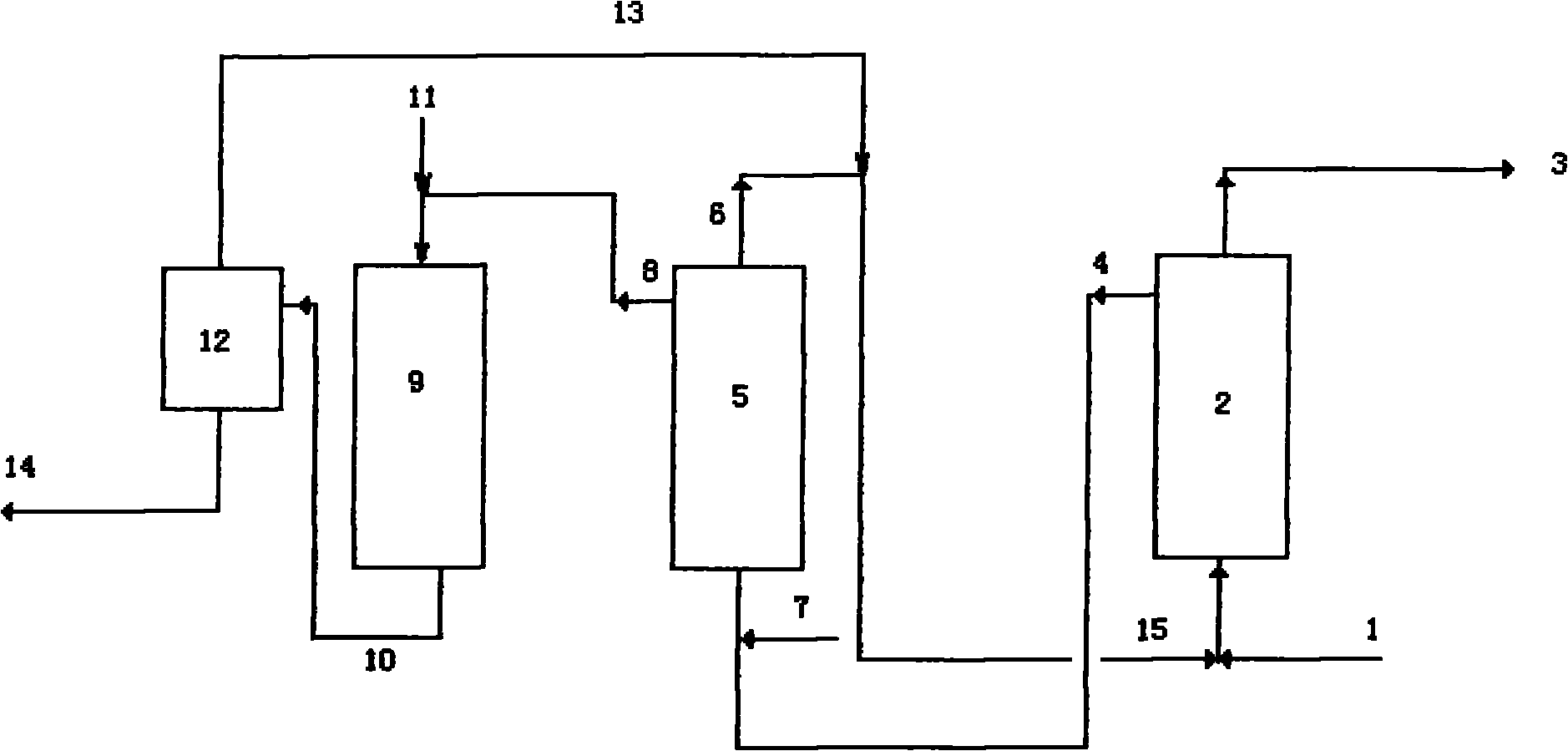

Hydrogenation method of heavy hydrocarbon multi-segment fluidized bed

ActiveCN101724453AReduce heat loadSave heatHydrocarbon oil crackingTreatment with hydrotreatment processesGas phaseFuel oil

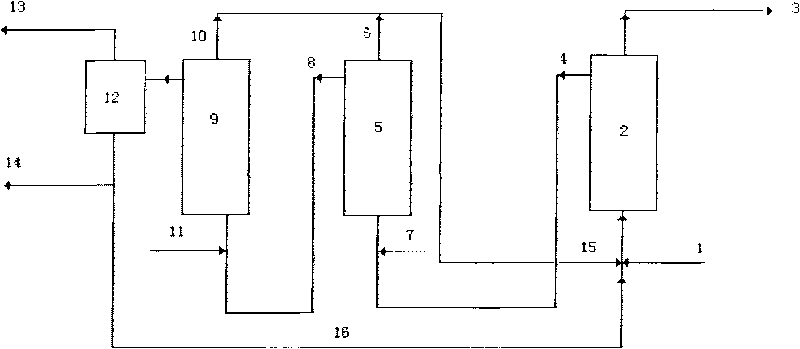

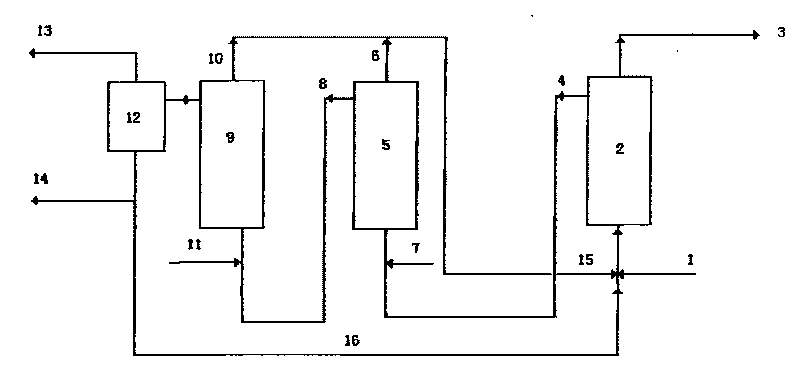

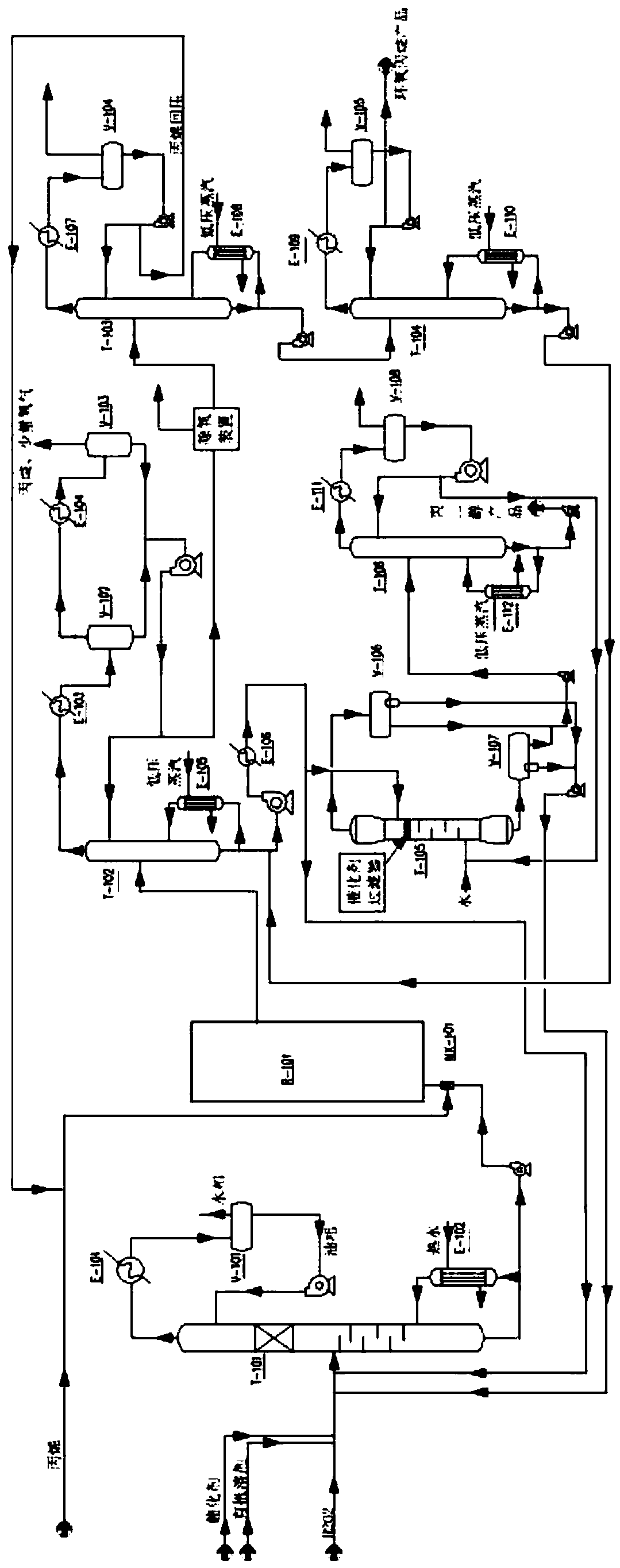

The invention discloses a hydrogenation method of a heavy hydrocarbon multi-segment fluidized bed. The technical process comprises the steps of: mixing thick heavy hydrocarbon raw materials with gas phase material flow which is discharged from a fluidized bed hydrogenation-desulfuration reactor and a hydrogenation-denitrification reactor to enter into a hydrogenation-demetalization reactor; cooling and purifying reacted gas phase material flow to be taken as recycle hydrogen; mixing the demetallized liquid phase material flow with hydrogen to enter into the fluidized bed hydrogenation-desulfuration reactor; mixing the desulfurated liquid phase material flow with hydrogen to enter into the hydrogenation-desulfuration reactor; and leading the denitrified liquid phase material flow to enter into a separating device. The technology adopts a new reactor assembly mode to machine heavy oil raw materials with high viscosity and bad quality, can provide a new flexible, high-efficiency and energy-saving operation mode, organically combines the performances of the raw materials with the characteristic of each hydrogenation reaction, makes full use of reaction heating on the premise that a device is guaranteed to be stably operated, provides a product with good quality, and can flexibly adjust the operation process according to the requirement of a refinery.

Owner:CHINA PETROLEUM & CHEM CORP +1

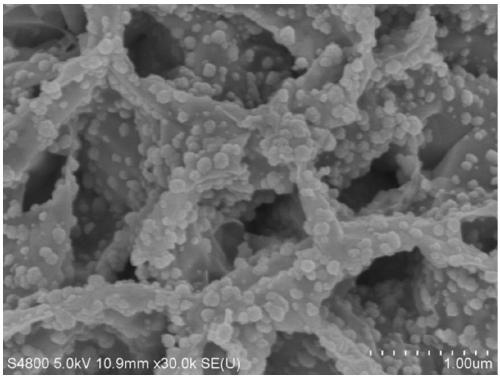

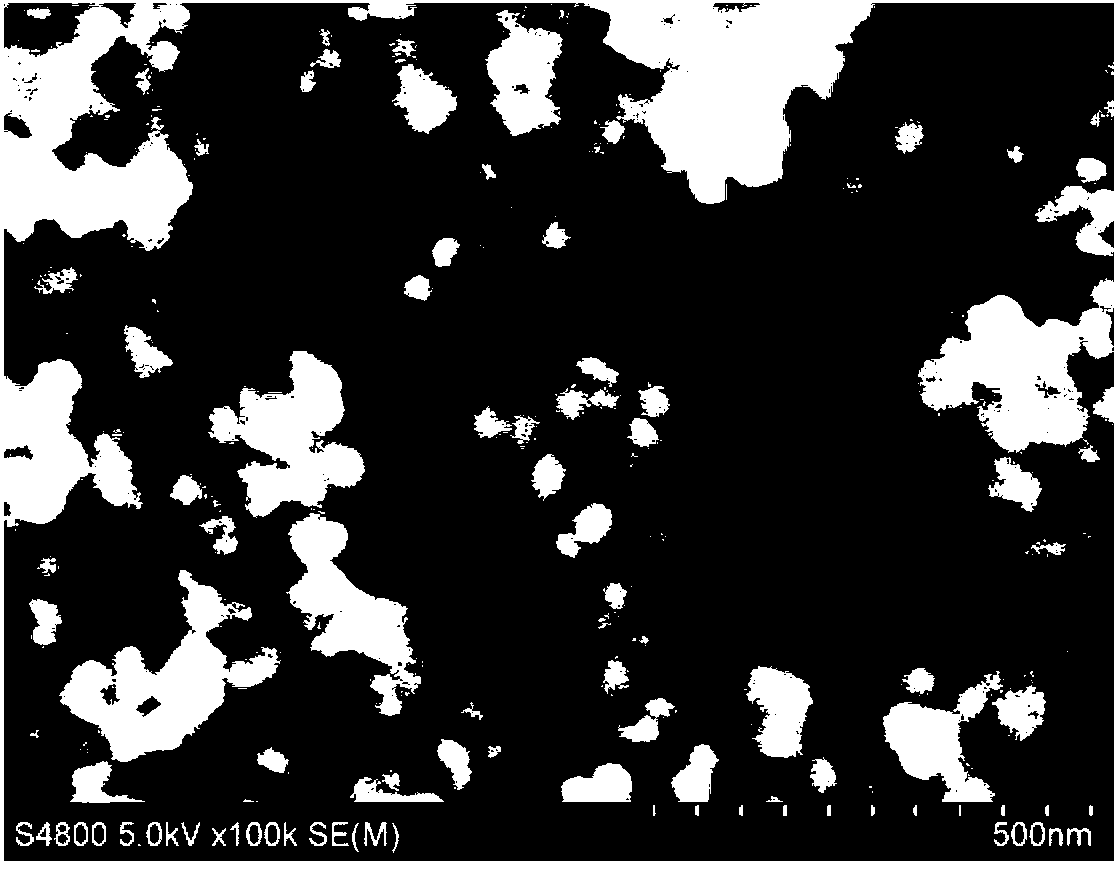

Method for preparing nano copper/carbon nano tube composite powder by liquid phase method

InactiveCN102198510APrevent oxidationReaction does not affectMaterial nanotechnologyFiltrationHydrazine compound

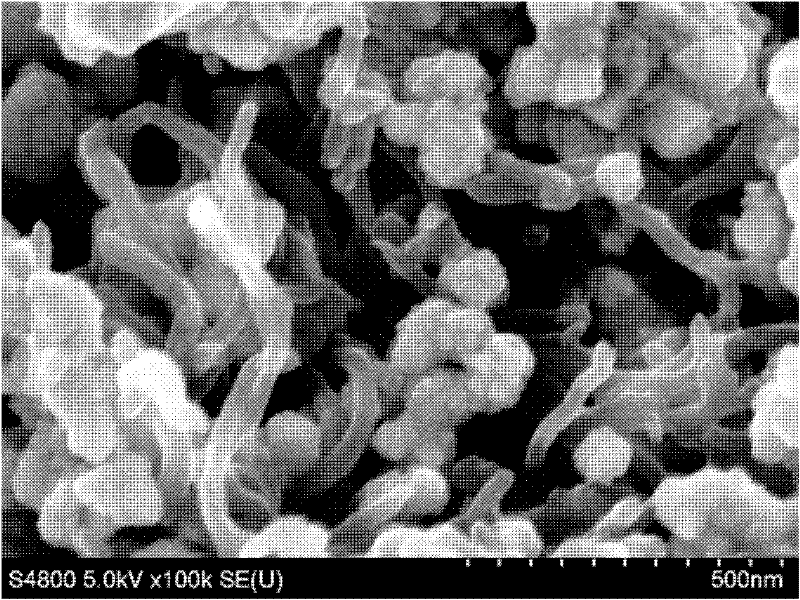

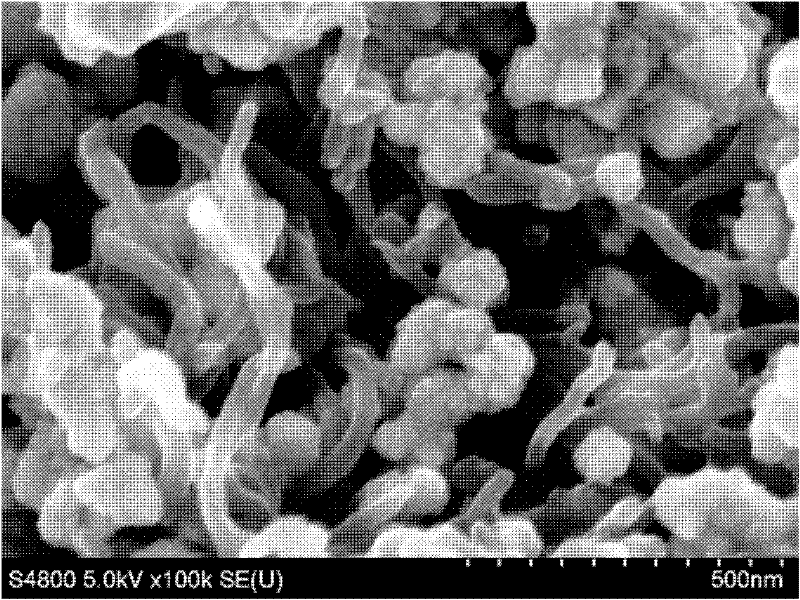

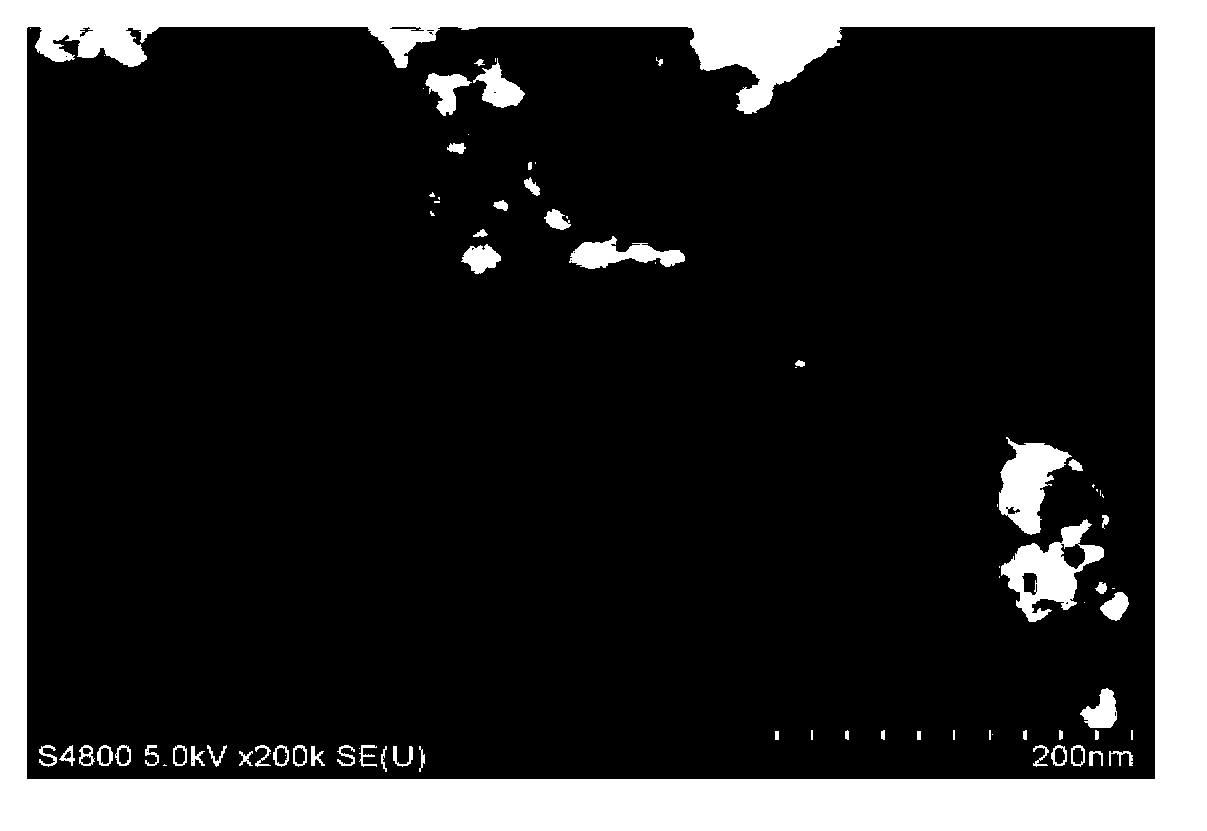

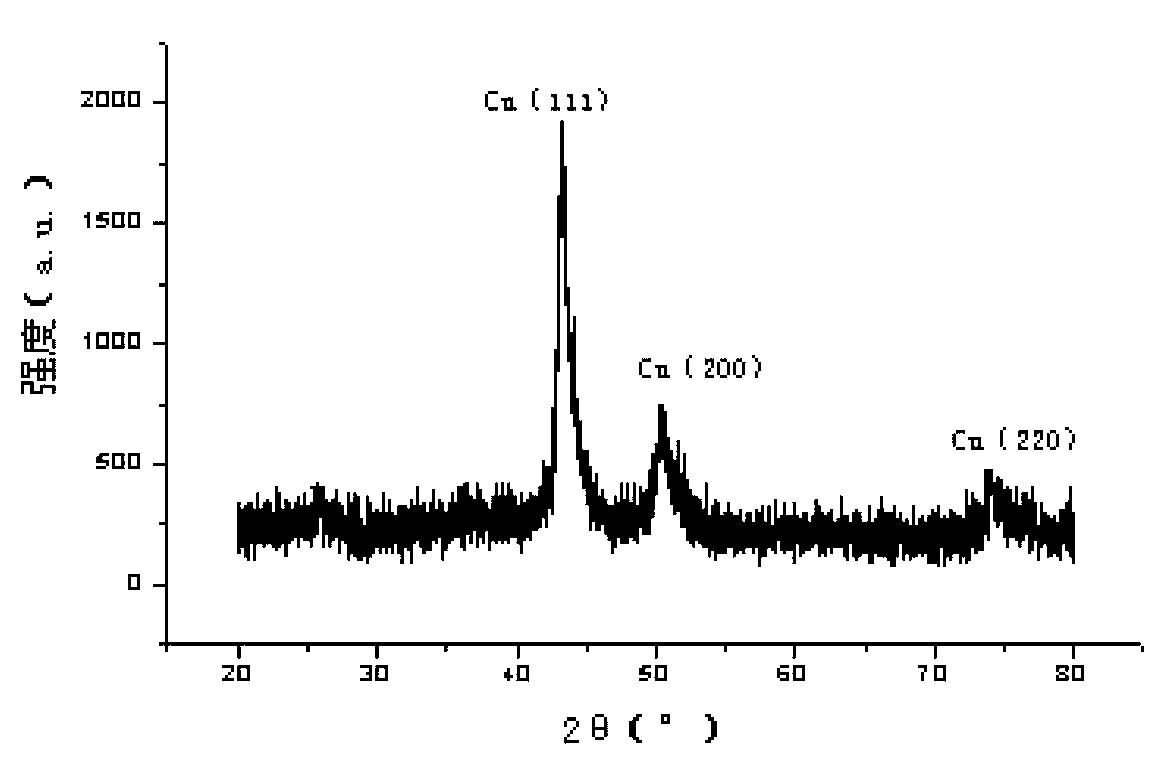

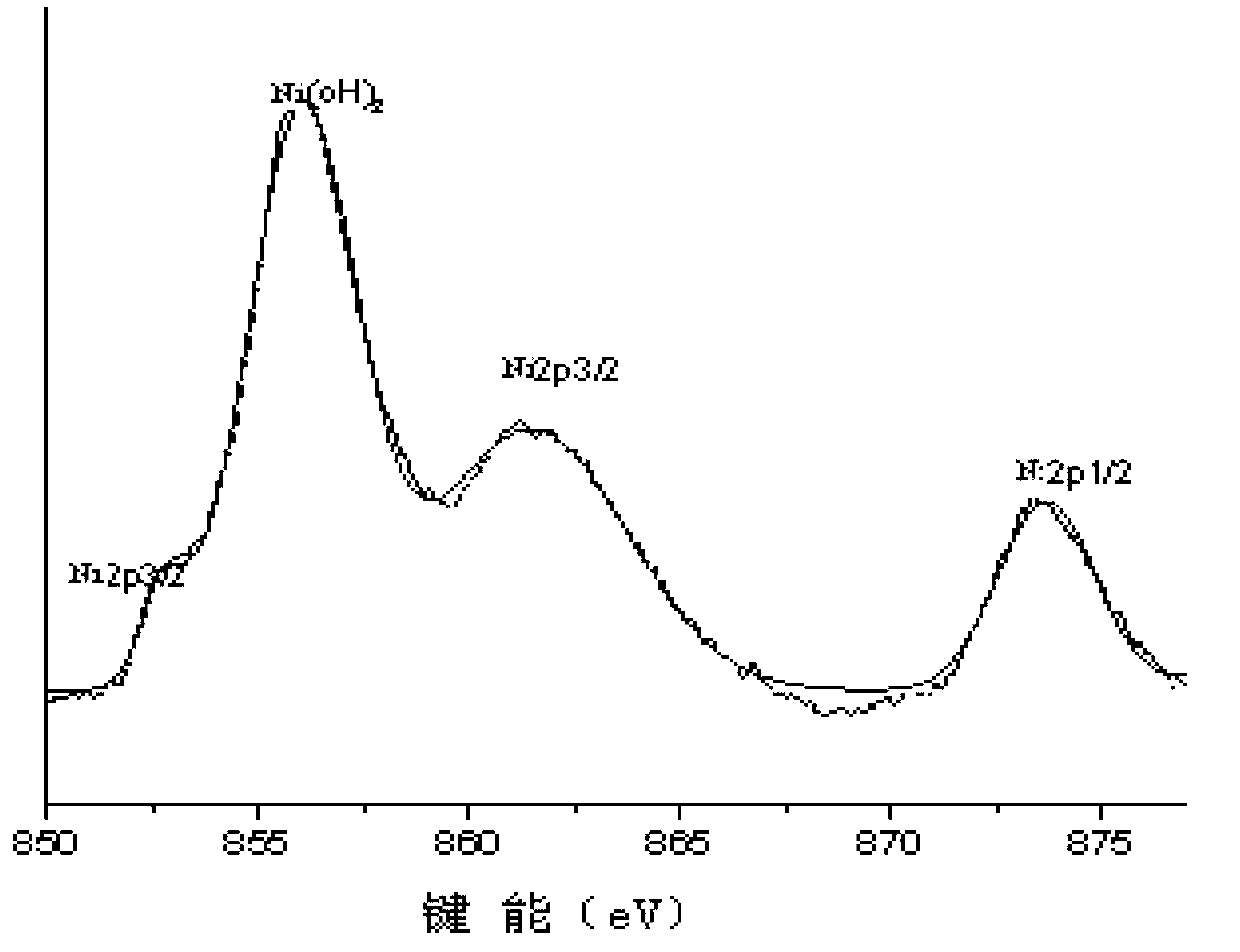

The invention discloses a method for preparing a nano copper / carbon nano tube composite powder by a liquid phase method, and relates to a preparation method of nano copper / carbon nano tube composite powder. The method solves the problems that the conventional preparation method of the nano copper / carbon nano tube composite powder is complex and high in cost and the nano copper particles are difficultly controlled. The method comprises the following steps of: adding acidified carbon nano tube and polyvinyl pyrrolidone (PVP) into copper sulfate solution, regulating pH, then adding hydrazine hydrate to obtain mixed solution, reacting the mixed solution at the temperature of between 60 and 80 DEG C, cooling to room temperature, performing suction-filtration to obtain powder, and drying the powder in vacuum at the temperature of 50 DEG C to obtain the composite powder. The nano copper in the prepared composite powder is uniformly distributed on the surface of the carbon nano tube, and the nano copper and the carbon nano tube form a chemical bond. Under the alkali condition, the hydrazine hydrate is used as a reducing agent, and a large amount of nitrogen is generated at the same time of reducing copper ions, so that oxidation of the nano copper can be effectively prevented; and the size of the nano copper particles can be controlled in a range of 40 to 50 nanometers by adding the PVP. The preparation method is simple in process and low in cost, and the nano copper particles are easily controlled.

Owner:HEILONGJIANG UNIV

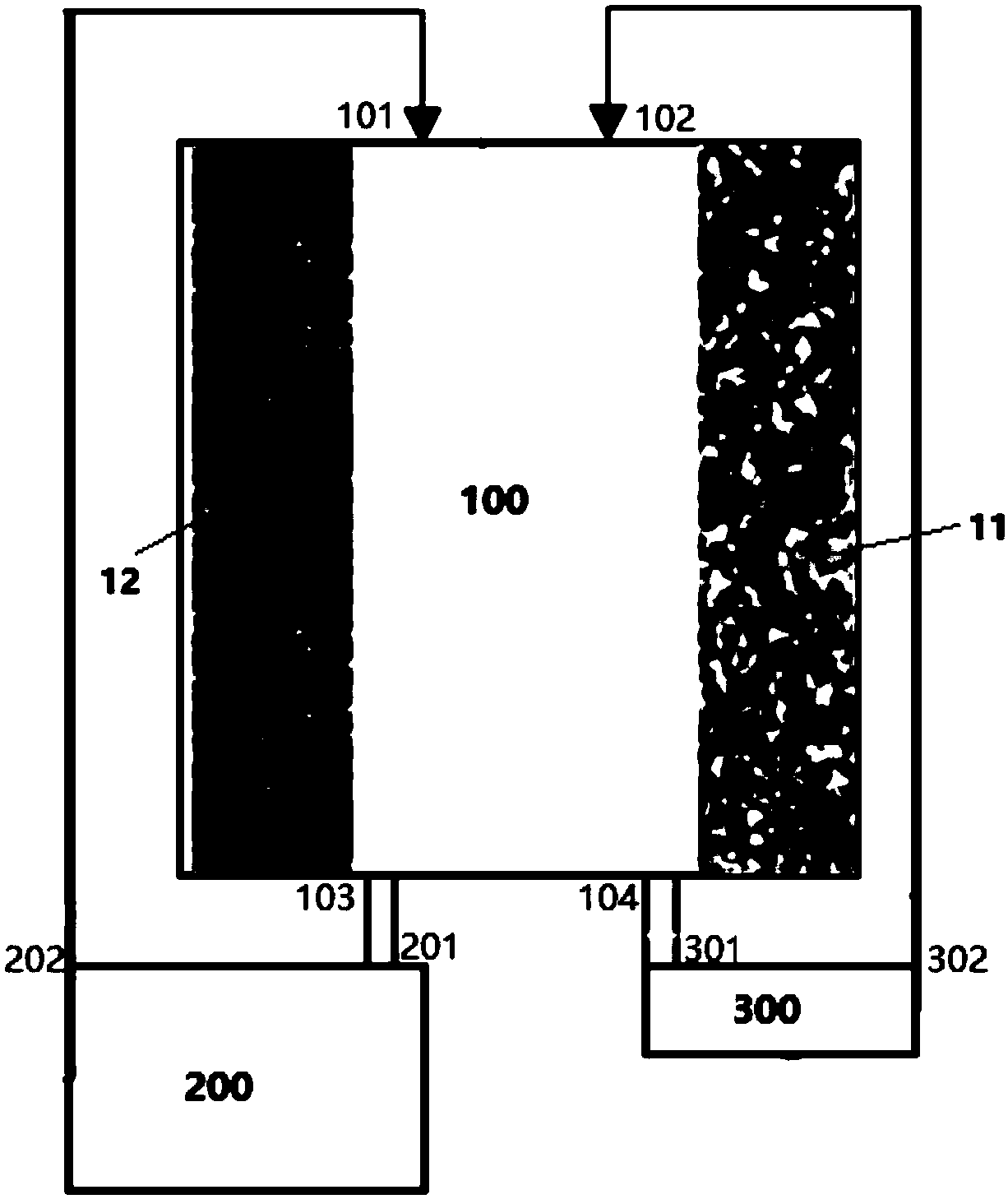

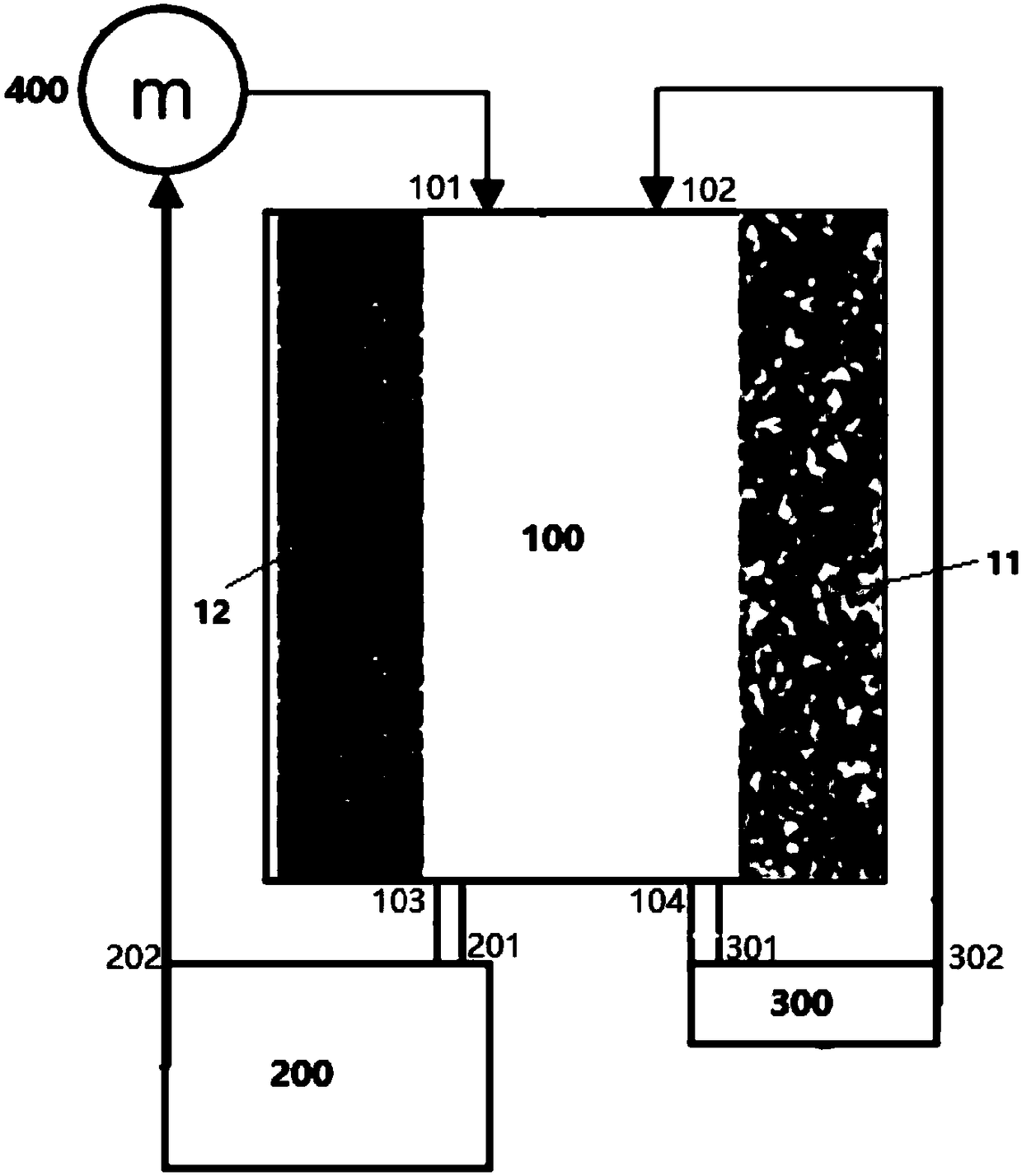

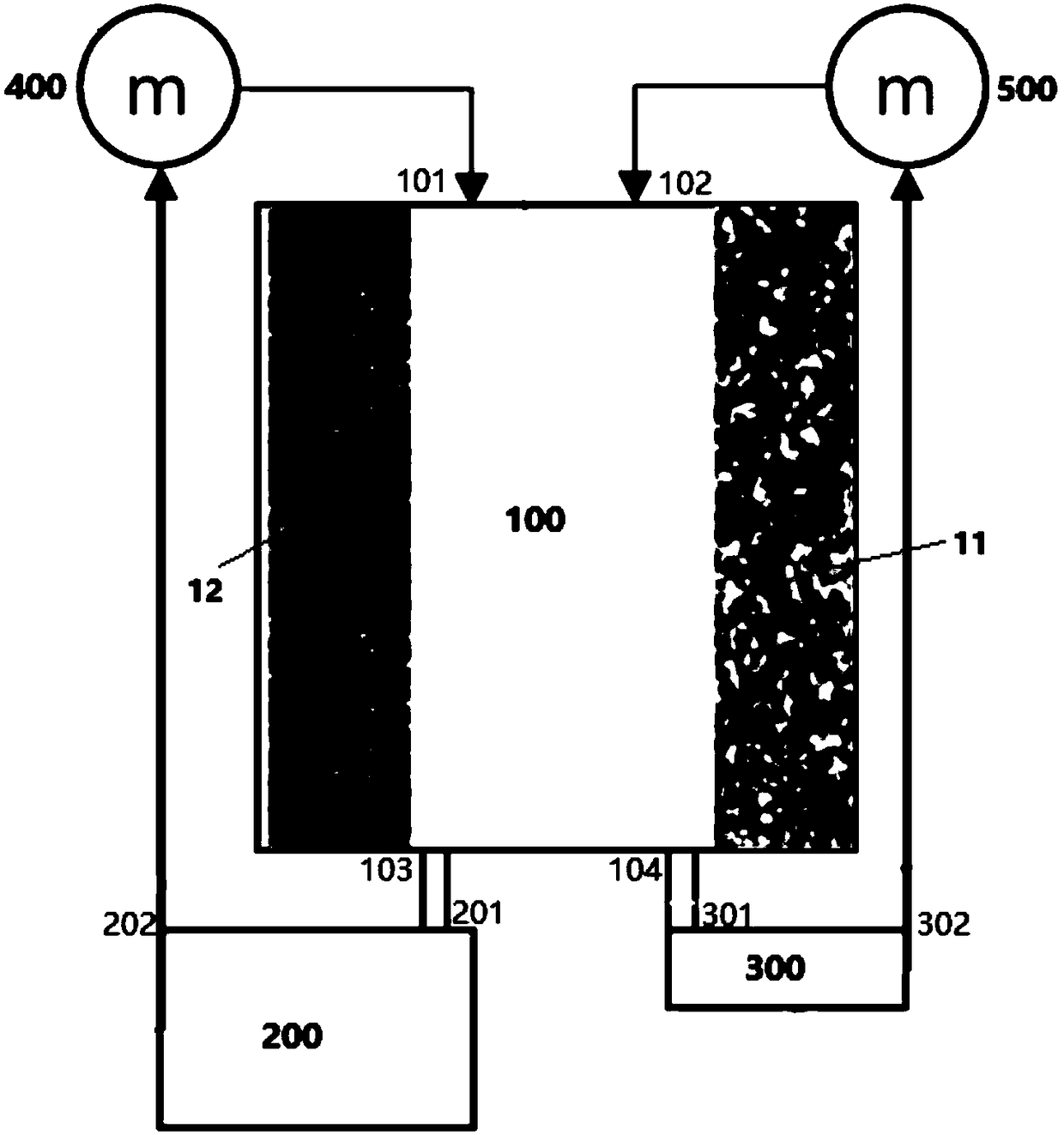

A system and method for avoiding downtime corrosion of a metal-air fuel cell

PendingCN109167125AAvoid Downtime CorrosionDowntime Corrosion RealizationFuel and primary cellsFuel and secondary cellsFuel cellsDowntime

The invention discloses a system and a method for avoiding corrosion of a metal-air fuel cell during shutdown. The system comprises a battery chamber, wherein an air positive electrode and a metal negative electrode arranged in a spacing are arranged in the battery chamber. The battery chamber is provided with a first electrolyte inlet, a first protective solution inlet, a first electrolyte outletand a first protective solution outlet. An electrolyte storage device having a second electrolyte inlet and a second electrolyte outlet, the second electrolyte inlet being connected to the first electrolyte outlet and the second electrolyte outlet being connected to the first electrolyte inlet; A protective liquid storage device having a second protective liquid inlet and a second protective liquid outlet, the second protective liquid inlet being connected to the first protective liquid outlet and the second protective liquid outlet being connected to the first protective liquid inlet. The system avoids the self-corrosion of the metal negative electrode of the metal-air fuel cell in the down state, and can switch the operation and stopping states of the cell freely at the same time. The service life of metal-air fuel cell is significantly prolonged.

Owner:TSINGHUA UNIV

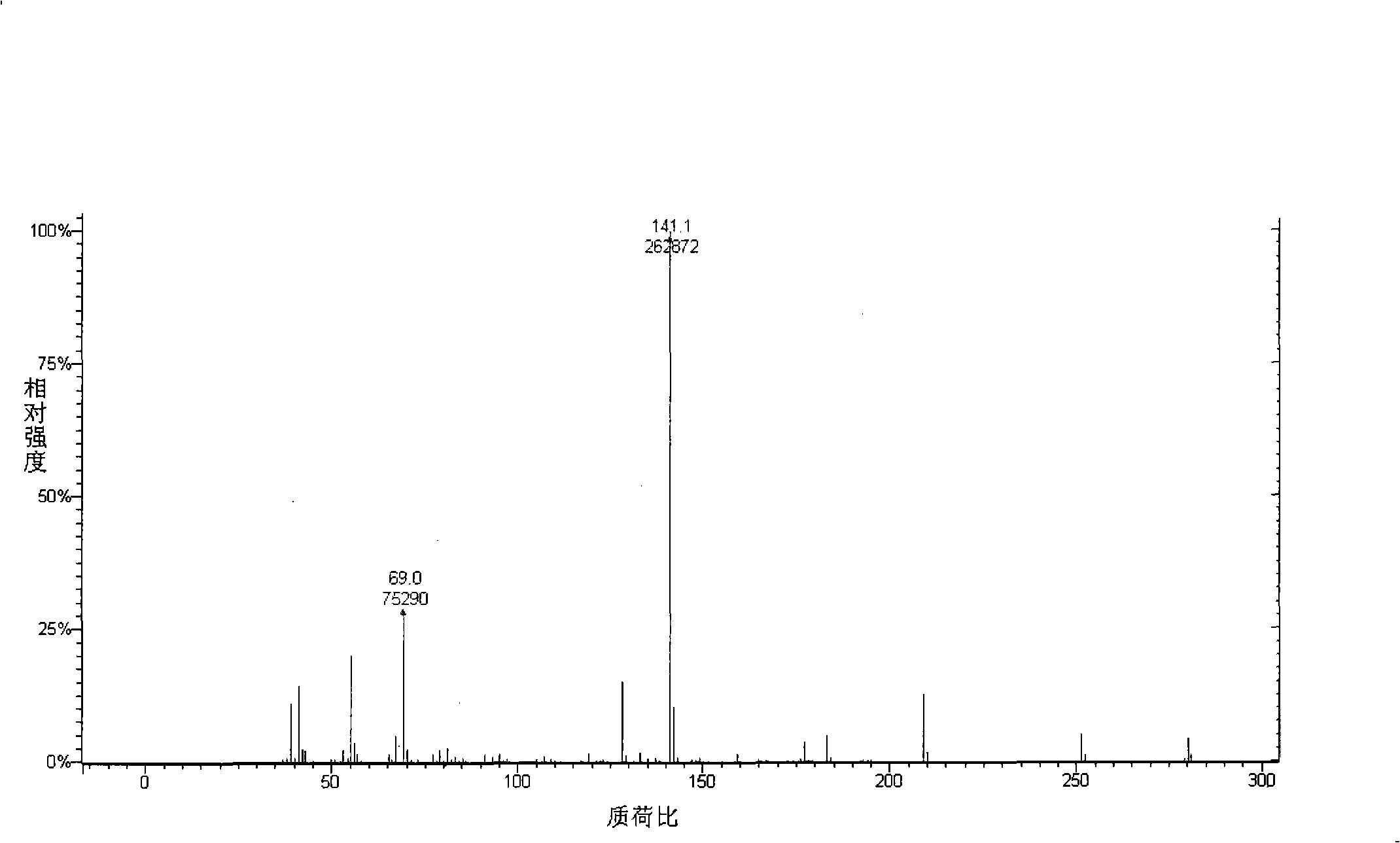

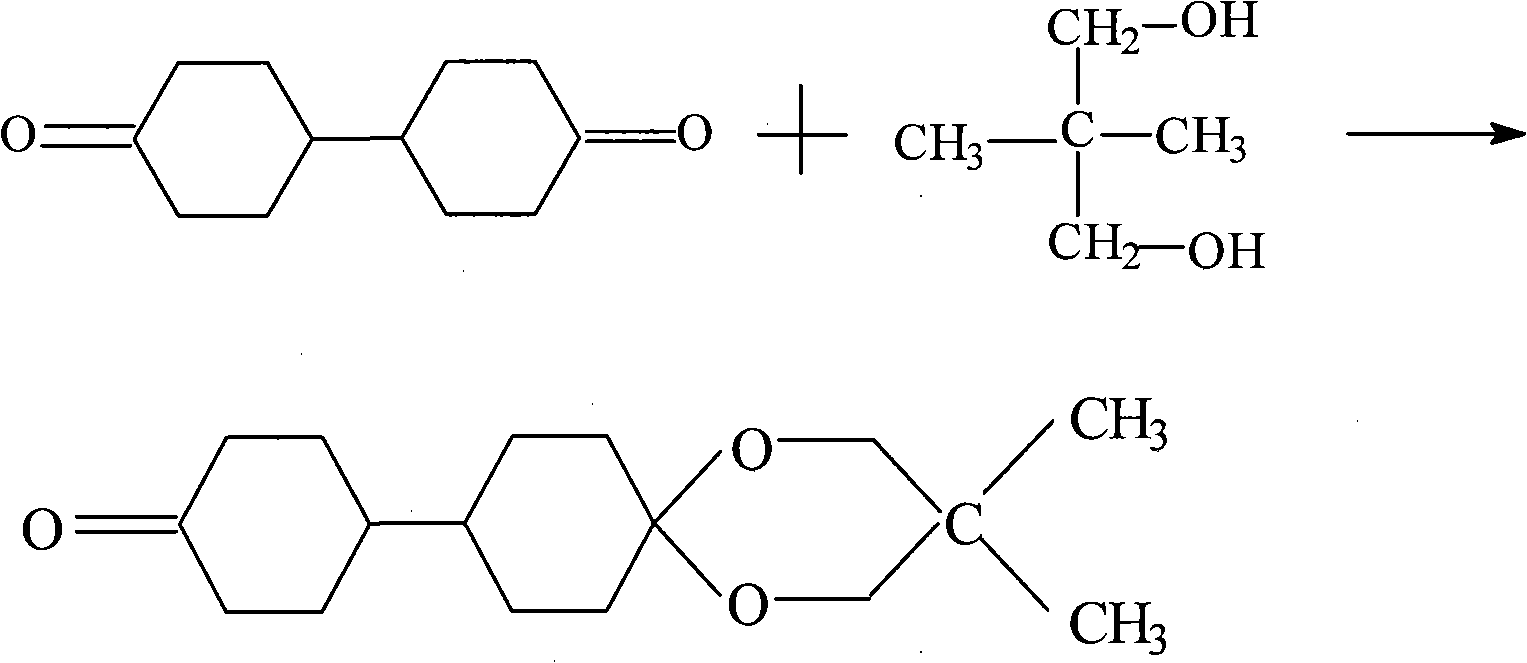

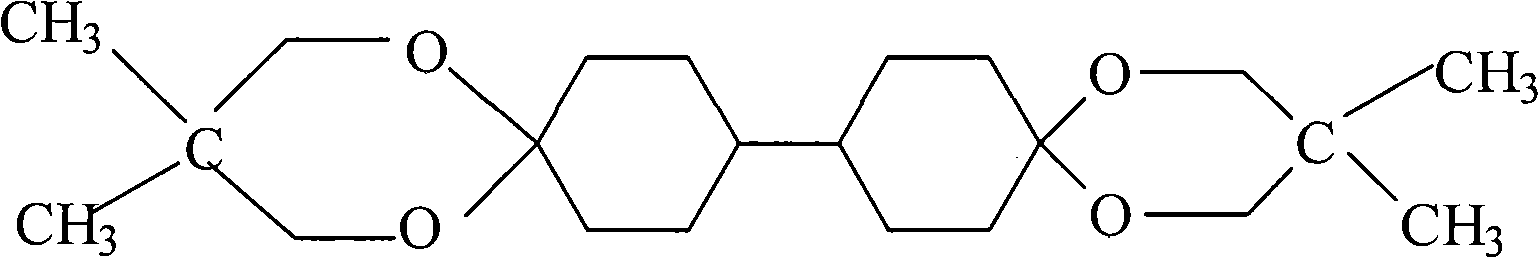

Preparation of bicyclohexyl neopentyl glycol single ketal

ActiveCN101407512AHigh yieldHigh purityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsReaction temperatureStrong acids

The invention relates to preparation of an organic compound, in particular to a method for preparing dicyclohexyl pentanediol mono-ketal and belongs to the technical field of organic compound preparation. The method takes dicyclohexyl diketone and neopentyl glycol as the raw materials to carry out the catalytic reaction under the catalyst of inert solvent cyclohexane and strong acid cation exchange resin, the reaction temperature is 0 to 110 DEG C, the dicyclo mono-ketal is prepared, and the conversion rate can reach 80 to 95 percent; simultaneously, dicyclohexyl pentanediol mono-ketal with high yield and high purity is obtained by acetone-water system, and the method is beneficial to later preparation of mono-crystalline, alkene and the like.

Owner:HEBEI MAIERSTON ELECTRONICS MATERIAL

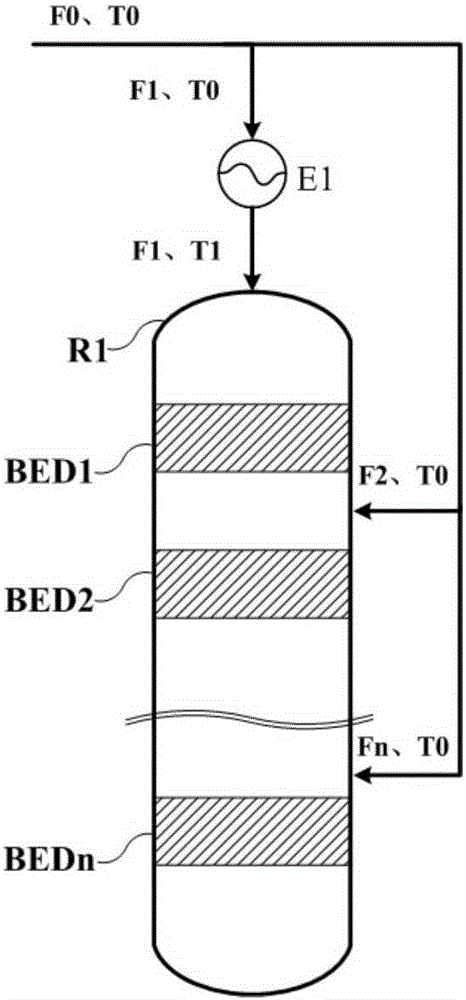

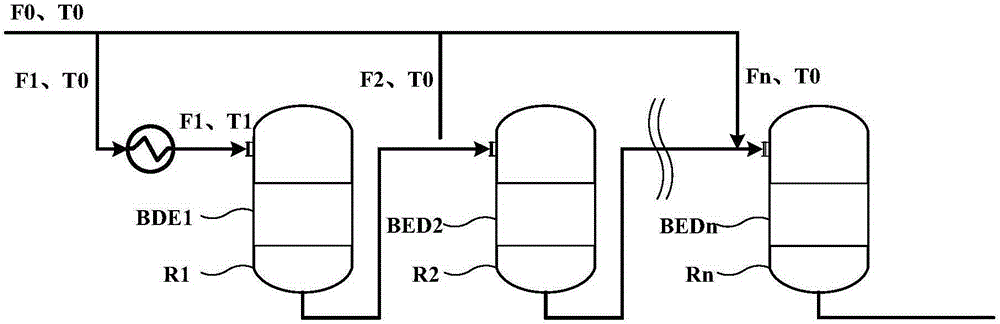

Multistage hydrogenation method for heavy hydrocarbon

ActiveCN102071059AWide applicability of raw materialsImprove product qualityTreatment with hydrotreatment processesHydrogenation reactionGas phase

The invention discloses a multistage hydrogenation method for heavy hydrocarbon. The method comprises the following technical steps of: mixing a condensed heavy hydrocarbon raw material and a gas phase material flow discharged from a hydrogenation desulfurization reactor and a hydrogenation denitrification reactor, and putting the mixture into a boiling bed hydrogenation demetalization reactor; cooling and purifying the reacted gas phase material flow and taking the cooled and purified reacted gas phase material flow as recycled hydrogen; mixing a liquid phase material flow subjected to the boiling bed demetalization reaction and the hydrogen, and putting the mixture into the hydrogenation desulfurization reactor; mixing the liquid phase material flow subjected to the desulfurization reaction with the hydrogen, and putting the mixture into the hydrogenation denitrification reactor, wherein at least one of the hydrogenation desulfurization reactor and the hydrogenation denitrification reactor is a fixed bed reactor. Compared with the prior art, the method provides a novel flexible, efficient and energy-saving operating mode for treating inferior heavy and residual oil raw materials; the property of the raw materials is organically combined with characteristics of the hydrogenation reactions, so the reaction released heat is fully used, the quality of the product is perfect and the operation process can be flexibly adjusted as required on the premise of guaranteeing the stable operation of a device.

Owner:CHINA PETROLEUM & CHEM CORP +1

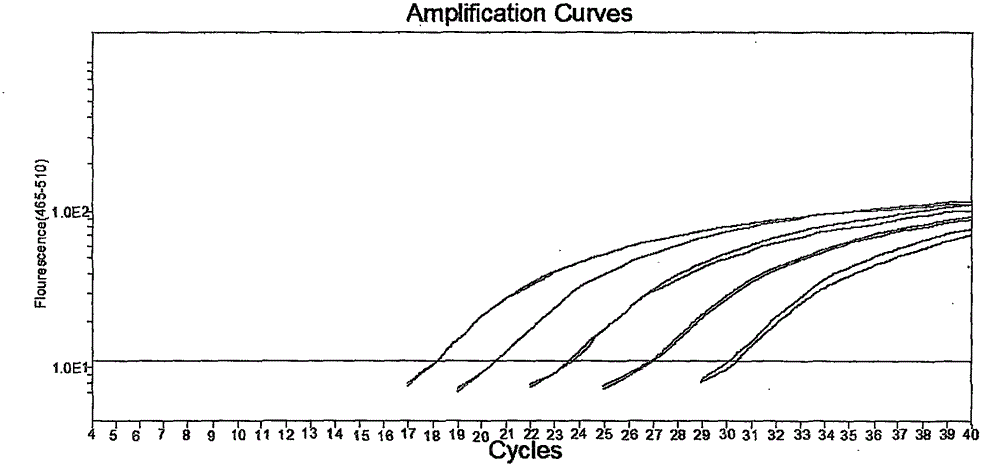

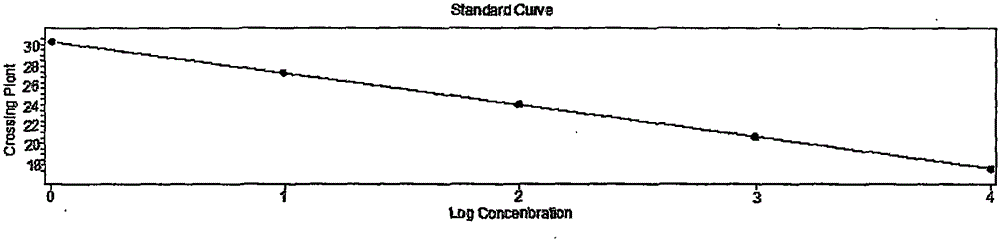

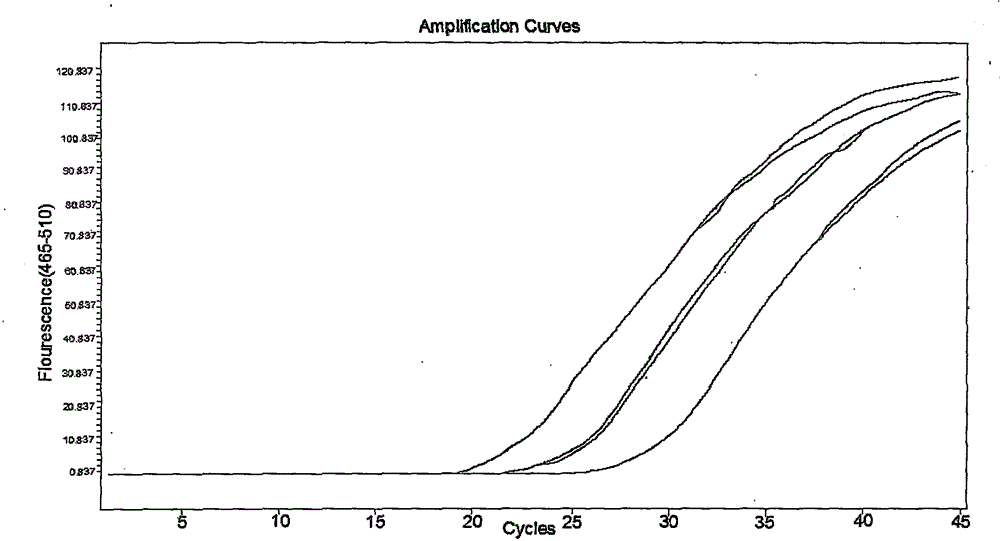

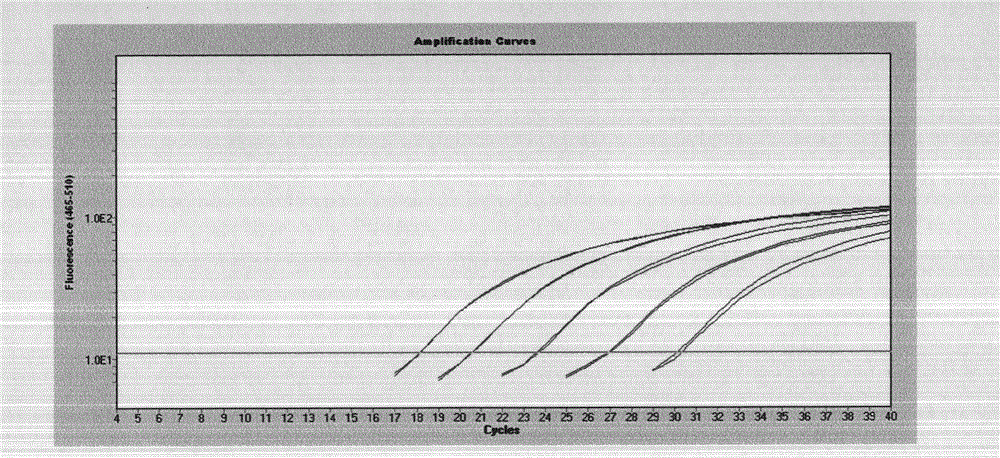

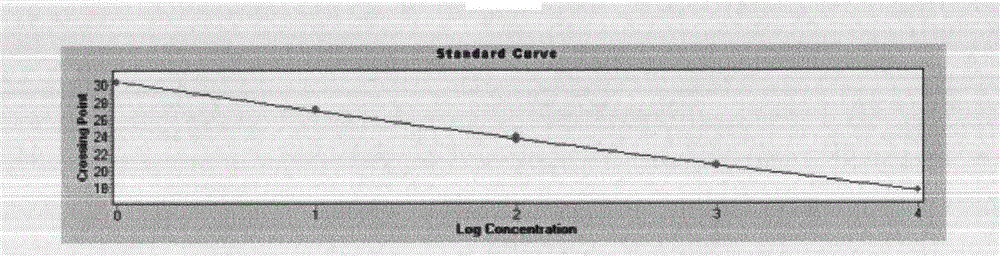

Method for fast and accurate quantitative determination of circulating DNA in blood

InactiveCN105219862AReaction does not affectFewer extraction stepsMicrobiological testing/measurementResponse sensitivityVenous blood

The invention discloses a method for fast and accurate quantitative determination of circulating DNA in blood. The method comprises the following specific steps that processing of plasma or serum is performed: peripheral venous blood is taken and arranged in an EDTA anticoagulant tube for standing at room temperature, or self-clotting whole blood is taken to undergo centrifugation under 1800-2200 g of centrifugal force for 4 to 6 minutes, upper-layer plasma is taken, the same volume of diluted reagent is added, even mixing is performed, stirring is performed at the temperature of 92-97 DEG C for 6 to 10 minutes, then centrifugation is performed again under 15000-17000 g of centrifugal force for 8 to 12 minutes, and supernate is taken as a template for PCR; a quantitative PCR reaction system is configured; quantitative PCR reaction is performed. The quantitative PCR reaction can be performed by directly using the processed plasma or serum, PCR reaction is not influenced, the amplification efficiency is consistent with the amplification efficiency of purified DNA, DNA extraction steps and experimental errors are decreased, a new fluorescent dye SuperGreen which is higher in concentration, high in fluorescent signal value and response sensitivity and capable of accurately detecting plasma free DNA as low as the nanogram level can be adopted, the reagent price is low, the using cost of a DNA extraction kit is reduced, and operation is easy and convenient.

Owner:宋现让

Method for quantitatively determining blood circulation DNA (Deoxyribonucleic Acid)

InactiveCN103146826AReaction does not affectFewer extraction stepsMicrobiological testing/measurementHigh concentrationVenous blood

The invention discloses a method for quantitatively determining blood circulation DNA (Deoxyribonucleic Acid). The method comprises the following steps of: obtaining 1ml of peripheral venous blood of the same tumor patient and placing the peripheral venous blood into an EDTA (Ethylene Diamine Tetraacetic Acid) anti-freezing pipe; standing for 4 hours at 10-20 DEG C; centrifuging 2000g of peripheral venous blood for 5 minutes; taking 100-200 microliters of upper-layer blood plasma; adding a buffering solution with the same volume and sufficiently and uniformly mixing; standing at 95 DEG C for 5-10 minutes; centrifuging 16000g of peripheral venous blood for 10 minutes; and taking a liquid supernatant as a template to be directly used for quantitative PCR (Polymerase Chain Reaction) amplification. The method disclosed by the invention has the beneficial effects that 1. blood plasma or blood serum can be directly used for a quantitative PCR reaction through special technical process treatment and the PCR reaction is not influenced; ratios of amplification efficiencies to the purified DNA are consistent, and extraction steps and experimental errors of the DNA are reduced; and 2. an adopted novel fluorescent dye Super Green has slight inhibition effect in a PCR amplification process and high concentration can be used; and a fluorescence signal value is high and the reaction sensitivity is high, and blood plasma free DNA which is at a nanogram level can be accurately detected.

Owner:宋现让

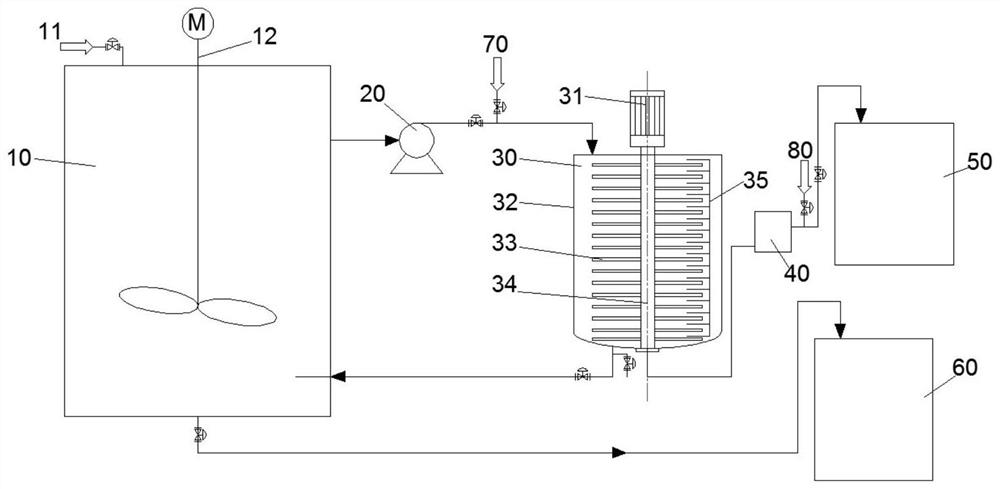

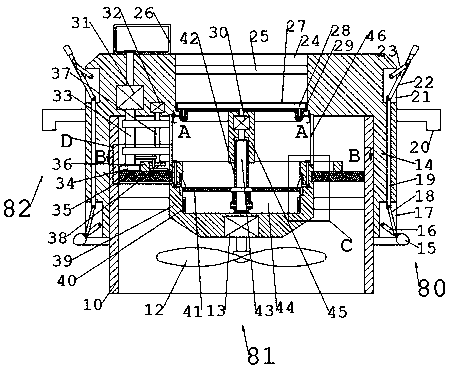

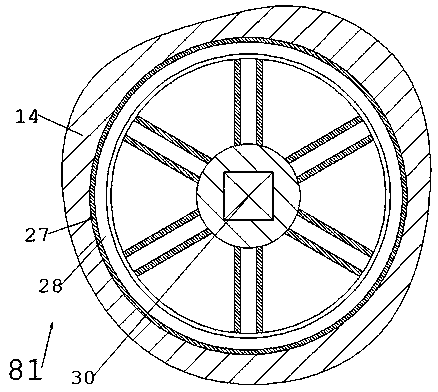

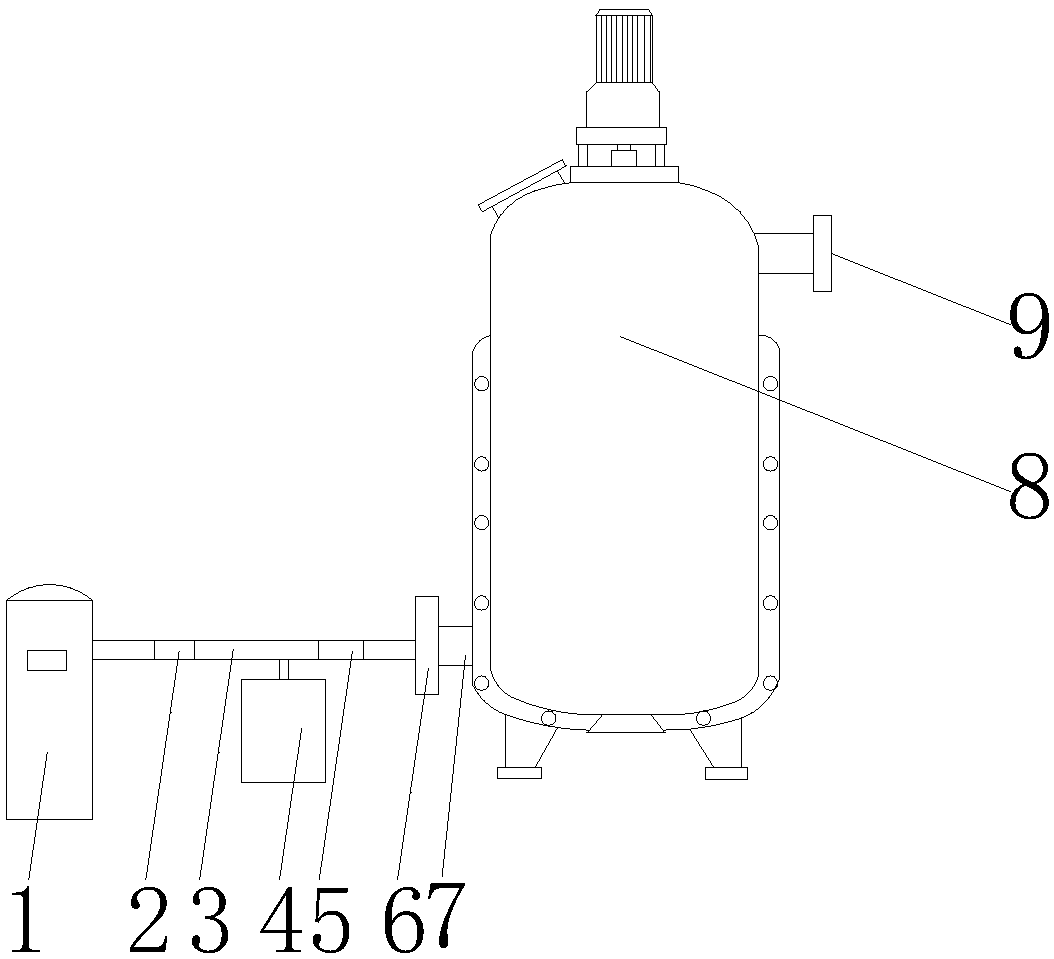

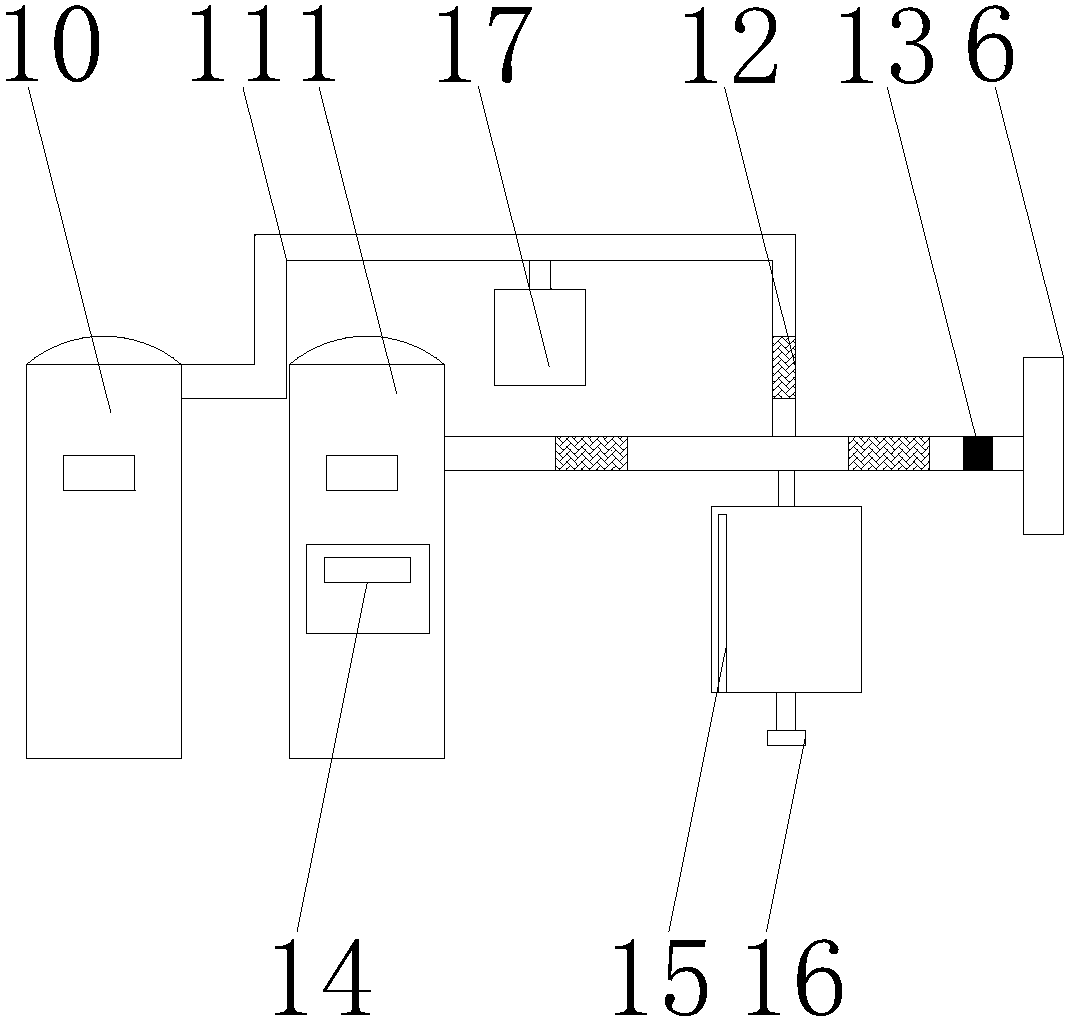

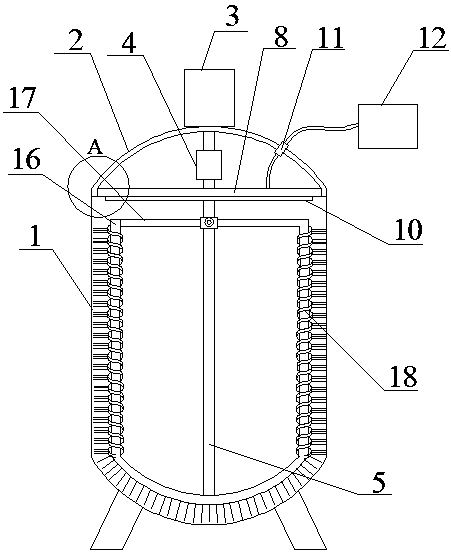

Preparation method of ternary positive electrode material precursor

PendingCN113968595AShorten production timeImprove responseCell electrodesChemical/physical/physico-chemical stationary reactorsReaction temperatureCirculator pump

The invention provides a preparation method of a ternary positive electrode material precursor, wherein a reaction kettle, a circulating pump and a dynamic separation device which are sequentially communicated to form a suspension loop are utilized, so that the reaction efficiency and the product uniformity are effectively improved. The method comprises the following steps: preparing a metal salt mixed solution, a precipitant solution and a complexing agent solution, and adding the solutions into a reaction kettle in a parallel flow manner; controlling the reaction temperature in the reaction kettle to be 20-95 DEG C, the pH value to be 10-13 and the ammonia concentration to be 5-12g / L, and reacting; after the reaction kettle reaches a set liquid level, conveying the suspension liquid in the reaction kettle to a dynamic separation device through a circulating pump, carrying out solid-liquid separation, collecting separated mother liquor clear liquid to a mother liquor discharge tank, returning concentrated slurry to the reaction kettle for continuous reaction, and stopping feeding until solid materials in the reaction kettle meet specified physical and chemical characteristics; and unloading the materials to a finished product storage tank to enter a subsequent treatment process.

Owner:SHANGHAI ANHORN ENVIRONMENTAL TECH CO LTD

Flue gas treatment system of large chimney for industrial waste gas emission

InactiveCN110215777AEasy to handleEmission complianceGas treatmentDispersed particle filtrationWater bathsRubber ring

The invention discloses a flue gas treatment system of a large chimney for industrial waste gas emission. The flue gas treatment system comprises an inner shell, and an outer shell arranged in the inner shell in a sliding manner, wherein first fixing spaces are symmetrically formed in the outer shell around the outer shell; mounting connecting rods are hinged onto the first fixing spaces; and elastic rubber rings that can be clamped with inner walls of the chimney are fixedly arranged on the connecting rods. A slide bar is pulled to slide upwards by a handle by pushing the handle upwards, a pull rod is pulled upwards by the slide bar, the connecting rods are pulled to rotate by the pull rod, so that the elastic rubber rings are clamped with the inner walls of the chimney, namely the innershell and the outer shell can be fixed on the chimney and mounted on the top of the chimney, and flue gas can be respectively subjected to dust fall treatment and water bath washing treatment. Therefore, emission of the flue gas is up to the standard, a filter screen can be automatically cleaned, manual working is reduced, the flue gas can be subjected to accelerated treatment, and the treatment rate is increased.

Owner:LONGYOU DAOSHI INTELLIGENT TECH CO LTD

Method for producing 4-cumylphenol and 2.4-dicumylphenol by using phenolic tar

InactiveCN102690174ANo lossReaction does not affectOrganic chemistryOrganic compound preparationDistillationFixed bed

The invention discloses a method for producing 4-cumylphenol and 2.4-dicumylphenol by using phenolic tar. The main research direction of the invention is to carry out catalytic cracking on phenolic tar and then recover acetophenone, phenol and alpha-vinyltoluene (alpha-alpha methyl styrene). The method comprises the following six steps: 1, carrying out rectification on the phenolic tar by using a high-vacuum molecular distillation device; 2. adding the obtained molecular distillation product (1.3 tons) into fresh phenol (200 kg), carrying out depolymerizing reaction on the obtained mixture by using a solid strong-acid molecular sieve fixed bed reactor, and then slowly adding alpha-vinyltoluene monomers (500 kg) into the reactor for reaction; 3, carrying out crystallization on the obtained reaction product through taking a mixture of dichloroethane and toluene as a solvent; 4, carrying out recrystallization on materials subjected to drying through taking a mixture of methanol, ethanol and isopropanol as a solvent; 5, carrying out crystallization on 4-cumylphenol (completely dissolved in a crystallization residue solution of methanol, ethanol and isopropanol) through taking a mixture of dichloroethane and toluene as a solvent; and 6, carrying out distillation on mother solutions of the mixtures of dichloroethane and toluene for crystallization in the step 3 and step 5. The method disclosed by the invention is used for producing 4-cumylphenol and 2.4-dicumylphenol.

Owner:丁彦春

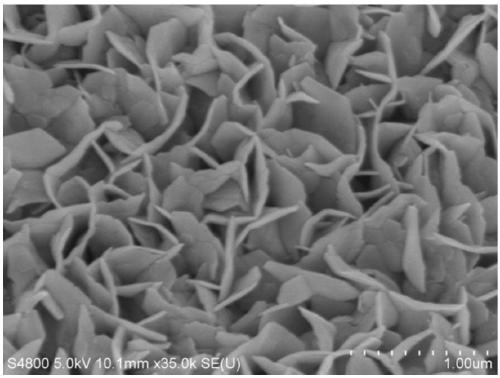

Cobalt-doped tin disulfide nano-sheet array material, preparation method and applications thereof

ActiveCN109289874AImprove stabilityLarge specific surface areaPhysical/chemical process catalystsElectrodesFiberSulfur

The invention provides a cobalt-doped tin disulfide nano-sheet array material, a preparation method and applications thereof. Compared with the method in the prior art, the method of the present invention has the following characteristics that in a closed high temperature and high pressure reaction kettle, isopropanol is used as a reaction solvent, a tin source, a sulfur source and a cobalt salt are uniformly mixed according to a certain ratio, and a reaction system is heated to generate a high pressure environment so as to prepare the cobalt-doped tin disulfide nano-sheet array material, wherein the two-dimensional nano-sheet structure increases the surface area of the whole material, and the small particles SnS2 attached to the surface of the nano-sheet can provide more active sites so as to easily transfer and transmit electrons, such that the material has good electrochemical catalytic response and good stability; and carbon fiber as a substrate has good electrical conductivity, can be used directly as a flexible electrode material, and cannot affect an electrode reaction, such that the carbon fiber material is selected as the substrate for hydrothermal synthesis, the two-dimensional structure grows on the surface of the carbon fiber, and the obtained material is directly used for catalyzing oxygen evolution reactions.

Owner:ANHUI NORMAL UNIV

Technical method for removing propylene glycol in hydrogen peroxide direct oxidation method used for preparing propylene oxide

ActiveCN109553593AGood effectReduce hydrolysisOrganic chemistryChemical recyclingOrganic solventPetrochemical

The invention relates to the field of petrochemical engineering, and particularly relates to a technical method for removing propylene glycol in a hydrogen peroxide direct oxidation method used for preparing propylene oxide. The technical method comprises the following steps: mixing dehydration is carried out on a catalyst with hydrogen peroxide and an organic solvent to obtain a mixed liquid; themixed liquid reacts with liquid propylene in a reaction system after dehydration to obtain a reaction working solution; the final reaction working solution enters a crude separation tower, light components such as propylene, epoxypropane and the like are distilled out from the top of the tower, and heavy components such as propylene glycol, a catalyst and the like are distilled out from the bottom of the tower; and further separation is carried out on the light components at the tower top and the heavy components at the tower bottom. According to the final reaction working solution provided by the invention, the heavy components are separated out first by utilizing the crude separation tower, most parts of heavy components containing the catalyst are directly recycled, and small parts ofthe heavy components containing the catalyst are treated by a filter of a water scrubbing tower for recycling the catalyst, so that loss of the catalyst and investment of the filter are reduced. Smallparts of the heavy components are treated by the water scrubbing tower and a propylene glycol recycling tower for recycling propylene glycol, and propylene glycol remaining in the reaction system does not influence the reaction. In addition, the amount of the heavy components is small, so that investment cost and operation cost of the water scrubbing tower and the propylene glycol recycling towerare reduced.

Owner:山东凯泰科技股份有限公司

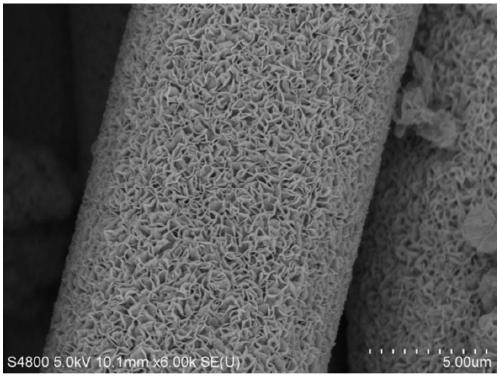

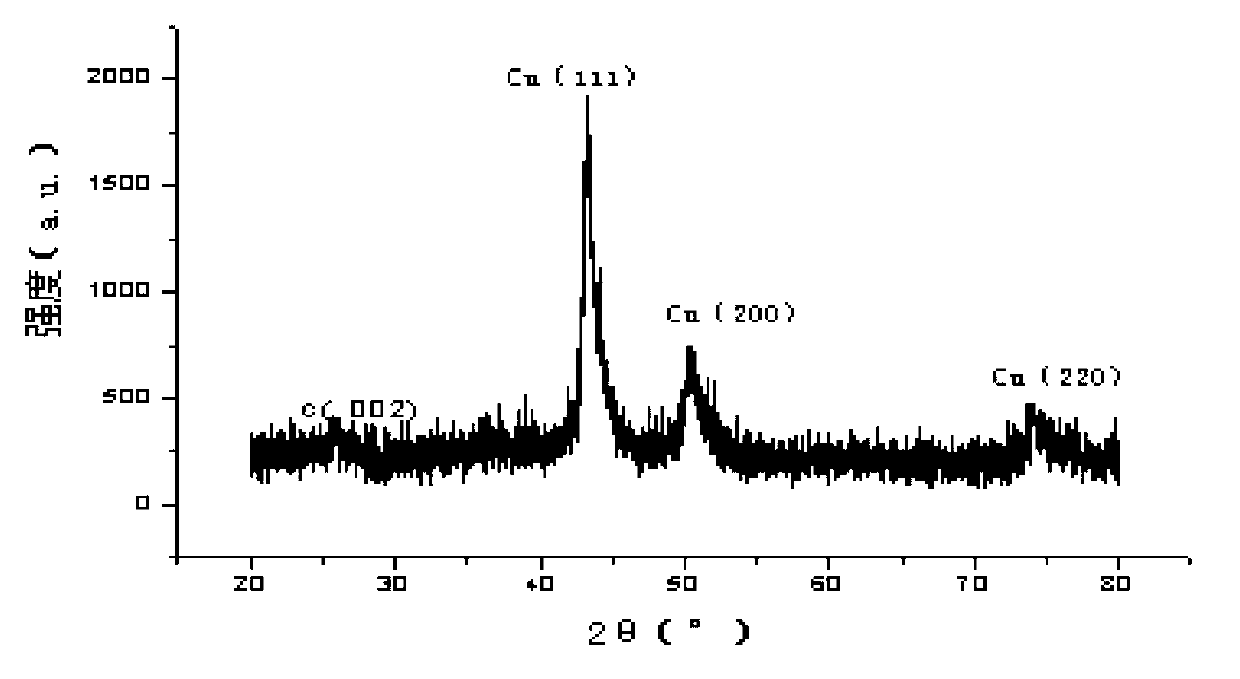

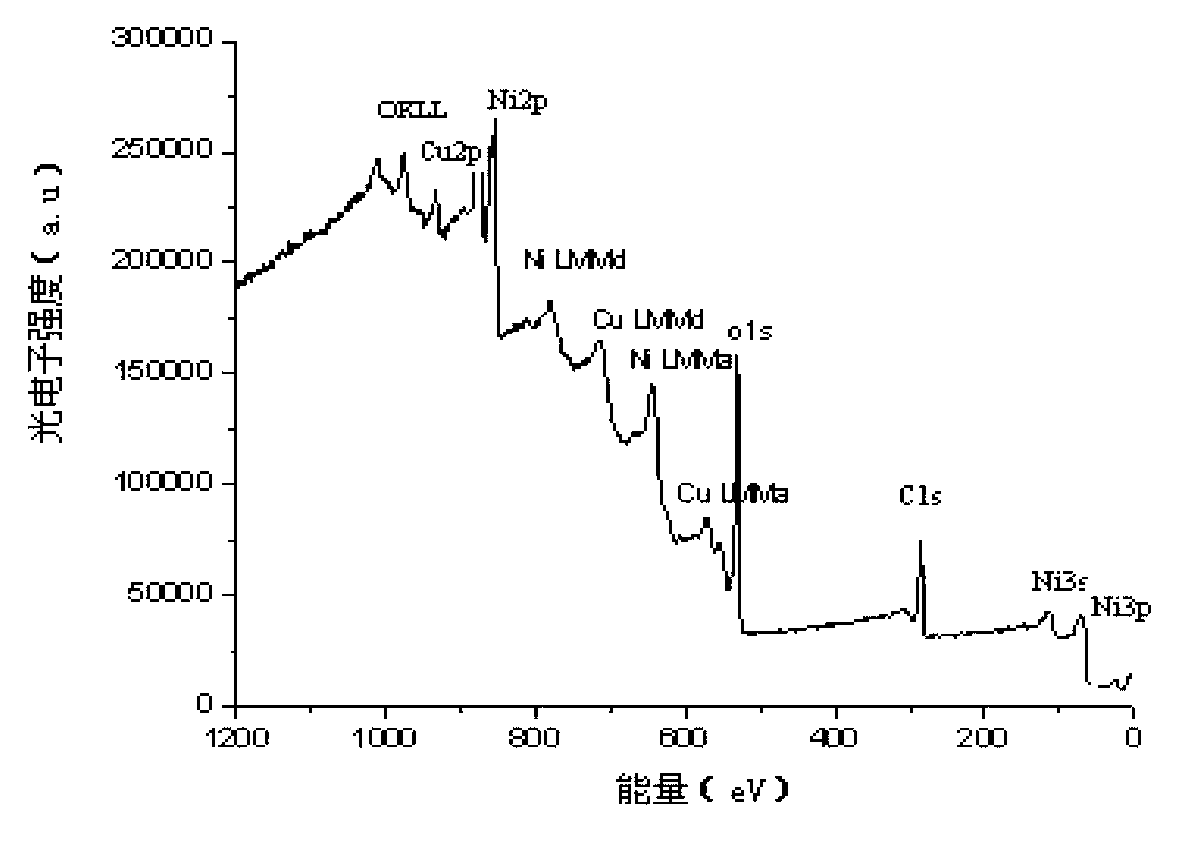

Method for preparing carbon nanotube-loaded nano-copper-nickel solid solution by utilizing microwave

The invention provides a method for preparing a carbon nanotube-loaded nano-copper-nickel solid solution by utilizing microwave, relates to the method for preparing the carbon nanotube-loaded nano-copper-nickel solid solution, and aims to solve the problems of complicated process, high cost and difficulty in control of nanoparticle sizes of the preparation method of the existing carbon nanotube-loaded nano-copper-nickel solid solution. The method provided by the invention comprises the following steps of: 1. mixing a NiSO4.6H2O solution with a CuSO4.5H2O solution to obtain a mixing solution A; 2. adding an acidulated carbon nanotube to the solution A to obtain a mixing solution B; 3. mixing a NaOH solution with a hydrazine hydrate solution to obtain a mixing solution C; 4. mixing the mixing solution B with the mixing solution C to obtain a primary extracting solution D after microwave treatment is carried out; and 5. filtering, eluting and drying the primary extracting solution D to obtain the carbon nanotube-loaded nano-copper-nickel solid solution powder. The method can be applied to the technical filed of nanotechnology engineering.

Owner:HEILONGJIANG UNIV

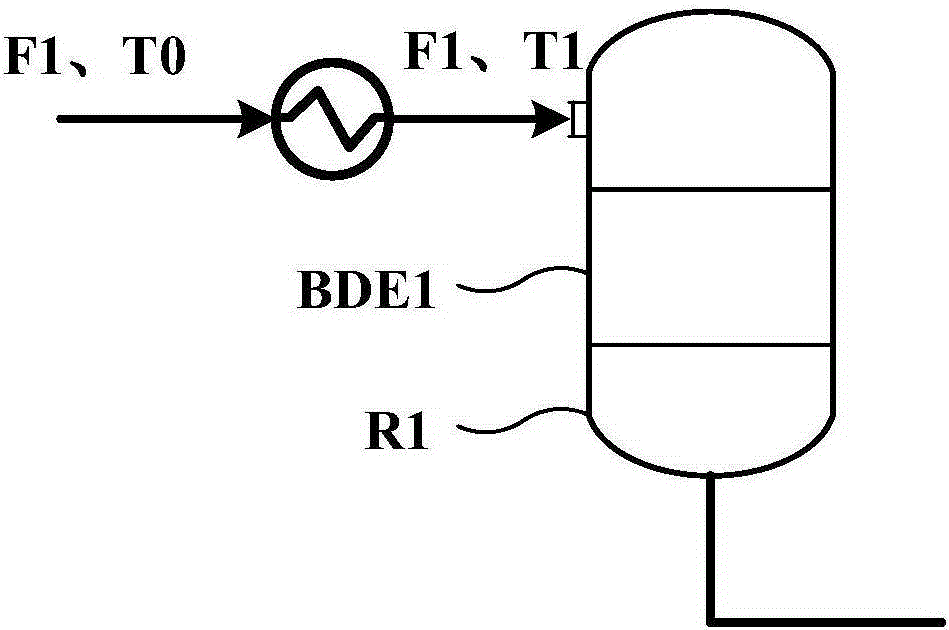

Method for controlling reaction temperature in preparation of dimethyl ether from methanol

InactiveCN106478382AReliable data supportSimple driveEther preparation by compound dehydrationReaction temperatureTemperature difference

The invention relates to a method for controlling reaction temperature in the preparation of dimethyl ether from methanol, and mainly solves the problems of an existing reaction apparatus for the preparation of dimethyl ether from methanol, such as large temperature differences of catalyst beds, high hot-spot temperature, high feed energy consumption, proneness to temperature runaway during reaction, proneness of catalysts to aging, and short service lives of the catalysts. The method includes measures: n reaction zones BED1-BEDn from top to bottom are sequentially arranged in a multi-section fixed-bed reactor, the sum of the feed quantities F1-Fn of the various reaction zones is F0, and the value of a feed distribution proportion Kn of the bed BEDn is equal to the ratio of the Fn to the F0. The method is characterized in that according to the technical scheme, the feed temperature T1 of the first bed BED1 is controlled by means of adjusting distribution proportion K1. The method has the advantages that the problems can be effectively solved by the aid of the method, and the method can be applied to the industrial production for the preparation of dimethyl ether from methanol and the preparation of propene from methanol.

Owner:CHINA PETROLEUM & CHEM CORP +1

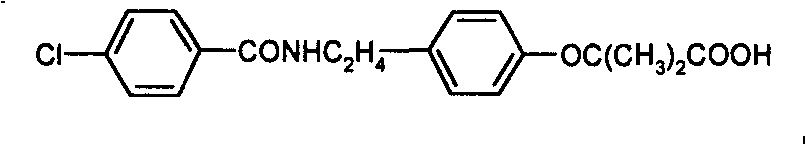

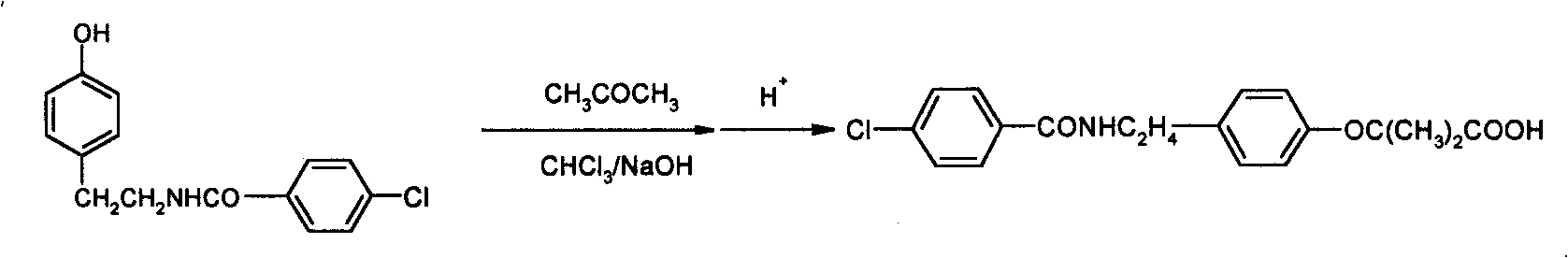

Preparation of bezafibrate

InactiveCN101353315AAvoid distillationShort reaction cycleOrganic compound preparationCarboxylic acid amides preparationDistillationOperational safety

The invention discloses a preparation method of bezafibrate. The preparation method is characterized in that N-p-hydroxybenzylethyl-4-chlorobenzamide, sodium hydroxide aqueous solution, acetone and a phase transfer catalyst are added to an organic solvent, chloroform is added dropwise to react, after the reaction is completed, water is added to the system to extract and stratify, the water layer is acidified, and the bezafibrate is obtained. In the preparation method, an organic solvent incompatible with water is added in the reaction, and the reaction is carried out in water condition, thus avoiding solvent distillation, rectification dehydration and the crushing of solid sodium hydroxide; and the preparation method shortens production cycle, reduces operation cost and improves operational safety, thus being favorable for industrialized production.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

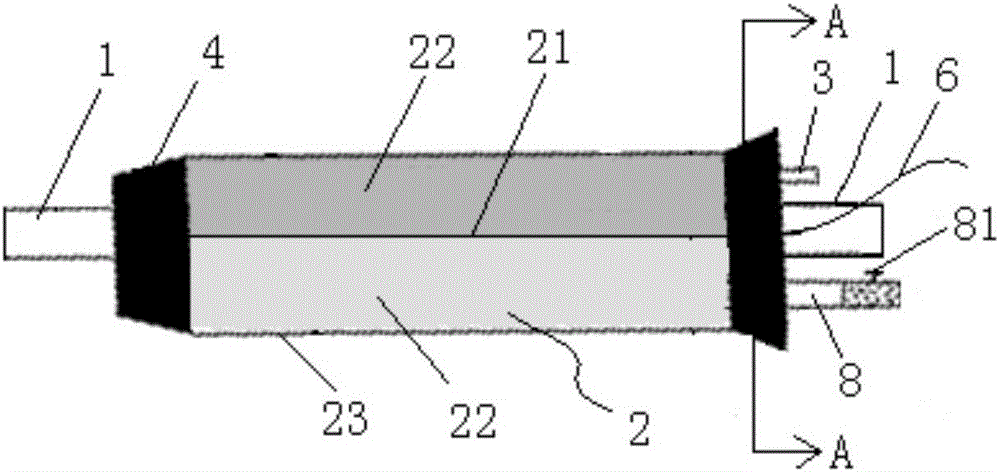

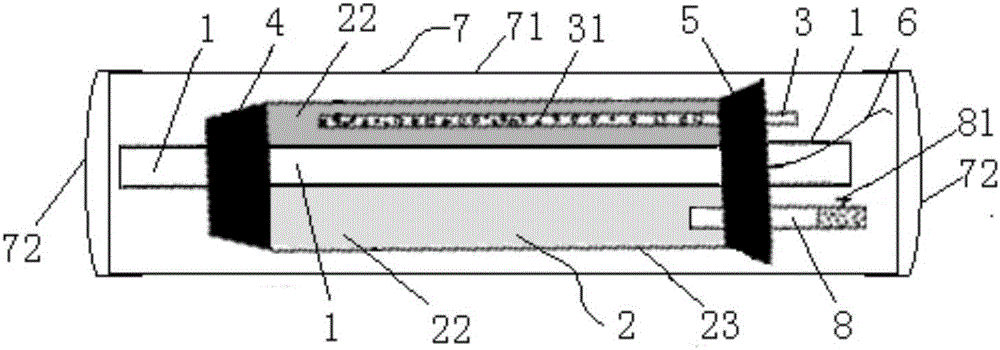

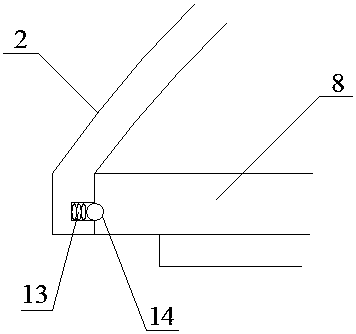

Hole sealing device for drilled hole

InactiveCN105822255AAvoid generation and developmentEasy to operateGas removalSealing/packingDrill holeMechanical engineering

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Preparation method of siloxane quaternary ammonium salt

The invention belongs to the field of organic silicon materials, and discloses a preparation method of a siloxane quaternary ammonium salt. The preparation method comprises the following steps of making allyl polyether carry out a hydrosilylation reaction with hydrogen-containing silicon oil under the action of a catalyst, so as to obtain polyether modified siloxane, afterwards, making the polyether modified siloxane carry out a reaction with chloracetyl chloride at 50 to 70 DEG C, after the reaction is completed, adding alkoxide of alkali metal and alcohol which serve as a neutralization reagent and a thinner respectively into a reaction system until the pH (potential of Hydrogen) value of the system is 8.8 to 9.5, filtering an obtained first mixture to remove a generated slat, so as to obtain acylated polyether modified siloxane, and then adding a quaternization reagent into the acylated polyether modified siloxane to carry out a quaternization reaction, removing a low-boiling-point substance, and filtering an obtained second mixture, so as to obtain the siloxane quaternary ammonium salt. According to the preparation method, the chloracetyl chloride is adopted as an acylation reagent; the alkoxide of the alkali metal is used as a neutralizer; the reaction activity is high; the condition is mild; water is not generated; side reactions are few; the yield is high; the product quality is favorable. The siloxane quaternary ammonium salt can be used as a self-emulsifying fabric softener.

Owner:GUANGZHOU TINCI MATERIALS TECH

Synthesis method of symmetrical imidazoline Gemini surfactant

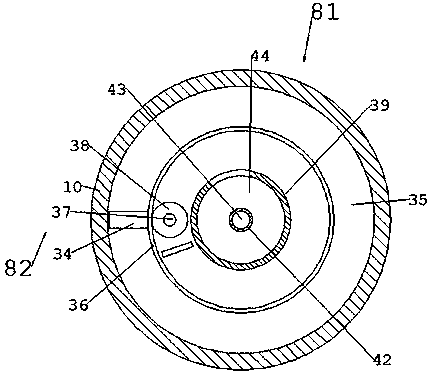

InactiveCN109912506AGuaranteed yieldEasily control the speed of joiningOrganic chemistrySolventDiethylenetriamine

The invention discloses a synthesis method of a symmetrical imidazoline Gemini surfactant. The synthesis method comprises the following steps: step 1) using fatty acid and diethylenetriamine as raw materials, xylene as a solvent and zinc powder as a catalyst, heating up to 190-210 DEG C and reacting for 6-10 h, distilling under reduced pressure at 130-150 DEG C to obtain an intermediate; step 2) adding dimethyl carbonate into the intermediate at 85 DEG C, reacting for 4-6 h, heating up to 90 DEG C, adding 1, 3-dibromopropane, reacting for 6-8 h; and step 3) cooling to 56 DEG C, adding acetone,filtering while hot to remove the zinc powder, standing for crystallization, filtering and then washing solids with acetone for several times to obtain the surfactant. The synthesis method has advantages of low cost, high yield, mild reaction conditions, and capability of stably acquiring the imidazoline Gemini surfactant.

Owner:XUZHOU INSTITUTE OF TECHNOLOGY

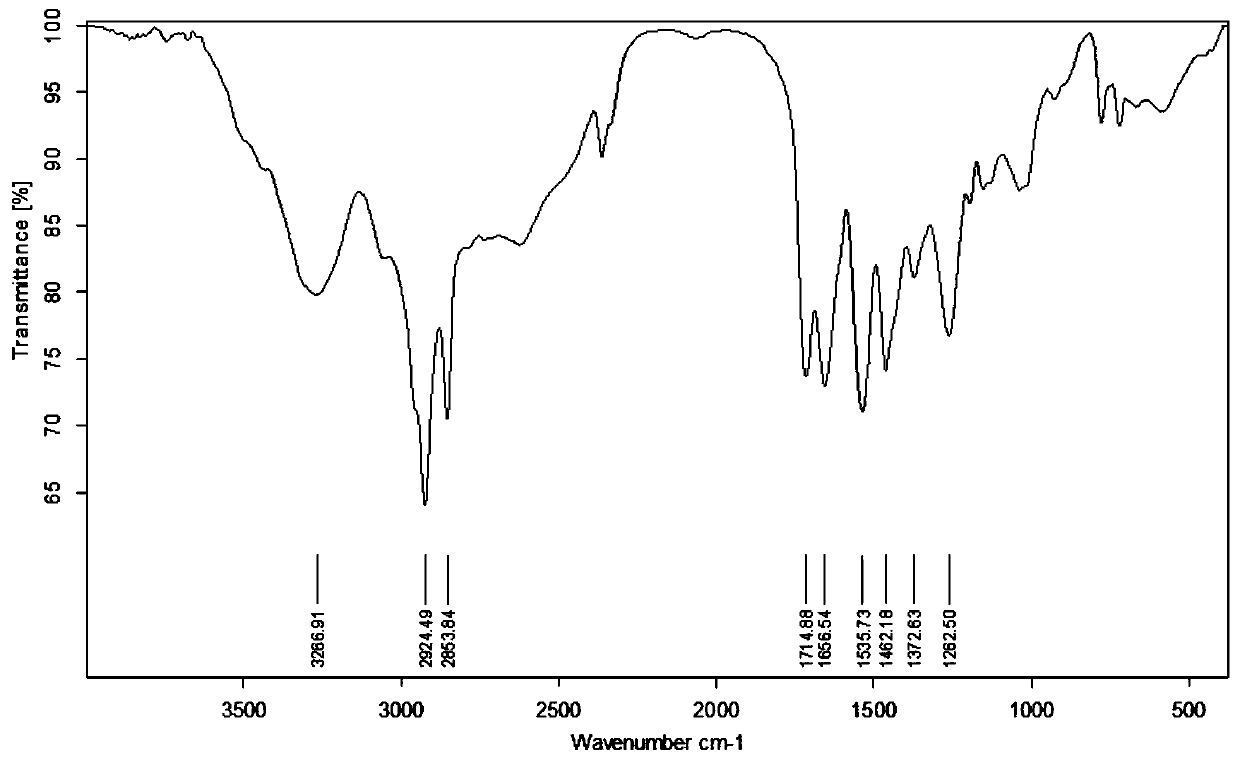

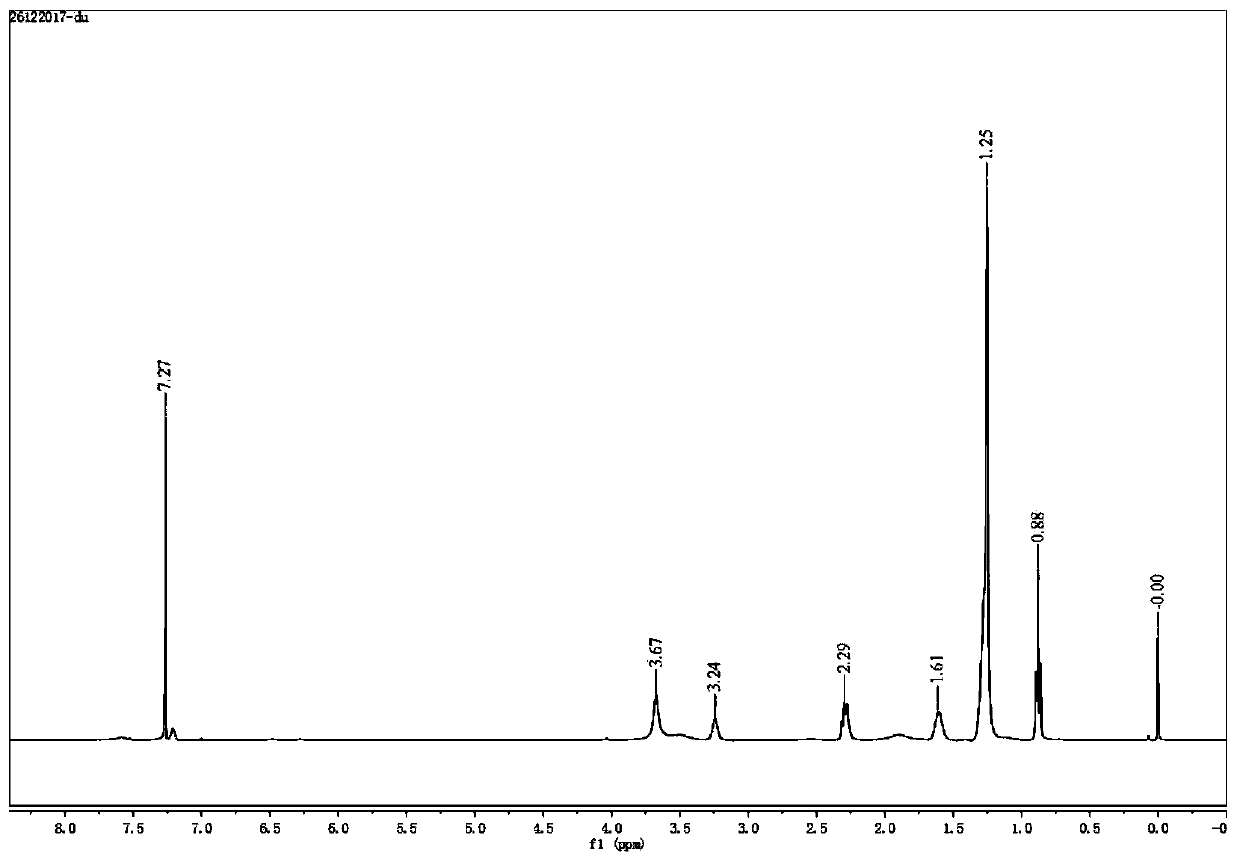

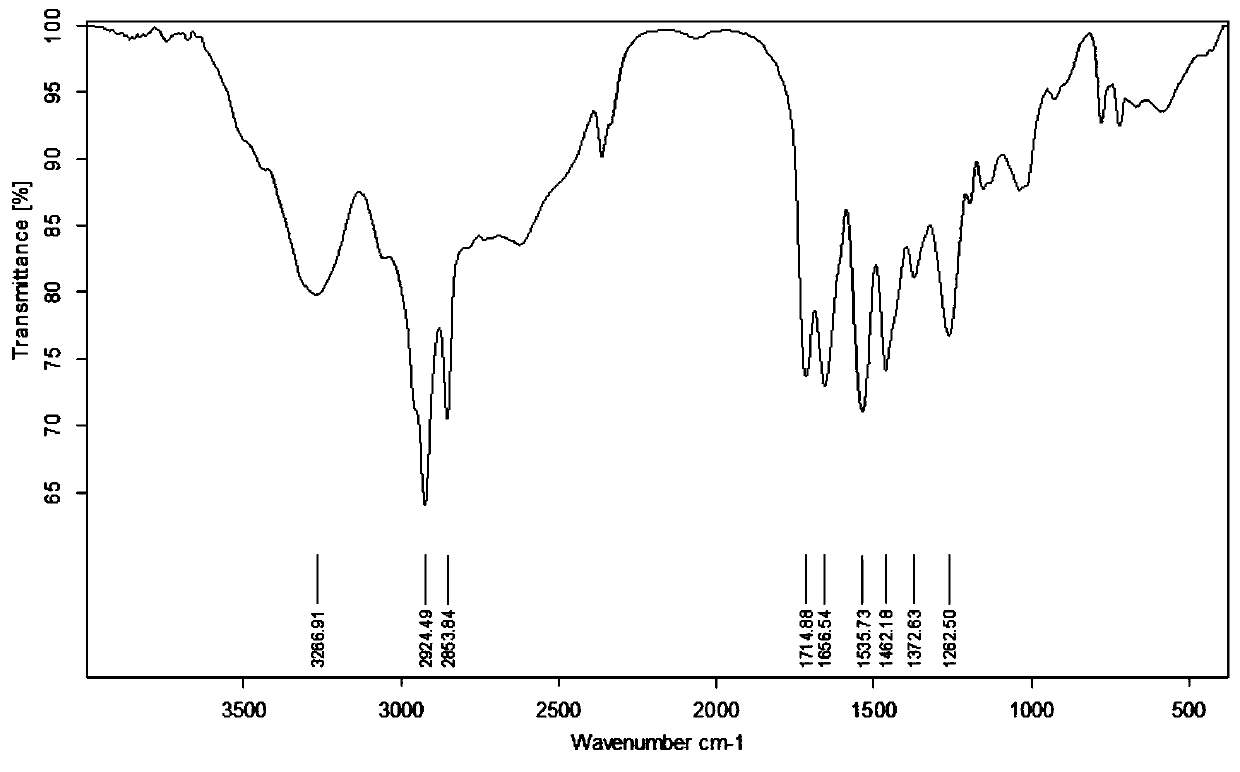

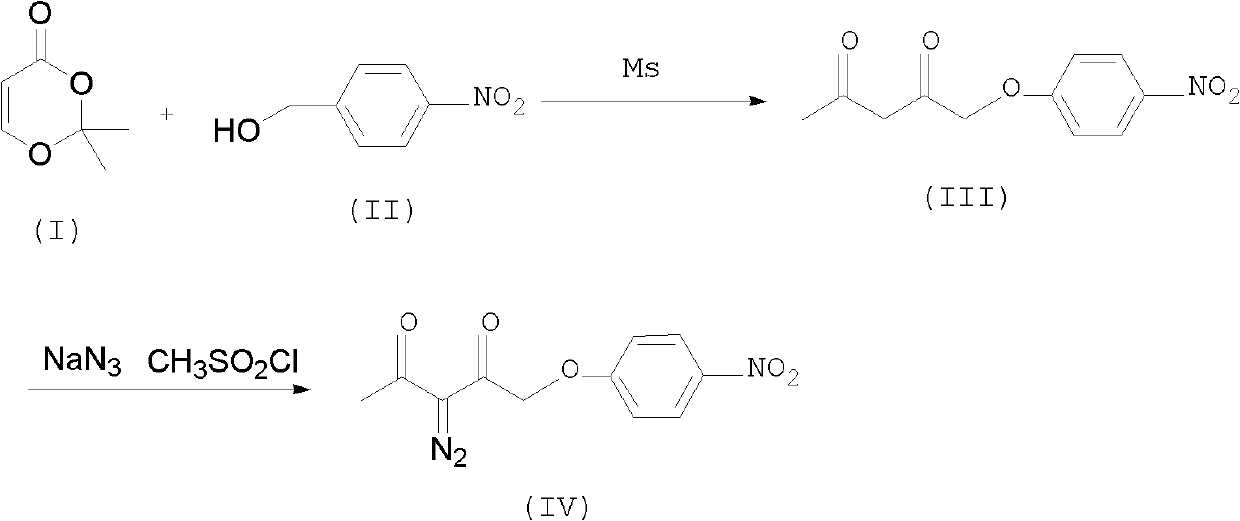

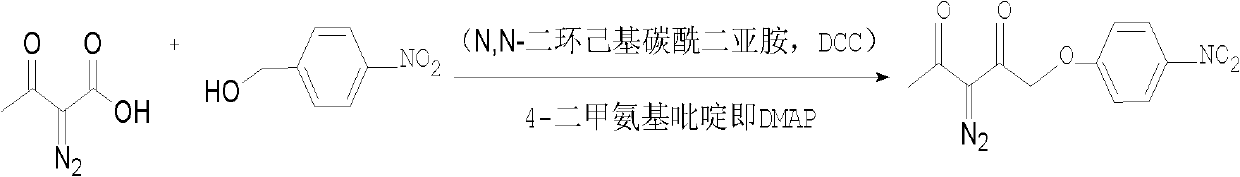

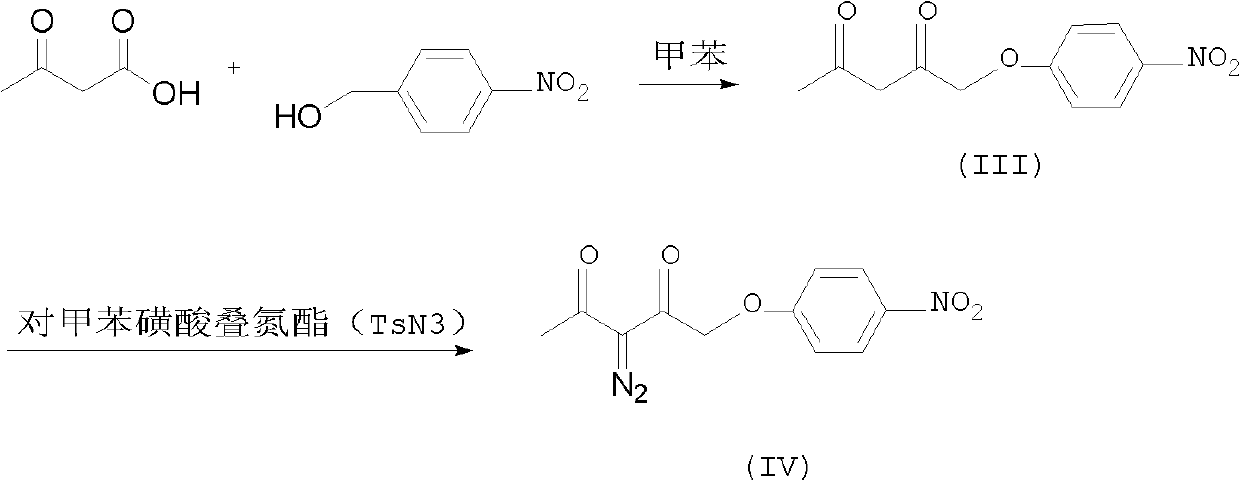

Preparation method of p-nitrobenzyl 2-diazoacetoacetate

ActiveCN101983958AEasy to operate the machineEase of industrial productionOrganic chemistryAcetic acidP-nitrobenzyl alcohol

The invention provides a preparation method of p-nitrobenzyl 2-diazoacetoacetate, wherein, the p-nitrobenzyl 2-diazoacetoacetate is made by two-step reaction. The preparation method has the advantages of simplified processing steps, easy industrialized production, lowered production cost, improved product quality and higher yield, wherein, by taking nitrobenzyl alcohol as a standard, the total mol yield reaches more than or equal to 95%, and the purity of the product compound (IV) reaches more than or equal to 99.5%.

Owner:江西如益科技发展有限公司

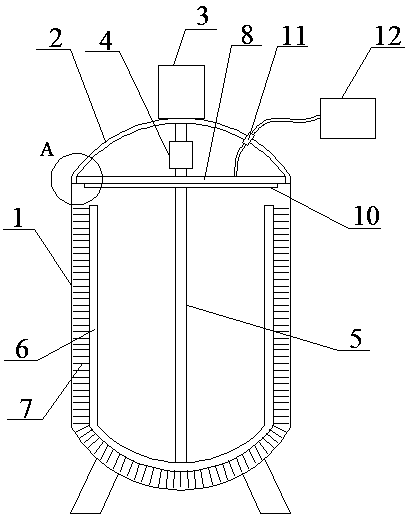

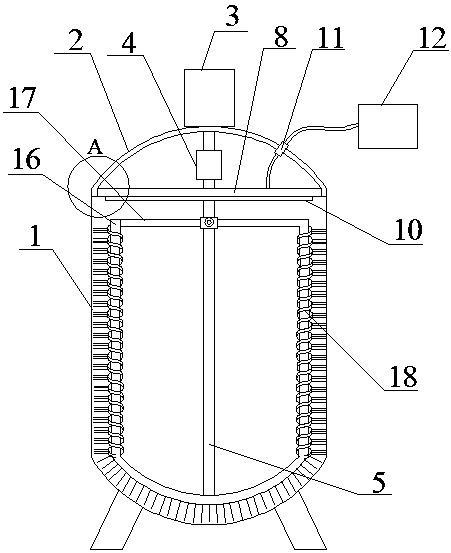

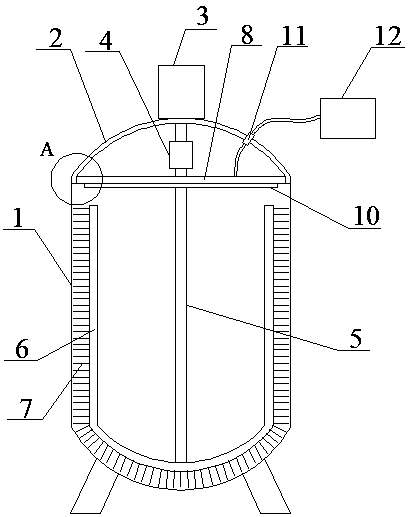

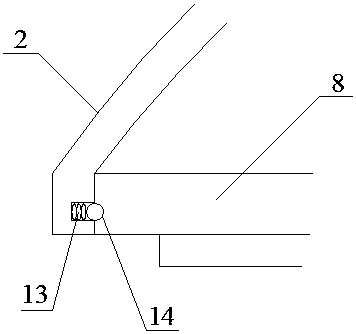

Chemical reaction kettle dirt clearing device

ActiveCN109107517AEasy to useThorough cleaningHollow article cleaningChemical/physical/physico-chemical stationary reactorsHigh pressureCircular disc

The invention discloses a chemical reaction kettle dirt clearing device, and belongs to the technical field of chemical reaction kettle maintenance equipment. The device comprises a reaction kettle, wherein the reaction kettle comprises a kettle body and a kettle cover, a motor is arranged on the kettle cover, a rotating shaft of the motor is arranged on the inner side of the kettle cover, the rotating shaft of the motor is connected with a dirt clearing mechanism through a coupler, and a spraying mechanism is arranged on the inner side of the kettle cover; the dirt clearing mechanism comprises a vertical rod and a U-shaped rod connected with the lower end of the vertical rod, wherein bristles are arranged on the outer side of the U-shaped rod, the spraying mechanism comprises a disk, a through hole for allowing the vertical rod to penetrate through is formed in the center of the disk, a spraying pipe is arranged on the bottom surface of the disk, a spraying pipe connector is arrangedon the kettle cover, the spraying pipe and the spraying pipe connector are communicated, and the other side of the spraying pipe connector is communicated with a water pump through a high pressure hose. By means of the chemical reaction kettle dirt clearing device, the reaction kettle is cleared comprehensively and thoroughly, and the cleaning efficiency is high.

Owner:ZHENGZHOU INST OF TECH

Vacuum safe sampling device for chemical reactor

InactiveCN107843457AGuaranteed pressureAdequate responseWithdrawing sample devicesInternal pressureChemical reactor

The invention discloses a vacuum safety sampling device for a chemical reaction kettle, which comprises a vacuum pump, a sampling tank, a pressure pump, a pressure sensor and a controller. The vacuum pump is connected to the sampling tank through a negative pressure tube, and the inside of the negative pressure tube is A first electric control valve is installed, the right side of the sampling tank is connected to the connecting flange through a pipe, and the right end of the connecting flange is fixed to the sampling port, the sampling port is opened at the lower end of the main body of the reaction kettle, and a pressure sensor is installed in the sampling port , a second electric control valve is installed in the pipeline between the sampling tank and the connecting flange, and the pipeline on the left side of the second electric control valve is connected to the pressurized pipe, and the other end of the pressurized pipe is connected to the pressurized pump The pressurized tube is connected to the nitrogen tank through a pipeline, and a third electric control valve is installed inside the pressurized tube, and the controller is installed on the outer wall of the vacuum pump. After sampling, the present invention has no residual liquid in the sampling tube, and ensures that the internal pressure of the reaction kettle remains unchanged, and does not affect the reaction of raw materials in the reaction kettle.

Owner:周蒙

Deacidfieation method of high-acid-value vegetable oil

InactiveCN109097191AHigh selectivityHigh catalytic efficiencyFatty-oils/fats refiningChemistryHigh energy

The invention discloses a deacidfieation method of high-acid-value vegetable oil. The deacidified vegetable oil is obtained by mixing and dissolving the high-acid-value vegetable oil and monoethanolamine in an organic solvent, adding a catalyst, reacting for 1-24 hours at the temperature of 50-100 DEG C, and removing the catalyst, the unreacted monoethanolamine and fatty acid glycollic amide in the vegetable oil after the reaction. The invention provides a deacidfieation process of the high-acid-value vegetable oil, calcium oxide which is extensive in sources, low in price and easy to obtain is taken as the catalyst, and monoethanolamine is taken as an acyl acceptor for an amidation reaction with free fatty acid in the high-acid-value vegetable oil, so that the problems of high consumptionof neutral oil, high energy consumption, a large number of byproducts, strict process, high cost and the like in the previous deacidfieation process are avoided, and the deacidfieation method is suitable for the high-acid-value vegetable oil. The deacidfieation method meets the new national standard for the vegetable oil that an acid value is not higher than 3 mg KOH per g, and is simple in process, low in cost, green, efficient, and huge in application potential.

Owner:JIANGNAN UNIV

A kind of preparation method of siloxane quaternary ammonium salt

Owner:GUANGZHOU TINCI MATERIALS TECH

Method for preparing copper-nickel solid solution powder by microwaves

The invention discloses a method for preparing copper-nickel solid solution powder by microwaves and relates to the method for preparing the copper-nickel solid solution powder. The invention aims to solve the problems that the process is complicated, the cost is high and nano-particles are hard to control in size by adopting a traditional method for preparing the copper-nickel solid solution powder. The method for preparing the copper-nickel solid solution powder by the microwaves disclosed by the invention comprises the following steps: I, mixing NiSO4.6H2O solution with CuSO4.5H2O to obtain mixed solution A; II, mixing NaOH solution and hydrazine hydrate solution to obtain mixed solution B; III, mixing the mixed solution B with the mixed solution A, and performing microwave processing to obtain original extract C; and IV, filtering, leaching and drying the original extract C to obtain the copper-nickel solid solution powder. The method for preparing the copper-nickel solid solution powder by the microwaves disclosed by the invention is suitable for the technical field of nanoengineering.

Owner:HEILONGJIANG UNIV

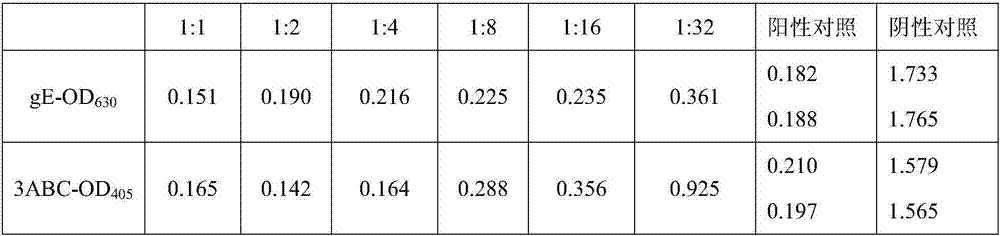

Bi-combined blocking ELISA antibody detection kit for detecting porcine PrV (pseudorabies virus) and FMDV (foot and mouth disease virus) and application of kit

InactiveCN107991481AReaction does not affectAccurate detectionMaterial analysisPositive controlTwo step

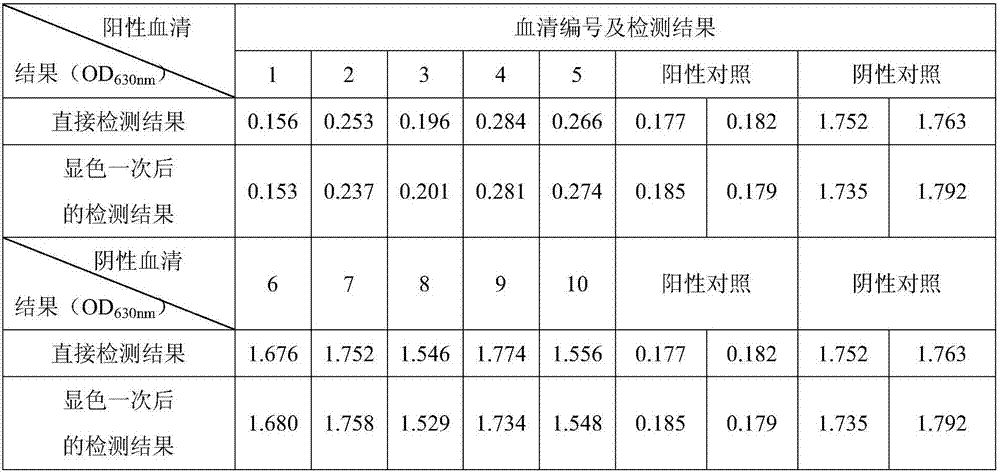

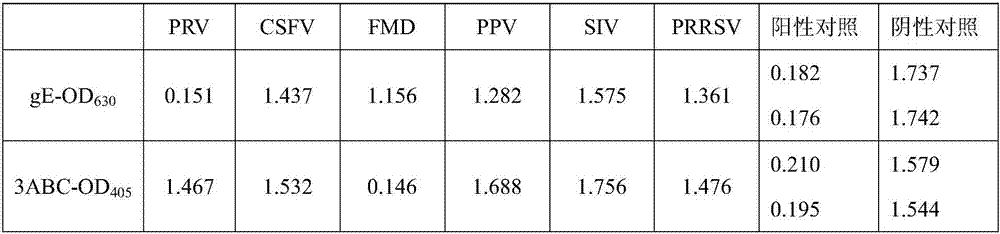

The invention belongs to the field of animal epidemic disease detection and particularly relates to a bi-combined blocking ELISA antibody detection kit for detecting a porcine PrV (pseudorabies virus)gE protein antibody and an FMDV (foot and mouth disease virus) 3ABC protein antibody and an application of the kit. The kit comprises an antigen detection plate coated with porcine PrV and FMDV 3B polypeptides, a mixed solution containing an enzyme-labeled anti-PrV gE protein monoclonal antibody and an enzyme-labeled anti-FMDV 3ABC protein monoclonal antibody, a porcine PrV gE protein enzyme-labeled monoclonal antibody developing system, a FMDV 3ABC protein enzyme-labeled monoclonal antibody developing system, a negative / positive control, a sample diluent and a washing solution. Two independent ELISA reactions are performed simultaneously in first two steps, unique developing systems are used, so that developing and termination of the last enzyme do not affect the reaction of the next enzyme, one sample incubation and one second-antibody incubation are realized for one part of serum, and two ELISA results are obtained.

Owner:WUHAN KEQIAN BIOLOGY CO LTD

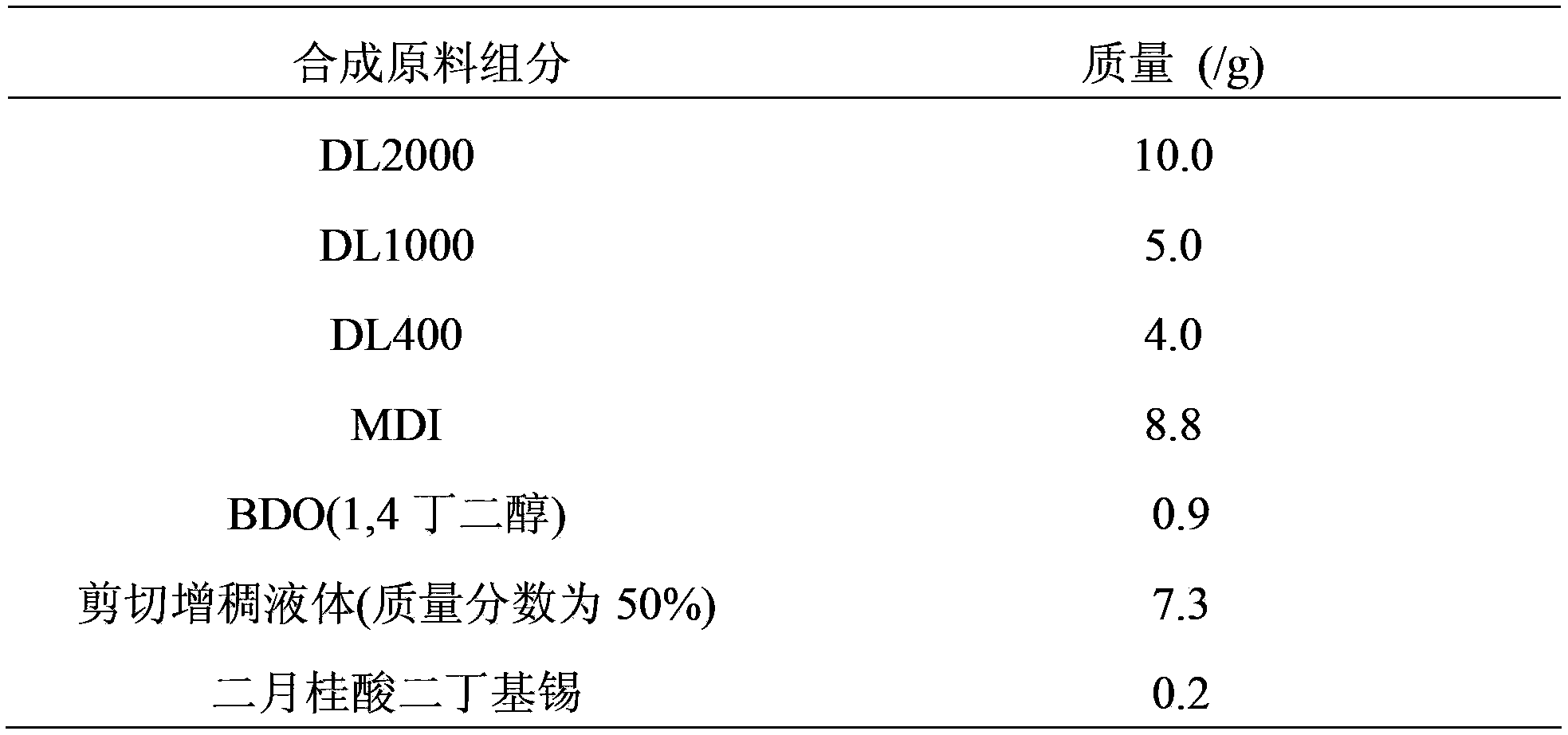

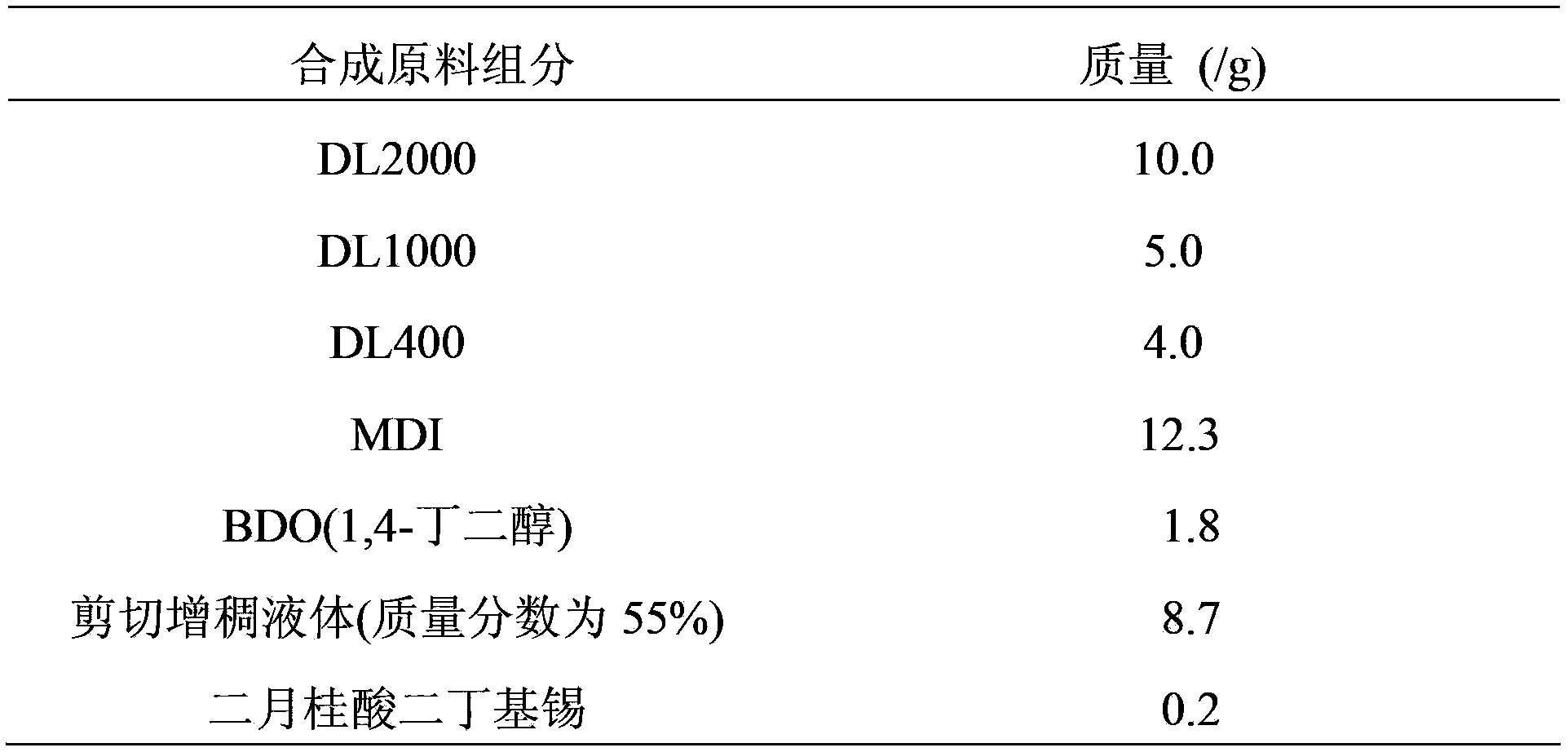

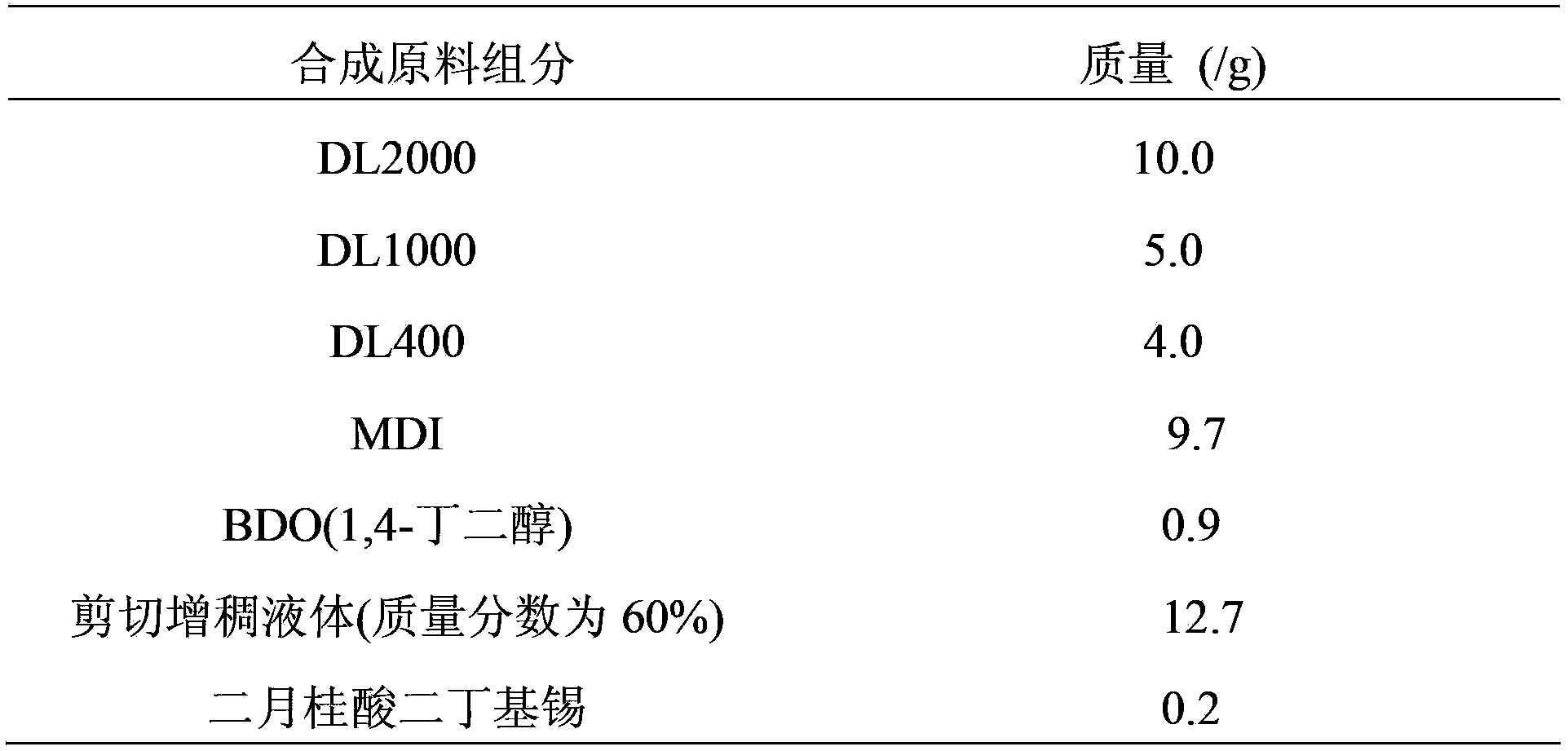

Preparation method of polyurethane energy-absorbing material

Owner:BEIJING UNIV OF CHEM TECH

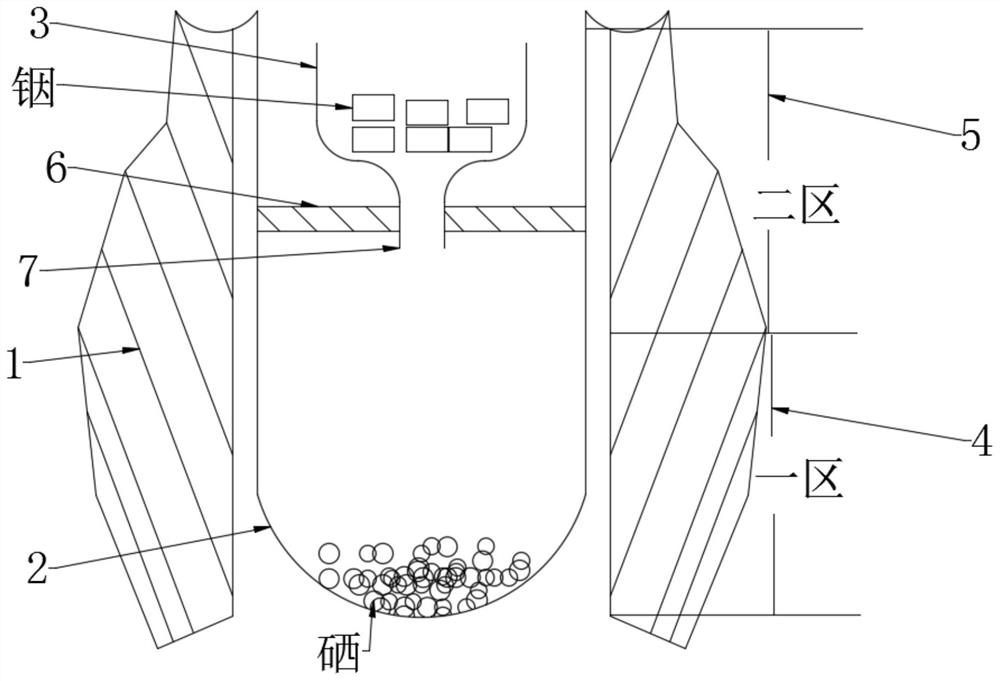

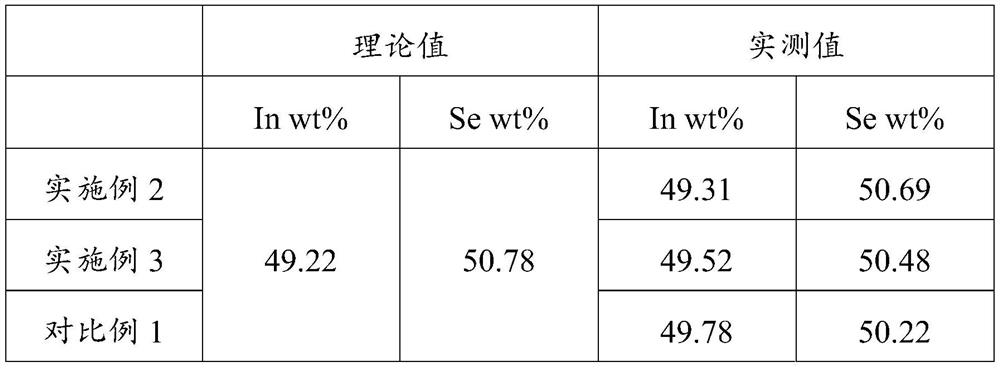

Device and method for preparing In2Se3

ActiveCN113117603AReduce volatilityLow equipment requirementsFinal product manufacturePressure vessel componentsMineralogyQuartz

The invention discloses a device and a method for preparing In2Se3. The device comprises a rocking furnace, a quartz tube and a quartz crucible. A first heating zone and a second heating zone are arranged in the rocking furnace. The quartz tube is vertically placed in the rocking furnace, the lower end of the quartz tube corresponds to the first heating zone, and the upper end of the quartz tube corresponds to the second heating zone. The quartz crucible is vertically placed in the upper end of the quartz tube through a supporting plate, and a material nozzle penetrating through the supporting plate is arranged at the bottom of the quartz crucible. In addition, the In2Se3 is prepared by adopting a two-step method, the In2Se3 is initially synthesized at first, and then the initially synthesized In2Se3 is subjected to homogenization treatment. According to the method, a large amount of In2Se3 can be produced in a single batch, less heat is released in unit time, the reaction temperature is low, the safety is high, the volatilization loss of Se is small, and after homogenization treatment, In2Se3 with uniformly distributed components can be obtained.

Owner:XIANDAO THIN FILM MATERIALS GUANGDONG CO LTD

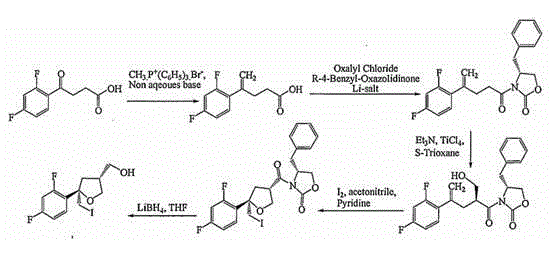

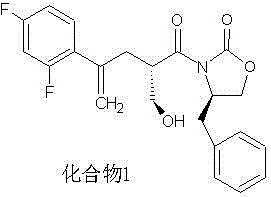

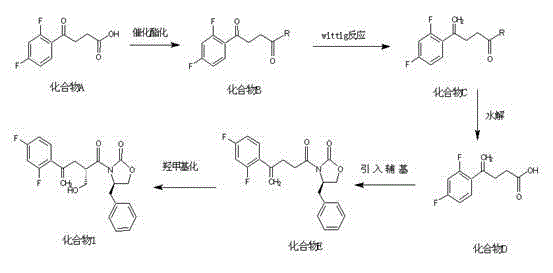

Method for preparing posaconazole intermediate

ActiveCN105693649ASolve the problem of poor salt solubilityReaction does not affectOxygen-containing compound preparationOrganic compound preparationAcylationDe esterification

The present invention belongs to the technical field of pharmaceutical chemistry, and specifically relates to a method for preparing a posaconazole intermediate. The method comprises steps of esterification, methylenation, hydrolysis, acylation and hydroxymethylation to obtain a target compound 1. Compared with the method reported in the literature, the synthesis method of the present invention has the characteristics of simple operation, easy purification of intermediate and high yield.

Owner:CHONGQING SHENGHUAXI PHARMA CO LTD +1

A chemical reactor fouling removal device

ActiveCN109107517BEasy to useEasy to install and disassembleHollow article cleaningChemical/physical/physico-chemical stationary reactorsChemical reactionEngineering

Owner:ZHENGZHOU INST OF TECH

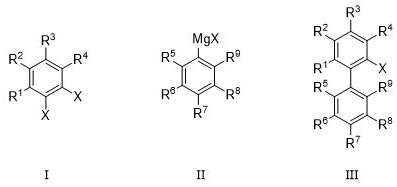

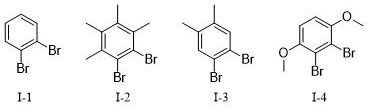

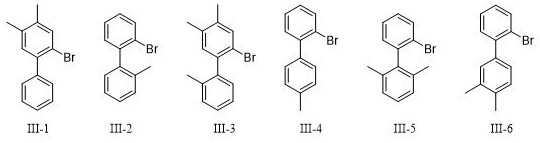

Synthesis method of halogenated biaryl compound

ActiveCN114805013ALess side effectsHigh yieldAmino preparation from aminesOrganic compound preparationOrganic synthesisGrignard reagent

The invention relates to the technical field of organic synthesis, in particular to a synthetic method of a halogenated biaryl compound, which comprises the following steps: in a non-reactive gas atmosphere, mixing a dihalogenated aryl compound, an aryl Grignard reagent, [1, 3-bis (2, 6-diisopropyl benzene) imidazole-2-fork] (3-chloropyridine) palladium dichloride, alkali and a solvent, and reacting at room temperature to obtain the halogenated biaryl compound. And reacting at the temperature of 50-75 DEG C. According to the invention, [1, 3-bis (2, 6-diisopropyl benzene) imidazole-2-fork] (3-chloropyridine) palladium dichloride is specially selected as a catalyst, so that the C-C coupling reaction of the dihalogenated aryl compound and the aryl Grignard reagent can be carried out under the mild condition of 50-75 DEG C, and the harsh condition of-78 DEG C in the traditional technology is not needed; and only a monosubstitution reaction can be carried out with high selectivity, so that the occurrence of side reactions is greatly reduced, and a target product of the halogenated biaryl compound is prepared with a higher yield.

Owner:JIANGSU SINOCOMPOUND CATALYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com