Preparation method of ternary positive electrode material precursor

A cathode material and precursor technology, which is applied in the field of preparation of ternary cathode material precursors for batteries, can solve the problem of increasing the technological process, the complexity of the operation and the production cost, affecting the uniformity of the reaction product of the material, and increasing the concentration of the slurry to a relatively low level. High solid content and other problems, to achieve the effect of high reaction space utilization, shortened production time and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Step S1: Prepare a nickel-cobalt-manganese sulfate mixed solution, and the total metal ion concentration is 2.0mol / L, configure a precipitant NaOH solution 8mol / L, and a complexing agent ammonia solution 5.5mol / L, and import through multiple raw materials 11 and flow into the reactor 10; the total feed flow of the control reaction raw materials is 400L / h.

[0045] Step S2: Control the reaction temperature in the reactor 10 to be 60° C., the pH value to be 11, and the ammonia concentration to be 8 g / L, and the stirring speed of the stirring device 12 to be 350 r / min.

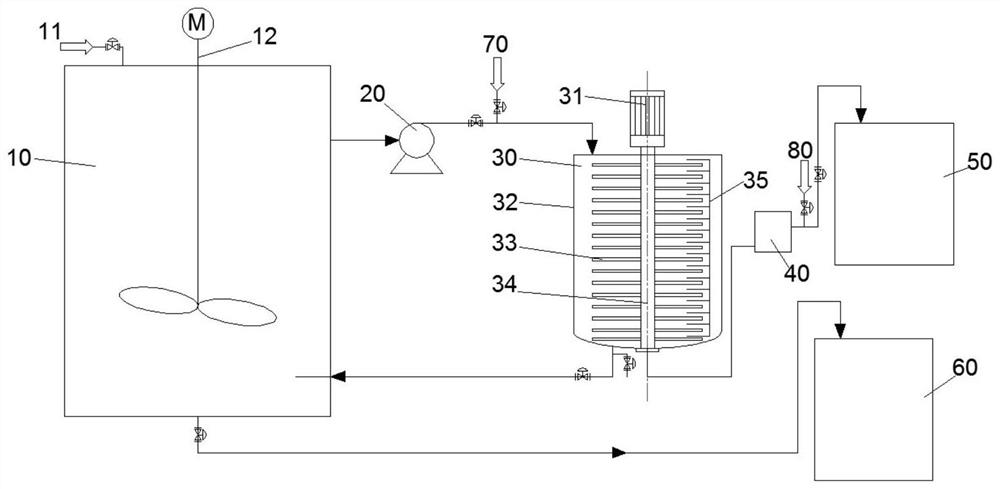

[0046] Step S3: When the liquid level of 10 in the reaction kettle reaches 80% of its volume, the circulation pump 20 is started, and the pressure difference of the membrane module of the dynamic separation device 30 is adjusted to 0.2Mpa through the outlet valve of the circulation pump 20, and the outlet flow rate of the circulation pump 20 is 600L / h, the flow rate of the circulating dope back to the reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com