Patents

Literature

37results about How to "Favorable for hydrogenation reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

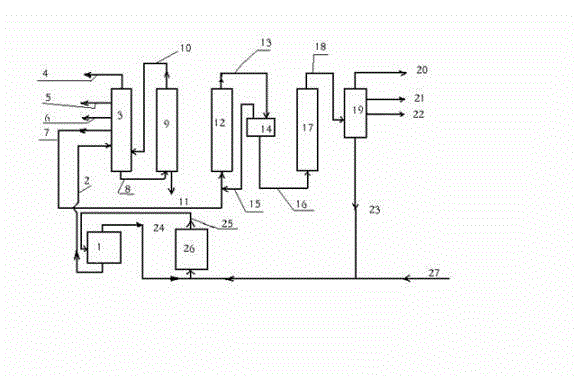

Hydrogenation method of heavy hydrocarbon multi-segment fluidized bed

ActiveCN101724453AReduce heat loadSave heatHydrocarbon oil crackingTreatment with hydrotreatment processesGas phaseFuel oil

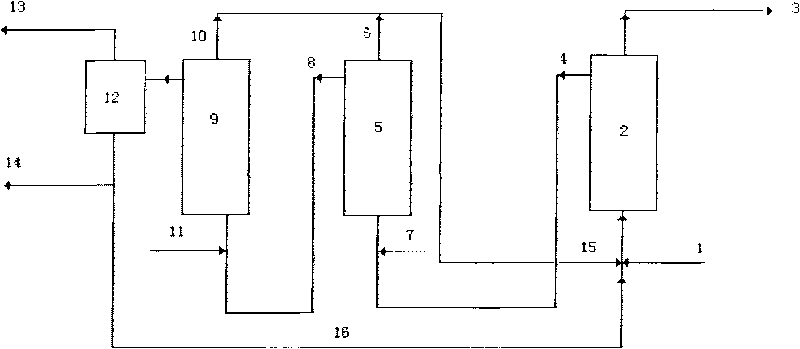

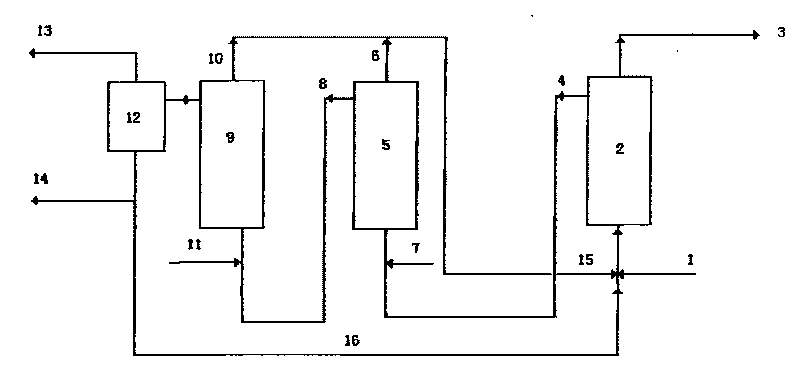

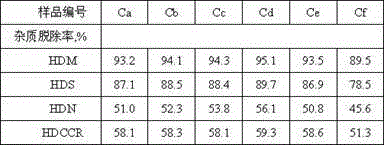

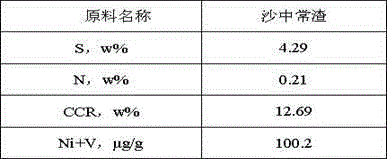

The invention discloses a hydrogenation method of a heavy hydrocarbon multi-segment fluidized bed. The technical process comprises the steps of: mixing thick heavy hydrocarbon raw materials with gas phase material flow which is discharged from a fluidized bed hydrogenation-desulfuration reactor and a hydrogenation-denitrification reactor to enter into a hydrogenation-demetalization reactor; cooling and purifying reacted gas phase material flow to be taken as recycle hydrogen; mixing the demetallized liquid phase material flow with hydrogen to enter into the fluidized bed hydrogenation-desulfuration reactor; mixing the desulfurated liquid phase material flow with hydrogen to enter into the hydrogenation-desulfuration reactor; and leading the denitrified liquid phase material flow to enter into a separating device. The technology adopts a new reactor assembly mode to machine heavy oil raw materials with high viscosity and bad quality, can provide a new flexible, high-efficiency and energy-saving operation mode, organically combines the performances of the raw materials with the characteristic of each hydrogenation reaction, makes full use of reaction heating on the premise that a device is guaranteed to be stably operated, provides a product with good quality, and can flexibly adjust the operation process according to the requirement of a refinery.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for recycling waste hydrogenation catalyst

ActiveCN105709853AReduce pollutionHarm reductionCatalyst carriersProcess efficiency improvementCarbon compositesUltrasound - action

The invention discloses a method for recycling a waste hydrogenation catalyst. The method comprises the following steps: (1) subjectintg the waste hydrogenation catalyst to deoiling and grinding successively so as to obtain powder; (2) washing the waste catalyst powder with hydrochloric acid and then successively carrying out filtering, washing and drying; (3) introducing chlorine and air into a container used in the step (2) under the action of supersonic waves and carrying out a reaction; (4) transferring a solid product obtained in the step (3) into a container filled with nitrogen, carrying out heating to allow metallic molybdenum and nickel or chloride or oxychloride of cobalt and vanadium to be volatilized, thereby separating a gas phase from a solid phase, carrying out condensation on the gas phase to recover metal, washing residual solids obtained after separation with water or an acidic solution and then carrying out drying; (5) subjecting a material obtained in the step (4) with an extrusion aid and a binder to kneading and compacting and then carrying out drying; and (6) roasting a molded carrier obtained in the step (5) in a nitrogen atmosphere so as to prepare an alumina-carbon composite carrier. The method not only can recover metallic active components and use waste alumina powder.

Owner:CHINA PETROLEUM & CHEM CORP +1

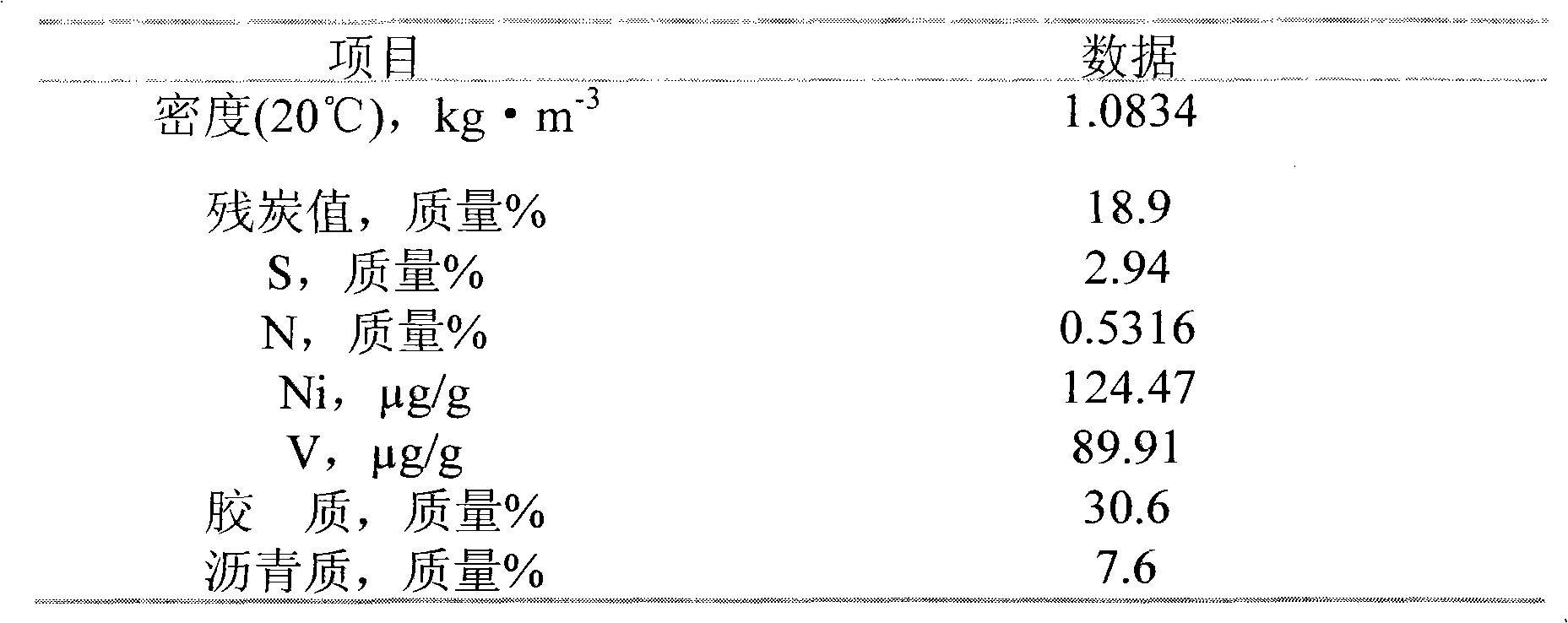

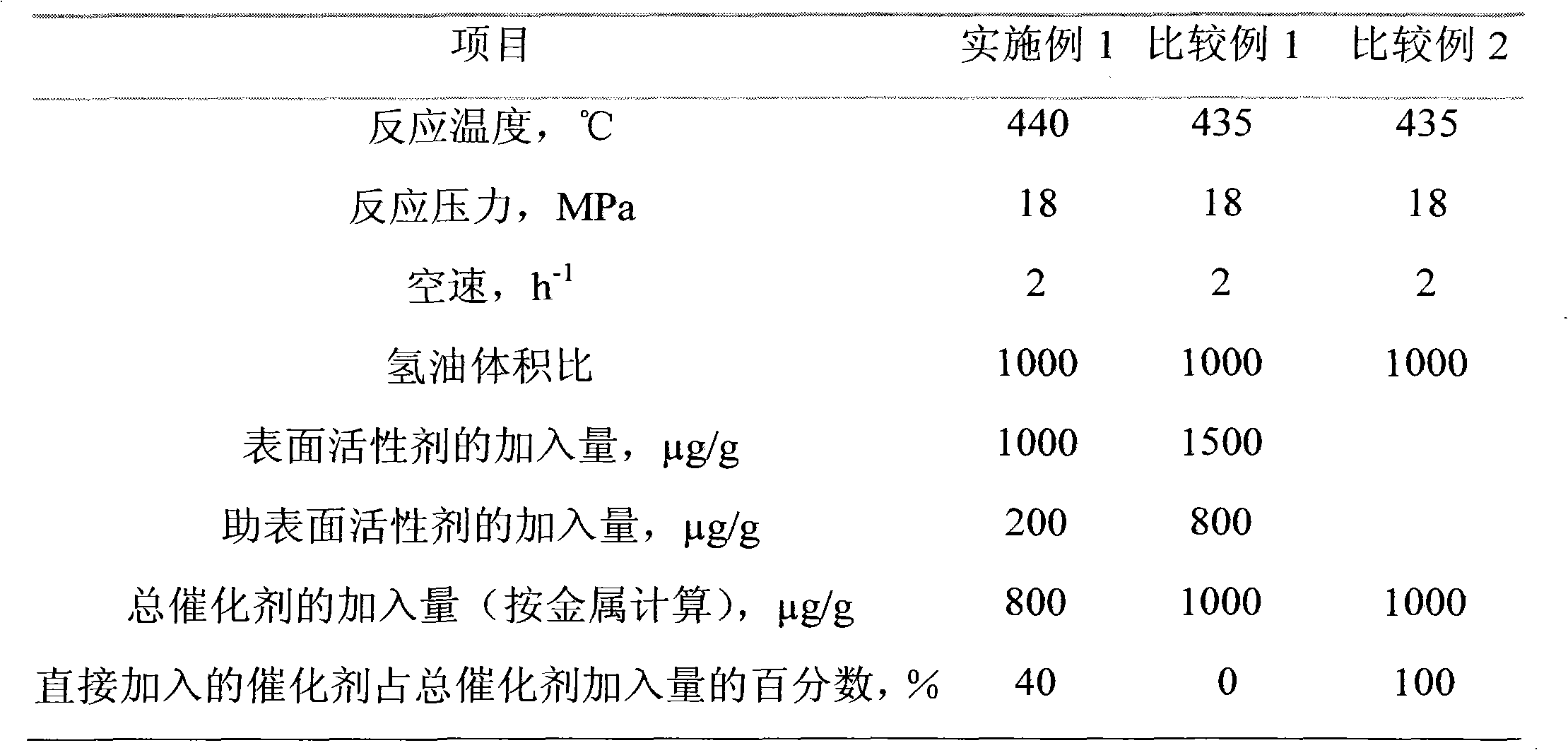

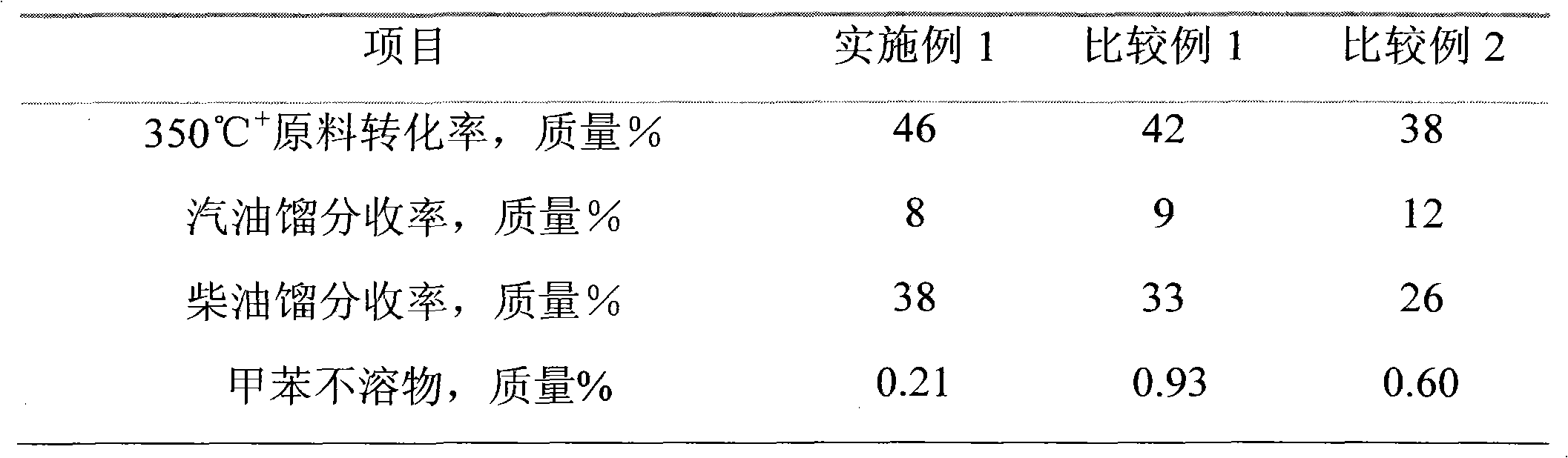

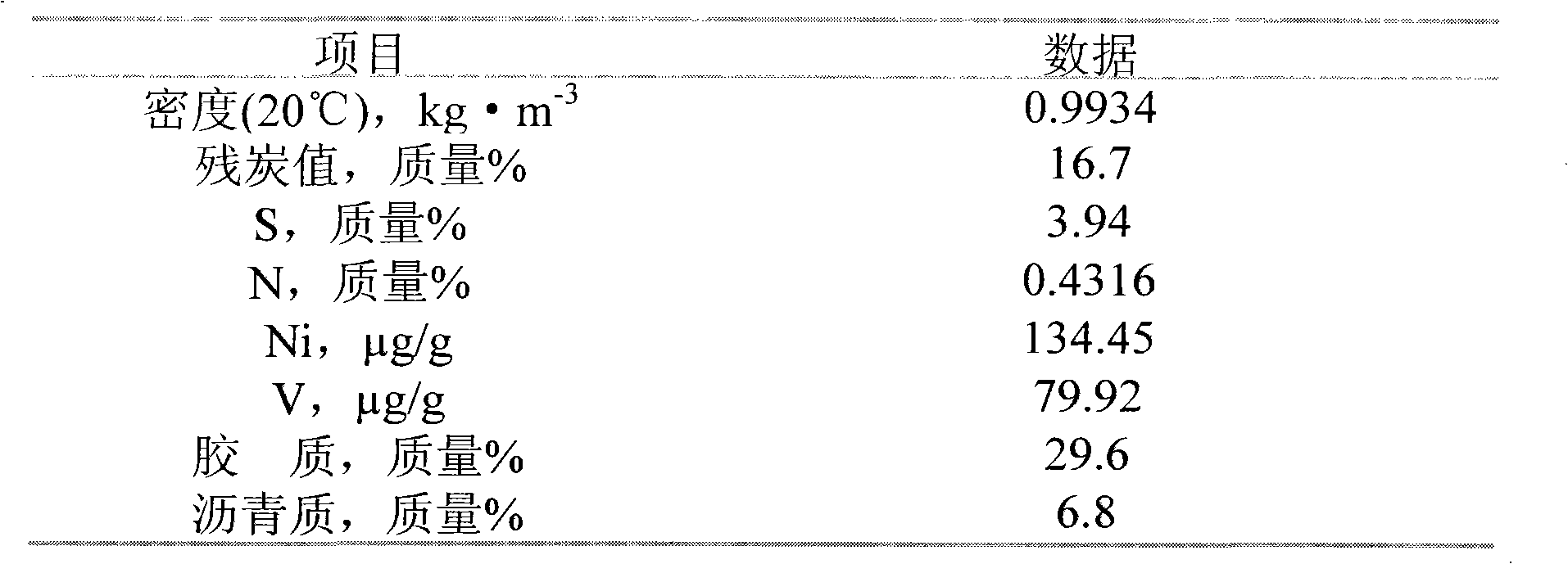

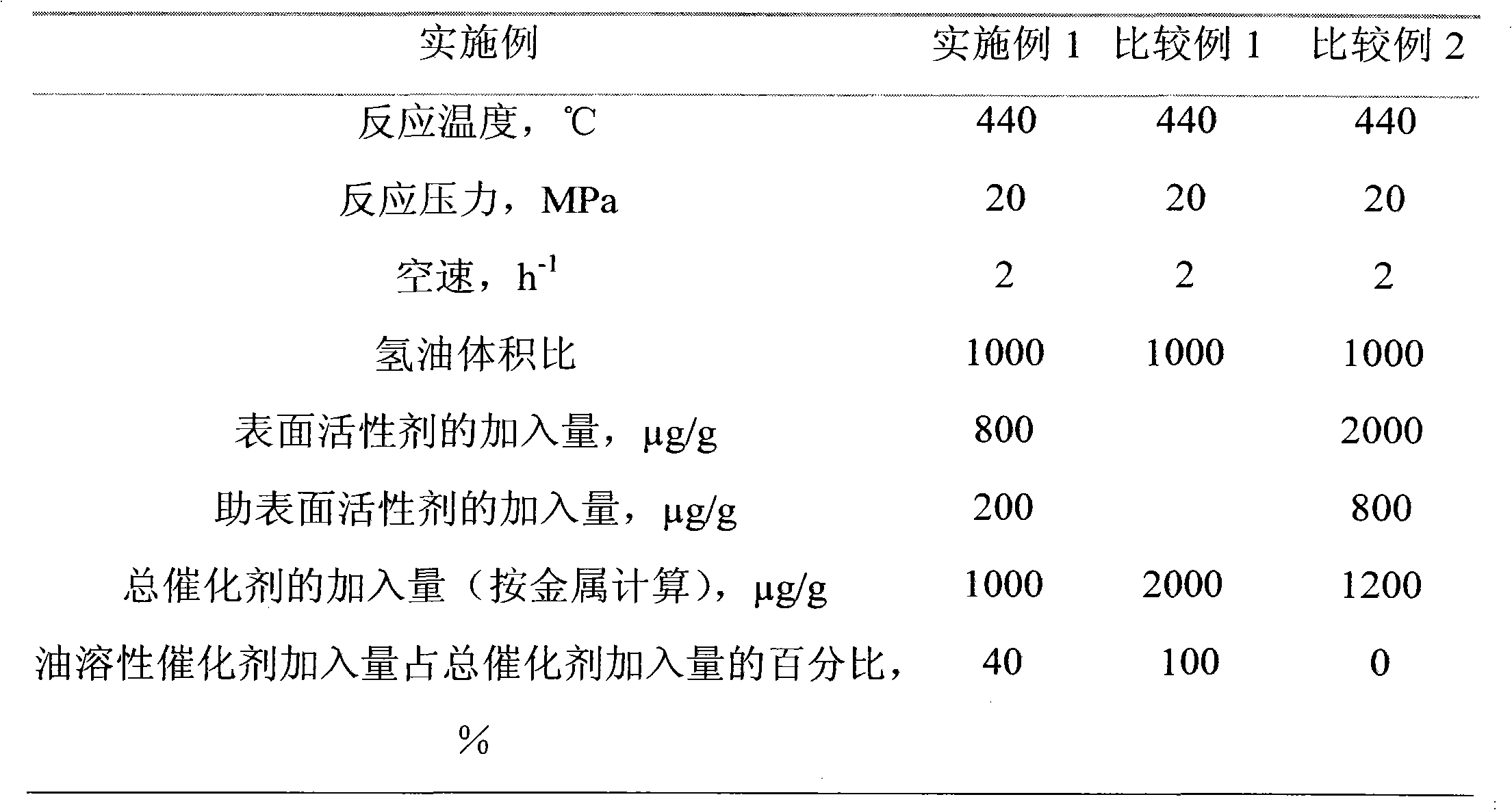

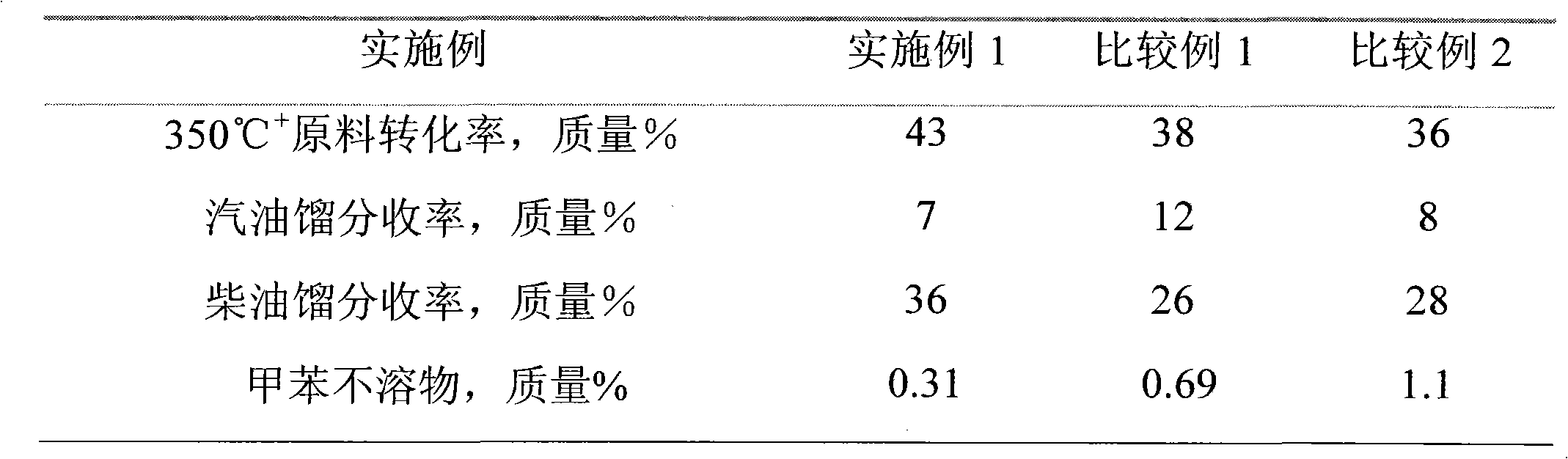

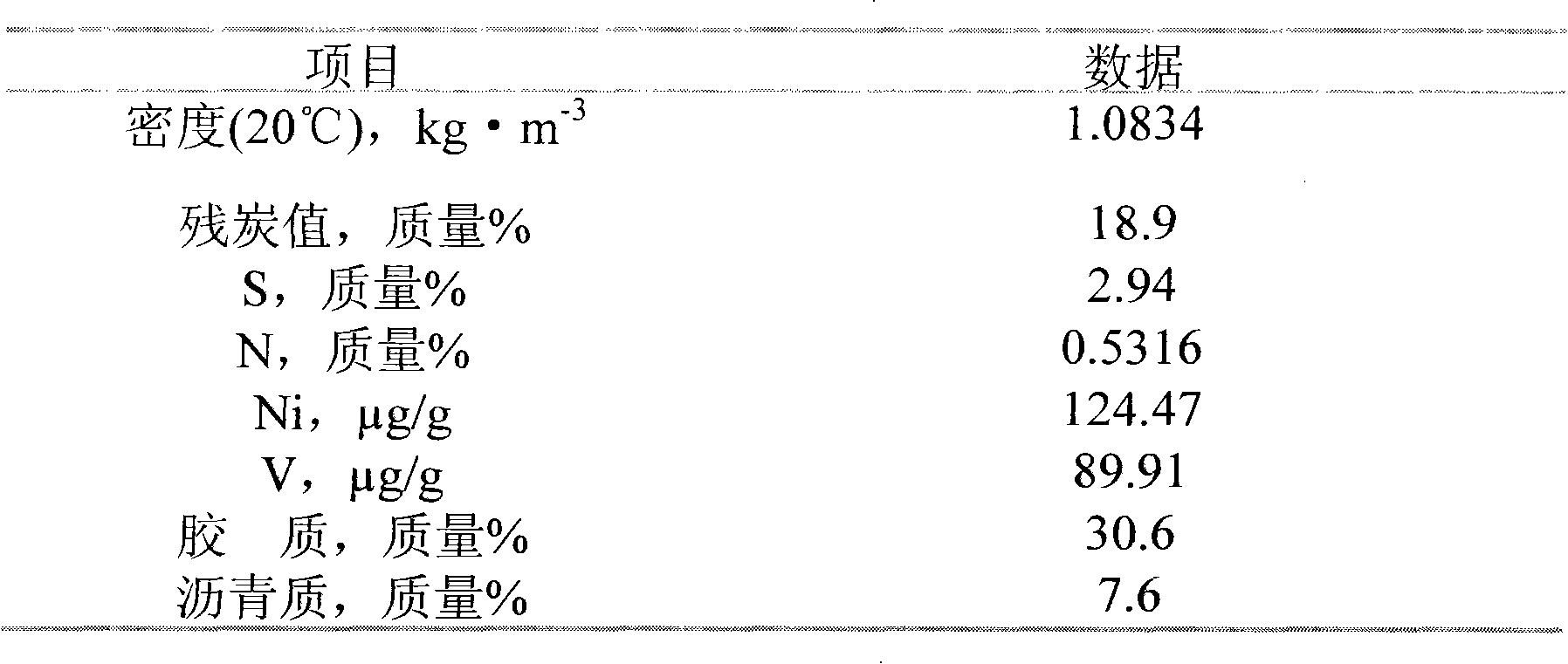

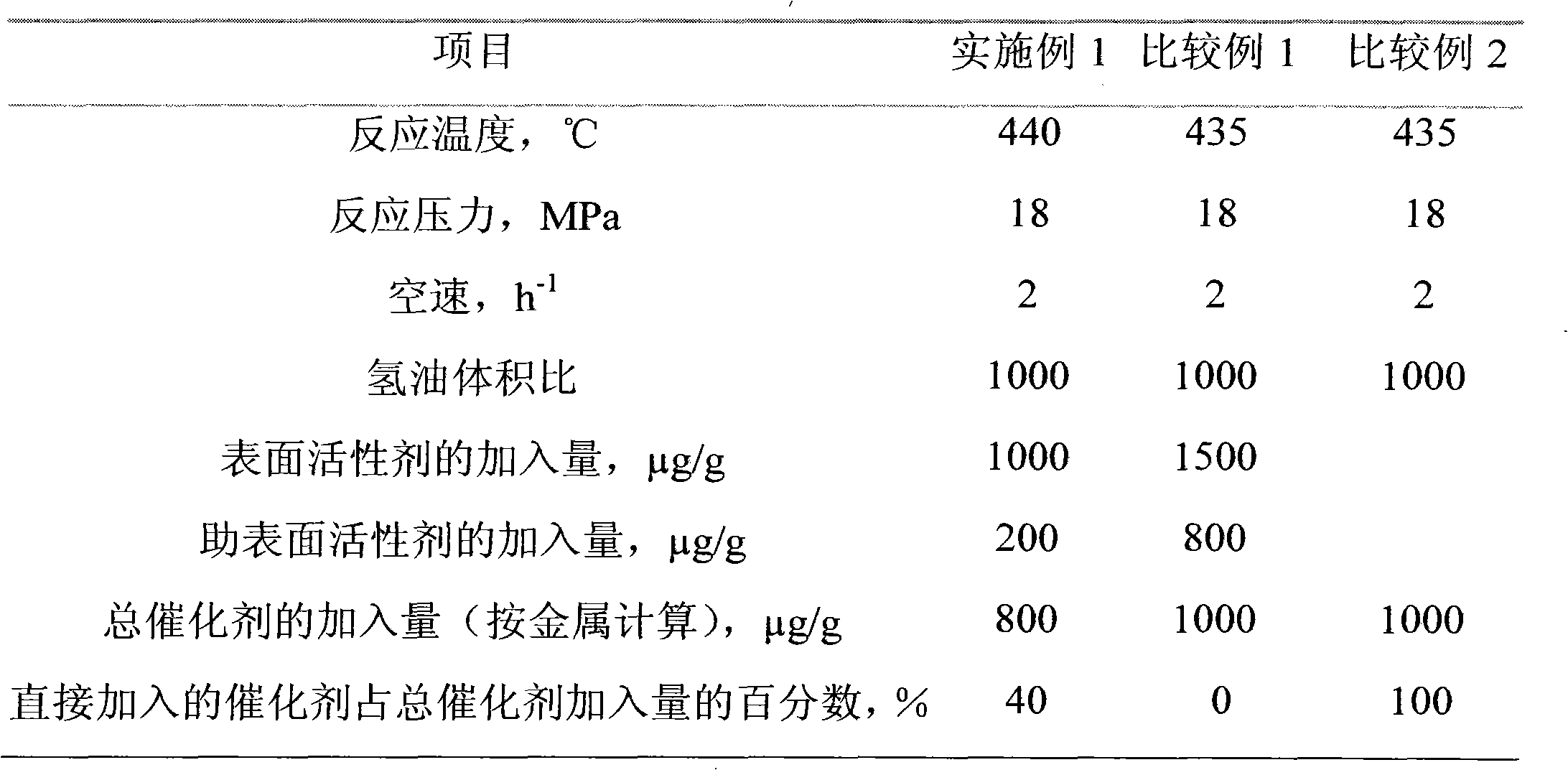

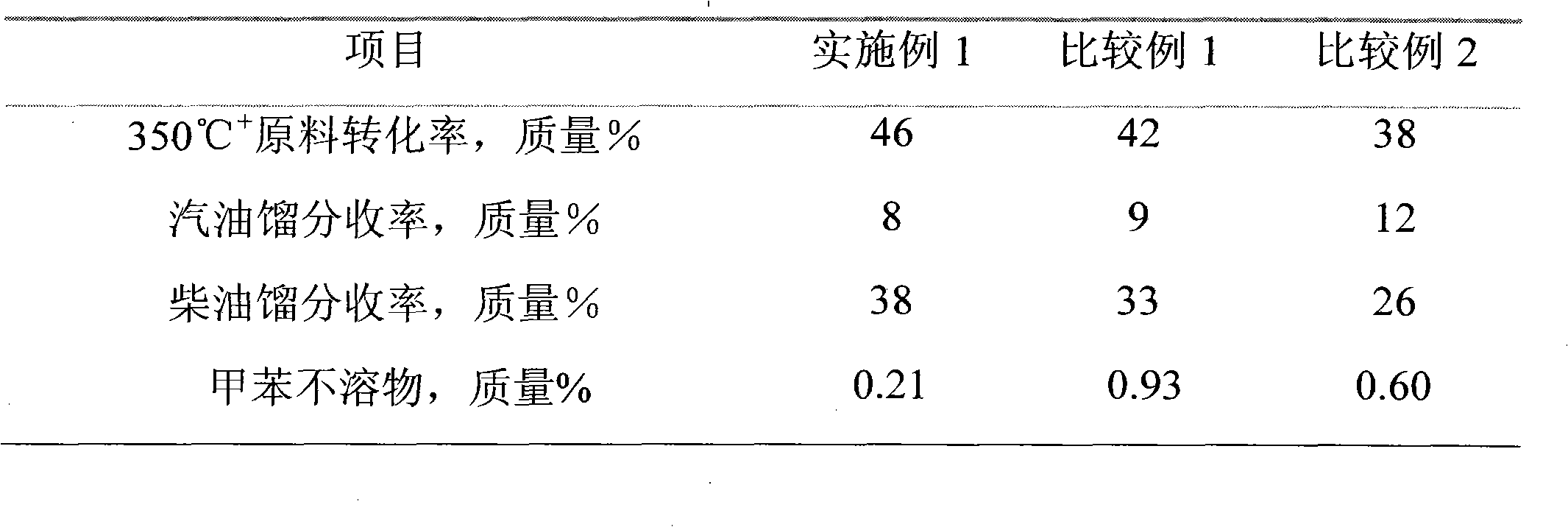

Heavy oil slurry bed hydrogenation method

ActiveCN101942324AInhibition of condensation cokeFully combinedHydrocarbon oil crackingAlkaneHydrogenation process

The invention discloses a heavy oil slurry bed hydrogenation method, in particular a slurry bed heavy oil hydrogenation process using a water-soluble catalyst. The method comprises the following processes of: first, directly dispersing part of the water-soluble catalyst in a heavy oil raw material; then, mixing part of the water-soluble catalyst and an emulsifying agent to obtain a mixture and adding the mixture into the heavy oil raw material; and finally, mixing the raw material mixed with the catalyst and hydrogen to obtain a mixture, adding the mixture into a slurry bed hydrogenation reactor; and performing a hydrocracking reaction under reaction conditions. By adopting the processes of the invention, the catalyst can be dispersedly in the heavy oil raw materials uniformly, so the components such as alkane, arene, colloid and asphaltine forming heavy oil are fully contacted with the catalyst so as to improve the hydrogenation modification reaction effect, inhibit the generation of coke and improve the yield of intermediate oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

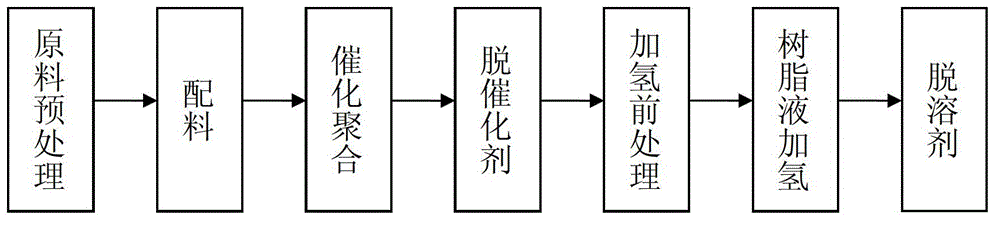

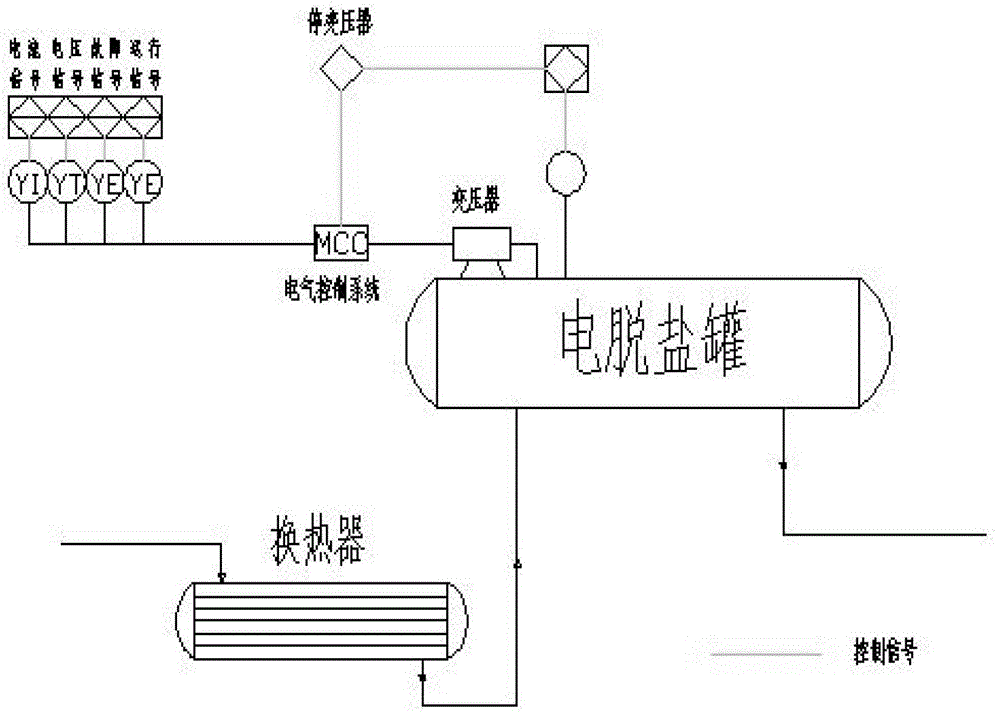

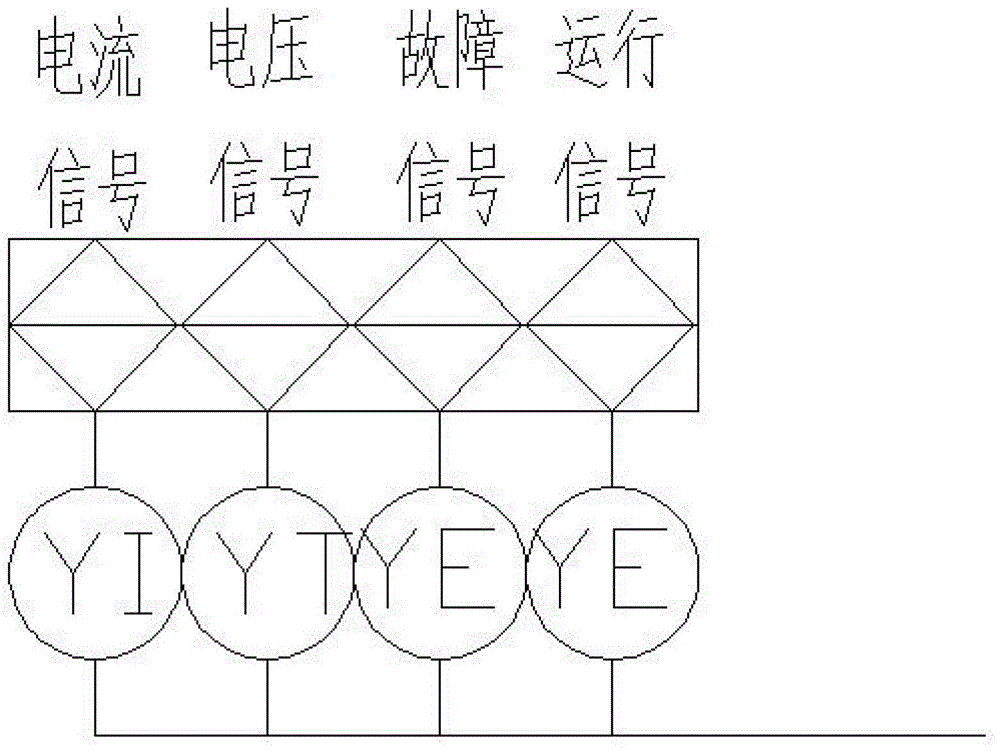

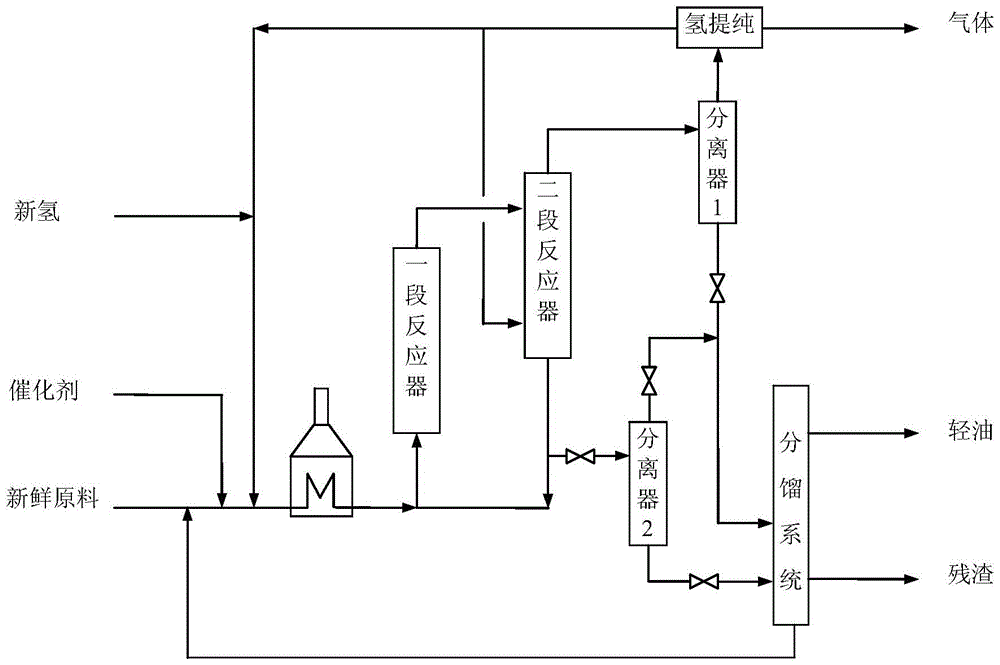

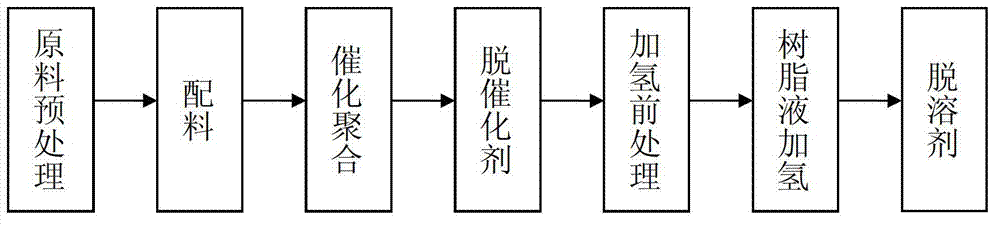

Preparation method of C5/C9 hydrocarbon resin

ActiveCN102718925AReduce reactivityGood compatibilityPhysical/chemical process catalystsOligomerBoron trifluoride

The invention relates to a preparation method of C5 / C9 hydrocarbon resin. The method comprises the following steps of: mixing piperlene fraction, crude isoamylene fraction and C9 fraction, pre-polymerizing the mixture at 180 to 230 DEG C, and finally polymerizing the mixture under the catalyzing of a gaseous boron trifluoride catalyst to obtain C5 / C9 hydrocarbon resin liquid; performing electrolytic desalting and dehydrating on the resin liquid, preprocessing the resin liquid through an active Al2O3 solid bed layer prior to hydrogenising, and then catalyzing and hydrogenising the resin liquid through a Pd / Zns / Al2O3 catalyst with ethyl methyl cyclohexane serving as solvent, and finally performing decompression and rectification on the resin liquid to remove the solvent and oligomer to obtain the C5 / C9 hydrocarbon resin. The C5 / C9 hydrocarbon resin prepared by the method based on hydrogenising has the advantages of light color, moderate softening point and high compatibility with most polarity resin, and can be widely used in the field of adhesives.

Owner:HENGHE MATERIALS & SCI TECH CO LTD

Combined process for treating residual oil

ActiveCN103059998ALess investmentHydrogenation Depth ModerationTreatment with hydrotreatment processesEngineeringHydrogen treatment

The invention discloses a combined process for treating residual oil. Boiling bed residual oil hydrotreatment, delayed coking, wax oil hydrotreatment and catalytic cracking are organically combined in the method. The method concretely comprises the following steps of: enabling a liquid-phase product obtained after residual oil raw materials are subjected to boiling bed hydrotreatment to directly enter a coking fractional distillation column to be in countercurrent contact with oil gas generated through coking, and then, carrying out fractional distillation to obtain a wax oil fraction, and enabling the wax oil fraction to enter a wax oil hydrotreatment device, wherein the liquid-phase product is not subjected to fractional distillation; enabling the obtained liquid-phase product as a raw material to enter a catalytic cracking unit for treating; enabling circulating oil obtained through the fractional distillation of the coking fractional distillation column to return to a delayed coking unit; generating gasoline and diesel products by the coking fractional distillation column; and carrying out catalytic cracking and fractional distillation to obtain liquefied gas, gasoline and diesel products. Compared with the prior art, the combined process has the advantages that a hydrogenization fractional distillation column can be omitted, the investment cost can be reduced, the coking and catalytic cracking raw material sources are expanded, and the coked and catalyzed light oil yield is increased; and meanwhile, the reaction heat energy is sufficiently utilized, and the production energy consumption is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

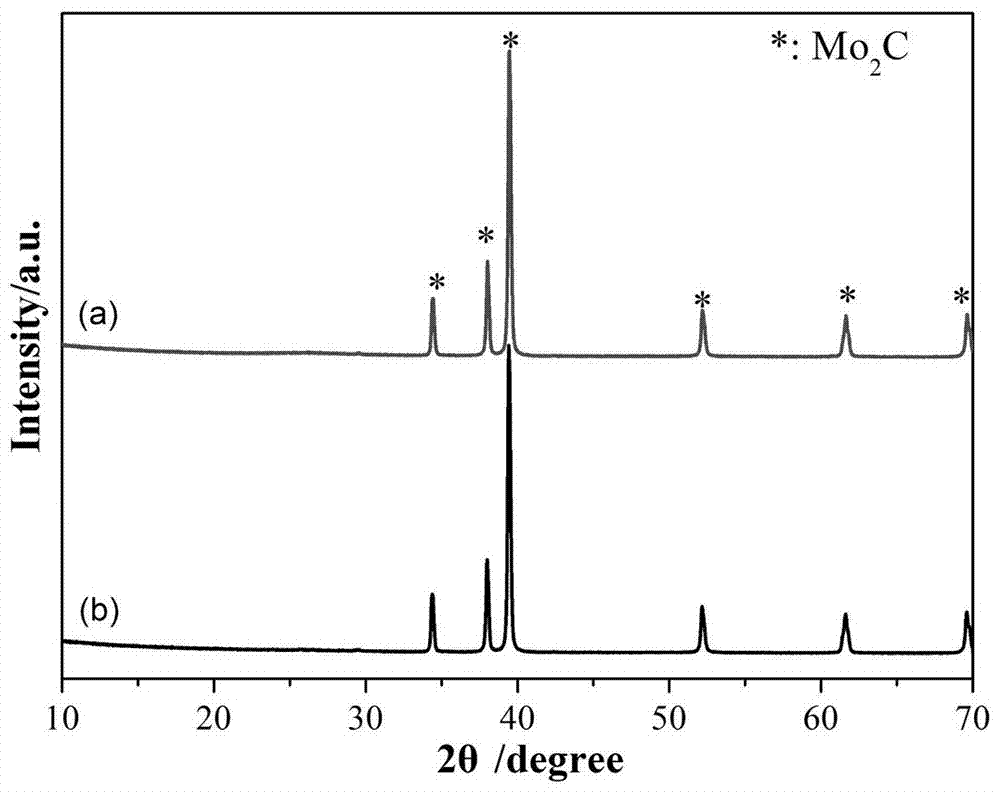

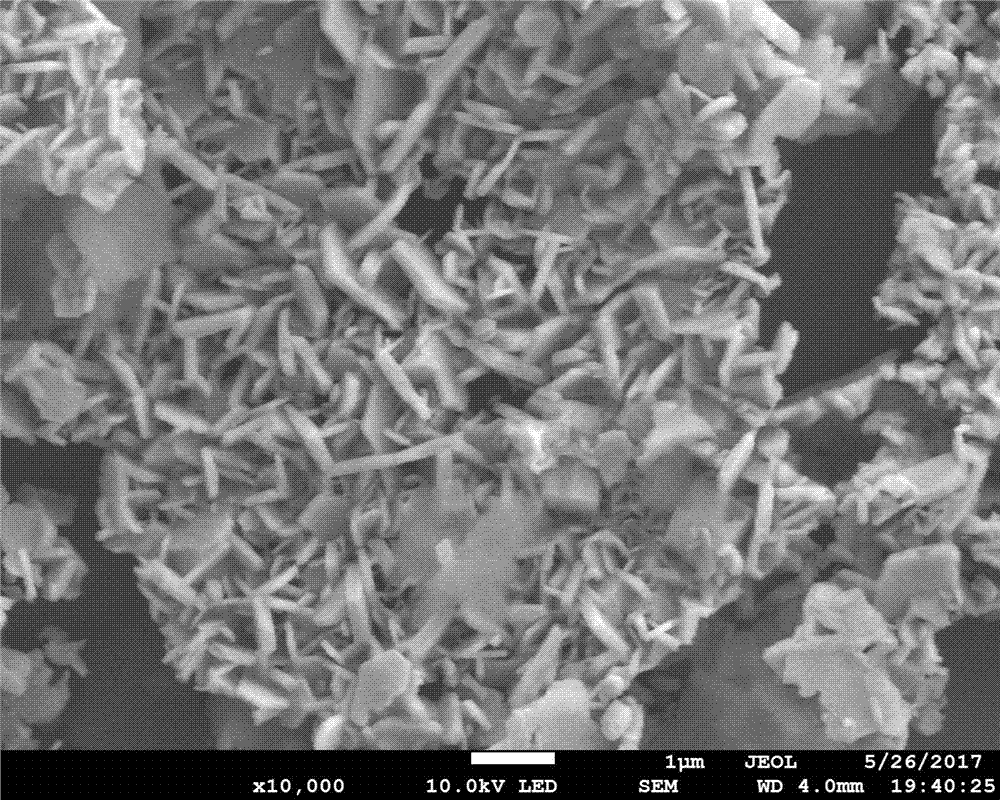

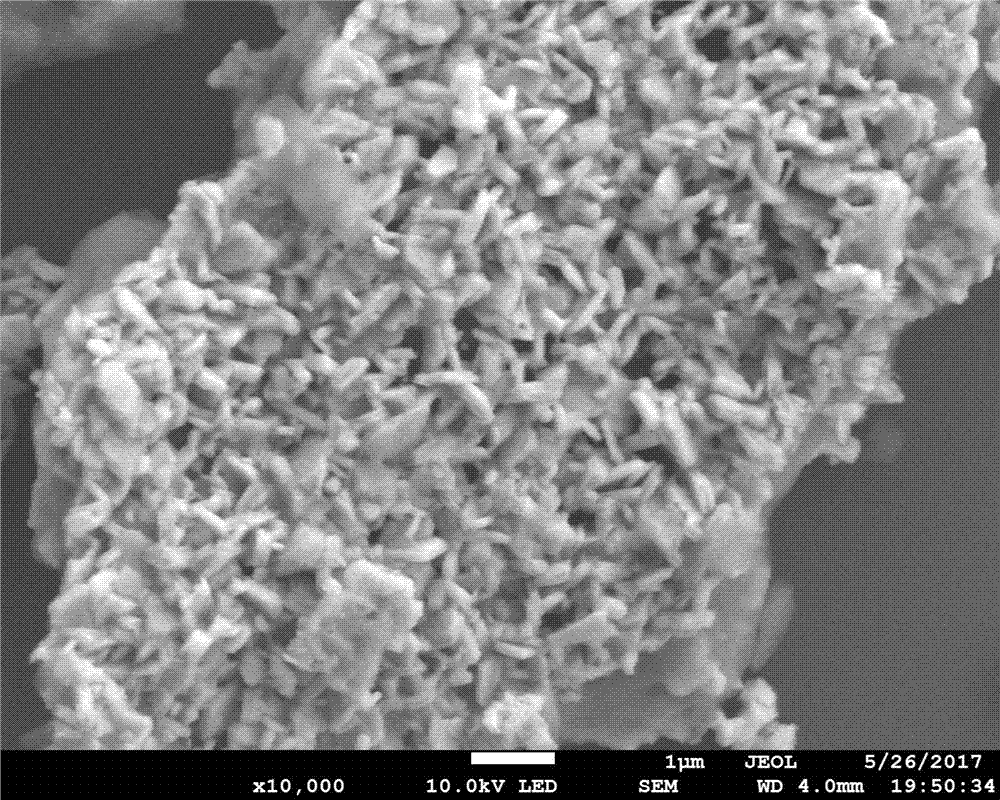

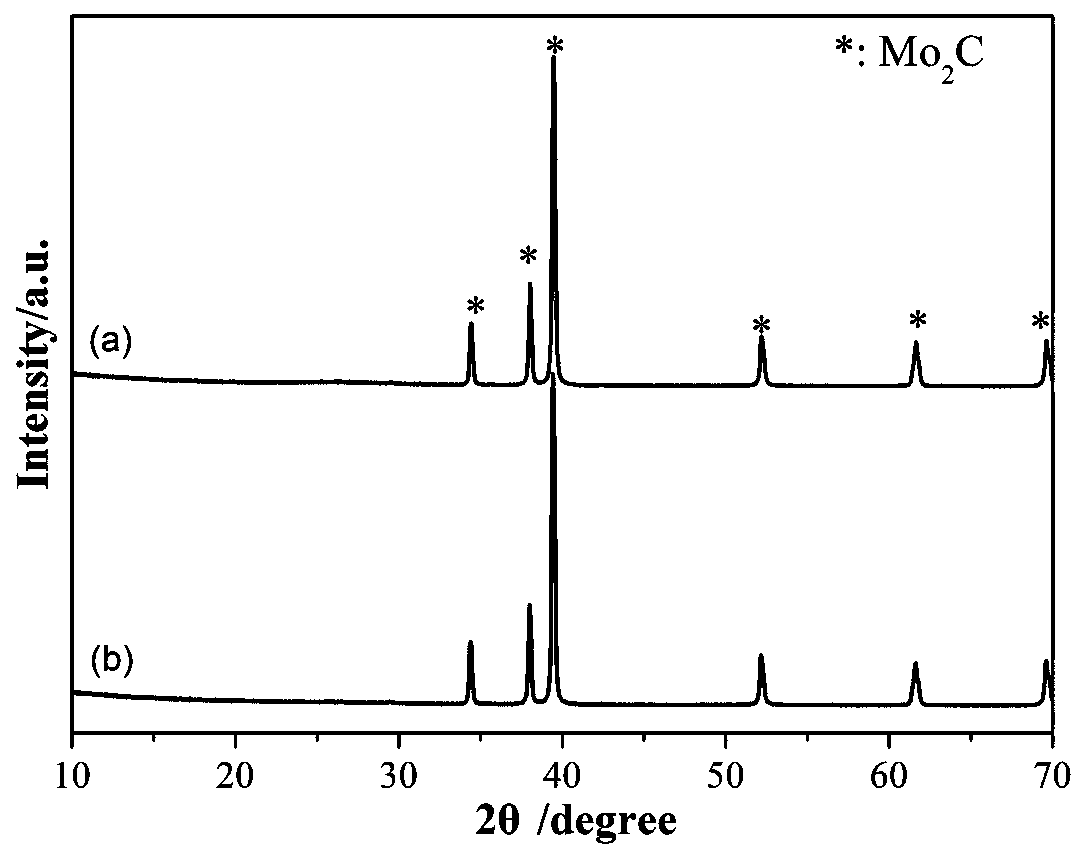

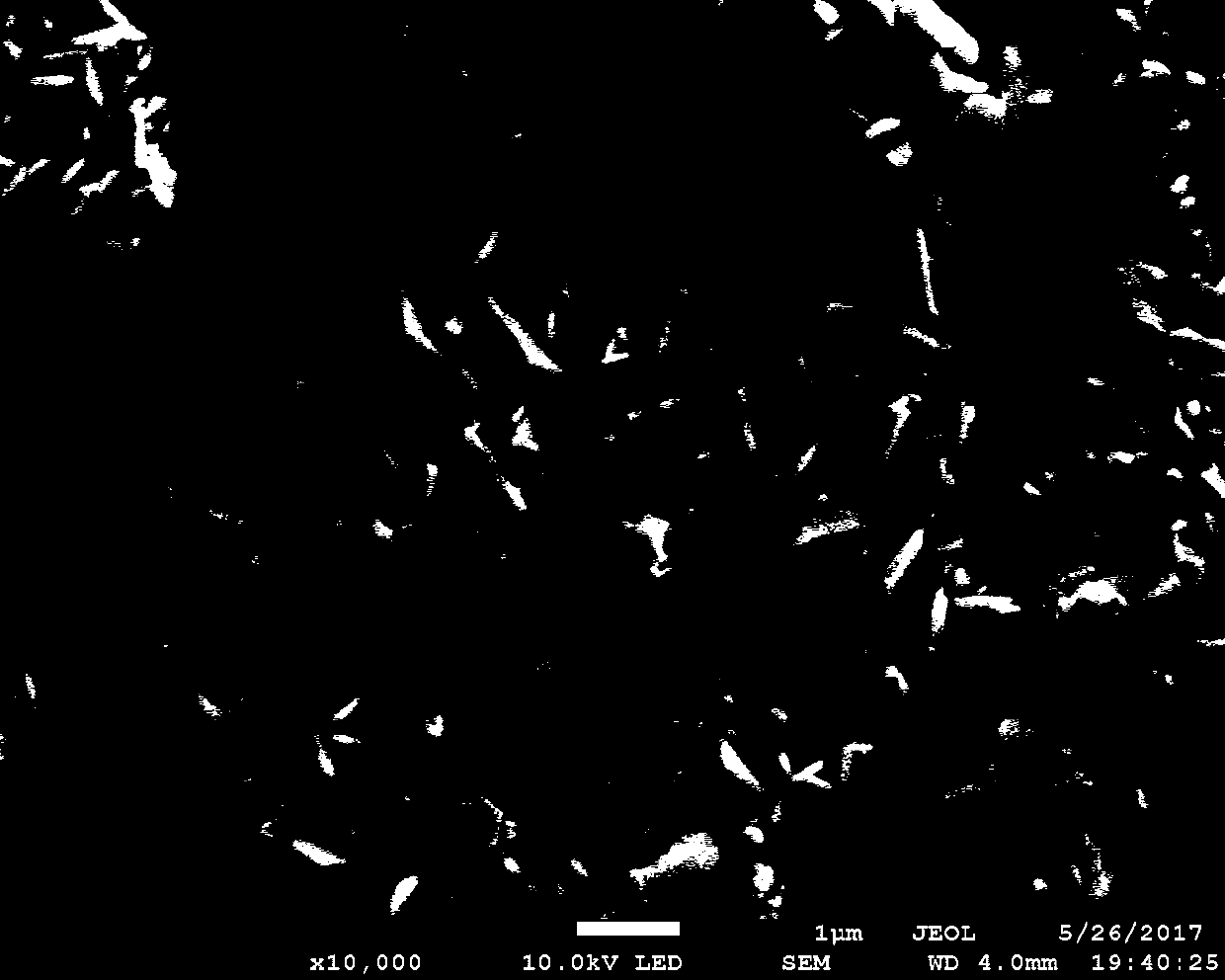

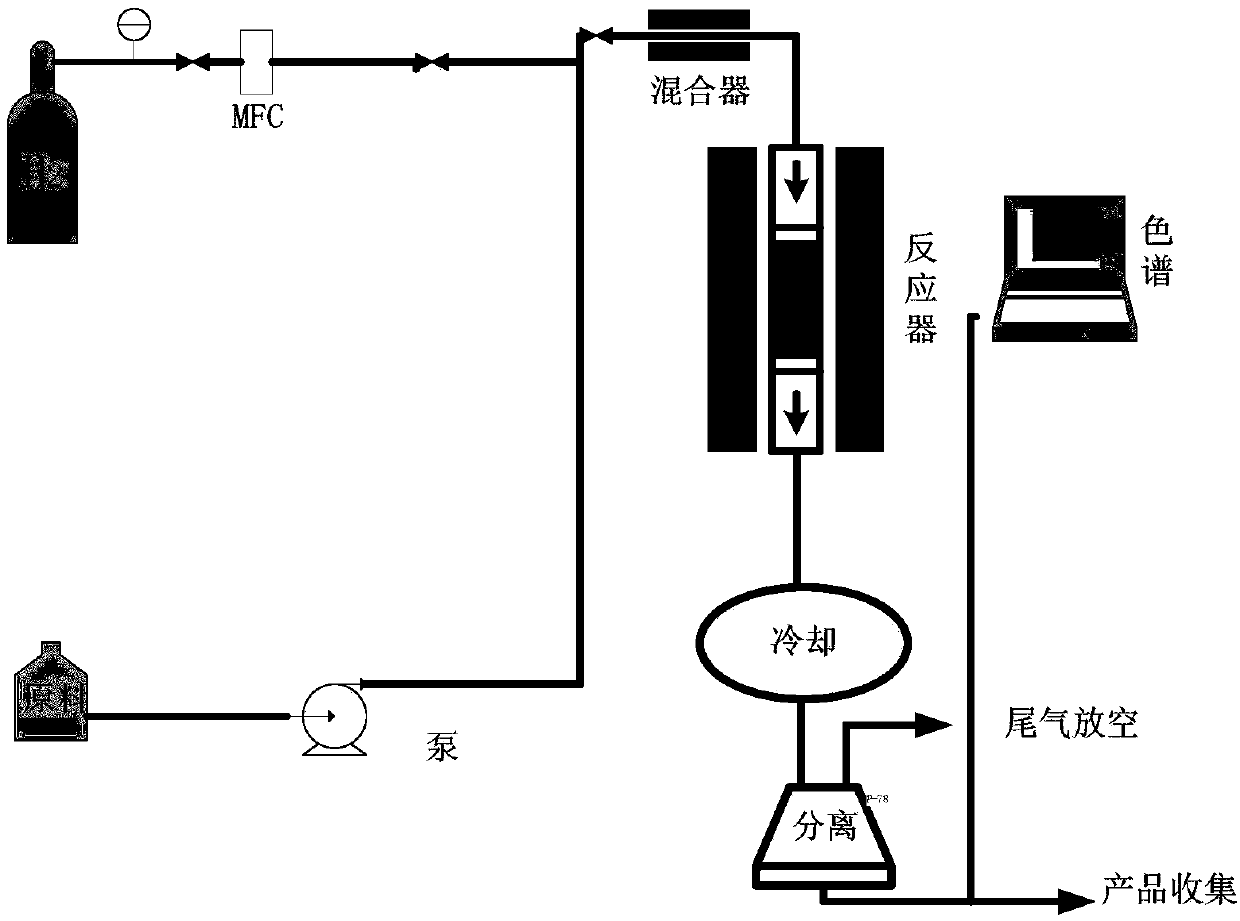

Preparation method of surface-functionalized molybdenum carbide-carbon catalyst for carbon dioxide hydrogenation reaction

ActiveCN107138171AAvoid sintering and agglomerationLarge specific surface areaCatalyst activation/preparationFreeze-dryingMolybdenum carbide

The application discloses a preparation method of a surface-functionalized molybdenum carbide-carbon catalyst for a carbon dioxide hydrogenation reaction. The preparation method mainly comprises the following steps: firstly, using deionized water as a solvent, uniformly mixing sodium alginate with an ammonium molybdate solution, and then putting a mixed solution into a freeze drying oven for carrying out freeze drying; secondly, carrying out high-temperature roasting in an inert atmosphere to obtain porous graphite carbon-inlaid high-dispersibility molybdenum carbide; thirdly, mechanically lapping the prepared porous graphite carbon-inlaid high-dispersibility molybdenum carbide and urea, putting a lapped material into a muffle furnace, and carrying out annealing treatment to obtain the surface-functionalized molybdenum carbide-carbon catalyst. The catalyst prepared by the preparation method has the characteristics of large specific surface area, abundant pore structures and high dispersibility, and shows good catalytic activity and selectivity in the carbon dioxide hydrogenation reaction.

Owner:CHONGQING TECH & BUSINESS UNIV

Heavy oil suspension bed hydro-upgrading method

InactiveCN101942323AInhibition of condensation cokeImprove bindingHydrocarbon oil crackingAlkaneHydrogen

The invention discloses a heavy oil suspension bed hydro-upgrading method, in particular to a suspension bed heavy oil hydro-upgrading technology of a dispersive catalyst. The method comprises the following steps: firstly dispersing the dispersive oil-soluble catalyst into the heavy oil raw material, then mixing the dispersive water-soluble catalyst with emulsifier, adding the mixture to the heavy oil raw material, mixing the raw material containing the catalyst with hydrogen and then feeding into a suspension bed hydrogenation reactor; and performing hydrocracking reaction under the reaction condition. In the process of the method of the invention, the catalyst can be evenly dispersed in the heavy oil raw material, so that alkane, aromatic hydrocarbon, colloid and asphaltene which form the heavy oil, can fully contact with the catalyst, thereby improving effects of the hydro-upgrading reaction, inhibiting coke generation, and enhancing yield of middle distillate.

Owner:FUSHUN RES INST OF PETROLEUM & PETROCHEMICALS SINOPEC CORP

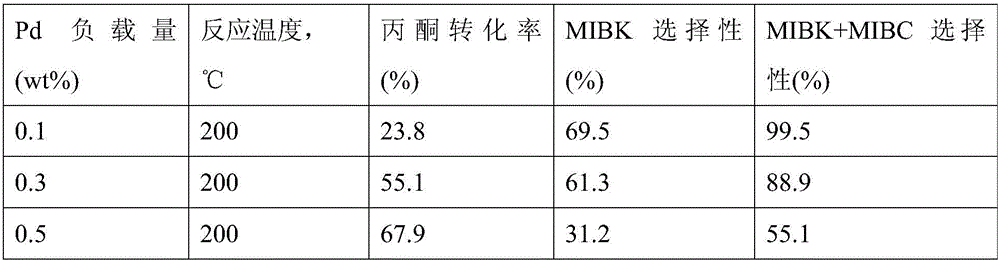

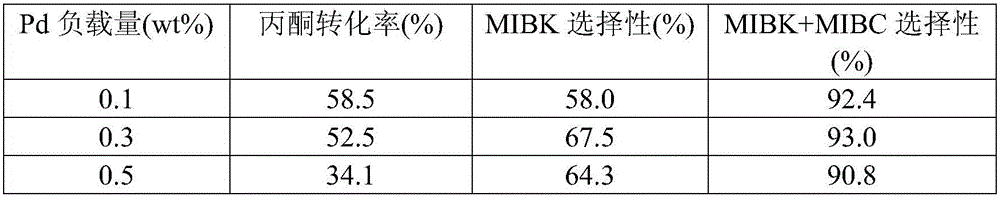

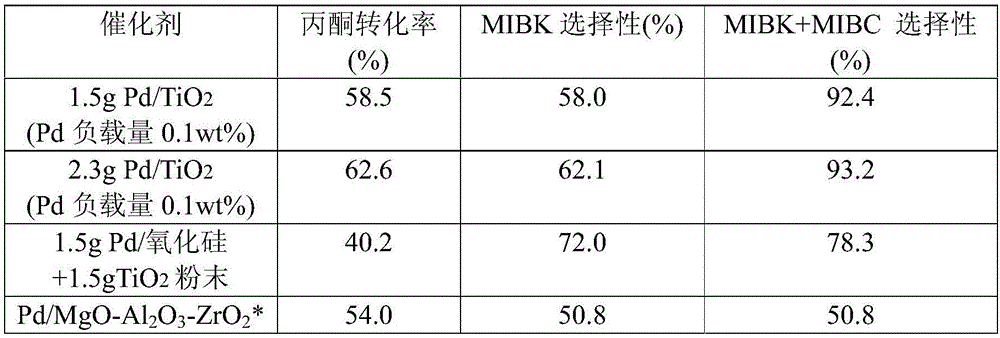

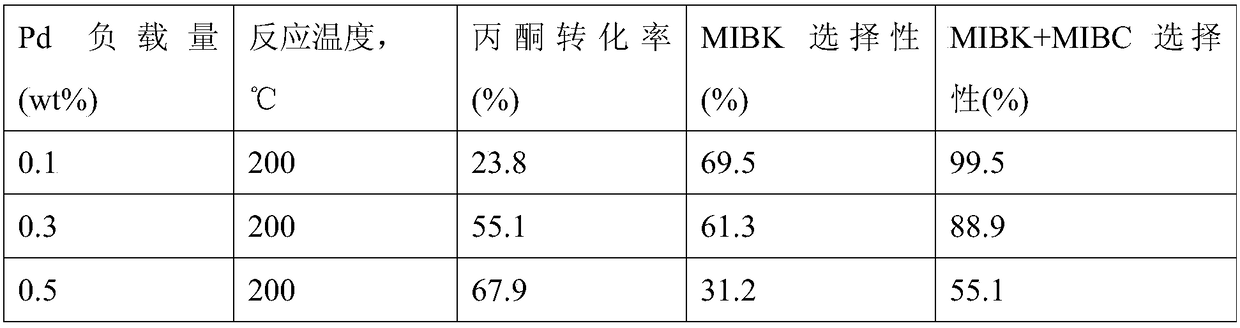

Preparation method for synthesis of methyl isobutyl ketone and methyl isobutyl alcohol

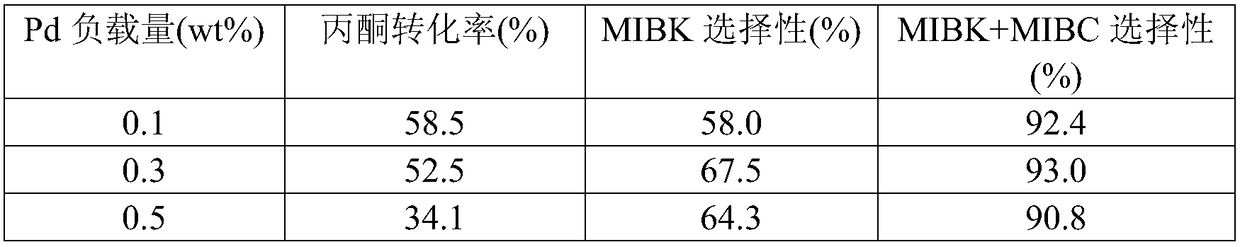

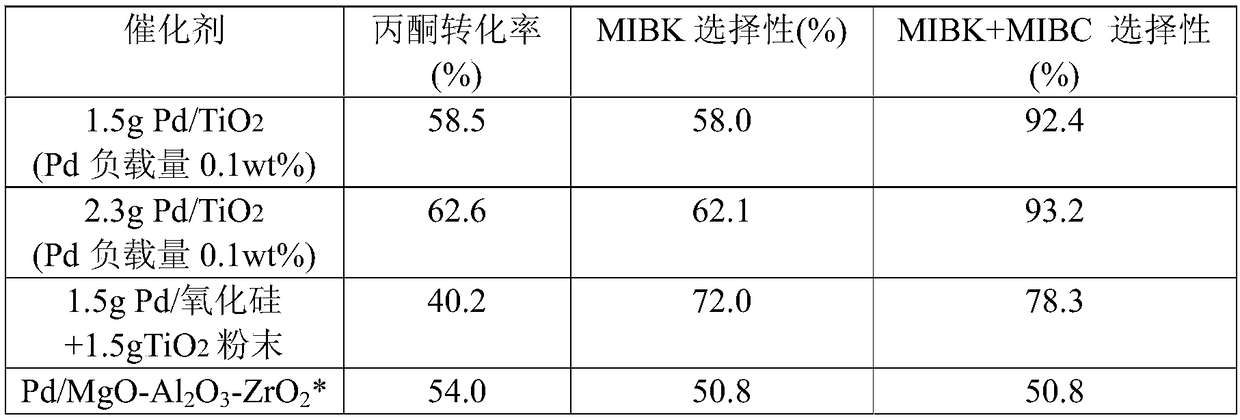

ActiveCN105732305AStrong hydrogenation functionPromote hydrogenationOxygen-containing compound preparationOrganic compound preparationIsobutyl alcoholMethylvinyl ketone

The invention discloses a preparation method for synthesis of methyl isobutyl ketone and methyl isobutyl alcohol. The acetone and hydrogen are used as raw materials to synthesize methyl isobutyl ketone and methyl isobutyl alcohol at the reaction temperature of 150-250 DEG C; in the reaction process, Pd / MyOx is used as a catalyst at atmospheric pressure state, the mole ratio of the hydrogen to the acetone is 50:1 to 3: 1, and the volume velocity of the hydrogen is 800-10000h<-1>; the Pd / MyOx is that the amphoteric metal oxide MyOx with baking temperature not higher than 600 DEG C is used as a carrier to load the Pd, x and y in the MyOx are respectively 1, 2 or 3, and M is selected from polyvalent metal in IVB-VIIB family elements, and is in corresponding high valence in the MyOx. The method is applied to the atmospheric pressure gas phase reaction for synthesizing methyl isobutyl ketone and methyl isobutyl alcohol through acetone hydrogenation, the highest conversion rate of the acetone can achieve 62.6%, the highest selectivity of the methyl isobutyl ketone and methyl isobutyl alcohol can achieve 93.2%, and the methyl isobutyl alcohol accounts for 1 / 3. Compared with the similar catalyst, the catalyst disclosed by the invention is not only simple in preparation method and low in cost, but also obviously improves the selectivity of the methyl isobutyl ketone and methyl isobutyl alcohol.

Owner:CENT SOUTH UNIV

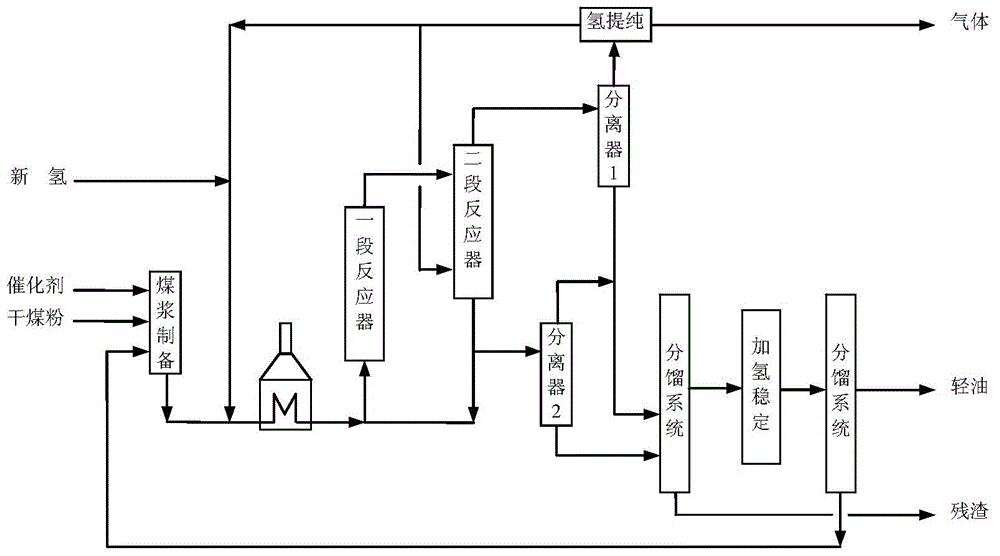

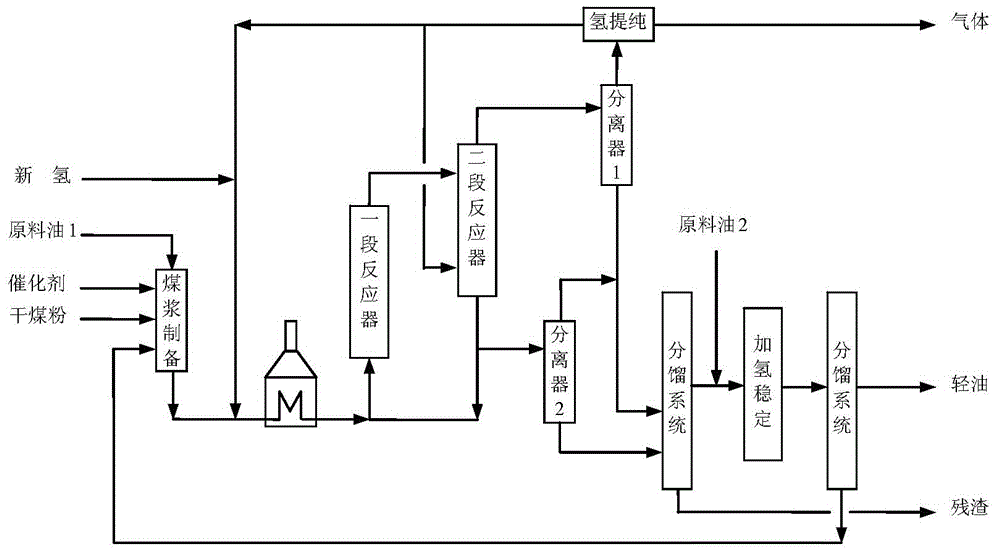

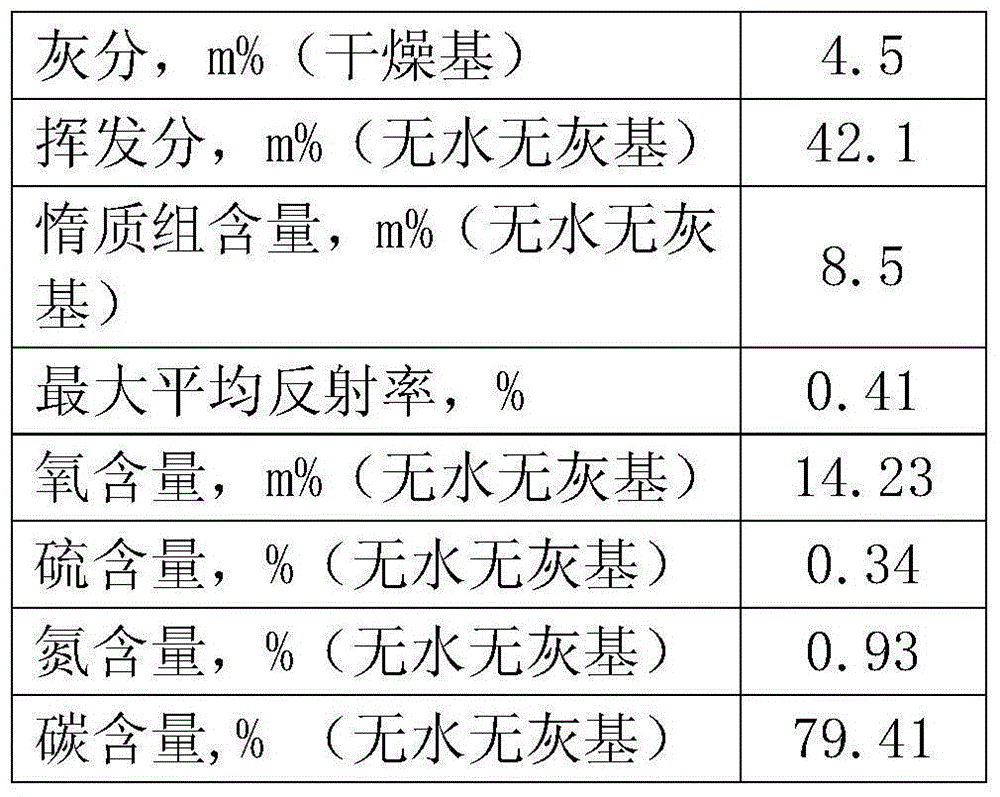

Method for directly liquefying coal

ActiveCN104560098AIncreased purity and hydrogen partial pressureSave construction investmentLiquid hydrocarbon mixture productionHydrocarbon oils treatmentChemistryStream flow

The invention relates to a method for directly liquefying coal, which comprises the following steps: coal slurry, hydrogen gas and a catalyst enter a first reaction region, and the mixture stream flows upwards in the first reaction region and reacts under the direct liquefying condition of slurry bed coal; after flowing out of the first reaction region, the mixture stream is subjected to gas-liquid separation into a gas-phase stream and a liquid-phase stream; the liquid-phase stream enters a second reaction region and flows downwards, performs countercurrent contact with the upward-flowing hydrogen gas in the second reaction region, and reacts under the direct liquefying condition of slurry bed coal; and the liquid-phase stream flowing out of the second reaction region partially or completely enters a separation system to perform separation. The method can lower the gas separation rate in the reactor and further enhance the direct liquefying effect of coal.

Owner:BLOOMING BEIJING TECH

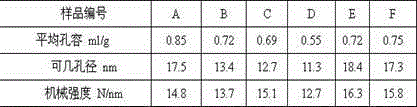

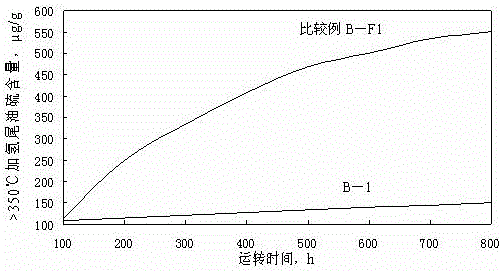

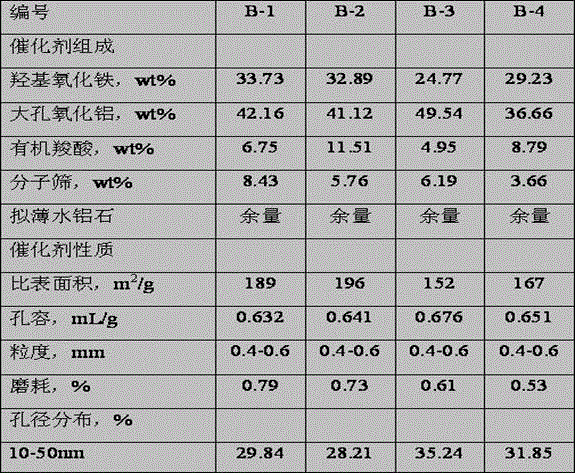

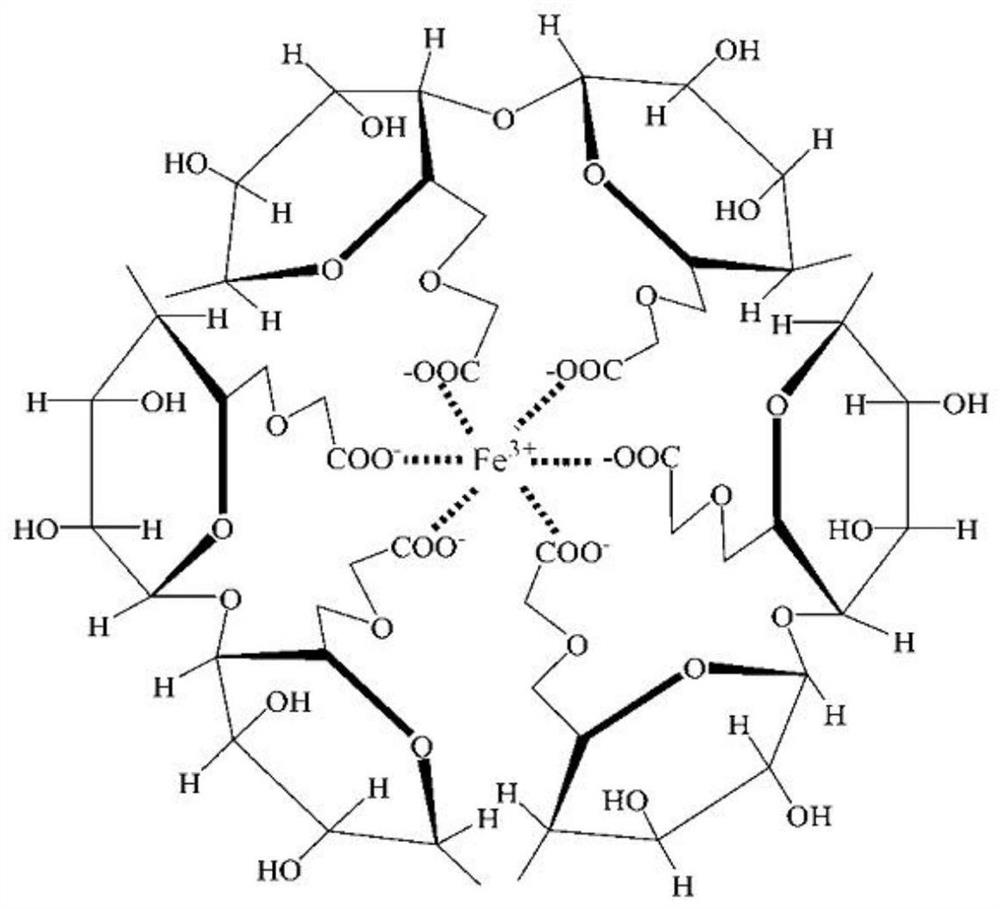

Coal tar hydrogenation catalyst, and preparation method and application thereof

ActiveCN104588109ALow costEvenly dispersedOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon oils refiningPtru catalystAluminium hydroxide

The invention discloses a coal tar hydrogenation catalyst, and a preparation method and application thereof. The catalyst comprises iron oxyhydroxide, organic polybasic carboxylic acid, macroporous alumina, a molecular sieve and pseudo-boehmite. The preparation method comprises the following steps: adding organic polybasic carboxylic acid into an iron oxyhydroxide filter cake and carrying out beating to obtain slurry; preparing aluminum hydroxide colloid, wherein the macroporous alumina and the molecular sieve are added before, during or after preparation of the aluminum hydroxide colloid so as to obtain the aluminum hydroxide colloid containing the macroporous alumina and the molecular sieve; adding the iron oxyhydroxide slurry before ageing of the aluminum hydroxide colloid; then carrying out filtering, washing, drying and molding; and carrying out drying so as to obtain the coal tar hydrogenation catalyst. The method provided by the invention adopts cheap iron oxyhydroxide as an active metal component, so cost is low. The catalyst prepared in the invention is especially applicable as a fluidized bed coal tar hydrogenation catalyst and has high hydrogenation activity, proper cracking activity and good stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

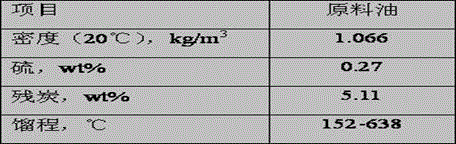

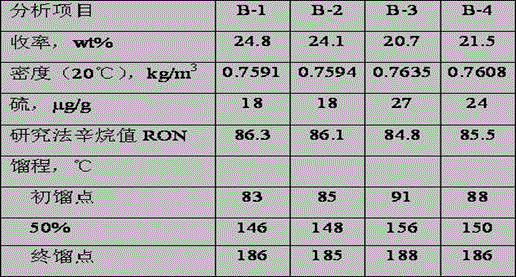

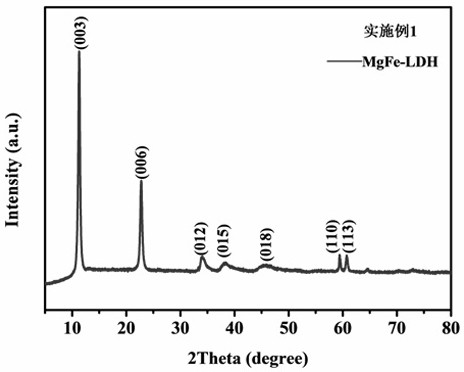

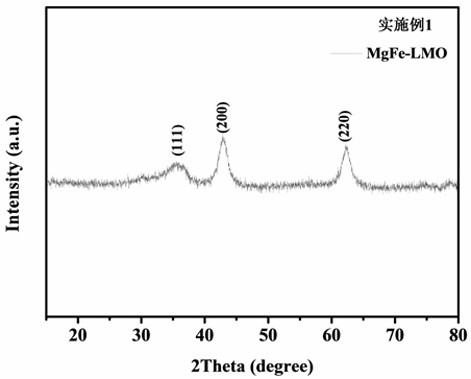

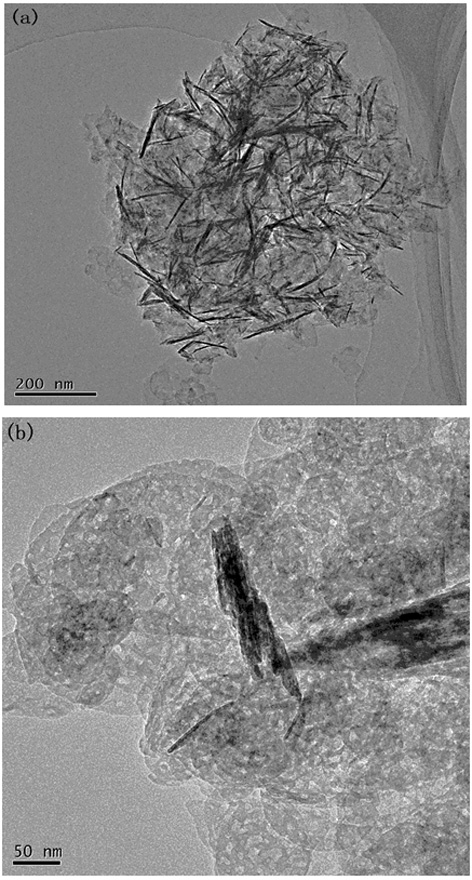

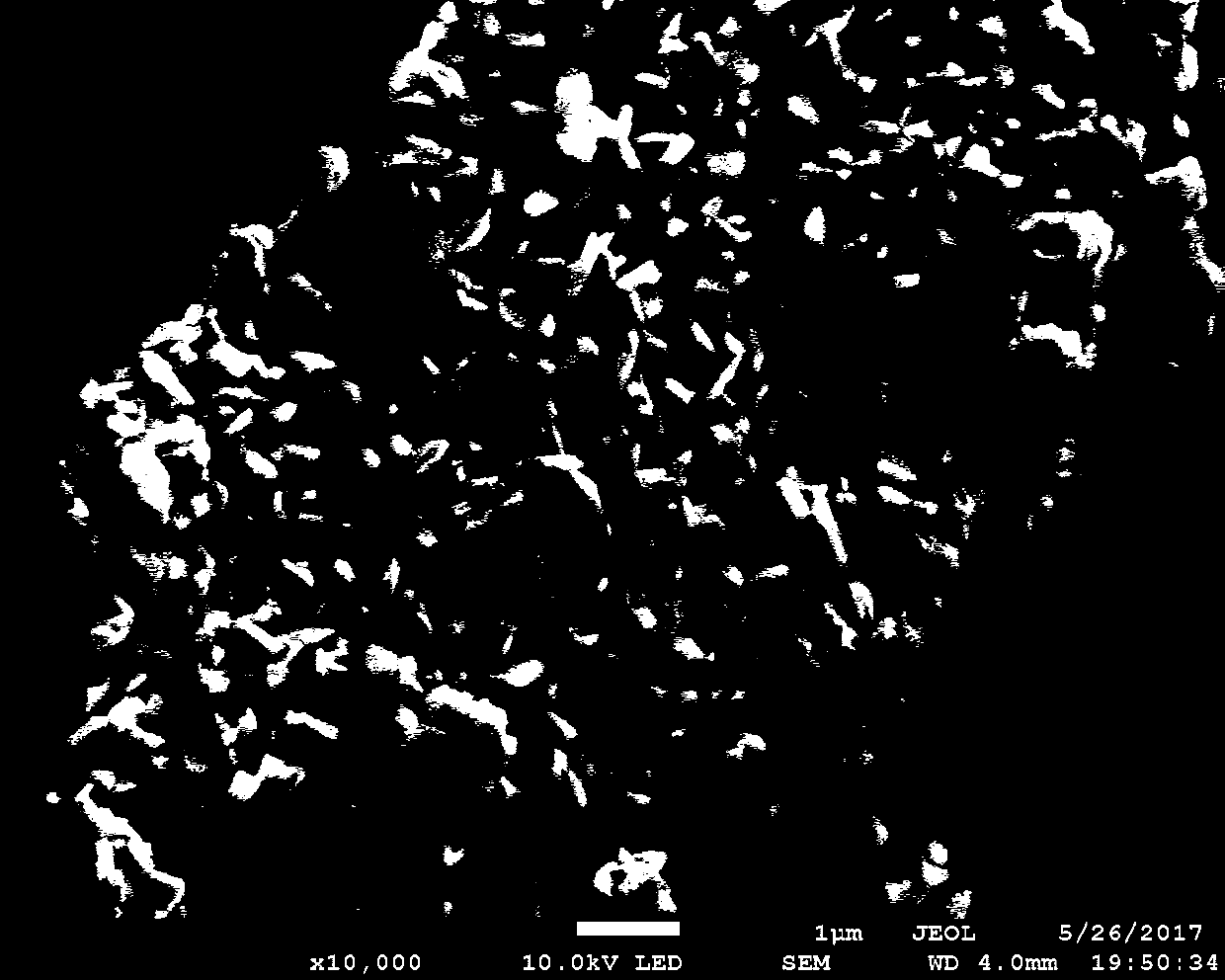

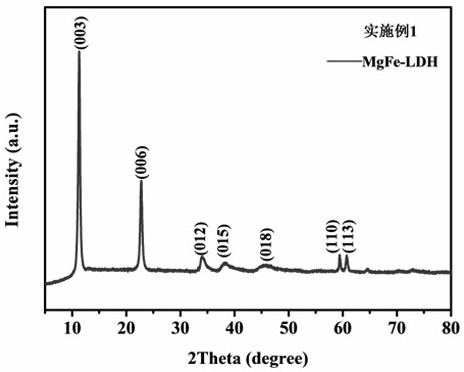

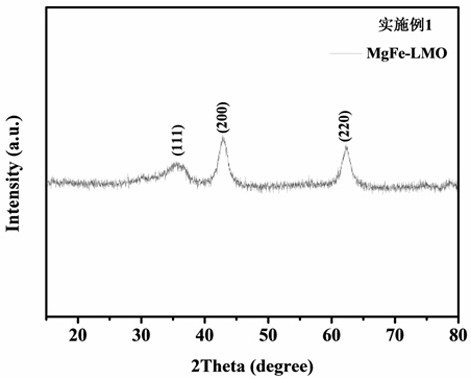

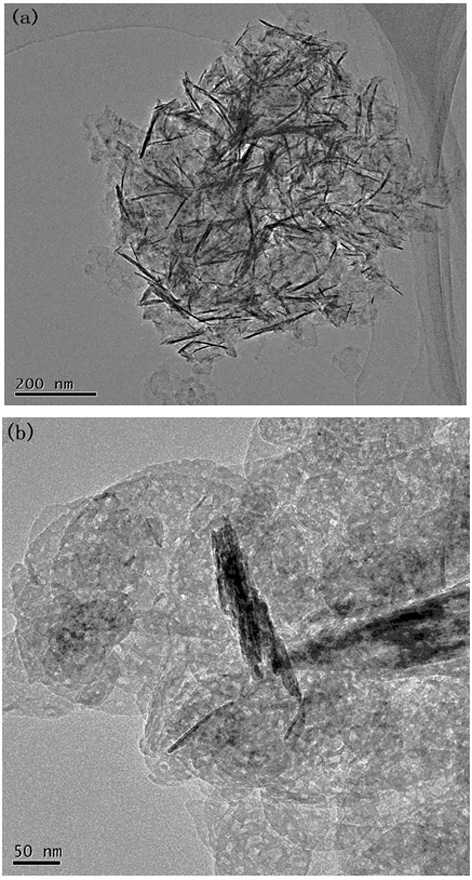

MgFe hydrotalcite-based catalyst and application thereof in production of biodiesel by hydrodeoxygenation in suspended bed

ActiveCN112808273AThe preparation process is green and simpleLow costBiofuelsCatalyst activation/preparationAir atmosphereChemistry

The invention discloses a layered porous magnesium iron hydrotalcite-based catalyst (MgFe-LMOs) and application thereof in production of biodiesel by hydrodeoxygenation in a suspended bed. The preparation method comprises the following steps: firstly, preparing MgFe-LDHs binary hydrotalcite with an intercalation structure by adopting a hydrothermal-co-precipitation method, and then roasting the MgFe-LDHs binary hydrotalcite in an air atmosphere to obtain the layered porous magnesium-iron catalyst material. The catalyst is applied to production of biodiesel through hydrodeoxygenation in a suspended bed with palm oil as raw material oil, the catalyst has high hydrodeoxygenation reaction activity and selectivity, and products of the hydrodeoxygenation mainly comprise C10-C18 alkanes and have a high combustion heat value, so that the catalyst has a good application prospect in industry.

Owner:FUZHOU UNIVERSITY

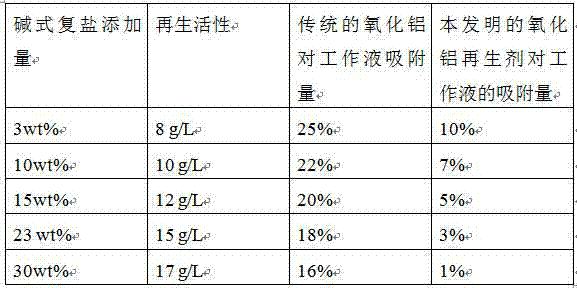

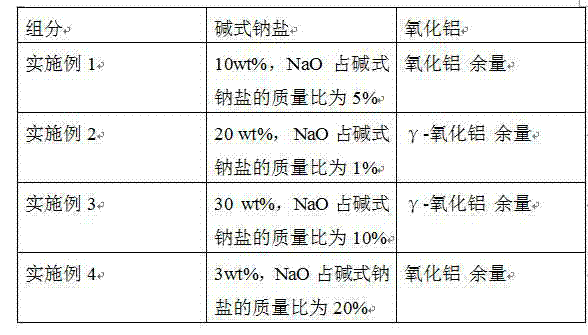

Alumina regenerant for preparing hydrogen peroxide by anthraquinone process

InactiveCN104555937AGood regenerative functionReduce consumptionPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesAnthraquinonesAqueous solution

The invention discloses an alumina regenerant for preparing hydrogen peroxide by an anthraquinone process. The alumina regenerant comprises the following components: alumina powder and basic sodium salt powder, wherein the dosage of basic sodium salt powder accounts for 10-20% of the total mass; the basic sodium salt powder satisfies that the pH value of a 1 g / ml aqueous solution containing basic sodium salt powder as the solute is 9-11; the basic sodium salt powder comprises sodium oxide; the content of sodium oxide accounts for 1%-4% of basic sodium salt powder in mass percent. The alumina regenerant has excellent regenerative activity, and greatly reduces the amount of organic residues, so as to reduce the environmental pollution, make a positive contribution to emission reduction, pollution elimination and loss reduction in the production of hydrogen peroxide, and create favorable conditions for the sustainable development of hydrogen peroxide.

Owner:何国炎

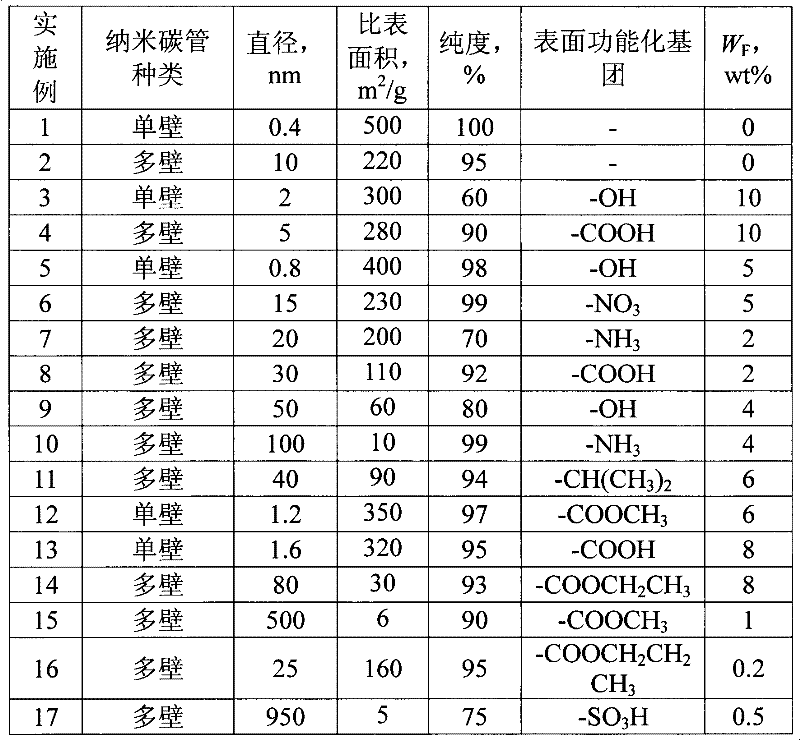

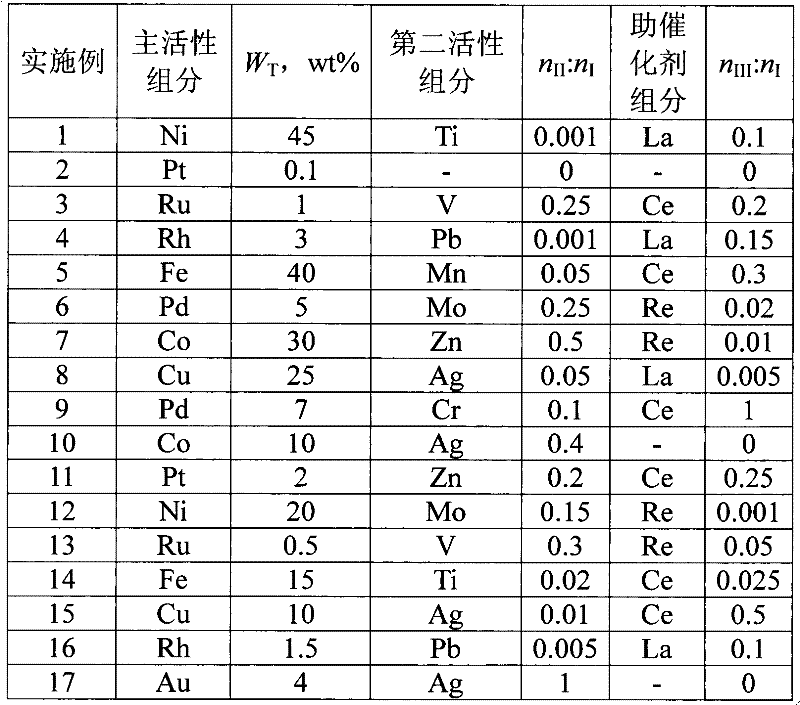

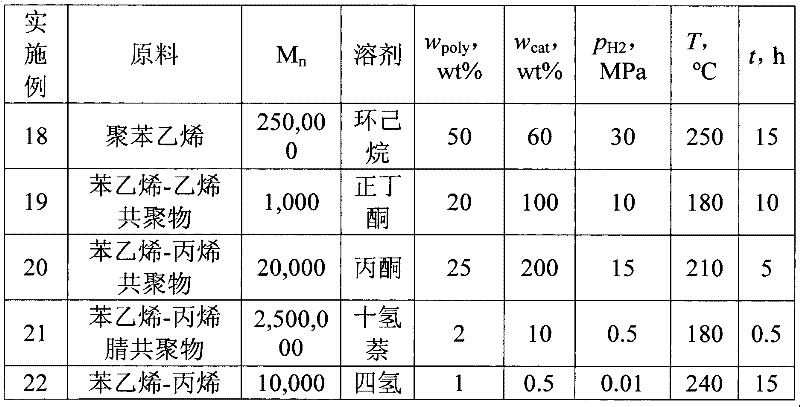

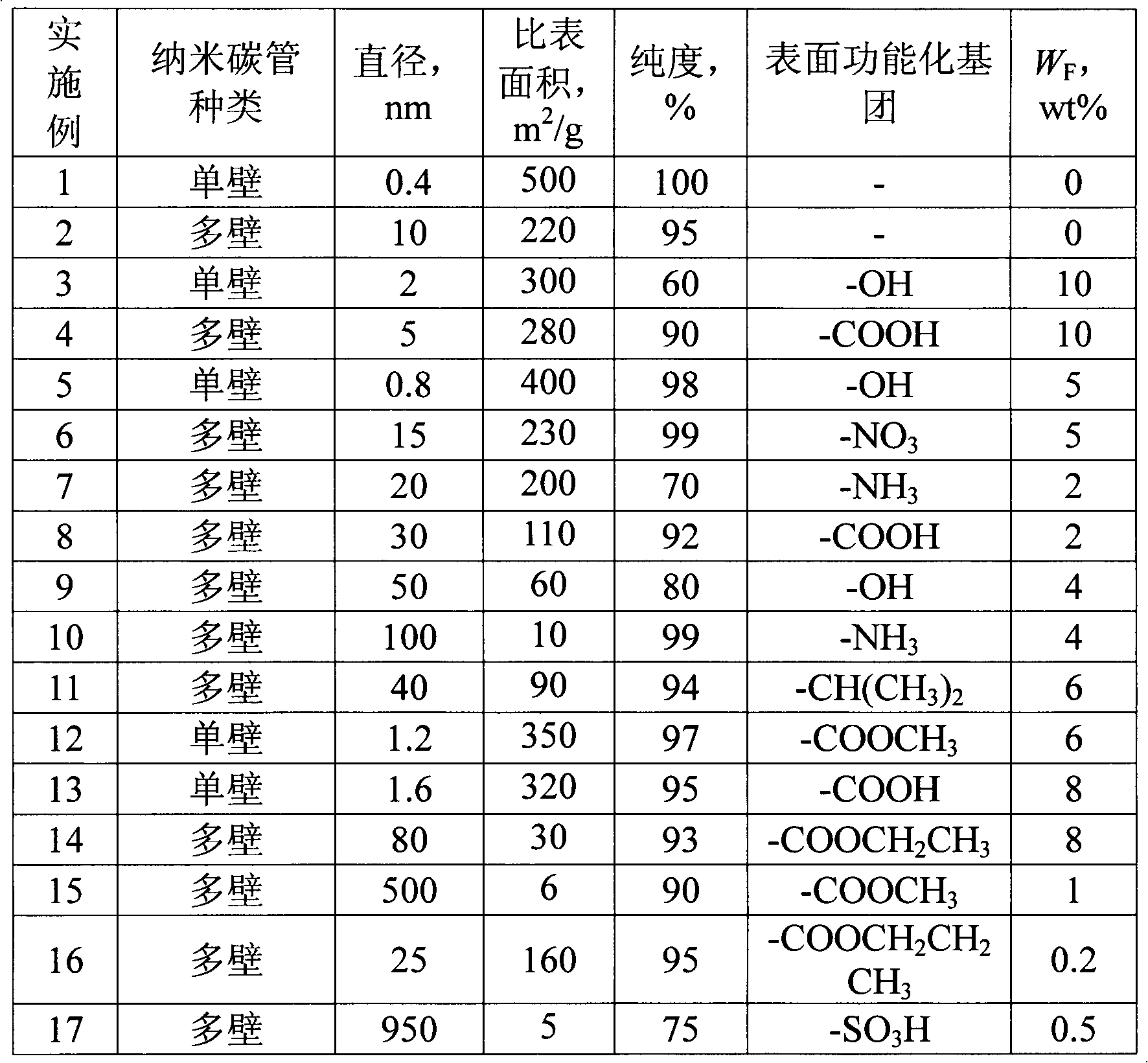

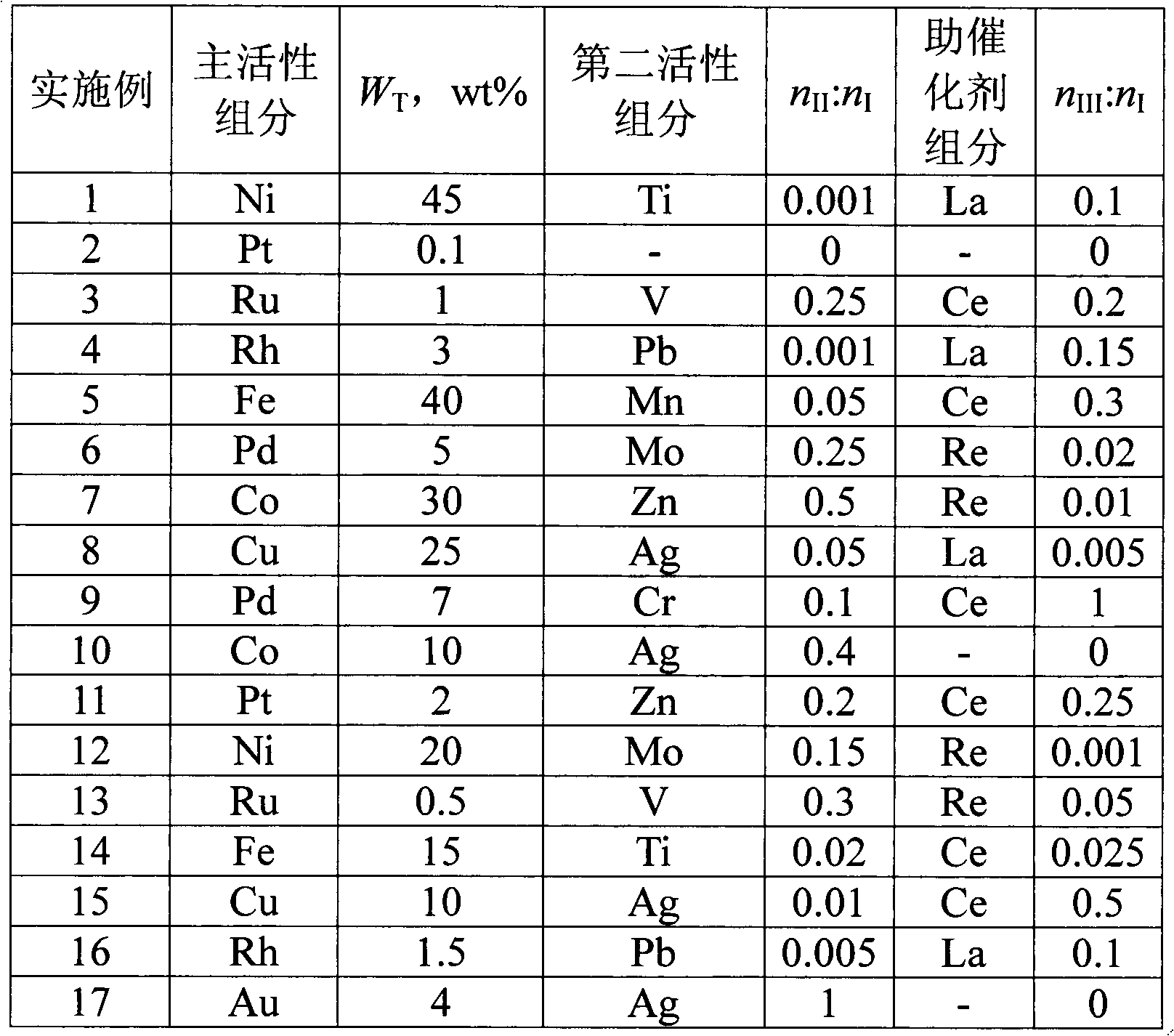

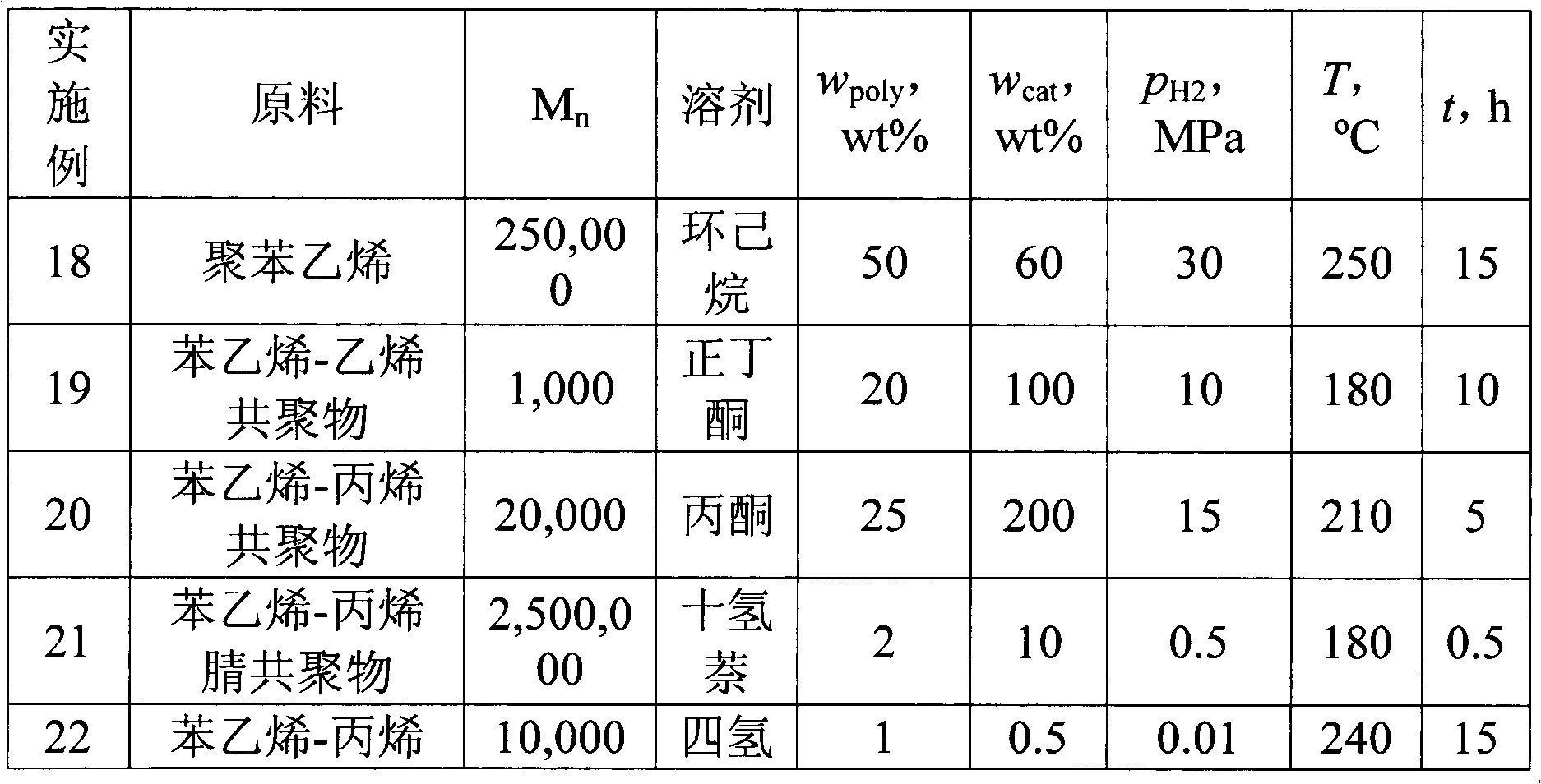

Preparation method for homopolymer or copolymer of cyclohexyl ethylene and catalyst

The invention discloses a catalyst, comprising a carbon nano-tube and a main active hydrogenation component, wherein in the catalyst, the carbon nano-tube is used as a catalyst carrier carried with the main active hydrogenation component, and the main active hydrogenation component is a conventional metal catalyst for catalytic hydrogenation reaction in the field of hydrogenation reaction. The invention further discloses a preparation method for the catalyst, and a preparation method for the homopolymer or copolymer of cyclohexyl ethylene. In the preparation methods disclosed by the invention, hydrogenation can be performed on the polymer solution of polystyrene or styrene copolymer in certain conditions by selecting special catalyst, thereby obtaining the homopolymer or copolymer of cyclohexyl ethylene.

Owner:EAST CHINA UNIV OF SCI & TECH

Aluminum oxide regenerant for preparing hydrogen peroxide through anthraquinone process

InactiveCN104724677AGood regenerative functionReduce consumptionPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesAnthraquinonesProcess engineering

The invention discloses an aluminum oxide regenerant for preparing hydrogen peroxide through an anthraquinone process. The aluminum oxide regenerant comprises the following components: aluminum oxide and basic sodium salt, wherein the adding amount of the basic sodium salt is 10-20% of the total mass; the basic sodium salt meets the condition that the pH value is 9-11 in 1g / ml water solution by taking the basic sodium salt as a solute; and the basic sodium salt comprises sodium oxide, wherein the content of the sodium oxide is 1-4% of that of the basic sodium salt. The technical solution of the invention is excellent in regenerative activity, the organic residual quantity is greatly reduced, the environment pollution is reduced, a positive contribution for reducing emission in the hydrogen peroxide production, eliminating the pollution and reducing the consumption is made and a favorable condition for the sustainable development of the hydrogen peroxide is created.

Owner:何国炎

Heavy oil slurry bed hydrogenation method

ActiveCN101942324BInhibition of condensation cokeFully combinedHydrocarbon oil crackingAlkaneHydrogenation process

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of hydrocracking method of heavy oil

ActiveCN104403686BReduce gas fractionHigh volume loadTreatment with hydrotreatment processesHydrogenGas phase

The invention relates to a hydrocracking method for heavy oil. The method comprises the following steps that the heavy oil, hydrogen and a catalyst enter a first reaction zone, the mixture flow of the heavy oil, the hydrogen and the catalyst flows upwards in the first reaction zone and reacts under the condition of hydrocracking on a suspended bed; after the mixture flow flows out of the first reaction zone, the mixture flow is divided into gas phase flow and liquid phase flow by gas-liquid separation; the liquid phase flow enters a second reaction zone, flows downwards and is in counter-current contact and reacts with the nitrogen flowing upwards under the condition of hydrocracking on the suspended bed; after the liquid phase flow flows out of the second reaction zone, part or all of the liquid phase flow enters a separation system to carry out product separation. According to the hydrocracking method for the heavy oil, not only can the separation rate of the gas in the reactor be reduced, but also a hydrocracking effect of the heavy oil can be further improved.

Owner:BLOOMING BEIJING TECH

Copper-based catalyst for neopentylene glycol preparation from hydrogenation method and preparation method thereof

InactiveCN102513107BStable in natureLow pricePreparation by oxygen reductionMetal/metal-oxides/metal-hydroxide catalystsCopper oxideSilicon dioxide

Owner:ZIBO MINGXIN CHEM

A preparation method of surface functionalized molybdenum carbide-carbon catalyst for carbon dioxide hydrogenation reaction

ActiveCN107138171BAvoid sintering and agglomerationLarge specific surface areaCatalyst activation/preparationGraphite carbonFreeze-drying

The application discloses a preparation method of a surface-functionalized molybdenum carbide-carbon catalyst for a carbon dioxide hydrogenation reaction. The preparation method mainly comprises the following steps: firstly, using deionized water as a solvent, uniformly mixing sodium alginate with an ammonium molybdate solution, and then putting a mixed solution into a freeze drying oven for carrying out freeze drying; secondly, carrying out high-temperature roasting in an inert atmosphere to obtain porous graphite carbon-inlaid high-dispersibility molybdenum carbide; thirdly, mechanically lapping the prepared porous graphite carbon-inlaid high-dispersibility molybdenum carbide and urea, putting a lapped material into a muffle furnace, and carrying out annealing treatment to obtain the surface-functionalized molybdenum carbide-carbon catalyst. The catalyst prepared by the preparation method has the characteristics of large specific surface area, abundant pore structures and high dispersibility, and shows good catalytic activity and selectivity in the carbon dioxide hydrogenation reaction.

Owner:CHONGQING TECH & BUSINESS UNIV

mgfe hydrotalcite-based catalyst and its application in suspended bed hydrodeoxygenation to produce biodiesel

ActiveCN112808273BThe preparation process is green and simpleLow costBiofuelsCatalyst activation/preparationAlkaneAir atmosphere

The invention discloses a layered porous magnesium-iron hydrotalcite-based catalyst (MgFe-LMOs) and its application in the production of biodiesel by hydrodeoxygenation in a suspended bed. In the present invention, the MgFe-LDHs binary hydrotalcite with an intercalation structure is firstly prepared by a hydrothermal-co-precipitation method, and then roasted in an air atmosphere to obtain a layered porous magnesium-iron catalyst material. The catalyst is applied to the production of biodiesel by suspended bed hydrodeoxygenation using palm oil as raw material oil, which has high hydrodeoxygenation reaction activity and selectivity, and its products are mainly C 10 -C 18 Alkanes mainly have high combustion calorific value, so they have good application prospects in industry.

Owner:FUZHOU UNIV

A kind of coal tar hydrogenation catalyst and its preparation method and application

ActiveCN104588109BLow costEvenly dispersedOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon oils refiningMolecular sieveFluidized bed

The invention discloses a coal tar hydrogenation catalyst, and a preparation method and application thereof. The catalyst comprises iron oxyhydroxide, organic polybasic carboxylic acid, macroporous alumina, a molecular sieve and pseudo-boehmite. The preparation method comprises the following steps: adding organic polybasic carboxylic acid into an iron oxyhydroxide filter cake and carrying out beating to obtain slurry; preparing aluminum hydroxide colloid, wherein the macroporous alumina and the molecular sieve are added before, during or after preparation of the aluminum hydroxide colloid so as to obtain the aluminum hydroxide colloid containing the macroporous alumina and the molecular sieve; adding the iron oxyhydroxide slurry before ageing of the aluminum hydroxide colloid; then carrying out filtering, washing, drying and molding; and carrying out drying so as to obtain the coal tar hydrogenation catalyst. The method provided by the invention adopts cheap iron oxyhydroxide as an active metal component, so cost is low. The catalyst prepared in the invention is especially applicable as a fluidized bed coal tar hydrogenation catalyst and has high hydrogenation activity, proper cracking activity and good stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

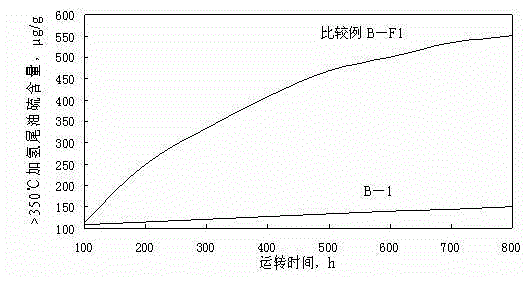

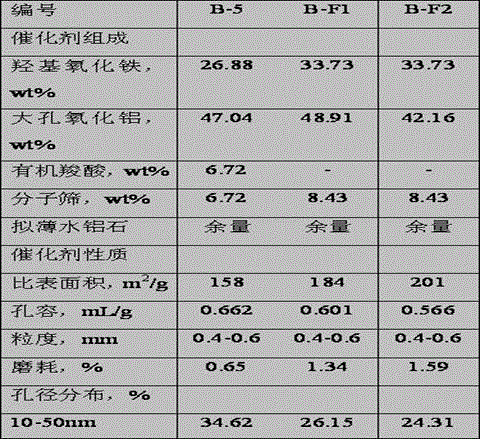

Hydrogenation process for reducing catalyst skimming

ActiveCN103102939BWithout human interventionReduce operational complexityTreatment with hydrotreatment processesHydrogenation reactionEconomic benefits

The invention provides a hydrogenation process for reducing catalyst skimming. According to the invention, a fixed bed reactor is used; 2 to 5 beds are arranged in the fixed bed reactor; a top bed is provided with a scale depositing basket penetrating the top bed; the middle part and the bottom of the scale depositing basket are respectively provided with a separator plate; each separator plate is welded with an overflow pipe; and a pressure rupture disk is hermetically mounted on the top of each overflow pipe. When the upper part / lower part of the catalyst beds has a great pressure drop, the pressure rupture disk on the top of the overflow pipe at the upper part / lower part ruptures under the action of pressure difference, and a gas-liquid material flow can continue flowing downwardly to participate in a hydrogenation reaction. According to the process provided by the invention, great improvement of a conventional apparatus is not needed, long-period running of the apparatus can be realized with small investment, a catalyst in the whole beds can be fully utilized, the pressure drop in the reactor can be reduced at the same time, production safety is guaranteed, and economic benefits are increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

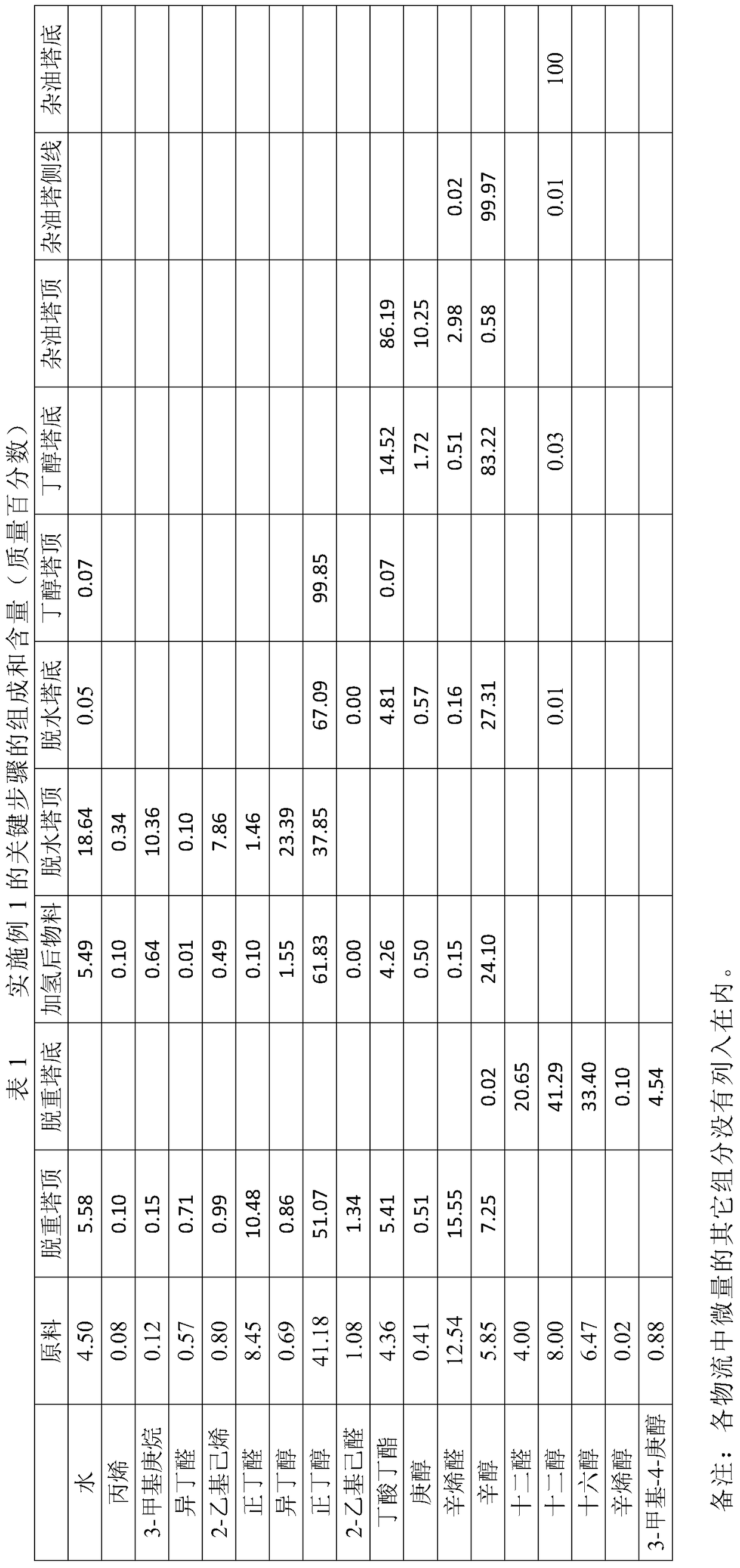

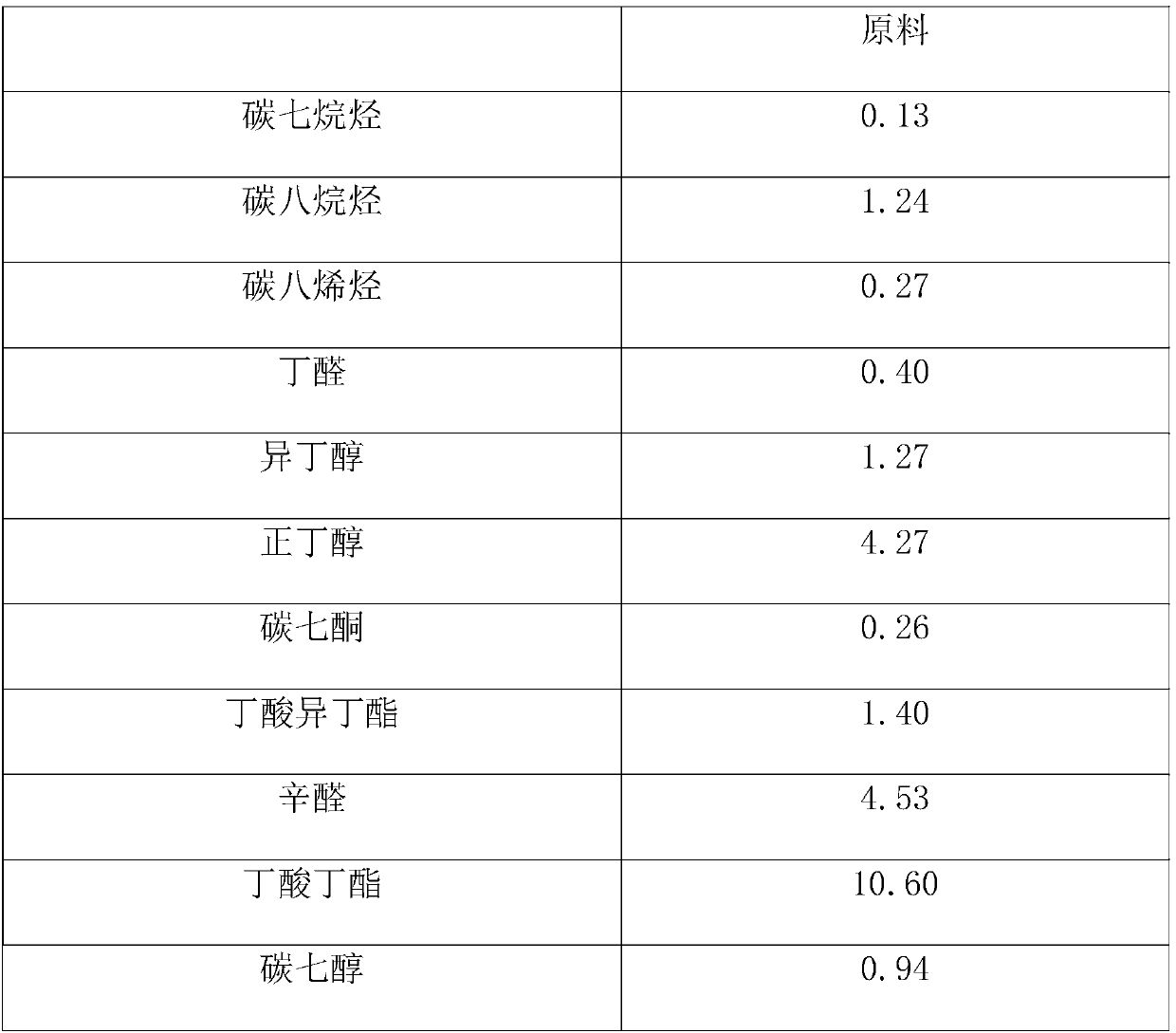

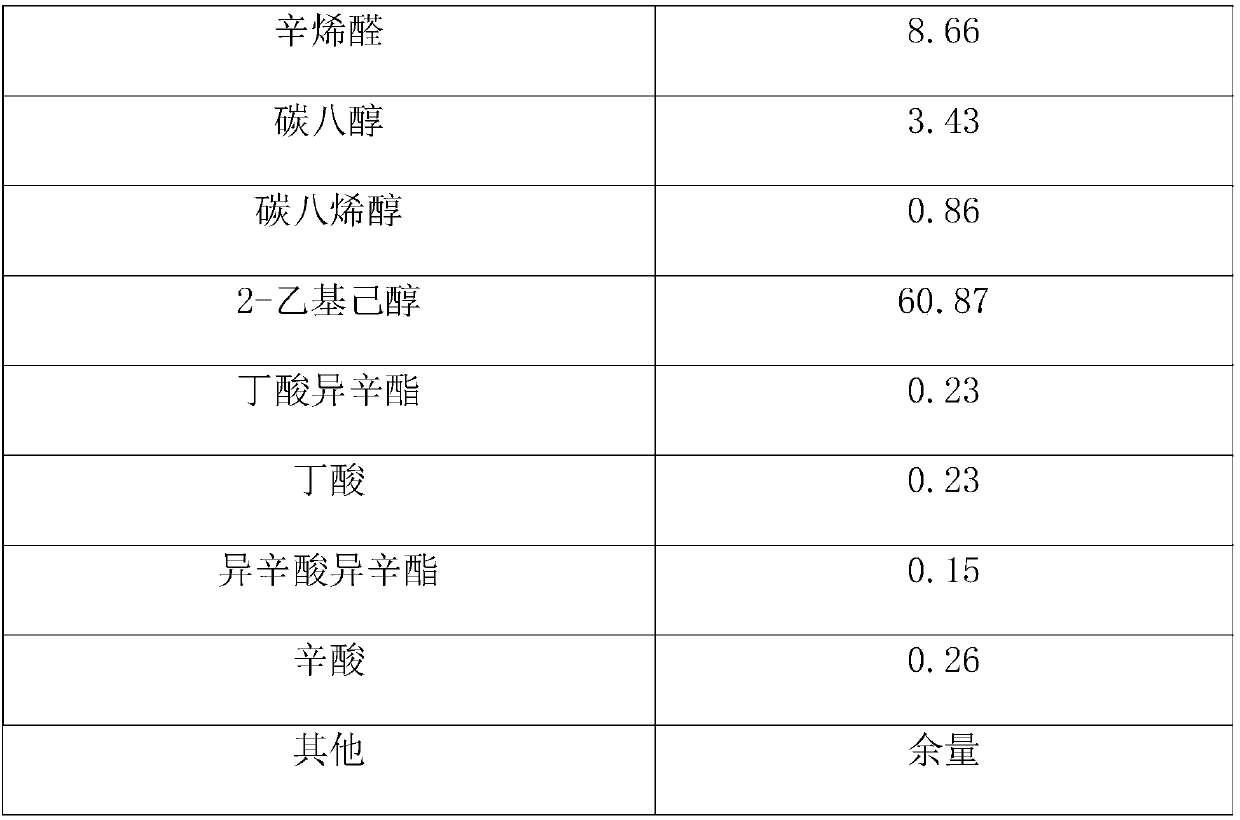

Separation method for pyrolysis and hydrogenation of butanol and octanol waste liquid

ActiveCN106187693BIncrease profitImprove stabilityOrganic compound preparationPreparation by hydrogenationAlcoholEconomic benefits

The invention discloses a separation method integrating splitting and hydrogenation for butanol and octanol waste liquid, and belongs to the technical field of butanol and octanol. In order to solve the problem that in the prior art, the utilization rate of raw materials of the butanol and octanol waste liquid is not high or the service life of a catalyst is short, the invention provides the method for firstly removing heavy constituents in the butanol and octanol waste liquid, performing reorganizing and splitting on the bottom of a heavy-constituent-removing tower for recycling, and performing mixing and hydrogenation on aldehydes so as to obtain alcohols; and then performing a rectification process so as to obtain high-purity butanol products and high-purity octanol products. The method comprises the specific steps of removing the heavy constituents, performing hydrogenation, performing dehydration, separating butanol products, and extracting octanol products from a lateral line and the like; and therefore, the utilization rate of the butanol and octanol waste liquid is greatly increased, the economic benefits are increased, the complexity of components of materials is also reduced, the difficulty of rectification units can be reduced, and the separation cost is reduced. In addition, in the separation method disclosed by the invention, firstly heavy constituents in C12 and C16 in the butanol and octanol waste liquid are removed, so that the colloid passing through a catalyst bed layer in a reactor is greatly reduced, prolonging of the service life of the catalyst is facilitated, and the stability of a hydrogenation device is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocarbons of carbon nano-tube loaded nickel-stannum and method of manufacturing the same and use thereof

InactiveCN100460068CImprove hydrogen storage performanceExcellent hydrogenation catalytic performanceOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsCarbon nanotubeFine chemical

The invention relates to the technical field of fine chemical products, in particular to a hydrogeneration catalyst of carbon nanotube supported nickel-tin, and a preparation method and an application of the catalyst. The hydrogeneration catalyst essentially comprises nickel, tin and carbon nanotube, wherein, the mass ratio of the three substances is 5-10:1-5:20-80, and the nickel and the tin can be distributed on the surface and in the aperture gap of the carbon nanotube evenly. The catalyst can be used for the synthesis of paraaminophenol through the catalytic hydrogenation of paranitrophenol, the synthesizing process of paraaminophenol is of short flow, large production capability, low labor intensity, high yield, few equipment investment and low comprehensive cost, is environment friendly and energy saving, and realizes the continuous clean production of synthetic paraaminophenol.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Preparation method of C5/C9 hydrocarbon resin

ActiveCN102718925BGood compatibilityExempt from cryogenic conditionsPhysical/chemical process catalystsOligomerBoron trifluoride

Owner:HENGHE MATERIALS & SCI TECH CO LTD

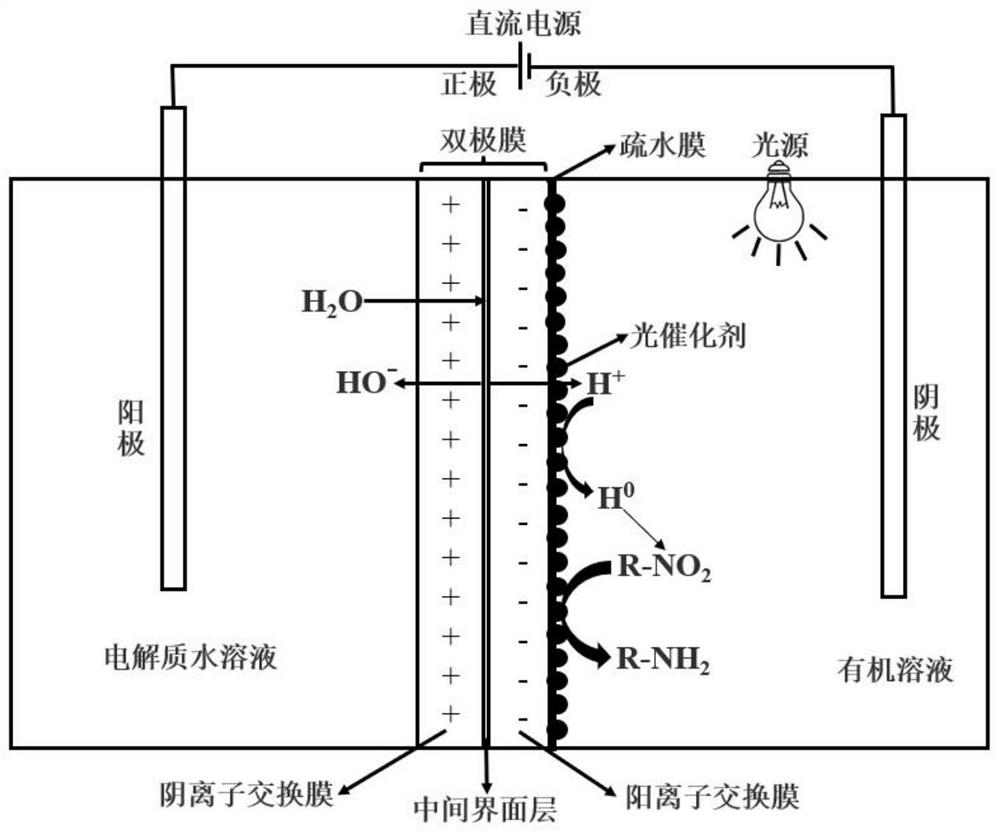

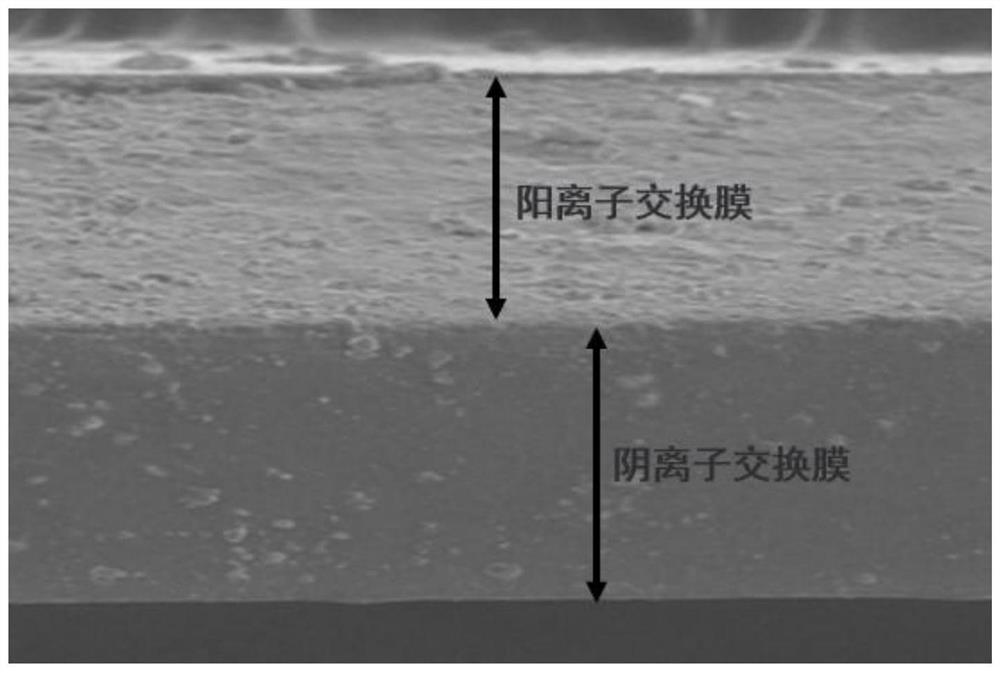

Photoelectrocatalytic hydrogen production and nitro-aromatic in-situ hydrogenation integrated device and application

PendingCN114411169AOvercome deficienciesAddressing Difficult-to-Access Catalyst SurfacesCellsOrganic diaphragmsElectrolyteHydrogen production

The invention belongs to the field of nitro-aromatic hydrogenation, and particularly relates to a photoelectrocatalytic hydrogen production and nitro-aromatic in-situ hydrogenation integrated device and application. In order to solve the problems that in an oil-water mixing system of catalytic hydrogenation reaction of nitro-aromatic hydrocarbon, contact between nitro-aromatic hydrocarbon molecules and H free radicals is difficult, and the rate of the H free radicals generated by photocatalysis is difficult to regulate and control, the invention provides a device containing a photoelectrocatalysis composite membrane. The invention relates to a serial reaction device for realizing photoelectrocatalytic hydrogen production and in-situ nitro-aromatic catalytic hydrogenation reaction. The device comprises a photoelectrocatalysis composite membrane, an anode chamber, a cathode chamber, an anode and a cathode, wherein the anode chamber and the cathode chamber are divided by the photoelectrocatalysis composite membrane. A photoelectrocatalysis composite membrane is used as a diaphragm of an anode chamber and a cathode chamber, an electrolyte aqueous solution is added into the anode chamber, a nitro-aromatic hydrocarbon organic solution is added into the cathode chamber, and a photoelectrocatalysis nitro-aromatic hydrocarbon catalytic hydrogenation reaction is carried out under xenon lamp illumination and external voltage.

Owner:SHANXI UNIV

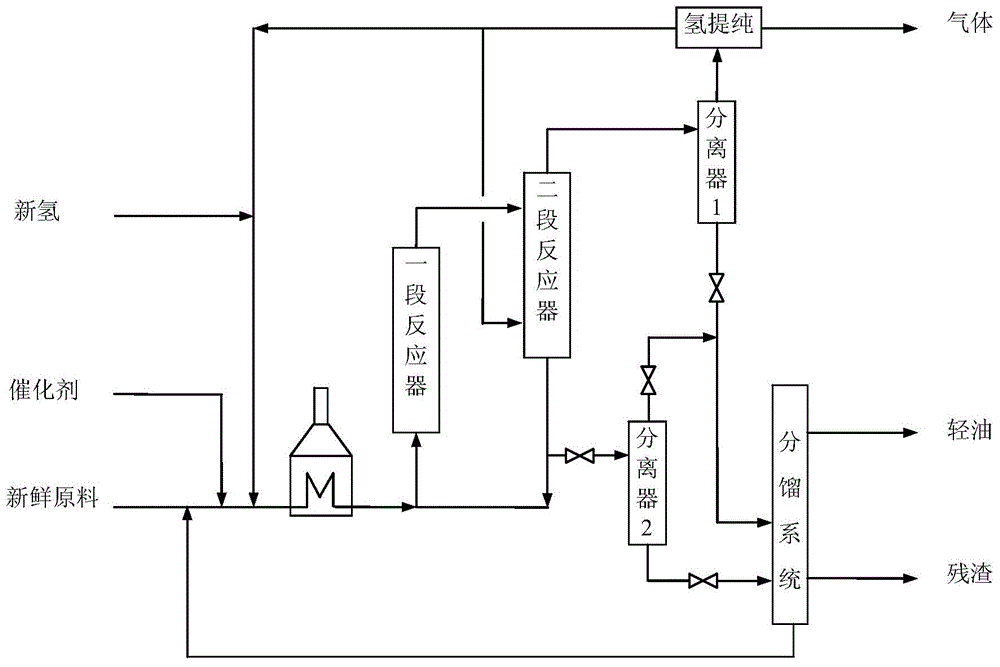

Crude octanol liquid phase hydrogenation catalyst and preparation method thereof

ActiveCN111068684AImprove hydrogenation activityReduce manufacturing costOrganic compound preparationHeterogenous catalyst chemical elementsPtru catalystFixed bed

The invention belongs to the field of hydrogenation, and particularly relates to a catalyst for liquid phase hydrogenation of crude octanol (containing isooctanol, octenol, octenal, other unsaturatedlight components and unsaturated heavy components) through a fixed bed reactor and a preparation method. The catalyst provided by the invention contains 5-45wt.% of NiO and the balance of SiO2 and Al2O3 as main components, and the mass ratio of Al2O3 to SiO2 is 1.35-2.5 (mass ratio); wherein more than 95% of pores in the catalyst are mesopores, pores of 6-8nm are mainly used, and the specific porevolume of the catalyst is more than or equal to 0.42 cm < 3 > / g. The catalyst has a proper pore structure, is beneficial to hydrogenation reaction of aldehydes, and is wide in range of adapting to process conditions and high in hydrogenation activity; according to the preparation method, the preparation cost of the catalyst is greatly reduced, an effective way is found for comprehensive utilization of a waste catalytic cracking catalyst, and good economic benefits and social benefits are achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking method for heavy oil

ActiveCN104403686AHigh volume loadIncreased purity and hydrogen partial pressureTreatment with hydrotreatment processesCounter currentChemistry

The invention relates to a hydrocracking method for heavy oil. The method comprises the following steps that the heavy oil, hydrogen and a catalyst enter a first reaction zone, the mixture flow of the heavy oil, the hydrogen and the catalyst flows upwards in the first reaction zone and reacts under the condition of hydrocracking on a suspended bed; after the mixture flow flows out of the first reaction zone, the mixture flow is divided into gas phase flow and liquid phase flow by gas-liquid separation; the liquid phase flow enters a second reaction zone, flows downwards and is in counter-current contact and reacts with the nitrogen flowing upwards under the condition of hydrocracking on the suspended bed; after the liquid phase flow flows out of the second reaction zone, part or all of the liquid phase flow enters a separation system to carry out product separation. According to the hydrocracking method for the heavy oil, not only can the separation rate of the gas in the reactor be reduced, but also a hydrocracking effect of the heavy oil can be further improved.

Owner:BLOOMING BEIJING TECH

Hydrogenation method of heavy hydrocarbon multi-segment fluidized bed

ActiveCN101724453BReduce heat loadSave heatHydrocarbon oil crackingTreatment with hydrotreatment processesGas phaseHydrodesulfurization

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method for homopolymer or copolymer of cyclohexyl ethylene and catalyst

Owner:EAST CHINA UNIV OF SCI & TECH

A kind of preparation method of synthesizing methyl isobutyl ketone and methyl isobutyl alcohol

ActiveCN105732305BHydrogenation promotionHigh yieldOxygen-containing compound preparationOrganic compound preparationHydrogenMethyl isobutyl ketone

The invention discloses a preparation method for synthesis of methyl isobutyl ketone and methyl isobutyl alcohol. The acetone and hydrogen are used as raw materials to synthesize methyl isobutyl ketone and methyl isobutyl alcohol at the reaction temperature of 150-250 DEG C; in the reaction process, Pd / MyOx is used as a catalyst at atmospheric pressure state, the mole ratio of the hydrogen to the acetone is 50:1 to 3: 1, and the volume velocity of the hydrogen is 800-10000h<-1>; the Pd / MyOx is that the amphoteric metal oxide MyOx with baking temperature not higher than 600 DEG C is used as a carrier to load the Pd, x and y in the MyOx are respectively 1, 2 or 3, and M is selected from polyvalent metal in IVB-VIIB family elements, and is in corresponding high valence in the MyOx. The method is applied to the atmospheric pressure gas phase reaction for synthesizing methyl isobutyl ketone and methyl isobutyl alcohol through acetone hydrogenation, the highest conversion rate of the acetone can achieve 62.6%, the highest selectivity of the methyl isobutyl ketone and methyl isobutyl alcohol can achieve 93.2%, and the methyl isobutyl alcohol accounts for 1 / 3. Compared with the similar catalyst, the catalyst disclosed by the invention is not only simple in preparation method and low in cost, but also obviously improves the selectivity of the methyl isobutyl ketone and methyl isobutyl alcohol.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com