A kind of preparation method of synthesizing methyl isobutyl ketone and methyl isobutyl alcohol

A technology for methyl isobutyl alcohol and methyl isobutyl ketone is applied in the field of synthesizing methyl isobutyl ketone and methyl isobutyl alcohol, and can solve the problems of poor thermal stability, short process and low energy consumption and other problems, to achieve the effect of promoting hydrogenation, high reaction efficiency and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1) TiO 2 Powder preparation

[0020] At room temperature, mix 10mL of tetra-n-butyl titanate and 35mL of absolute ethanol in a closed flat-bottomed three-necked flask, stir vigorously for 30 minutes, then take 20mL of glacial acetic acid, 1mL of absolute ethanol, and 0.2mL of distilled water, mix well, and add to the above mixture In the solution, stir vigorously for 1h. At this time, a clear and transparent golden yellow solution was obtained. This solution was evaporated to dryness at about 100°C, and solid powder was precipitated, and then calcined at 500°C for 3h to obtain TiO 2 powder.

[0021] 2)Pd / TiO 2 (Pd loading 0.1wt%) preparation

[0022] Add 5g of the TiO obtained in 1) 2 The powder is immersed in 7.5mL of 0.01mol / L H 2 PdCl 4 In the solution, ultrasonic for 0.5h, after drying at 110°C, roasting at 350°C for 3h, then reducing with potassium borohydride for 0.5h, washing, suction filtration, and finally vacuum drying at 50°C in a vacuum drying oven to obtain Pd / T...

Embodiment 2

[0024] 1)Pd / V 2 O 5 (Pd loading 0.1wt%) preparation

[0025] Dip 5.0g of commercial vanadium pentoxide powder in 7.5mL of 0.01mol / L H 2 PdCl 4 In the solution, ultrasonic for 0.5h, after drying at 110°C, roasting at 350°C for 3h, then reducing with potassium borohydride for 0.5h, washing, suction filtration, and finally vacuum drying at 50°C in a vacuum drying oven to obtain Pd / V 2 O 5 (Pd loading 0.1wt%).

[0026] 2)Pd / V 2 O 5 The catalyst is applied to the hydrogenation of acetone to prepare methyl isobutyl ketone and methyl isobutyl alcohol

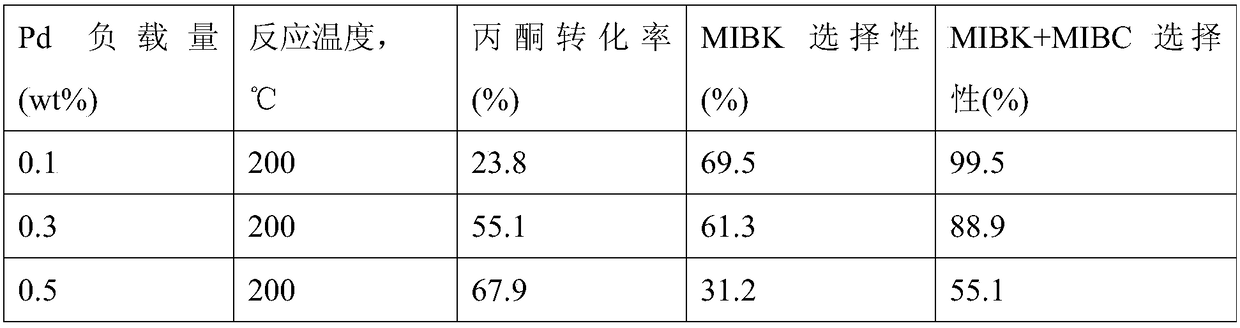

[0027] Using hydrogen with a flow rate of 15mL / min to carry acetone at 5°C, add the Pd / V prepared in Example 2 2 O 5 The catalyst reacts in a quartz reaction tube with an inner diameter of 8 mm. The reaction temperature is 200°C. Absorb all reaction products with absolute ethanol at 5°C. After collecting for 2 hours, Shimadzu GC-2010 gas chromatograph was used to analyze the product composition. The conversion of acetone and the selectivi...

Embodiment 3

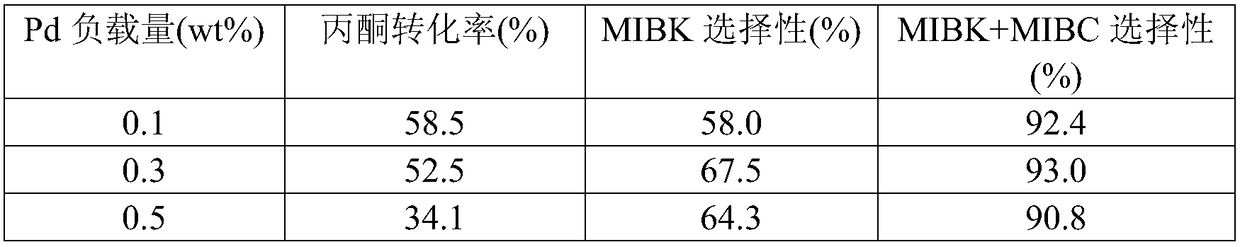

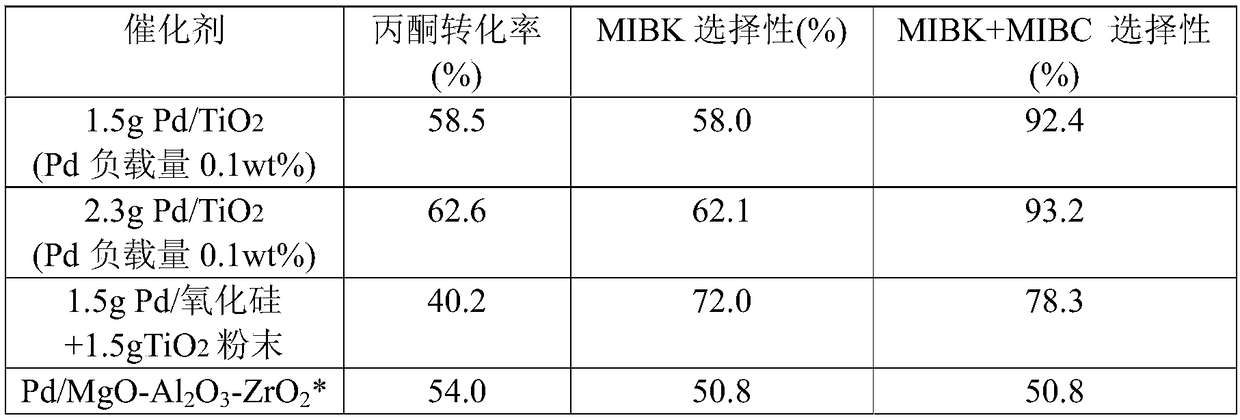

[0032] Pd / TiO 2 The catalyst is applied to the hydrogenation of acetone to prepare methyl isobutyl ketone and methyl isobutyl alcohol

[0033] Using hydrogen with a flow rate of 15 mL / min to carry acetone at 5°C, add the Pd / TiO prepared in Example 1 2 The catalyst reacts in a quartz reaction tube with an inner diameter of 8 mm. The reaction temperature is 200°C. Absorb all reaction products with absolute ethanol at 5°C. After collecting for 2 hours, Shimadzu GC-2010 gas chromatograph was used to analyze the product composition. Table 2 and Table 3 show the conversion rate of acetone and the selectivity of methyl isobutyl ketone and methyl isobutyl alcohol for different Pd loadings and different catalysts.

[0034] Table 2 Pd loading amount versus Pd / TiO 2 Effect of Catalytic Performance of Acetone One-Step Synthesis of MIBK and MIBC

[0035]

[0036] It can be seen from Table 2 that Pd / TiO 2 The catalyst can convert acetone and hydrogen into methyl isobutyl ketone and methyl isobu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com