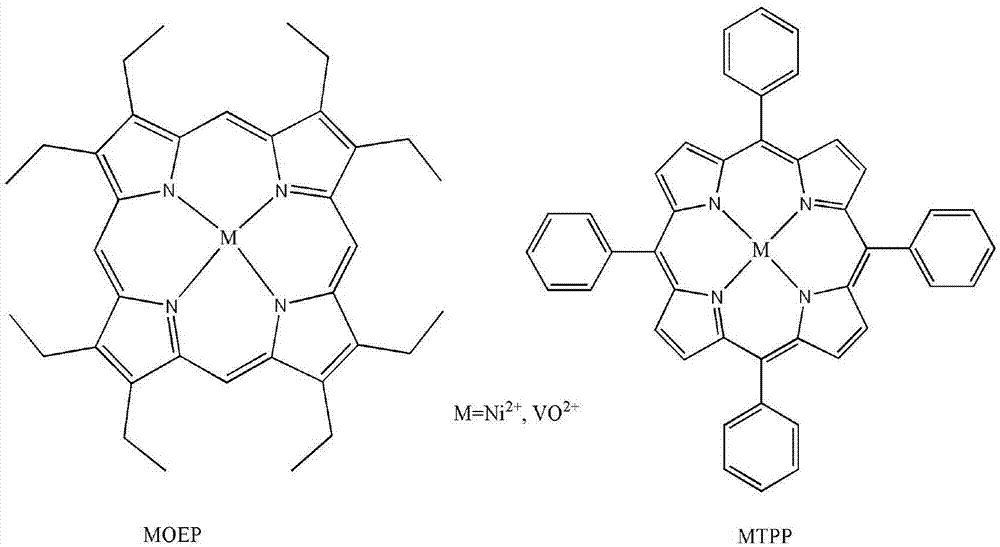

A method for hydrogenation of polycyclic aromatic hydrocarbons catalyzed by primary metalloporphyrins of heavy oil

A technology of porphyrin catalyzing polycyclic aromatic hydrocarbons and primary metals, which is applied in the field of thermal upgrading of heavy oil, and achieves the effects of mild and easy-to-control reaction conditions, short reaction time and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

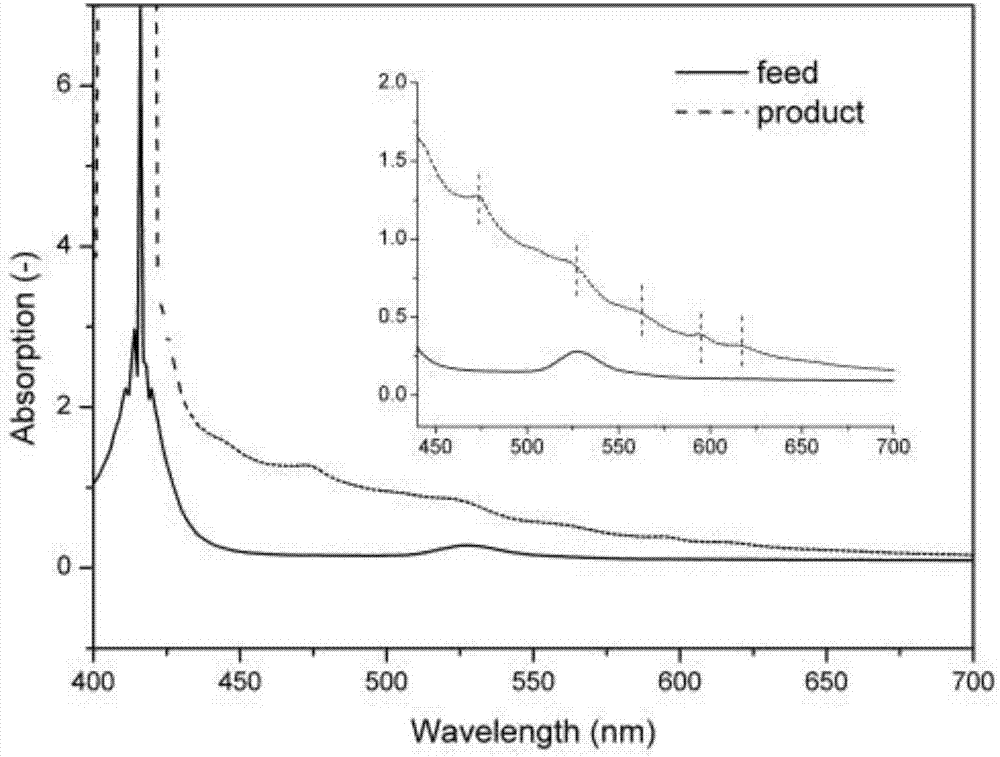

Method used

Image

Examples

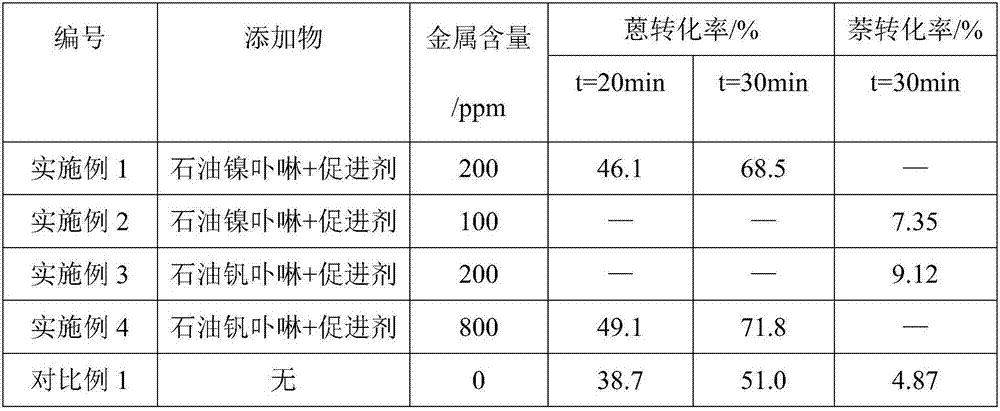

Embodiment 1

[0024] Adopt acetonitrile extraction, silica gel column chromatographic separation and purification to obtain the petroleum nickel porphyrin in the heavy atmospheric residue (Ni content is 68ppm, V content is 1.7ppm), after anthracene and petroleum nickel porphyrin are dissolved with dichloromethane, carry out homogenization Mixed, heated to reflux (treatment temperature is 60° C., treatment time is 0.5 h), evaporated the solvent and vacuum dried for 1 h to obtain the reaction raw material. Wherein, the addition ratio of anthracene and petroleum nickel porphyrin is determined by the nickel content (taking the nickel content as 200ppm) in the reaction raw material, and the specific mathematical relationship is as follows:

[0025] For petroleum nickel porphyrin components, but

[0026] where w Me For the content of metal nickel in the reaction raw material, the unit is ppm; w Me ' is the content of metal nickel in the petroleum nickel porphyrin component, in ppm; m PP an...

Embodiment 2

[0029] Adopt same petroleum nickel porphyrin in embodiment 1, naphthalene and petroleum nickel porphyrin are according to the standard of nickel content 100ppm, adopt the same mixing method among the embodiment 1 to obtain reaction raw material, get 0.1g raw material and add 0.05g carbon disulfide again at 460 ℃, 20MPa and hydrogen reaction for 30min. The results of naphthalene hydrogenation are listed in Table 1.

Embodiment 3

[0031] Adopt acetonitrile extraction, silica gel column chromatographic separation and purification to obtain the petroleum vanadium porphyrin in the heavy atmospheric residue (Ni content is 68ppm, V content is 1.7ppm) used in embodiment 1, with naphthalene and petroleum vanadium porphyrin by vanadium content 200ppm The standard, using the same mixing method in Example 1 to obtain the reaction raw materials, take 0.1g of raw materials and then add 0.005g of sulfur elemental hydrogen reaction at 400 ℃, 20MPa for 30min. The results of naphthalene hydrogenation are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com