Heavy oil slurry bed hydrogenation method

A suspended bed, heavy oil technology, applied in the fields of hydrocarbon oil cracking, petroleum industry, etc., can solve the problems of poor coke suppression effect, large particles, uneven catalyst dispersion, etc., and achieve the effect of suppressing the formation of coke and increasing the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A certain amount of concentration is 9.2% (according to the metal weight in the catalyst) aqueous solution of nickel phosphomolybdate directly added in the heavy oil raw material, then adopts the mode of magnetic stirring, the catalyst is dispersed in the heavy oil raw material (main properties are shown in Table 1); Part concentration is 9.2% (according to the metal weight calculation in the catalyst) the aqueous solution of nickel phosphomolybdate and surfactant Tween-85 and co-surfactant n-hexanol are fully mixed and then added in the above-mentioned heavy oil raw material, adopt high shear Cut the stirring method to evenly disperse the catalyst aqueous solution in the heavy oil raw material, and then mix the obtained mixed raw material with hydrogen into a high-temperature and high-pressure reactor for hydrogenation reaction. After the reaction, the product is distilled under normal pressure to obtain gasoline fraction, diesel fraction and hydrogenation tail oil , wh...

Embodiment 2~4

[0029] According to the process described in Example 1, using the conditions described in Table 4, the reaction results are shown in Table 5.

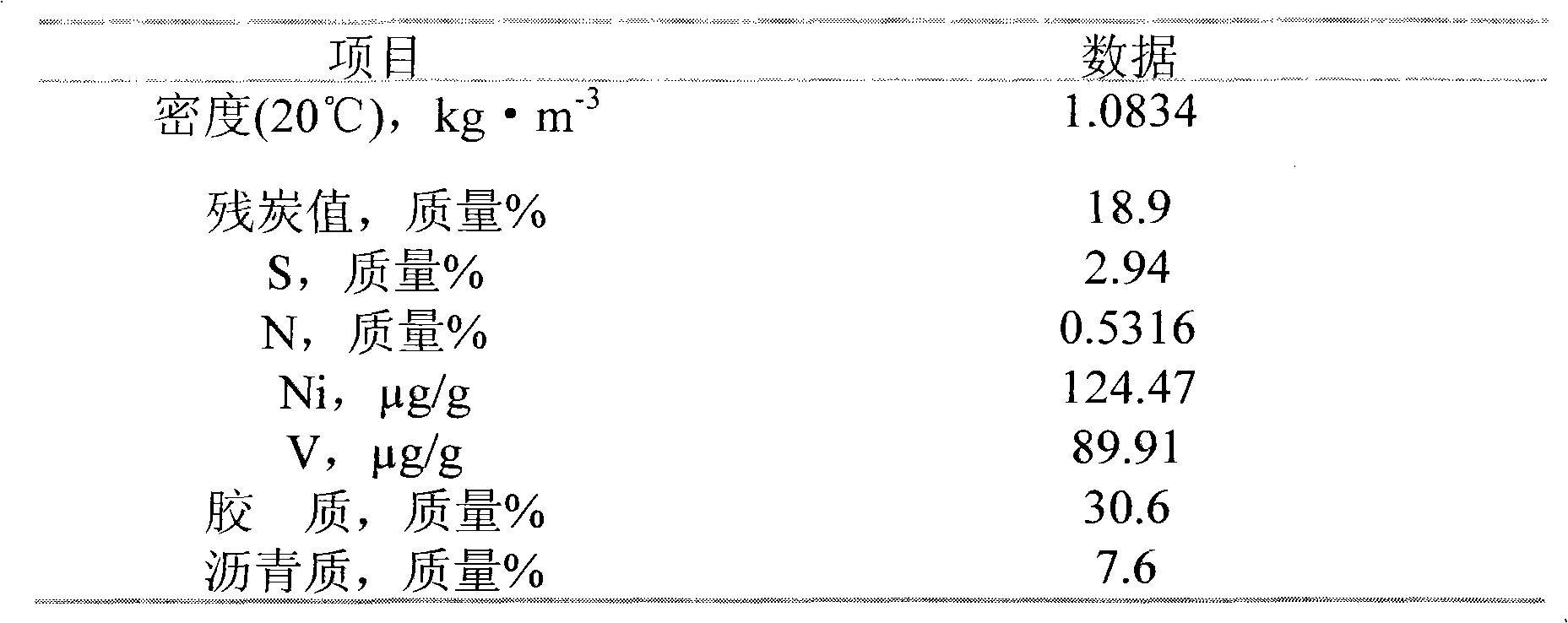

[0030] Table 1 Properties of heavy oil raw materials

[0031]

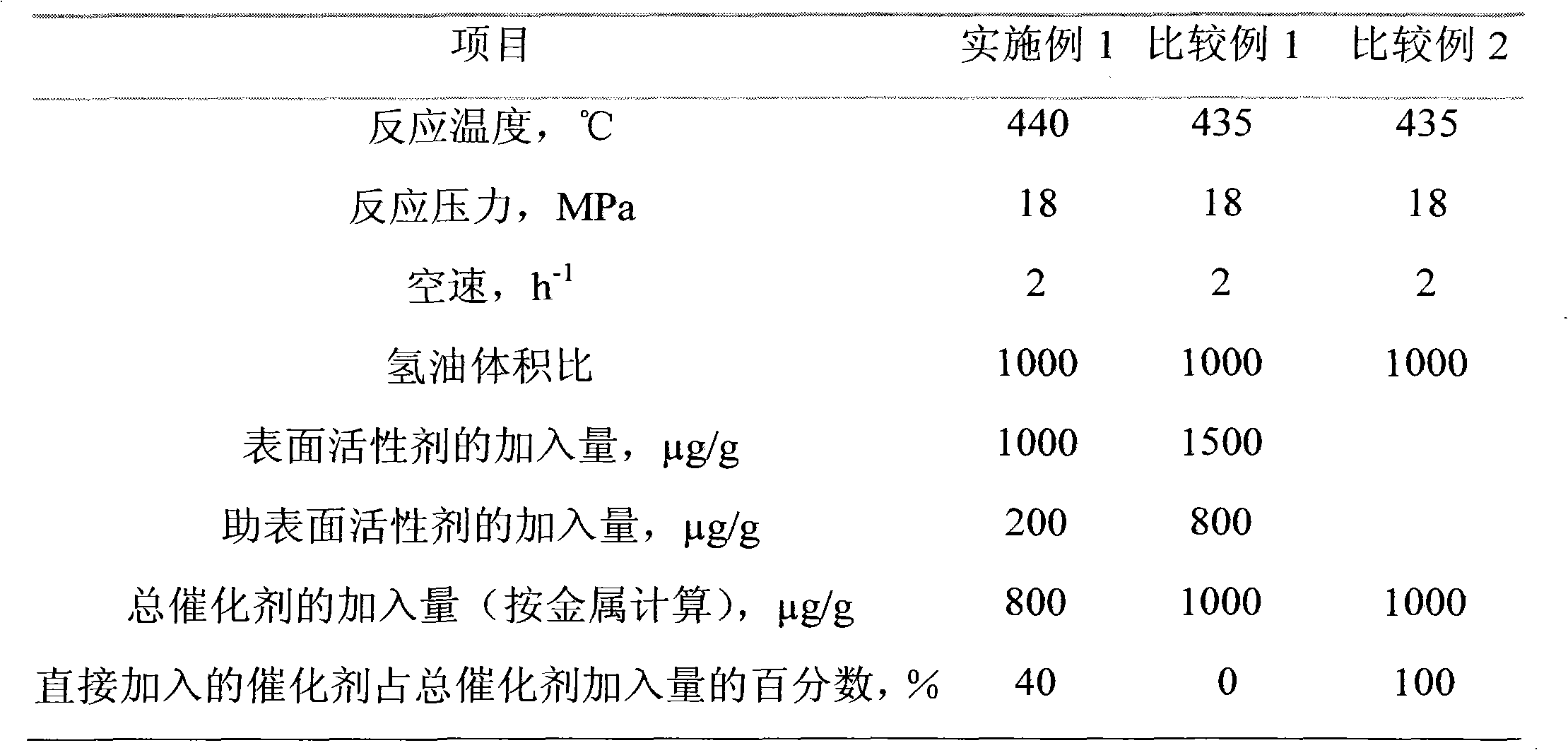

[0032] Table 2 Embodiment 1 and comparative example operating conditions

[0033]

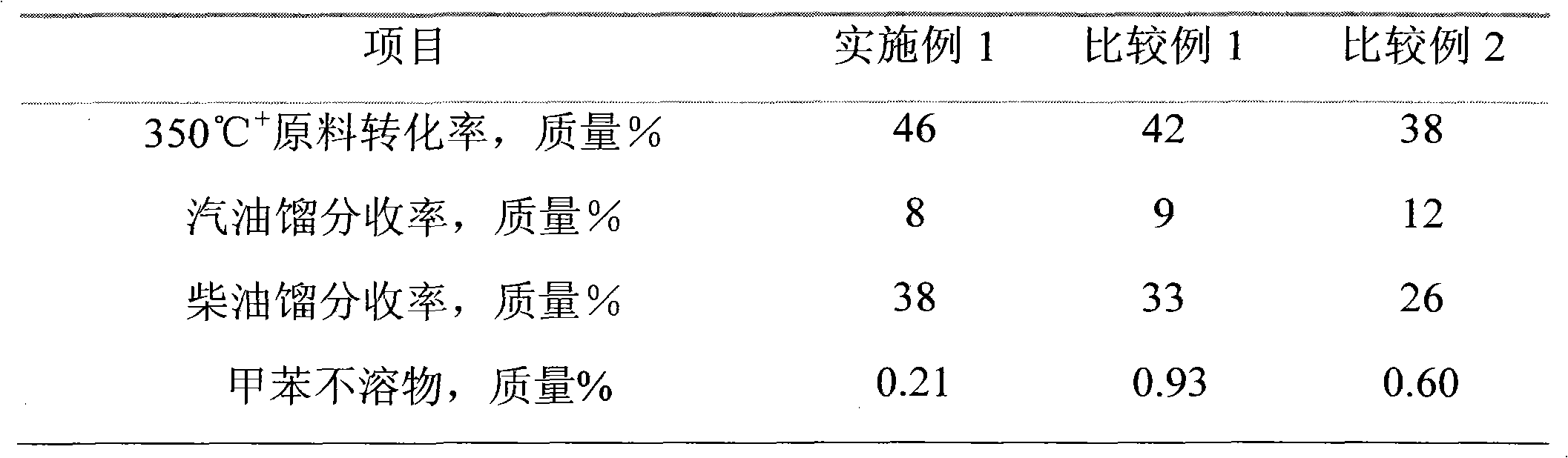

[0034] Table 3 embodiment 1 and comparative example test result

[0035]

[0036] Table 4 Embodiment 2~4 operating conditions

[0037]

[0038] Table 5 Example 2~4 test results

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com