Method using hydrogen donor for thermal conversion processing of greasy filth

A technology of thermal conversion and hydrogen supply agent, which is applied in the direction of pyrolysis treatment of sludge, etc., can solve the problems of waste of petroleum resources, pollution of water bodies and vegetation, acidification or alkalization, etc., achieve good flexibility, reduce coke production, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

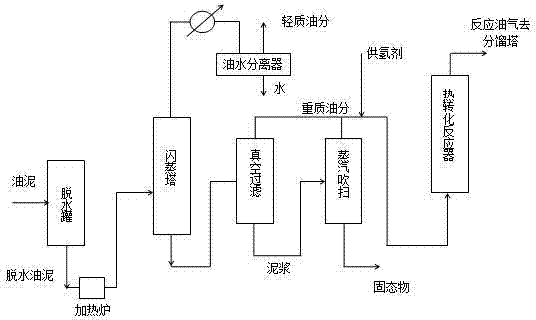

[0025] Take the sludge at the bottom of a refinery oil tank as an example to illustrate this embodiment, the process flow is as follows figure 1 shown. Oil sludge contains 75% oil, 14% water, and the rest is solid matter.

[0026] After the oil sludge is dehydrated by mechanical stirring, it is heated to 250°C under anaerobic conditions and sent to the flash tower for flash evaporation. Water vapor and light hydrocarbon vapor are obtained at the top of the tower, which are condensed and separated by an oil-water separator to obtain light oil, and the sewage enters the sewage treatment system. The bottom of the flash tower is mud mixed with heavy oil and solids. Filter the mud to obtain heavy oil and solid matter; at 400°C, use N 2 Sweep solids to carry oil and gas out of them. The pressure of purging is controlled at 0.2MPa.

[0027] Heavy oil is recovered, and tetralin is added for mixing, and the blending ratio of tetralin is 5%. The heavy oil mixed with tetralin is he...

Embodiment 2

[0030] Take the sludge at the bottom of a refinery oil tank as an example to illustrate this embodiment, the main process flow is as follows figure 1 shown. Oil sludge contains 67% oil, 23% water, and the rest is solid matter.

[0031] In this example, catalytic cracking oil slurry is used as the hydrogen donor, and the ratio of the hydrogen donor is 10%. The reaction temperature of the thermal conversion reactor is 450° C., and the reaction time is 120 minutes.

[0032] After the oil sludge undergoes thermal conversion reaction, the gas yield is 12%, the fraction yield at 350°C is 42%, and the coke yield is 4%. . (The yield of each component is based on the oil content in the sludge).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com