mgfe hydrotalcite-based catalyst and its application in suspended bed hydrodeoxygenation to produce biodiesel

A biodiesel, hydrodeoxygenation technology, applied in catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of high cetane number and production process of biodiesel Complex, low freezing point and other problems, to achieve the effects of low cost, high yield, green and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

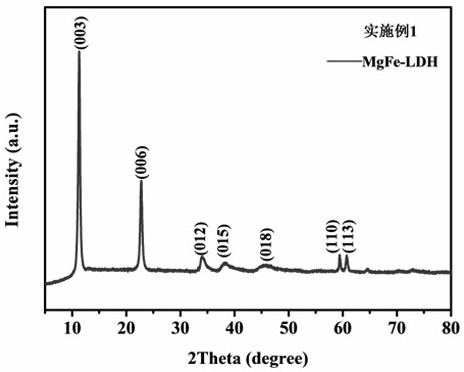

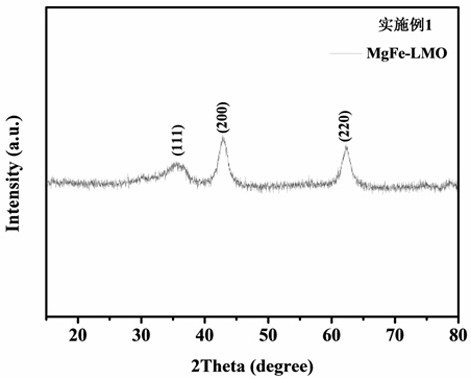

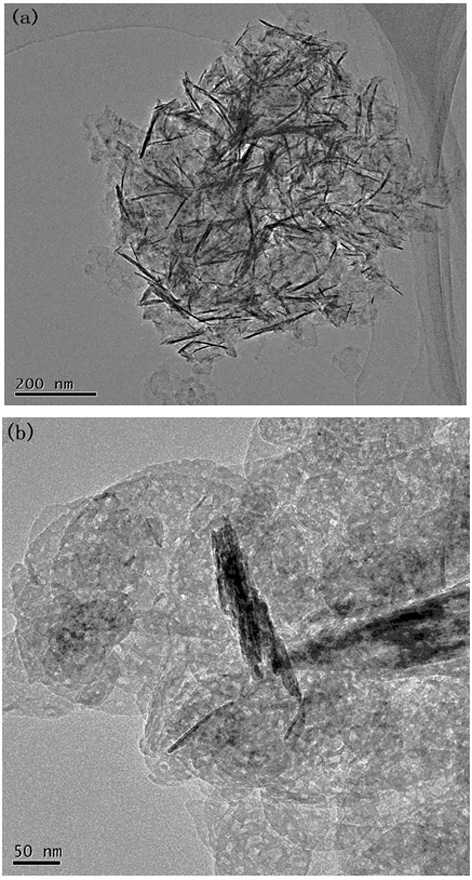

Embodiment 1

[0032] 0.03 mol MgCl 2 •6H 2 O and 0.01 mol FeCl 3 •6H 2 O was dissolved in 100 ml deionized water to form a 0.4mol / L A solution, and 0.08 mol NaOH, 0.005 mol NaOH 2 CO 3 Add to 80 ml of deionized water to obtain a 1.0mol / L clear B solution, under the condition of vigorous stirring (800 rpm), slowly add the obtained B solution to the A solution drop by drop to form a uniform suspension, and then Stir vigorously at room temperature for 1 h, then transfer the aged suspension to a stainless steel reactor with a polytetrafluoroethylene liner, statically crystallize at 140 °C for 12 h, take it out and cool to room temperature, the obtained The precipitate was filtered and washed, and then dried in an oven at 120 °C to constant weight to obtain the precursor of binary magnesium-iron hydrotalcite, and finally the obtained binary magnesium-iron hydrotalcite precursor was placed in a muffle furnace and calcined at 500 °C for 6 h to obtain a layered porous magnesium-iron hydrotalci...

Embodiment 2

[0035] 0.027 mol MgCl 2 •6H 2 O and 0.013 mol FeCl 3 •6H 2 O was dissolved in 100 ml deionized water to form a 0.4mol / L A solution, and 0.08 mol NaOH, 0.0067 mol Na 2 CO 3 Add to 80 ml of deionized water to obtain a 1.0mol / L clear B solution, under the condition of vigorous stirring (800 rpm), slowly add the obtained B solution to the A solution drop by drop to form a uniform suspension, and then Stir vigorously at room temperature for 1 h, then transfer the aged suspension to a stainless steel reactor with a polytetrafluoroethylene liner, statically crystallize at 140 °C for 12 h, take it out and cool to room temperature, The resulting precipitate was filtered and washed, and dried in an oven at 120 °C to constant weight to obtain a binary magnesium-iron hydrotalcite precursor. Finally, the obtained binary magnesium-iron hydrotalcite precursor was placed in a muffle furnace and calcined at 500 °C After 6 h, the layered porous magnesium-iron hydrotalcite-based catalyst wa...

Embodiment 3

[0038] 0.02 mol MgCl 2 •6H 2 O and 0.02 mol FeCl 3 •6H 2 O was dissolved in 100 ml deionized water to form a 0.4mol / L A solution, and 0.08 mol NaOH, 0.01 mol NaOH 2 CO 3 Add to 80 ml of deionized water to obtain a 1.0mol / L clear B solution, under the condition of vigorous stirring (800 rpm), slowly add the obtained B solution to the A solution drop by drop to form a uniform suspension, and then Stir vigorously at room temperature for 1 h, then transfer the aged suspension to a stainless steel reactor with a polytetrafluoroethylene liner, statically crystallize at 140 °C for 12 h, take it out and cool to room temperature, the obtained The precipitate was filtered and washed, and then dried in an oven at 120 °C to constant weight to obtain the precursor of binary magnesium-iron hydrotalcite, and finally the obtained binary magnesium-iron hydrotalcite precursor was placed in a muffle furnace and calcined at 500 °C for 6 h to obtain a layered porous magnesium-iron hydrotalcit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com