Hydrogenation method of heavy hydrocarbon multi-segment fluidized bed

A fluidized bed, heavy hydrocarbon technology, applied in hydrotreating process, hydrocarbon oil cracking, treatment of hydrocarbon oil, etc. Hydrodenitrogenation and hydrogen partial pressure, etc., to achieve the effect of optimizing the overall operating conditions, high-quality product quality, and ensuring the operation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

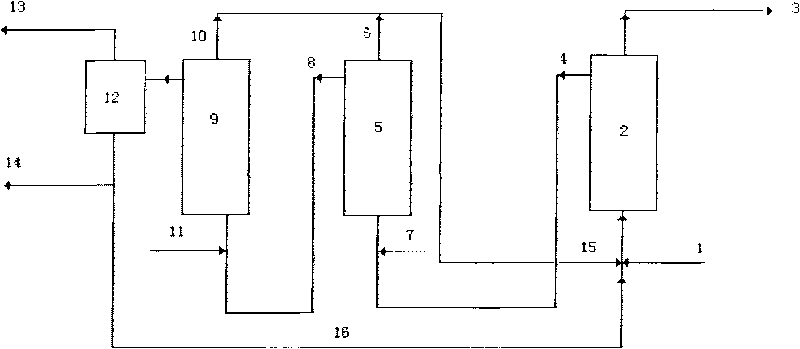

[0032] This embodiment is a kind of implementation scheme of fluidized bed processing technology, and the schematic diagram of operation flow chart refers to the appended figure 1 .

[0033] The process is as follows: the raw material heated to 360°C by the heating furnace (about 40°C lower than the heating temperature required by the traditional process) is mixed with the 440°C hydrodesulfurization and hydrodenitrogenation reaction gas in the pipeline 15, The above flow pattern enters the ebullated bed hydrodemetallization reactor 2 for hydrodemetallization reaction, wherein the reaction conditions are shown in Table 2. The gas-liquid streams after the reaction flow out from the reactor respectively, and the hydrogen-rich gas obtained after the gas phase stream is cooled and purified through the pipeline 3 is recycled, and the condensed liquid enters the atmospheric and vacuum distillation device to obtain gasoline and diesel fractions; the liquid phase stream passes through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com