Copper-based catalyst for neopentylene glycol preparation from hydrogenation method and preparation method thereof

A technology of copper-based catalyst and neopentyl glycol, which is applied in the field of catalysts, can solve the problems of difficult continuous and large-scale production, fast deactivation, and high production costs, and achieve the effects of reducing pollution, stable properties, and cheap prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

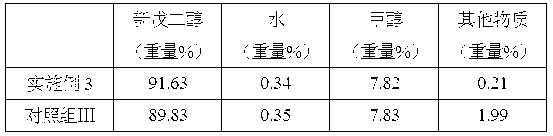

Examples

Embodiment 1

[0012] This embodiment includes the following steps:

[0013] Step 1: Prepare copper hydroxide precipitate by co-precipitation method, prepare 0.05mol / L copper sulfate solution, and prepare 0.1mol / L sodium hydroxide solution at the same time, add copper sulfate solution and refined diatomite (average average) to the reactor. The particle size is 2 μm), the mass ratio of purified diatomite and copper sulfate is 35:130, stirring at a temperature of 35 ° C, then adding the prepared sodium hydroxide solution, adjusting the pH value to 8, stirring for 3 hours, The stirring speed is 200r / min; the reaction equation is:

[0014]

[0015] In step 2, the solution obtained in step 1 is filtered through a plate and frame filter press to make a filter cake, and the filter cake is washed and filtered twice with water, and then under the environmental conditions of good illumination, temperature -5 ° C, and relative humidity of 10% , dry for 1 day, and then send it to the feeder after dr...

Embodiment 2

[0024] Step 1: Prepare copper hydroxide precipitate by co-precipitation method, prepare 0.1 mol / L copper sulfate solution, and prepare 0.1 mol / L sodium hydroxide solution at the same time, first add copper sulfate solution and copper sulfate solution with an average particle size of 2 μm to the reactor. Refined diatomite, the mass ratio of purified diatomite and copper sulfate is 28:144, stir at 37 ° C temperature, then add the prepared sodium hydroxide solution, adjust the pH value to 9, stir for 4 hours, stir The speed is 300r / min; its reaction equation is:

[0025]

[0026] In step 2, the solution obtained in step 1 is filtered through a plate and frame filter press to make a filter cake, and the filter cake is washed and filtered with water for 3 times and then under the environmental conditions of good illumination, temperature of 37 ° C and relative humidity of 60%, Dry for 1 day, and then send it to the feeder after drying, and then use the feeder to transport it int...

Embodiment 3

[0035] Step 1: Prepare copper hydroxide precipitate by co-precipitation method, prepare 0.1mol / L copper sulfate solution, and simultaneously prepare 0.1mol / L sodium hydroxide solution, first add copper sulfate solution and refined diatomite (average) to the reactor. The particle size is 2 μm), the mass ratio of purified diatomite and copper sulfate is 20:160, stirring at a temperature of 40 ° C, then adding the prepared sodium hydroxide solution, adjusting the pH value to 10, stirring for 4 hours, The stirring speed is 350r / min; its reaction equation is:

[0036]

[0037] In step 2, the solution obtained in step 1 is filtered through a plate and frame filter press to make a filter cake, and the filter cake is washed and filtered with water for 3 times and then under the environmental conditions of good illumination, temperature of 20 ° C and relative humidity of 30%, Dry for 1 day, and then send it to the feeder after drying, and then use the feeder to transport it into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com