Photoelectrocatalytic hydrogen production and nitro-aromatic in-situ hydrogenation integrated device and application

A technology of photoelectric catalysis and nitroaromatics, which is applied in electrodes, electrolytic components, electrolytic processes, etc., can solve the problems of difficult contact between nitroaromatic molecules and H radicals, and the difficulty in regulating the rate of H radicals, so as to improve the efficiency of photoelectric catalysis , promote effective separation, and promote the effect of directional migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

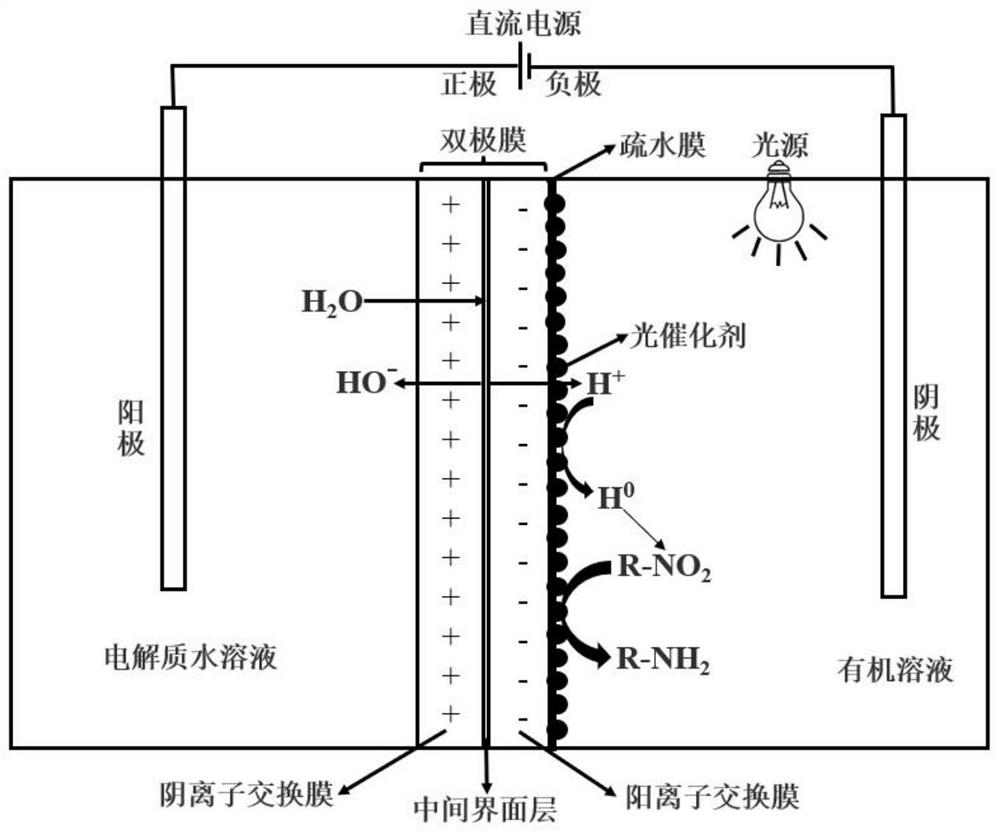

[0029] like figure 1 As shown, an integrated device for photoelectric catalytic hydrogen production and in-situ hydrogenation of nitroaromatics, including a reactor, a photoelectric catalytic composite membrane, a cathode, an anode, a light source and a DC power supply; the photoelectric catalytic composite membrane is set in the reactor , the reactor is divided into an anode chamber and a cathode chamber, the cathode and anode are respectively arranged in the cathode chamber and the anode chamber, the positive pole and the negative pole of the DC power supply are respectively connected with the anode and the cathode, and the light source is arranged above the cathode chamber ;

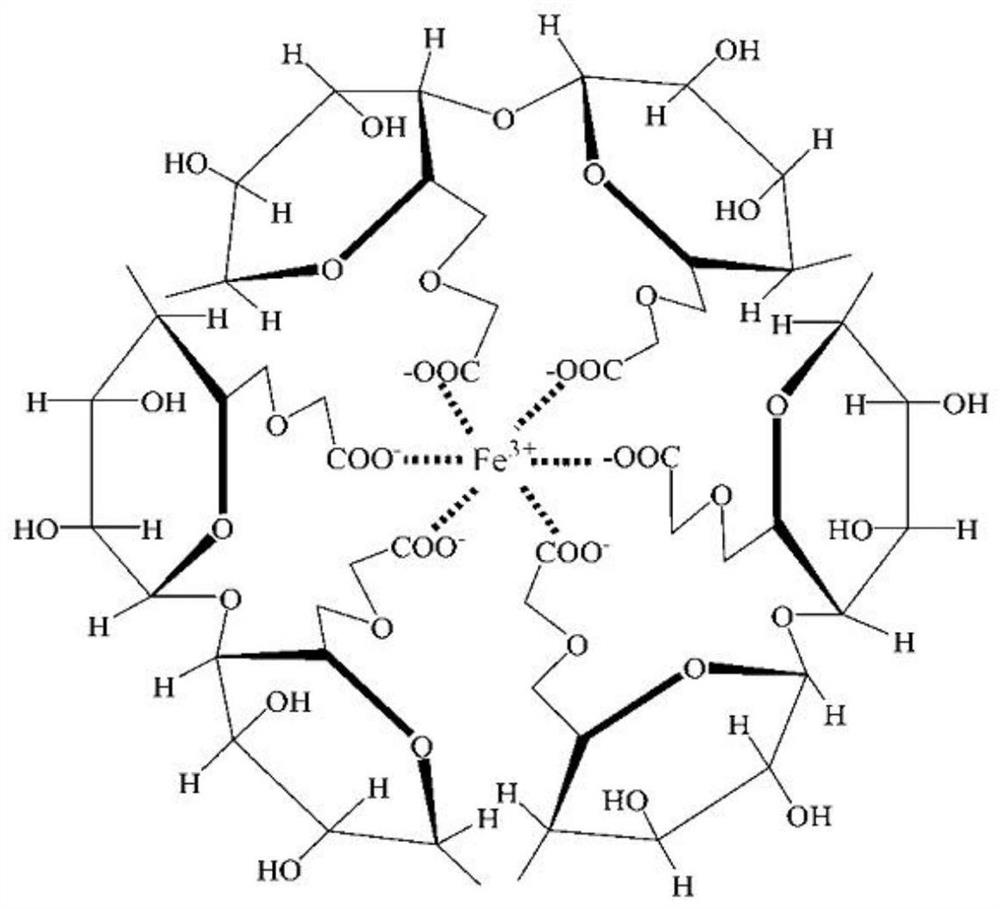

[0030] The photoelectrocatalytic composite membrane is composed of a bipolar membrane and a hydrophobic membrane loaded with a photocatalyst on the surface, the bipolar membrane is composed of an anion exchange membrane and a cation exchange membrane, the anode chamber is an aqueous electrolyte soluti...

Embodiment 2

[0040] Different from Example 1 is the preparation method of the photocatalytic composite film, the specific steps are as follows:

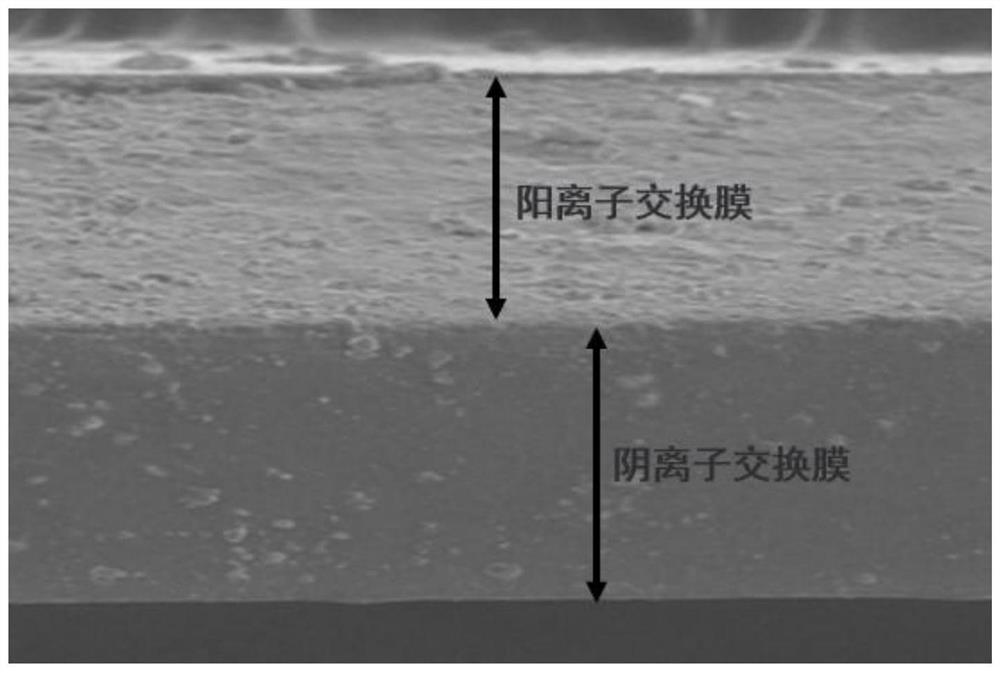

[0041] (1) After mixing polypyrrolidone and quaternary ammonium polysulfone with a mass ratio of 2:1, pour it into a beaker, add an aqueous solution of acetic acid with a mass fraction of 0.02%, stir continuously in a constant temperature water bath at 50°C, and add glutaraldehyde after completely dissolving, Continue to stir for 1 hour, after standing still for defoaming, cast on a flat and clean glass plate with a frame, put it into a blast drying oven to dry, and obtain an anion exchange membrane;

[0042] (2) Mix polyvinylpyrrolidone and phosphocellulose with equal mass and pour it into a beaker, add deionized water under stirring, heat to 60°C to dissolve, and add CaCl after it is completely dissolved 2 Solution, continue to stir for 1h, after static defoaming, cast on the surface of the anion exchange membrane prepared above to obtain a cat...

Embodiment 3

[0046] Different from Example 1 is the preparation method of the photocatalytic composite film, the specific steps are as follows:

[0047] (1) Mix polyphenylene ether and polyimide with a mass ratio of 3:1 and pour them into a beaker, add acetic acid aqueous solution with a mass fraction of 0.03%, stir continuously in a constant temperature water bath at 60°C, and add pentane after completely dissolving Dialdehyde, continue to stir for 1.5h, after static degassing, cast on a flat and clean glass plate with a frame, put it into a blast drying oven and dry it to obtain an anion exchange membrane;

[0048] (2) Mix polyvinylpyrrolidone and sulfonic acid fibers of equal mass and pour them into a beaker, add deionized water while stirring, heat to 70°C to dissolve, and add CaCl after completely dissolved 2 The solution was continuously stirred for 1 hour, and after standing for defoaming, it was cast on the surface of the anion exchange membrane prepared above to obtain a cation ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com