Preparation method of surface-functionalized molybdenum carbide-carbon catalyst for carbon dioxide hydrogenation reaction

A surface functionalization, hydrogenation reaction technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of low activity and limited hydrogenation capacity, and achieve simple and good parameter control. Effects of reactivity and operational safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment discloses a method for preparing a surface-functionalized molybdenum carbide-carbon catalyst for carbon dioxide hydrogenation reaction, which mainly includes the following steps:

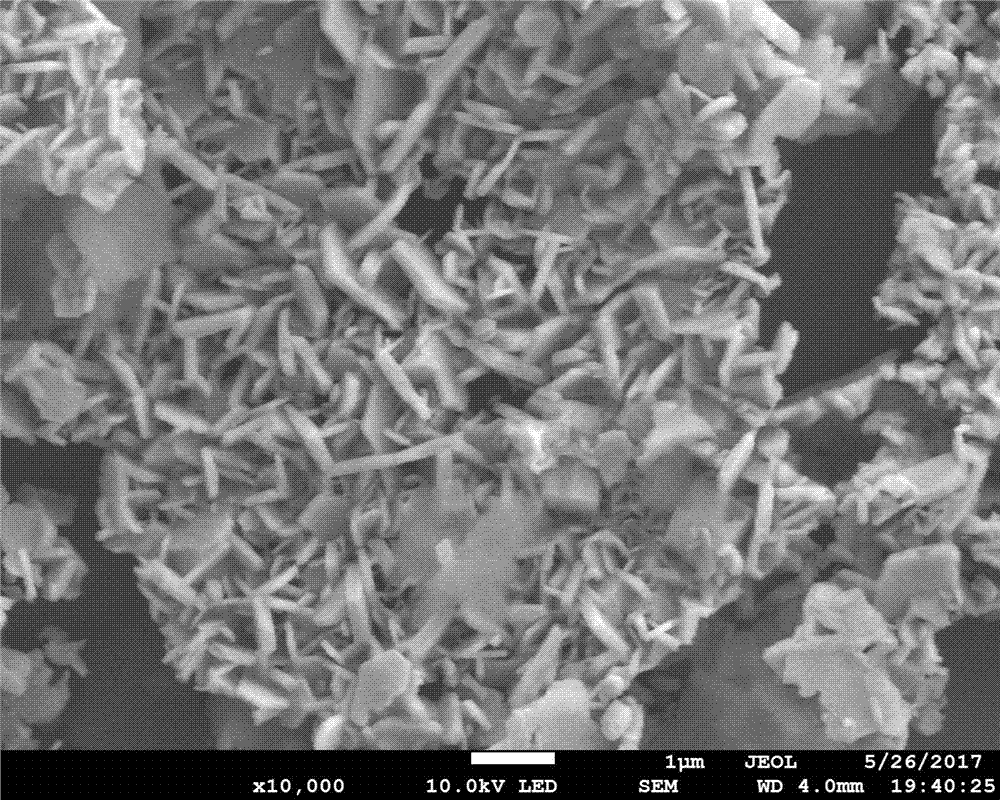

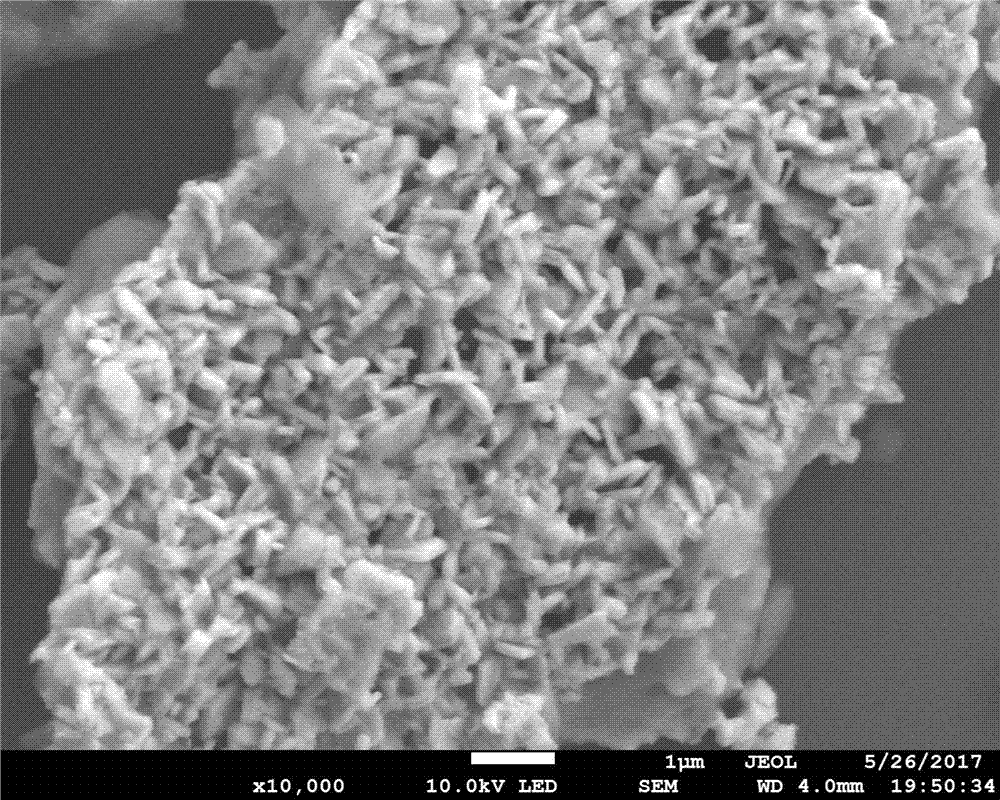

[0028] (1) Use deionized water as a solvent to prepare sodium alginate solution. During the stirring process, ammonium molybdate is introduced into the sodium alginate solution to form a mixed solution. The mass concentration of sodium alginate in the mixed solution is 10g / L, molybdic acid The mass concentration of ammonium is 5g / L; sodium alginate and ammonium molybdate are mixed evenly and placed in a freeze drying box for freeze drying to obtain a sample;

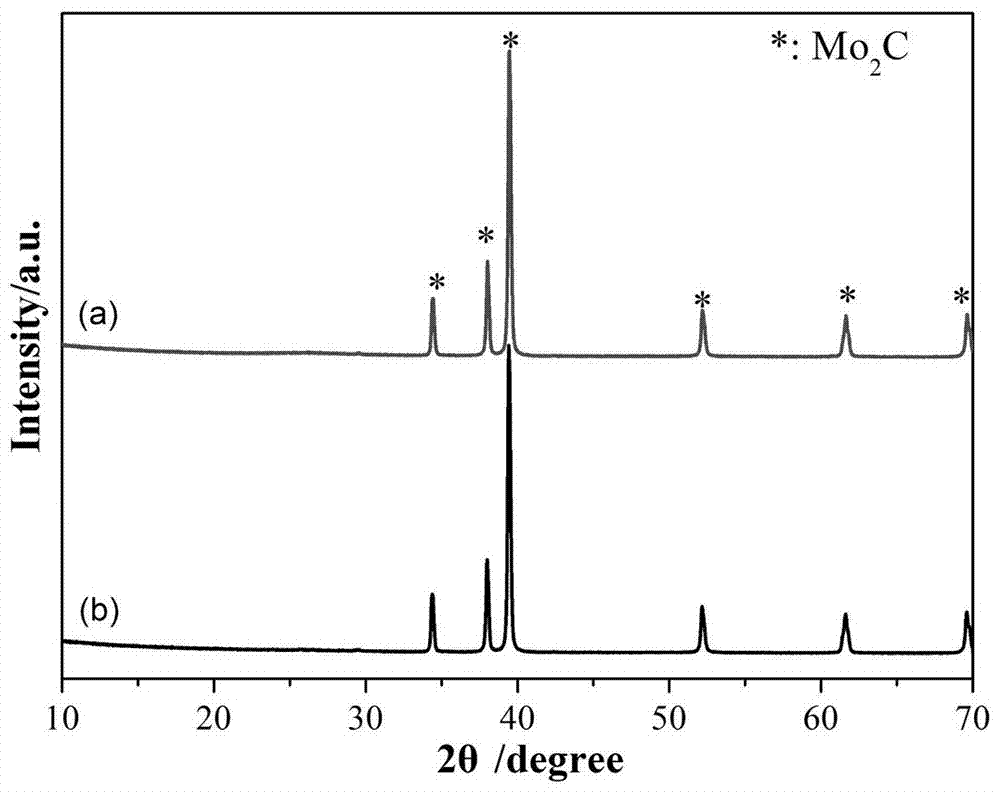

[0029] (2) Put the freeze-dried sample in step (1) into a tube furnace, and bake it at 950°C for 5 hours under an inert atmosphere. After cooling to room temperature, take out the sample and grind it, and deionize the sodium salt in the sample Washing off, drying in a vacuum oven to obtain a catalyst for porous graphite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com