Coal tar hydrogenation catalyst, and preparation method and application thereof

A hydrogenation catalyst, catalyst technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc. Beneficial to the hydrogenation reaction, avoiding the effect of agglomeration or decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

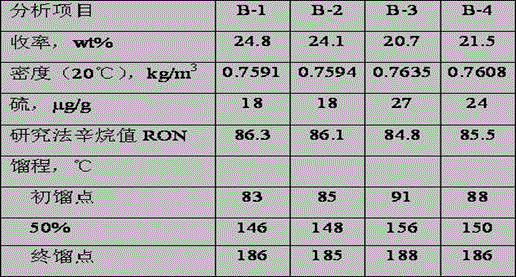

Embodiment 1

[0039] Weigh 1000g of ferric oxyhydroxide filter cake prepared by wet air oxidation method, which contains 400g of ferric oxyhydroxide, add 80g of citric acid dissolved in 1L of water to it and stir to make it evenly mixed, the modification treatment time is 1h, and the treated slurry is use.

[0040] Preparation of sodium metaaluminate solution concentration is 50gAl 2 o 3 / L, a total of 1L, heated to 75°C for use, the concentration of aluminum sulfate solution is 20gAl 2 o 3 / L for a total of 2L, heated to 75°C for use.

[0041] Add 1.0L of distilled water into the gel tank and heat to 75°C. Weigh 500g macroporous alumina (specific surface area 220m 2 / g, pore volume 0.92mL / g, average pore diameter 17nm) and 100g Y-type molecular sieve (SiO 2 / Al 2 o 3 =11.5), add it into the gelling tank and stir evenly, and then add sodium metaaluminate solution and aluminum sulfate solution, the gelling temperature is kept at 75°C, and the pH value is kept at 7.5. After gelling, ...

Embodiment 2

[0044] Other conditions are with embodiment 1, just change citric acid addition into 140g, Y type molecular sieve (SiO 2 / Al 2 o 3 =11.5) was changed to 70g, the treatment time was 2h, the gelling temperature was 85°C, the pH value of gelling was 8.0, the aging temperature was 150°C, and the aging time was 6h, and the catalyst B-2 was prepared.

Embodiment 3

[0046] Other conditions are the same as in Example 1, but the preparation of sodium metaaluminate solution concentration is 60gAl 2 o 3 / L totals 2L, the concentration of aluminum sulfate solution is 20gAl 2 o 3 / L is 4L in total, the bottom water in the gel-forming tank is 3L, and 800g of alumina is added to prepare catalyst B-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com