Hydrocracking method for heavy oil

A technology for hydrocracking and heavy oil, which is applied in hydrotreating process, petroleum industry, treatment of hydrocarbon oil, etc., can solve the problems of reducing the efficiency of high-pressure reactors, and the effect of hydrocracking needs to be further improved, so as to facilitate stable operation and control. , The effect of uniform load and full conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

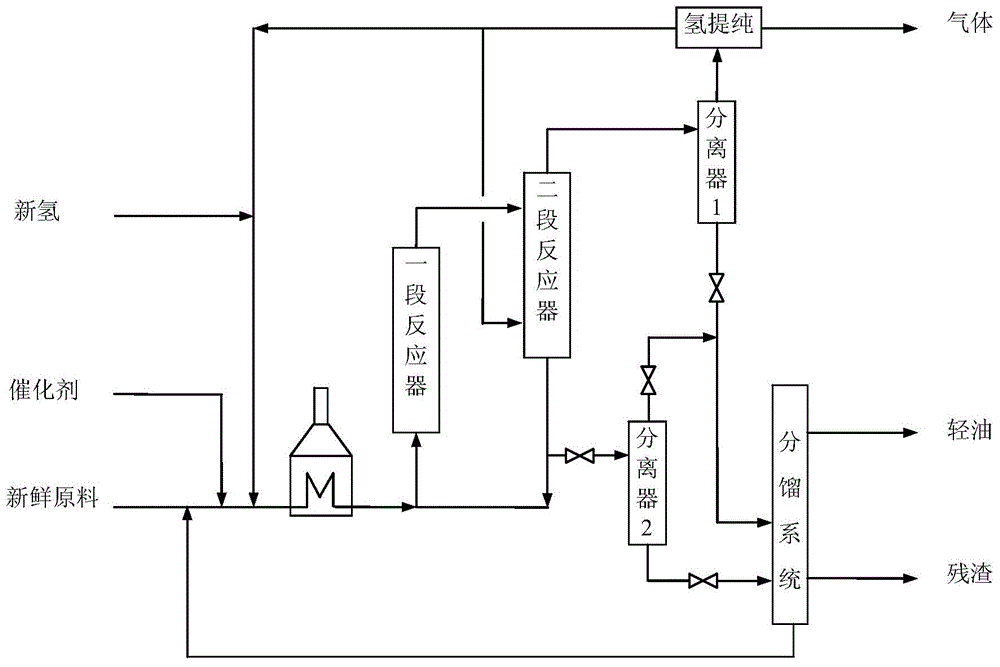

[0048] use figure 1 In the process shown, the raw material oil is the atmospheric residue of crude oil from a certain area of Liaohe Oilfield, and its properties are listed in Table 1. The catalyst is a solid powder catalyst with a maximum particle size of 5 μm and an average particle size of 0.8 μm. The catalyst contains 90m% of ferrous sulfide and 10m% of molybdenum sulfide. Adopt two identical empty barrel reactors connected in series, the volume of the reactor is 500ml, the first reactor is operated according to the first reaction zone described above, and the second reactor is operated according to the second reaction zone described above , the specific operating conditions are listed in Table 2, and the product distribution obtained is listed in Table 3.

[0049] During the test, by measuring the pressure difference ΔP between the upper and lower parts of the reactor and the height difference ΔH between the upper and lower parts of the reactor, according to the compos...

Embodiment 2

[0065] The difference between this embodiment and Embodiment 1 is that the temperature of the first stage reactor is 435°C, and the operating temperature of the second reactor is 455°C. Other aspects not listed are all the same as Example 1. The resulting product distribution is listed in Table 5.

[0066] Table 5 Distribution of two-stage hydrocracking products in Example 2

[0067] Enter

Embodiment 3

[0069] The difference between this embodiment and embodiment 2 is that: the vacuum distillate oil and part of the vacuum residue (containing solid catalyst) obtained from the separation system are used as circulating materials, and the circulation ratio is 0.5; the amount of catalyst is reduced. Other aspects not listed are all the same as Example 2. The resulting product distribution is listed in Table 6.

[0070] Table 6 Distribution of two-stage hydrocracking products in Example 3

[0071] Enter

[0072] hydrogen

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com