Aluminum oxide regenerant for preparing hydrogen peroxide through anthraquinone process

A technology of alumina and hydrogen peroxide, applied in the directions of peroxide/peroxyhydrate/peroxyacid/superoxide/ozone, inorganic chemistry, chemical instruments and methods, etc. problem, to achieve the effect of reducing clay consumption, improving interfacial tension and reducing consumption of anthraquinone

Inactive Publication Date: 2015-06-24

何国炎

View PDF4 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The pollution caused by the reprocessing of waste alumina discharged from the production of hydrogen peroxide appeared in my country as early as 30 years ago. With the rapid increase of hydrogen peroxide production capacity, the amount of reprocessing of waste alumina has also increased, and now it is no less than 70,000 tons per year. It can be seen How serious is its pollution to the environment? Since this kind of pollution has been unable to be effectively controlled, it has become out of control. Under the situation of environmental protection and high pressure, the hydrogen peroxide industry is facing a situation of limiting production.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

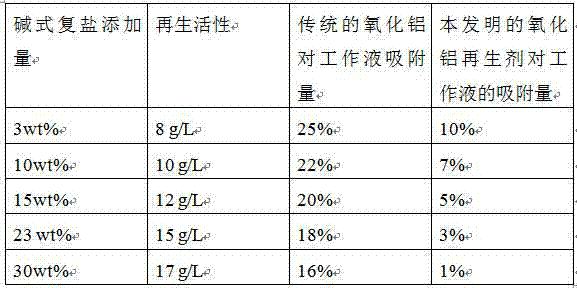

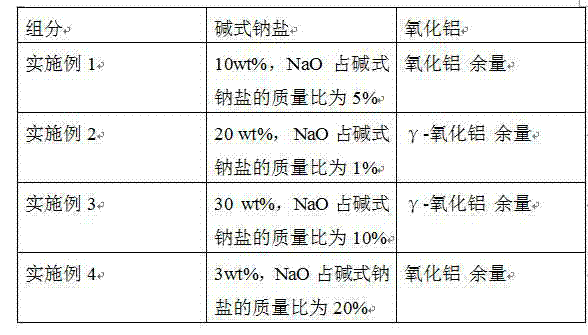

The invention discloses an aluminum oxide regenerant for preparing hydrogen peroxide through an anthraquinone process. The aluminum oxide regenerant comprises the following components: aluminum oxide and basic sodium salt, wherein the adding amount of the basic sodium salt is 10-20% of the total mass; the basic sodium salt meets the condition that the pH value is 9-11 in 1g / ml water solution by taking the basic sodium salt as a solute; and the basic sodium salt comprises sodium oxide, wherein the content of the sodium oxide is 1-4% of that of the basic sodium salt. The technical solution of the invention is excellent in regenerative activity, the organic residual quantity is greatly reduced, the environment pollution is reduced, a positive contribution for reducing emission in the hydrogen peroxide production, eliminating the pollution and reducing the consumption is made and a favorable condition for the sustainable development of the hydrogen peroxide is created.

Description

technical field [0001] The invention relates to the production technology of hydrogen peroxide (hydrogen peroxide) industrial regeneration agent, specifically refers to the aluminum oxide regeneration agent used for preparing hydrogen peroxide by anthraquinone method. Background technique [0002] The production of hydrogen peroxide (hydrogen peroxide) by the anthraquinone method is currently the most mature production method in the world. The process generally uses 2-ethylanthraquinone (EAQ) as the carrier, heavy aromatics (AR) and trioctyl phosphate (TOP ) is a mixed solvent, prepared as a working solution with a certain composition, and it is passed into a hydrogenation bed equipped with a catalyst together with hydrogen, and 2-ethylanthraquinone (EAQ) undergoes a hydrogenation reaction with hydrogen at a certain pressure and temperature, Generate the corresponding hydrogen anthraquinone (HEAQ), and the resulting solution is called hydrogenation solution. The hydrogenate...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C01B15/023

CPCB01J20/08B01J20/3433B01J20/345

Inventor 何国炎

Owner 何国炎

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com