Patents

Literature

92 results about "Aluminium recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminium recycling is the process by which scrap aluminium can be reused in products after its initial production. The process involves simply re-melting the metal, which is far less expensive and energy-intensive than creating new aluminium through the electrolysis of aluminium oxide (Al₂O₃), which must first be mined from bauxite ore and then refined using the Bayer process. Recycling scrap aluminium requires only 5% of the energy used to make new aluminium from the raw ore. For this reason, approximately 36% of all aluminium produced in the United States comes from old recycled scrap. Used beverage containers are the largest component of processed aluminum scrap, and most of it is manufactured back into aluminium cans.

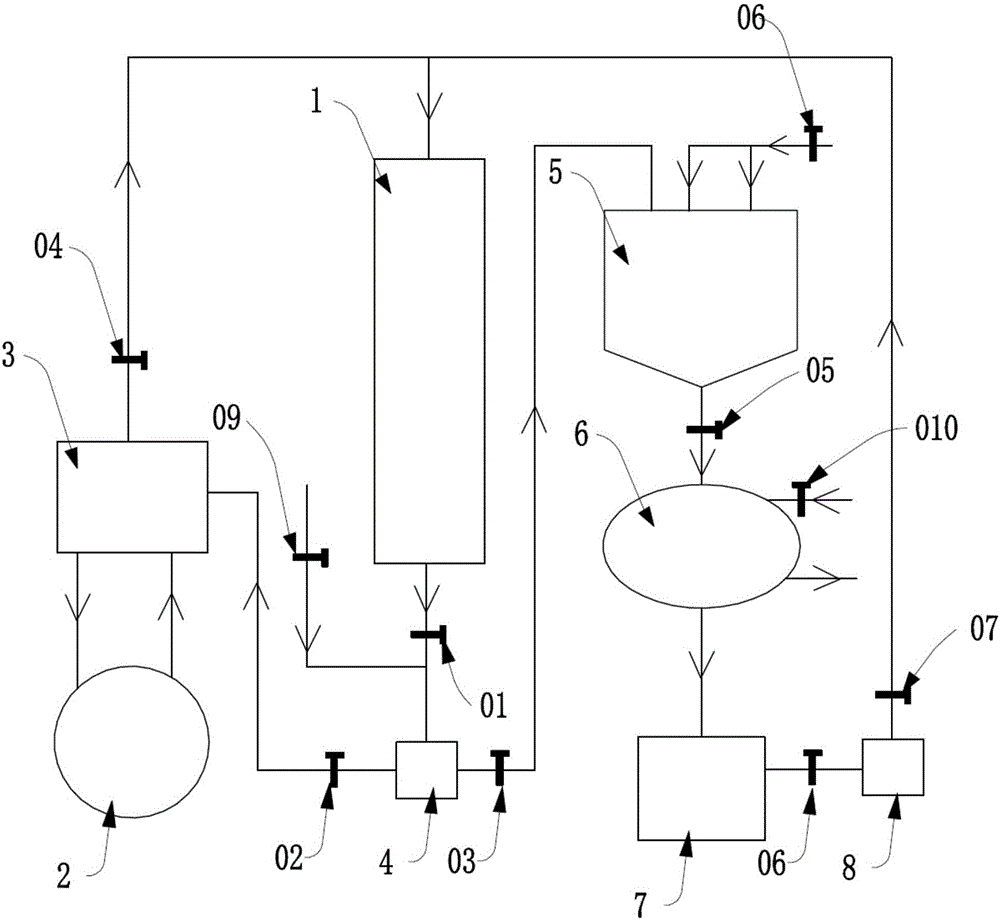

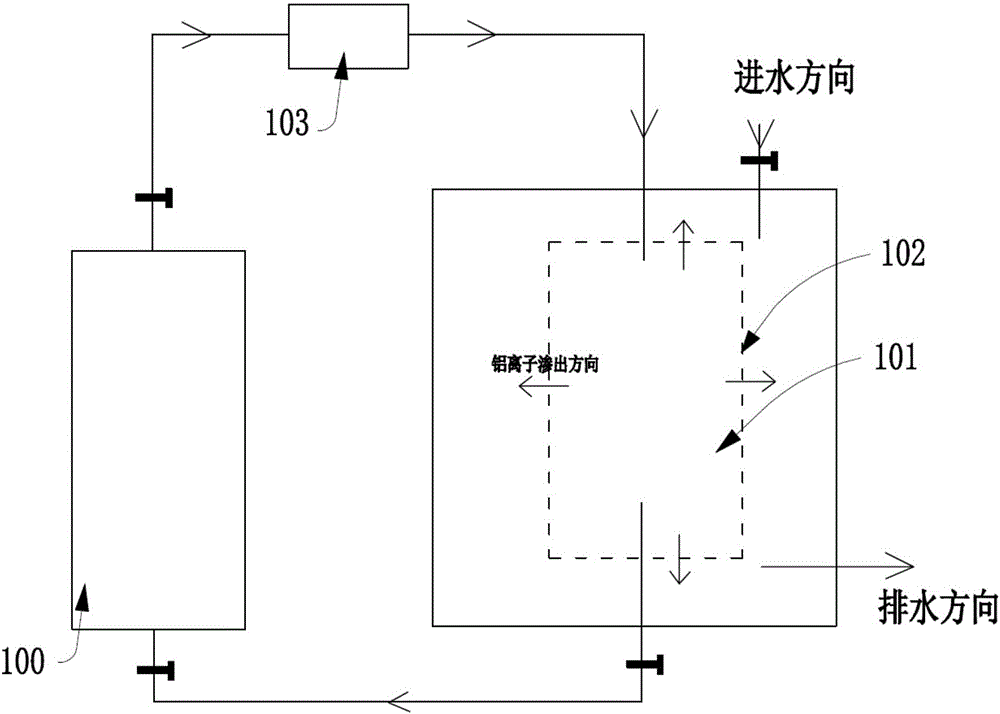

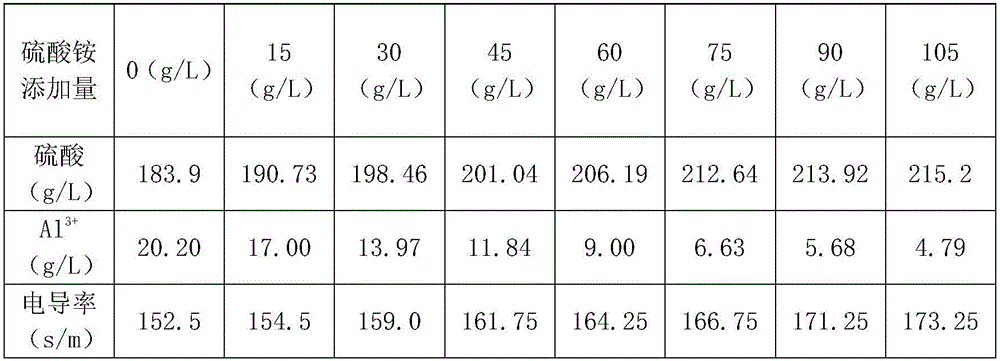

Energy-saving device and process for oxidation tank aluminum ion and sulfuric acid recycling and oxidation liquid corrosion inhibition

ActiveCN106757258ALower resistanceReduce the amount of dissolutionCellsAnodisationAmmonium sulfateAluminium salts

The invention discloses an energy-saving device and process for oxidation tank aluminum ion and sulfuric acid recycling and oxidation liquid corrosion inhibition. The process comprises an oxidization liquid cyclic cooling step, an aluminum ion crystal product recycling step, a sulfuric acid oxidization liquid recycling step, a gas stirring step and a defrosting step; the aluminum ion crystal product recycling step includes that oxidization liquid is guided into a reaction tank, ammonium aluminum sulfate crystals are precipitated out after ammonium sulfate is added into the reaction tank, and then materials in the reaction tank are guided into a centrifugal machine to be centrifuged so that solid and liquid after solid-liquid separation can be acquired; and the sulfuric acid oxidization liquid recycling step includes that oxidization liquid after crystallization treatment is collected, and is conveyed to an anodic oxidization tank to be cyclically used after being subjected to regeneration treatment. The energy-saving device and process for oxidation tank aluminum ion and sulfuric acid recycling and oxidation liquid corrosion inhibition are provided, by extracting aluminum in the oxidization liquid, sulfuric acid is recycled, the resistance of the oxidization liquid is reduced, a corrosion inhibition agent is added in the oxidization liquid, oxidization energy conservation is achieved by reducing the dissolving amount of an oxidization film, and more than 20% of energy is saved.

Owner:FOSHAN SANSHUI XIONGYING INNOVATION CENT FOR ALUMINUM SURFACE TECH

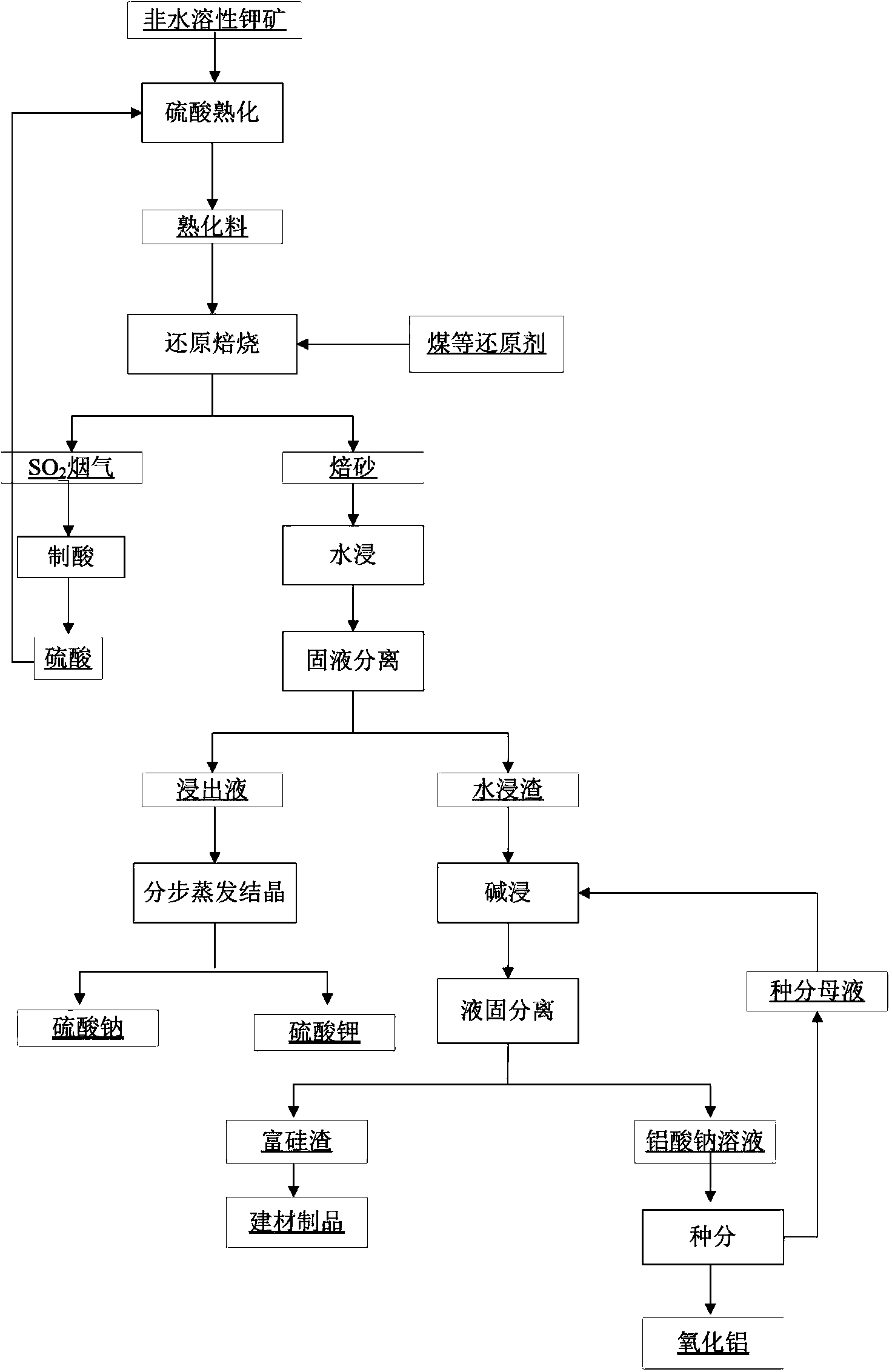

Method applied to acid-base combined extraction of aluminum, potassium and sodium from water-insoluble potassium ore

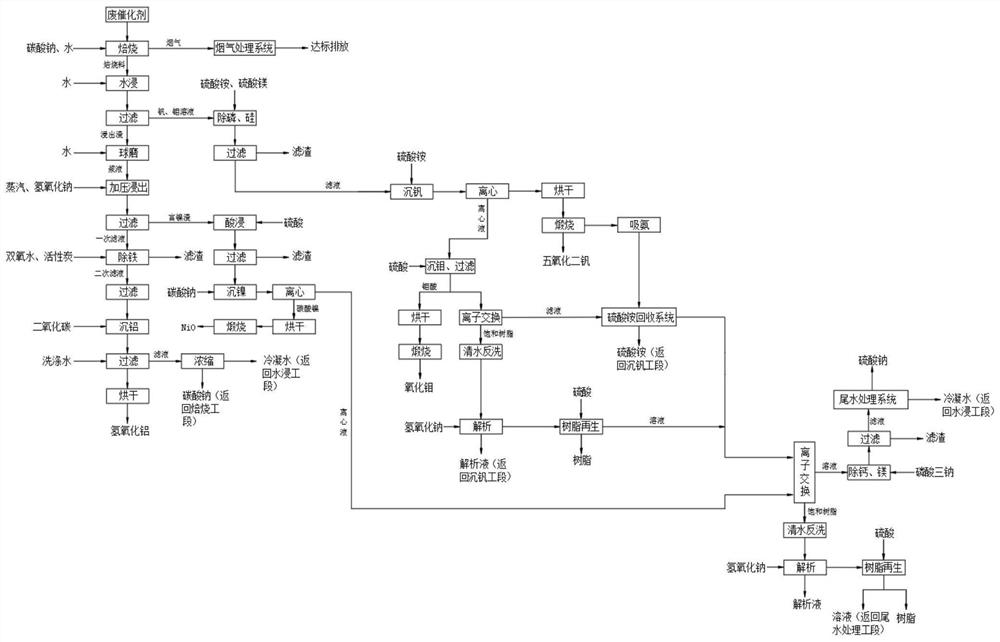

ActiveCN104388668AAchieve dissolutionKeep aliveProcess efficiency improvementAluminium recyclingFlue gas

The invention discloses a method applied to acid-base combined extraction of aluminum, potassium and sodium from water-insoluble potassium ore resource such as nepheline, potassium feldspar and the like. The method comprises the following steps: uniformly mixing finely-ground water-insoluble potassium ore with a proper amount of concentrated sulfuric acid, curing, and carrying out rapid high-temperature reduction roasting desulfurization at a certain temperature by a reducing agent, wherein the sulfur-containing flue gas is used for acid preparation to achieve regeneration and cyclic utilization of sulfuric acid; extracting potassium and sodium by water from the reduced calcine, and preparing aluminum oxide by alkaline leaching. By virtue of the method, the decomposition of aluminosilicate-containing material phase in the water-insoluble potassium ore resource such as nepheline, potassium feldspar and the like is enhanced by high-temperature reaction of concentrated sulfuric acid; the cyclic utilization of sulfuric acid is realized. The method can be used for comprehensively recycling aluminum, potassium and sodium resources; the recycling rate of aluminum oxide is high; the energy consumption is low; the corrosion to equipment is small; the large-scale industrialization is easy to implement.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

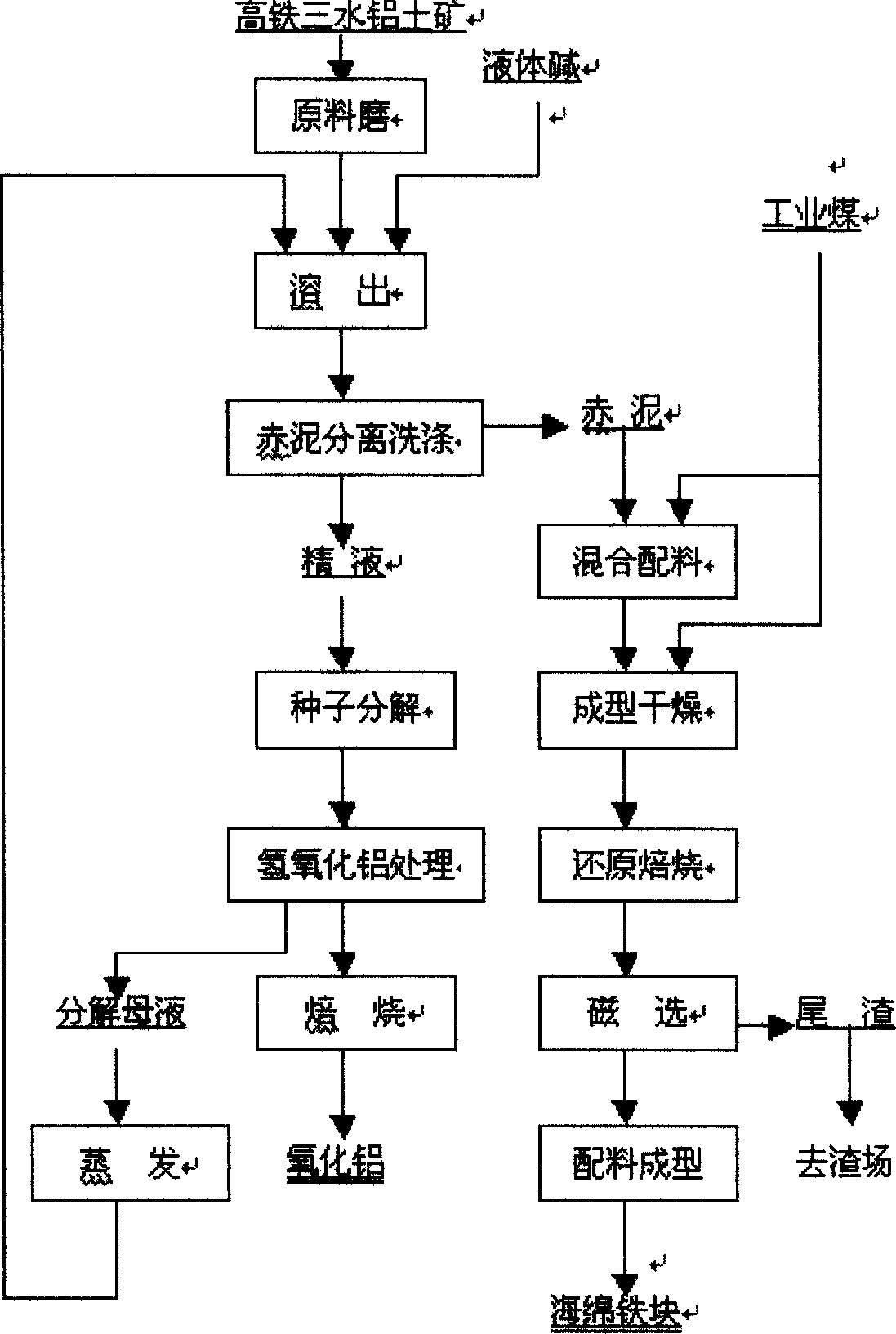

Method for extracting aluminium and iron from high-iron bauxite trihydrate

InactiveCN1743475ARealize comprehensive utilizationSimple processSolid separationRotary drum furnacesRed mudAluminium hydroxide

This invention provides a method for extracting Al and iron from a ferric gibbsite, which grinds and dissolves the ferric gibbsite then carries out rough and fine separation-washing to the red mud and sends the refined liquor to the resolving plant to separate AlOH and bake it to get A10. The red mud is matched with recovery coal and burning coal to be dried and baked then to be ground and selected magnetically to get sponge iron power to be filtered and matched with raw material, dried to get sponge iron balls.

Owner:GUIYANG AL-MG DESIGN & RES INST

Method for manufacturing aluminum alloy anode metal plate of aluminum-air battery

InactiveCN105057679ASave the process of electrolytic machining againSolving Recycling ProblemsFuel and primary cellsMolten spray coatingElectrolysisElectrical battery

The invention discloses a method for manufacturing an aluminum alloy anode metal plate of an aluminum-air battery, and belongs to the field of aluminum-air battery electrodes. Aluminum skimmings produced due to industrial aluminum machining are adopted to serve as raw materials, and the aluminum alloy anode metal plate is obtained in the steps that water drainage and oil removal are carried out, the skimmings are smashed, mixed with zinc powder, compacted and formed, and thermal treatment and thermal spraying are carried out. The aluminum skimmings produced due to metal cutting serve as the raw materials, so that the problem of waste aluminum recycle is solved, the process that the aluminum skimmings are electrolyzed again is omitted, and manufacturing cost of metal electrodes is reduced. The surface of an aluminum skimmings plate formed by pressing the aluminum skimmings is provide with holes, the specific contact area of electrolyte is large, and electrode discharge reaction is enhanced. Gallium, tin and bismuth are added and little in required amount, and electrode activity can be effectively improved.

Owner:TAIYUAN UNIV OF TECH

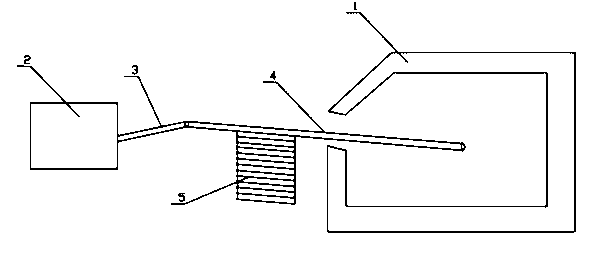

Production process of recycled aluminum

InactiveCN102703739AStir wellReduce burning rateStirring devicesAluminium recyclingProcess engineering

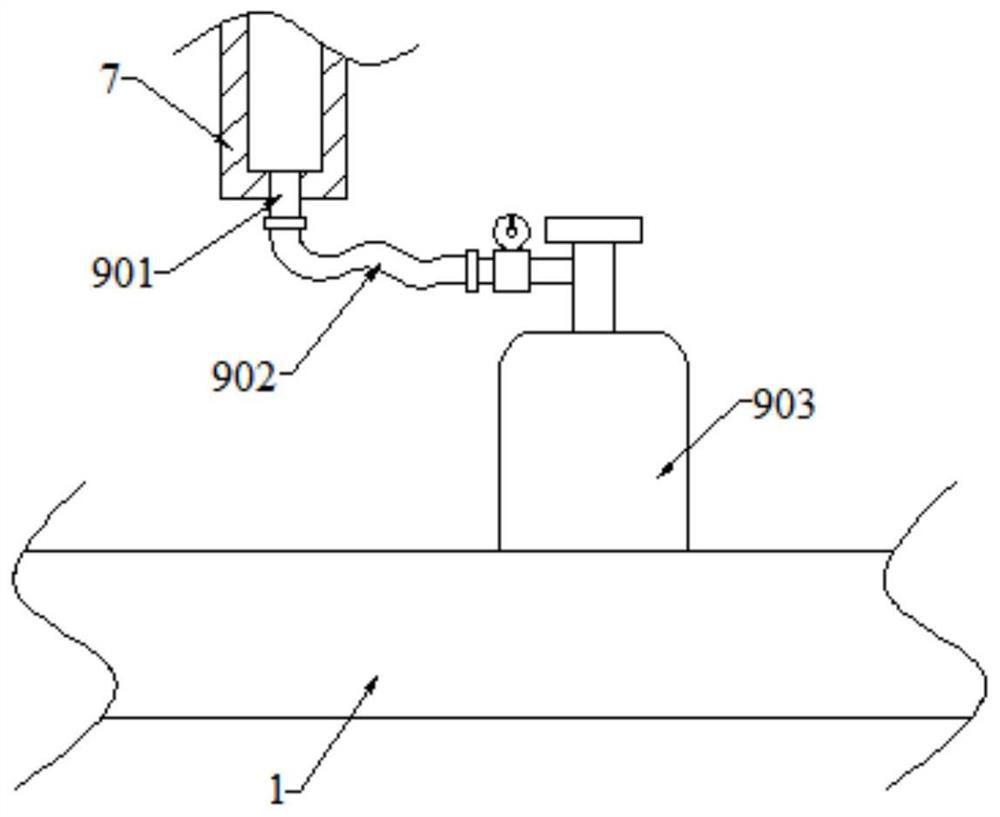

The invention relates to a production process of recycled aluminum and belongs to the technical field of metal aluminum recycle. The production process modifies a stirring step in a smelting procedure in the existing production process of recycled aluminum and adopts an air compressor which is connected with one end of a vibration rod through a pipeline. The other end of the vibration rod stretches into a furnace cavity of a smelting furnace. The air compressor is started in stirring to drive the vibration rod to stir in vibration mode in the furnace cavity. The production process has the advantages of improving product quality, improving production efficiency, reducing production cost, reducing labor quantity and improving working environment.

Owner:遂宁市新华西铝业有限公司

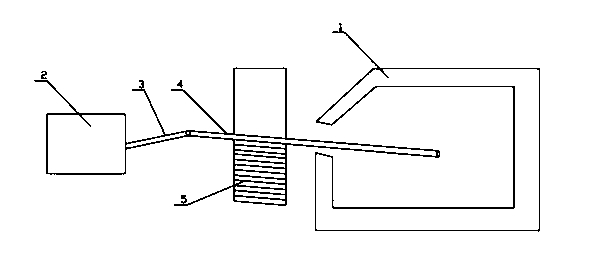

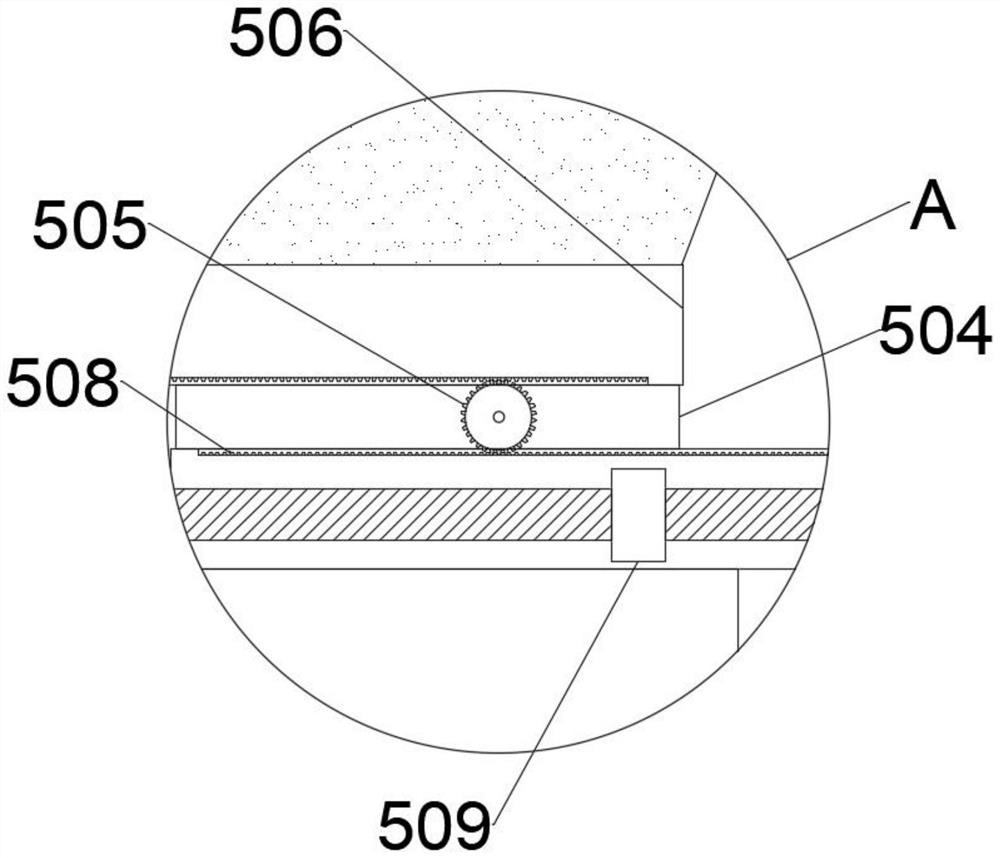

Molten aluminum impurity removal device for waste aluminum recovery and implementation method thereof

ActiveCN112760490ATo achieve the purpose of removing impuritiesReasonable structural designProcess efficiency improvementAluminium recyclingSlag

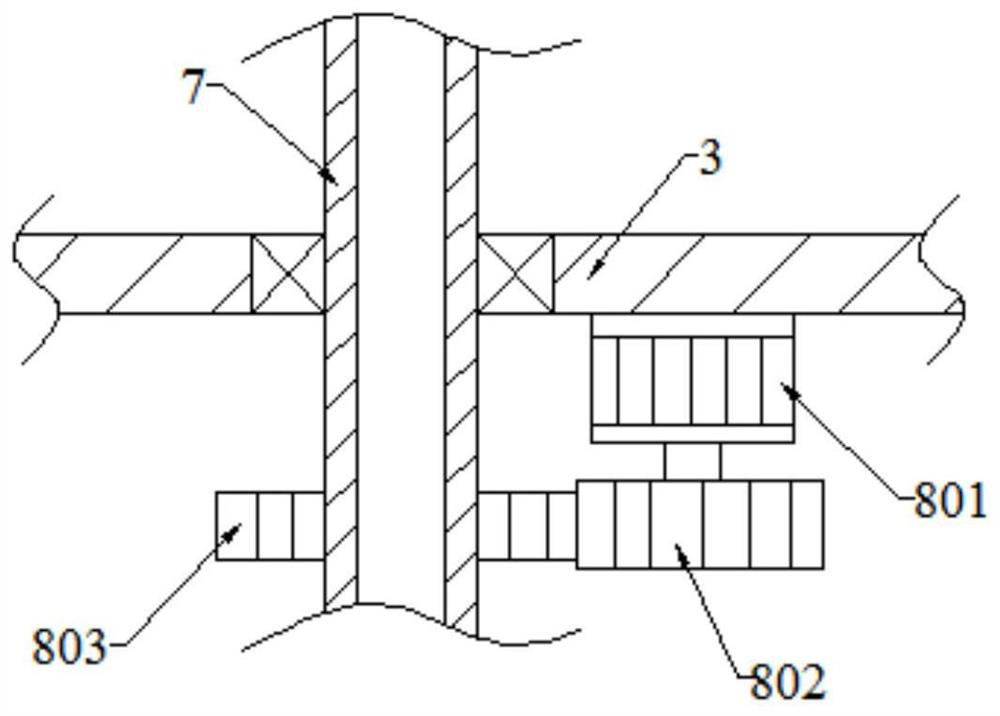

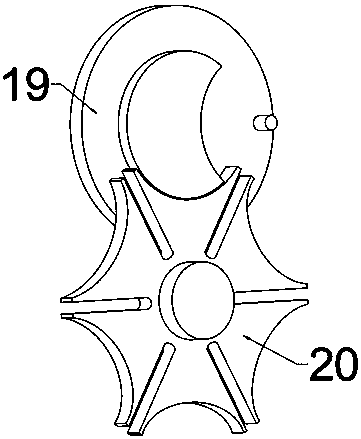

A molten aluminum impurity removal device for waste aluminum recovery comprises a bottom plate, two sets of supporting columns are fixedly connected to the upper end of the bottom plate, an impurity removal box is fixedly connected to the upper ends of the supporting columns, filter plates are hinged to the lower end of a partition plate in a bilateral symmetry mode, a rotating assembly is arranged on the lower side of a hollow shaft, a gas inlet assembly is connected to the bottom of the hollow shaft, and the side wall of the upper portion of the hollow shaft communicates with multiple hollow stirring rods. A slag salvaging assembly is arranged in the upper side of the impurity removal box. An impurity removal agent and molten aluminum are mixed to remove condensed impurities; meanwhile, nitrogen is discharged into the molten aluminum through a gas inlet assembly, the impurity removal aim is achieved, and the impurity removal effect is good; and the hollow stirring rods are driven by the rotating assembly to rotate, the molten aluminum is stirred and mixed, and the impurity removal effect is improved. By means of the slag salvaging assembly, impurities floating on the surface of the molten aluminum can be taken away through a slag salvaging plate, manual skimming is not needed, time and labor are saved, and potential safety hazards are avoided. The molten aluminum is further filtered and subjected to impurity removal through the filter plates, the filter plates vibrate in a reciprocating mode, the filter effect is improved, and the impurities are prevented from being accumulated on the filter plate.

Owner:东海县宏巨金属材料有限公司

Smelting method of high-aluminum stainless steel

ActiveCN103397141AReduce Si contentHigh recovery rateManufacturing convertersAluminium recyclingSS - Stainless steel

The invention discloses a smelting method of high-aluminum stainless steel and belongs to the technical field of smelting of stainless steel. The method comprises the following steps: I, tapping steel from a converter; II, performing vacuum oxygen decarbonization (VOD) blowing; III, slagging off; IV, performing VOD reduction; V, performing VOD aluminum alloying; and VI, performing ladle furnace (LF) refining. According to the method, the Si content of molten steel is effectively reduced, the Si content of steel is less than or equal to 0.10%, the recovery rate of aluminum is increased and is more than or equal to 80%, and the production cost is reduced.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Method for directly preparing aluminum alloy refiner through waste aluminum recycle

ActiveCN110835697AReduce generationEmission reductionProcess efficiency improvementWire rodAluminium recycling

The invention relates to a method for directly preparing an aluminum alloy refiner through waste aluminum recycle, and belongs to the technical field of refiners. The method comprises the following steps that waste aluminum is pretreated; pretreated aluminum scraps are remelted, an iron remover is added, heat preservation is carried out, salt mixture is added, stirring is carried out, then a covering agent is added, standing is carried out in an argon environment, then an Al-0.4V alloy and an Al-0.4Zr alloy are added, heat preservation is continued, then slag removing is carried out to obtainaluminum melt; and finally, the obtained aluminum melt is subjected to semi-solid-state variable-diameter extrusion molding to prepare an Al-Ti-B-Zr-C-V alloy refiner wire. The method effectively reduces the production cost of the grain refiner, and realizes the effective recycle of the waste aluminum resources; and the method has the advantages that the preparation process is simple, and can achieve industrial production.

Owner:ZHONGBEI UNIV

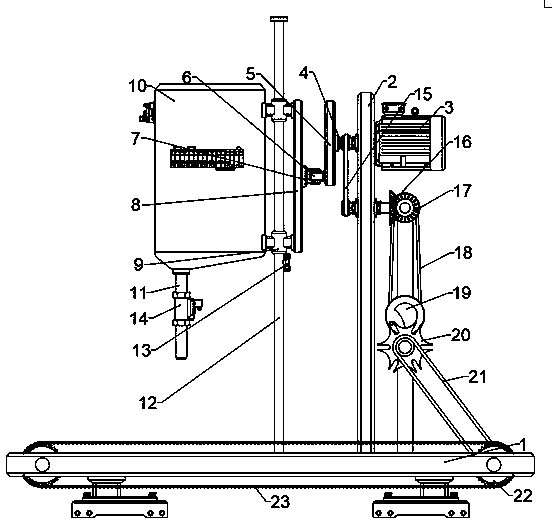

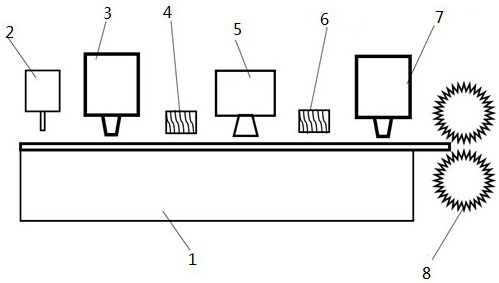

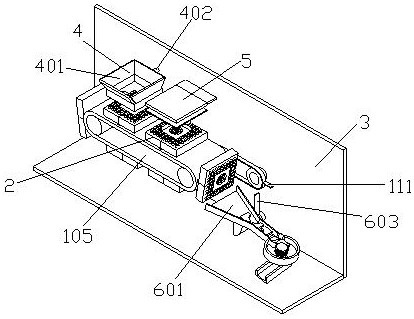

Equipment for manufacturing casting by recycling waste aluminum and process method

ActiveCN111054908ARealize automatic casting functionAccurate positioning walkingProcess efficiency improvementMould handling equipmentsAluminium recyclingProcess engineering

The invention discloses equipment for manufacturing a casting by recycling waste aluminum and a process method. The equipment comprises a working platform, a vertical supporting piece which is mountedabove the working platform and a hot melting furnace which is movably arranged above the working platform and is used for recycling waste aluminum by hot melting, a casting mechanism which is mountedon the supporting piece is used for driving the hot melting furnace to move up and down in a reciprocating manner; the casting mechanism is connected with a walking mechanism through a transmission assembly, the walking mechanism is installed on the working platform and used for driving a casting sand mold to intermittently travel; and the hot melting furnace is connected with a controller and the a through spring electric lead. According to the equipment for manufacturing the casting by recycling waste aluminum and the process method, a motor is utilized to drive an output shaft to rotate, the output shaft drives a rotating part and a No.1 bevel gear to rotate at the same time, the rotating part drives a shifting column to drive a sleeve part and the hot melting furnace to move up and down along a guide rod in a reciprocating mode under the matching effect of a clamping groove and a sliding part, a travel switch is combined to achieve the automatic casting function, and a rotating bevel gear set drives the Maltese cross machine core wheel set to drive a chain wheel to operate precisely and intermittently, so that a chain belt is driven to intermittently drive the sand mold to walk, and the functions of precise positioning walking and continuous casting are achieved.

Owner:XINGHUA YONGTAI ALUMINUM IND

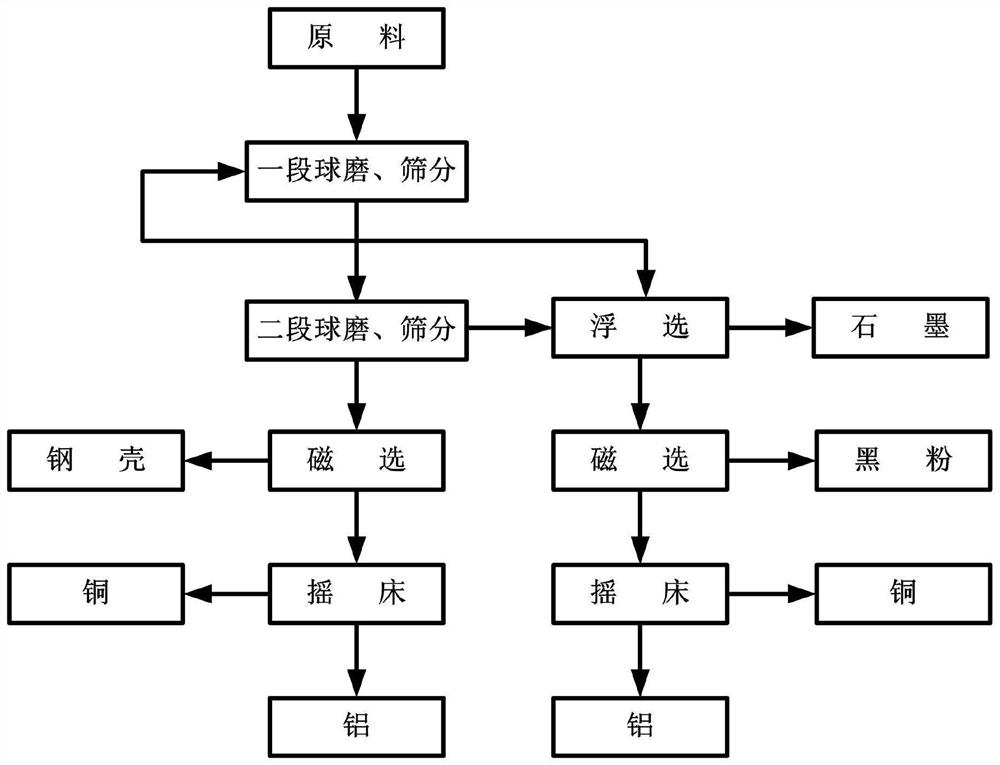

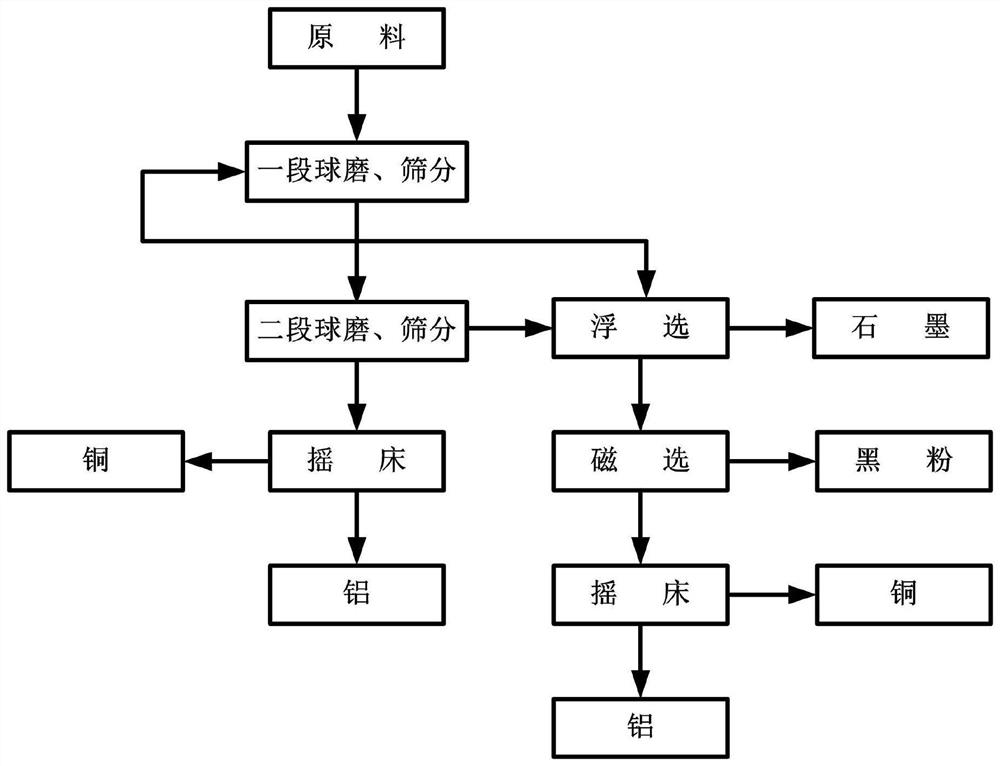

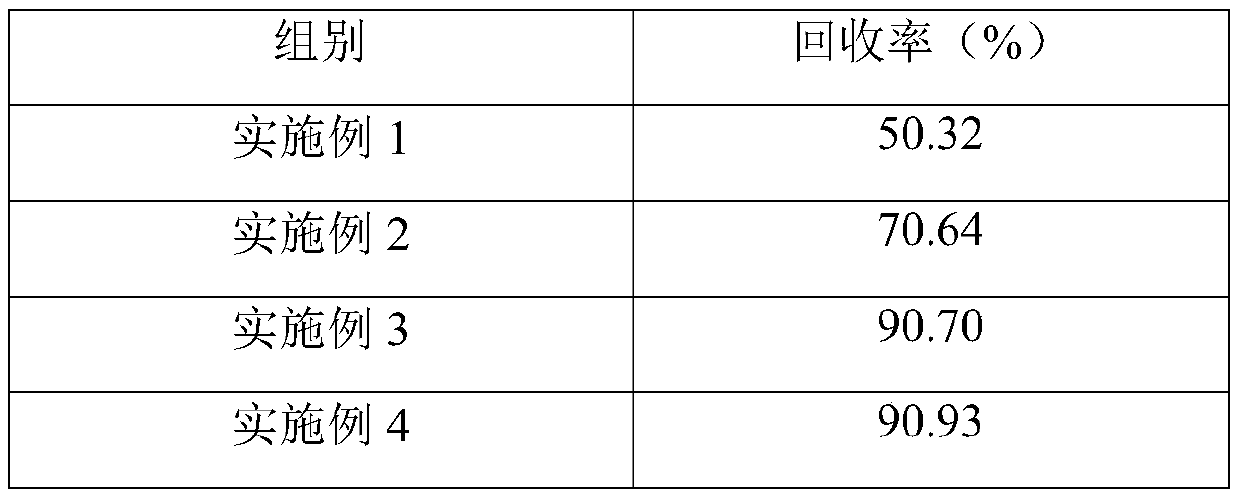

Wet separation technology for waste lithium batteries and application thereof

ActiveCN112756104AImprove securityLow costReclaiming serviceable partsWaste accumulators reclaimingElectrical batterySeparation technology

The invention belongs to the field of battery material recovery, and discloses a wet separation technology for waste lithium batteries and application of the wet separation technology. The wet separation technology comprises the following steps of carrying out wet ball milling on separation raw materials of the waste lithium batteries to obtain a ball-milled product; screening the ball-milled product to obtain coarse-grained screened materials, medium-grained screened materials and fine-grained screened materials; carrying out wet ball milling, screening, magnetic separation and table concentration on the medium-grained screened materials to obtain copper, aluminum and steel shells; and carrying out flotation, magnetic separation and table concentration on the fine-grained screened materials to obtain positive electrode material powder, graphite, copper and aluminum. According to the wet separation technology, the gravity, magnetism and flotation combined treatment is adopted, the recovery rate of the steel shells is 99%, the recovery rate of the graphite is 90% to 92%, the recovery rate of cobalt in the positive electrode material powder is 99% or above, the recovery rate of nickel is 99% or above, the recovery rate of manganese is 99% or above, the recovery rate of the copper is 93% to 95%, and the recovery rate of the aluminum is 93% to 95%.

Owner:HUNAN BRUNP RECYCLING TECH +2

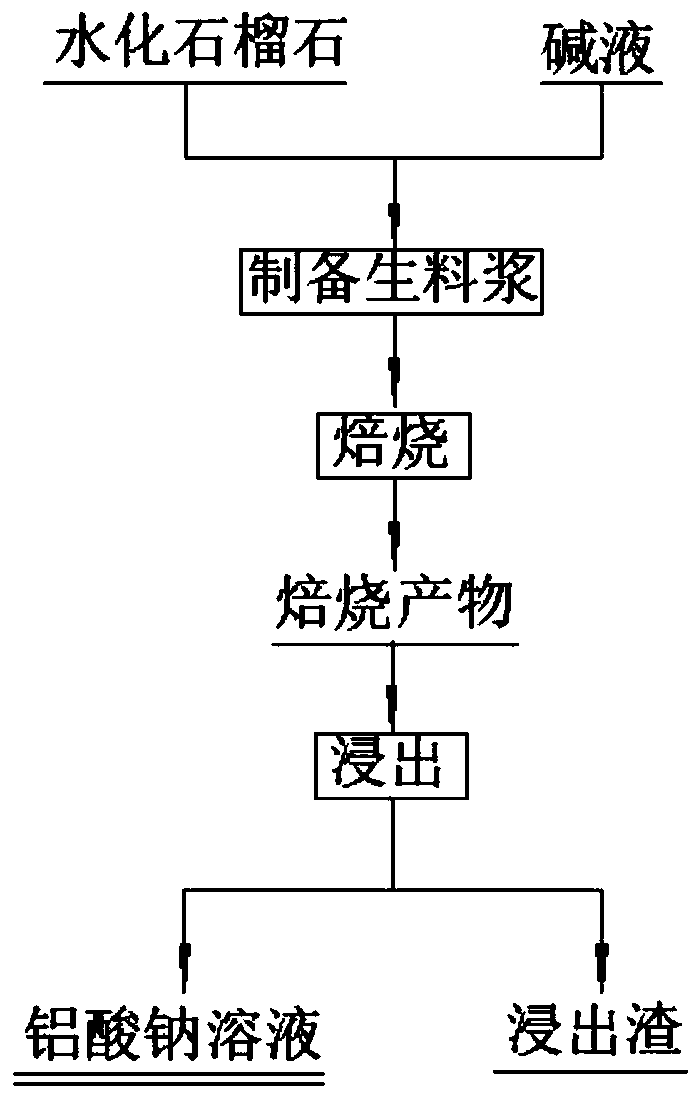

Recovery method of aluminum oxide in hydrated garnet

InactiveCN109809452AHigh recovery rateReduce consumptionAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationRecovery methodResource recovery

The invention discloses a recovery method of aluminum oxide in hydrated garnet, and belongs to the technical field of resource recovery. The recovery method comprises the following steps: uniformly mixing the hydrated garnet with a certain amount of alkaline solution, thus preparing raw slurry; carrying out low-temperature roasting on the raw slurry; putting a roasted product in an alkaline solution for low-temperature leaching, and carrying out solid-liquid separation after leaching, thus obtaining a sodium aluminate solution and leaching residue. According to the recovery method disclosed bythe invention, the aluminum oxide in the hydrated garnet can be effectively recovered, the recovery rate can be up to 90 percent, the recovery method has the characteristics of low temperature and short process of a roasting process, energy saving and environment protection are facilitated, and higher industrial popularization value is expressed.

Owner:CENT SOUTH UNIV

Multi-element recycling of residual oil hydrogenation waste catalyst

PendingCN113293297AReduce consumptionLess investmentVanadium oxidesChemical recyclingPtru catalystAluminium hydroxide

Owner:江苏瑞孚再生资源有限公司

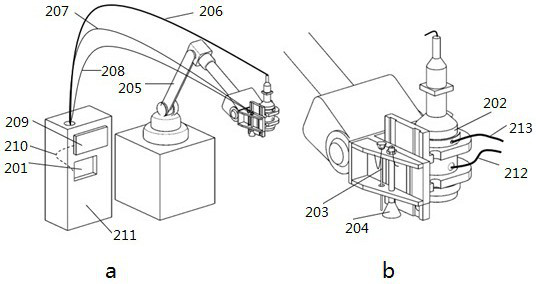

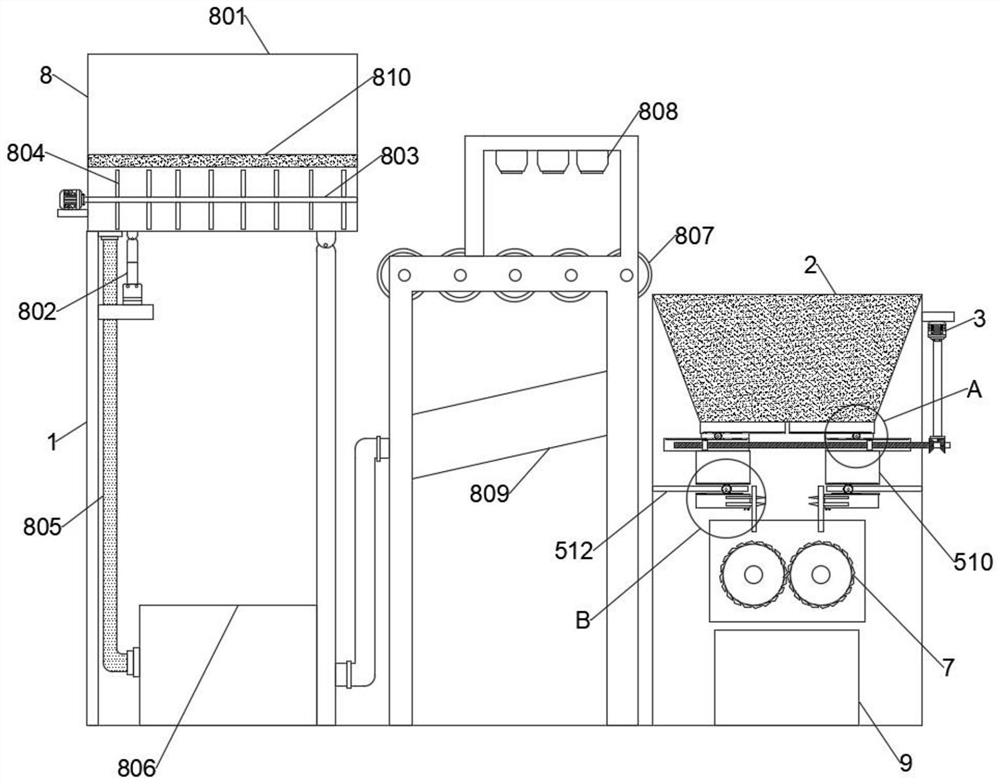

Waste aluminum recycling and direct forming device and method

ActiveCN111979508AReasonable structural designImprove yieldMolten spray coatingMetal rolling stand detailsAluminium recyclingRoll forming

The invention relates to a waste aluminum recycling and direct forming device and method. The waste aluminum recycling and direct forming device comprises an induction heating system, smelting furnaces, temperature adjusting devices, a composite material stirring device, a conveying device and a double-roller rolling device, wherein the heating system, the smelting furnace I, the temperature adjusting device I, the composite material stirring device, the temperature adjusting device II, the smelting furnace II and the double-roller rolling device are all arranged around the conveying device, atreated stainless steel plate is conveyed into the heating system, heated and slightly melted and then conveyed to the smelting furnace, molten waste aluminum is sprayed to the steel plate, temperature measurement and temperature adjustment are carried out, strengthening particles are sprayed to the surface of the waste aluminum, secondary temperature measurement and temperature adjustment are carried out, the surfaces of the strengthening particles are covered with molten aluminum, the strengthening particles are sent into double rollers, rolling forming is carried out to obtain a steel / aluminum / strengthening particle / aluminum wavy composite plate, and laser shock is carried out on the surface of the steel / aluminum / strengthening particle / aluminum wavy composite plate. The wavy compositeplate is directly machined and formed from waste aluminum, the problems of high cost, difficulty in operation, complex structure and the like are solved, the yield is high, the production efficiency and the qualified rate of products are favorably improved, continuous production can be realized, and the wavy composite plate has the advantages of energy conservation and environmental protection.

Owner:ZHONGBEI UNIV

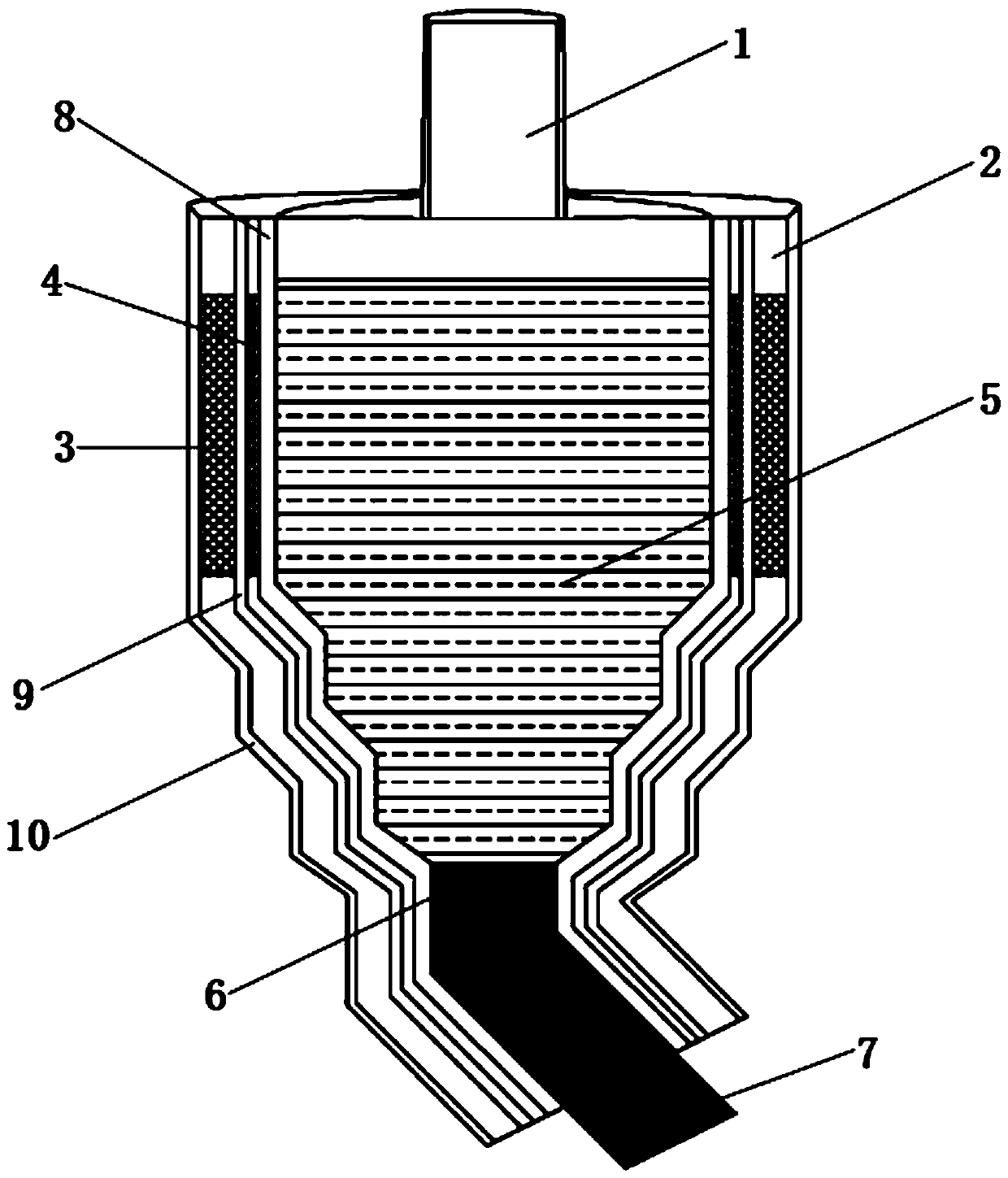

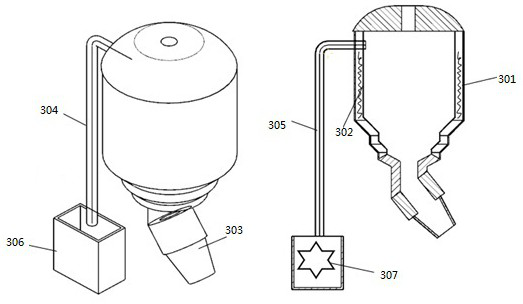

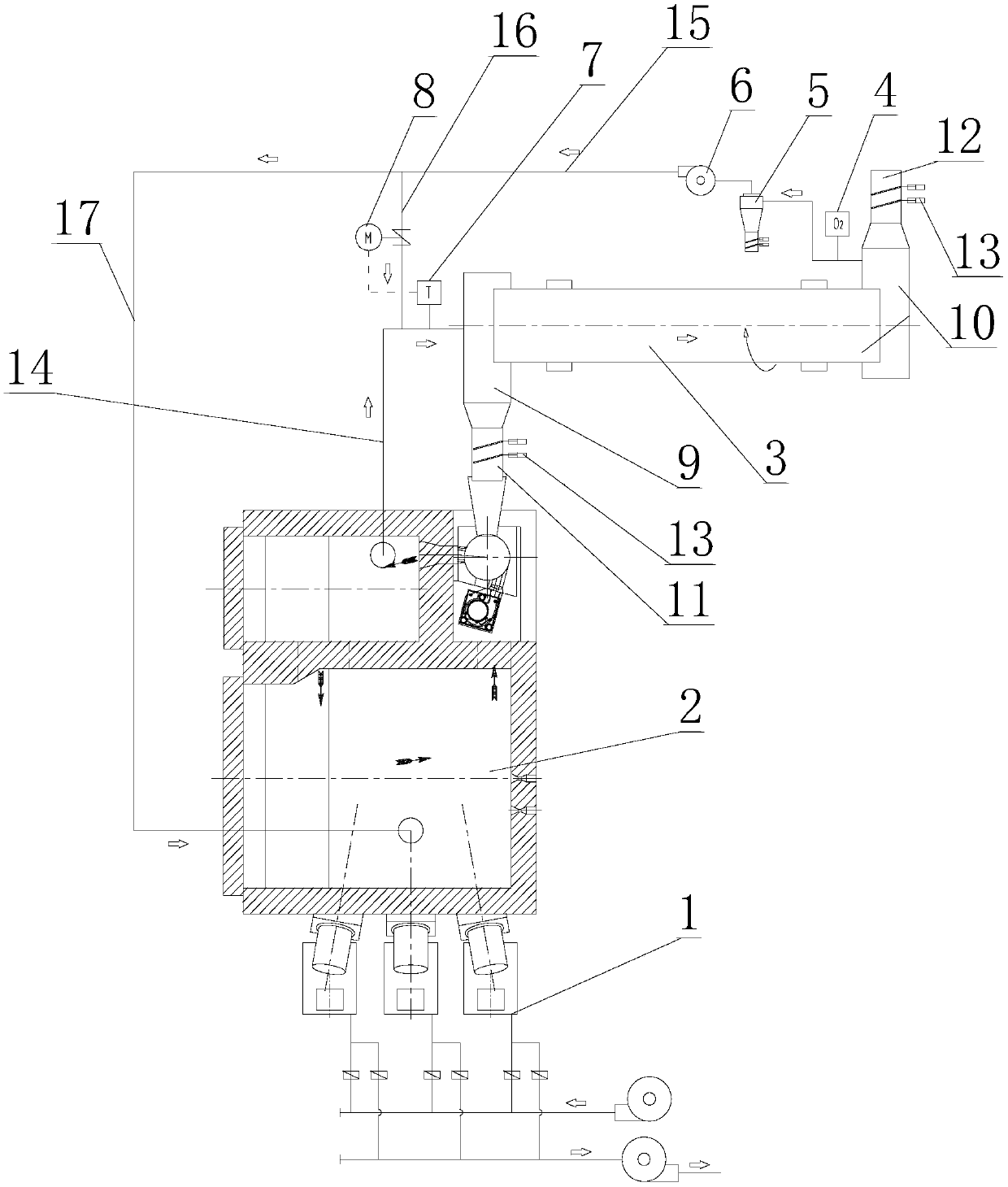

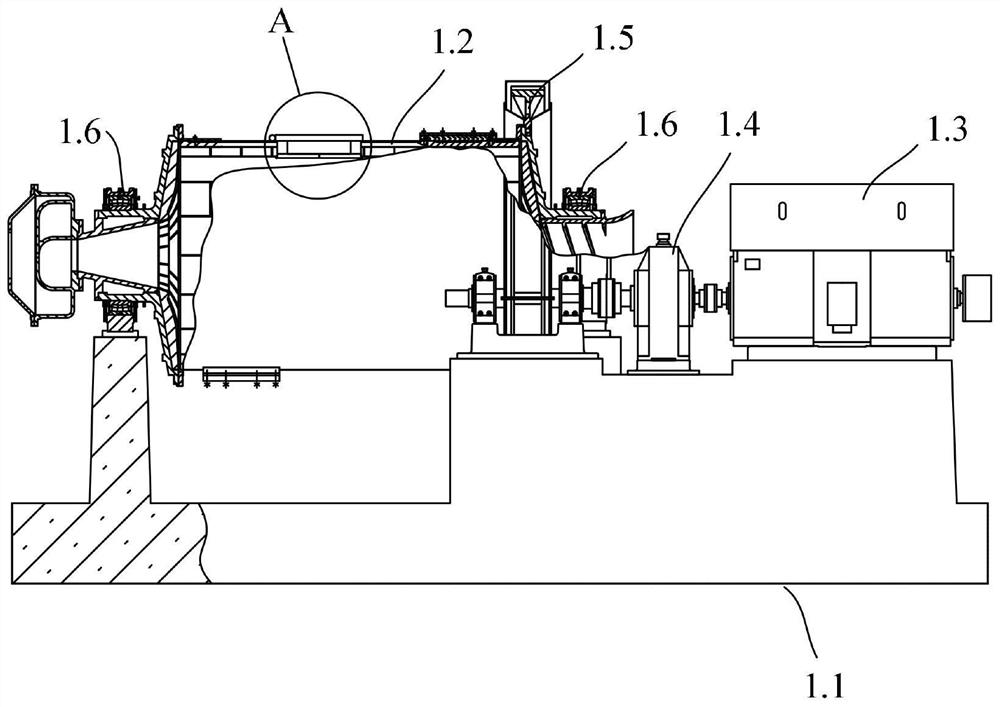

Recycled aluminum smelting recovery system and recovery process adopting same

InactiveCN109609764AAchieve recyclingInhibition of "dioxin" and NOXProcess efficiency improvementScrapDecomposition

The invention provides a recycled aluminum smelting recovery system and a recovery process adopting the same. The recycled aluminum smelting recovery system comprises a smelting furnace for recoveringand smelting waste aluminum, a rotary cylinder for pre-treatment of waste materials and flue gas pipelines which connect the smelting furnace and the rotary cylinder into one. The recovery process comprises the steps of preheating treatment of the waste materials, smelting furnace recovery treatment and circulating treatment of circulating high temperature flue gas in the smelting furnace betweenthe rotary cylinder and the smelting furnace. The smelting furnace for recovering and smelting waste aluminum and the rotary cylinder for pre-treatment of the waste materials are connected into one,a combined operation mode is adopted, heat of the high temperature flue gas in the smelting furnace is directly utilized to treat the waste materials, decomposition of oil contamination, coatings andplastics is realized, no additional burner device is required to be added, no additional fuel consumption generates, and waste heat of waste material combustion are recycled; and production of 'dioxins' and NOX is inhibited in the recovery process of the waste aluminum, and energy conservation and environmental protection requirements in the recovery process of the waste aluminum are realized.

Owner:苏州中阳热能科技有限公司

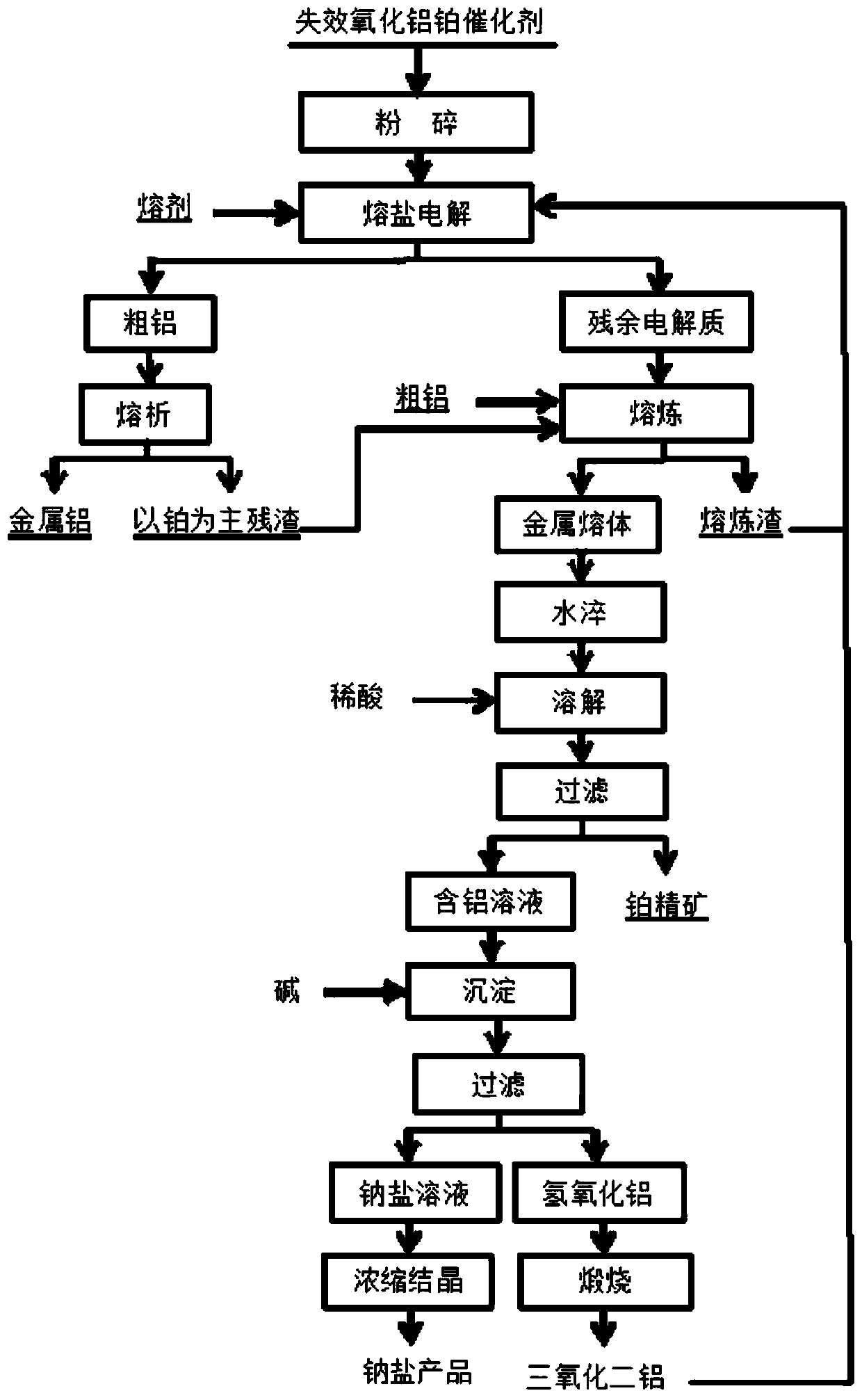

Method for enriching platinum from deactivated alumina platinum catalyst for cogeneration of metal aluminum

ActiveCN111455180AIncrease the added value of the carrierImprove resource utilizationProcess efficiency improvementChemical recyclingMetallic aluminumPtru catalyst

The invention discloses a method for enriching platinum from a deactivated alumina platinum catalyst for cogeneration of metal aluminum, and relates to the technical field of rare and precious metal metallurgy. The method comprises the following steps that the deactivated alumina platinum catalyst and a fluxing agent are subjected to an electrolytic reaction to obtain crude aluminum and residual electrolytes; the crude aluminum is subjected to liguation to obtain metal aluminum and residue; the residue, a part of residual electrolytes and a part of crude aluminum are jointly smelted to obtainsmelting slag and metal melt; the smelting slag returns to an aluminum electrolytic cell, and the metal melt is subjected to water quenching treatment; a water quenching product reacts with dilute acid to obtain platinum ore concentrates and an aluminum-contained solution; the aluminum-contained solution and sodium hydroxide have a reaction to obtain aluminum hydroxide and sodium salt solutions; and the aluminum hydroxide is burned to obtain aluminum oxide to return to the aluminum cell, and the sodium salt solutions are concentrated and crystallized to obtain sodium salt products. According to the method, platinum and aluminum can be recycled from the deactivated alumina platinum catalyst, the platinum recycling rate is larger than 98.0%, the aluminum recycling rate is larger than 92.0%,the platinum enrichment multiple is larger than 120 times, and the aluminum product purity is larger than 98.0%.

Owner:KUNMING BOREN PRECIOUS METALS +1

Method for preparing rare earth containing aluminium alloy

A method for preparing rare earth-containing aluminum alloys, which is carried out in the following steps: (1) treating the surface of waste 6063 aluminum alloys; preparing metal aluminum and the like as smelting material alloys and excess metal magnesium; (2) putting metal aluminum into an induction furnace , after melting, add mixed salt, and then add waste 6063 aluminum alloy; (3) Add part of the smelting material alloy; (4) Use a bell jar to press into part of the smelting material alloy, pour it after degassing; (5) After preheating, heat at 450 Rolling at ±10°C, cold rolling after annealing treatment; (6) Water quenching after cold rolling solution treatment, and then aging. The method of the invention reduces the consumption of industrial pure aluminum, realizes the recycling of waste aluminum alloys, realizes the sustainable development of the aluminum industry, and has the advantages of high recovery rate of waste aluminum, low cost, less pollution and the like.

Owner:胡桂芳

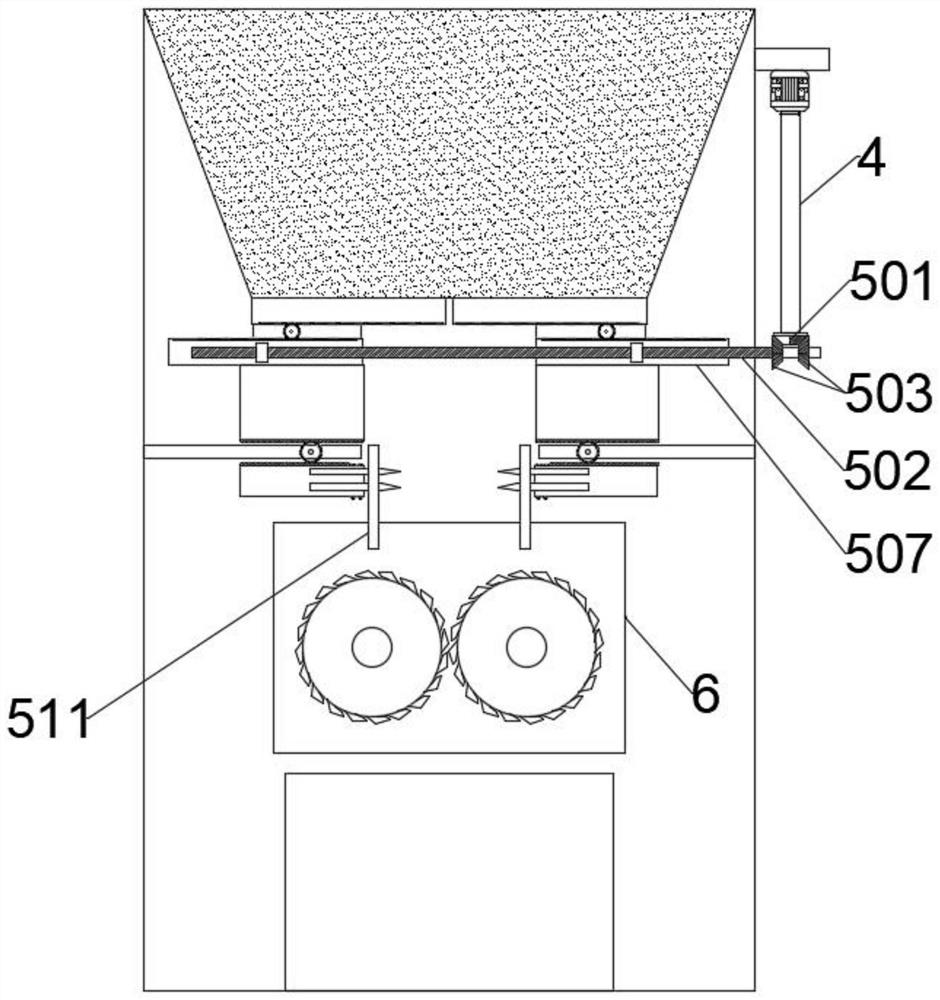

Cutting and crushing equipment for waste aluminum recovery

PendingCN114558654AEasy to crushSmash thoroughlyTransportation and packagingSolid waste disposalAluminium recyclingElectric machine

The invention discloses cutting and crushing equipment for waste aluminum recovery, relates to the technical field of metal cutting, and aims to solve the problem that a crushing roller cannot crush some waste aluminum with a quasi-circular section due to the fact that an existing device does not extrude the waste aluminum before crushing the waste aluminum. A first motor is installed at the top of the rack, a rotating rod is fixed to the output end of the first motor through spot welding, an extrusion assembly is installed at the bottom of the material collecting box and comprises a first bevel gear, the first bevel gear is fixedly connected to the bottom end of the rotating rod, and a threaded rod is movably connected to the middle of the rack through a bearing; the outer side of one end of the threaded rod is sleeved with two second bevel gears. Compared with the prior art, before waste aluminum is crushed by the crushing roller, quasi-circular waste aluminum can be extruded into sheets, so that the waste aluminum is conveniently crushed by the crushing roller, and the problem that the quasi-circular waste aluminum cannot be quickly crushed by an existing device is effectively avoided.

Owner:安徽永茂泰铝业有限公司

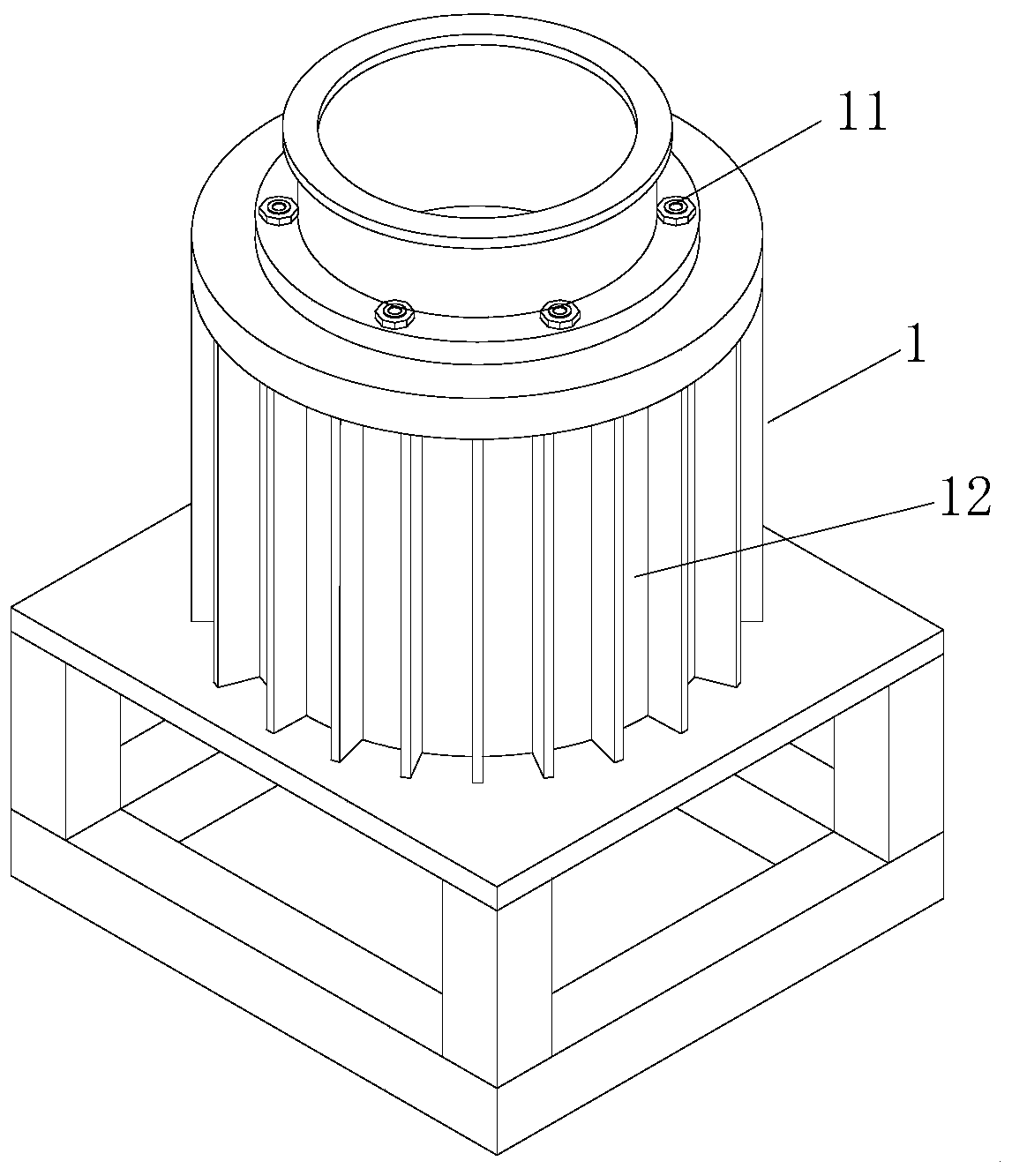

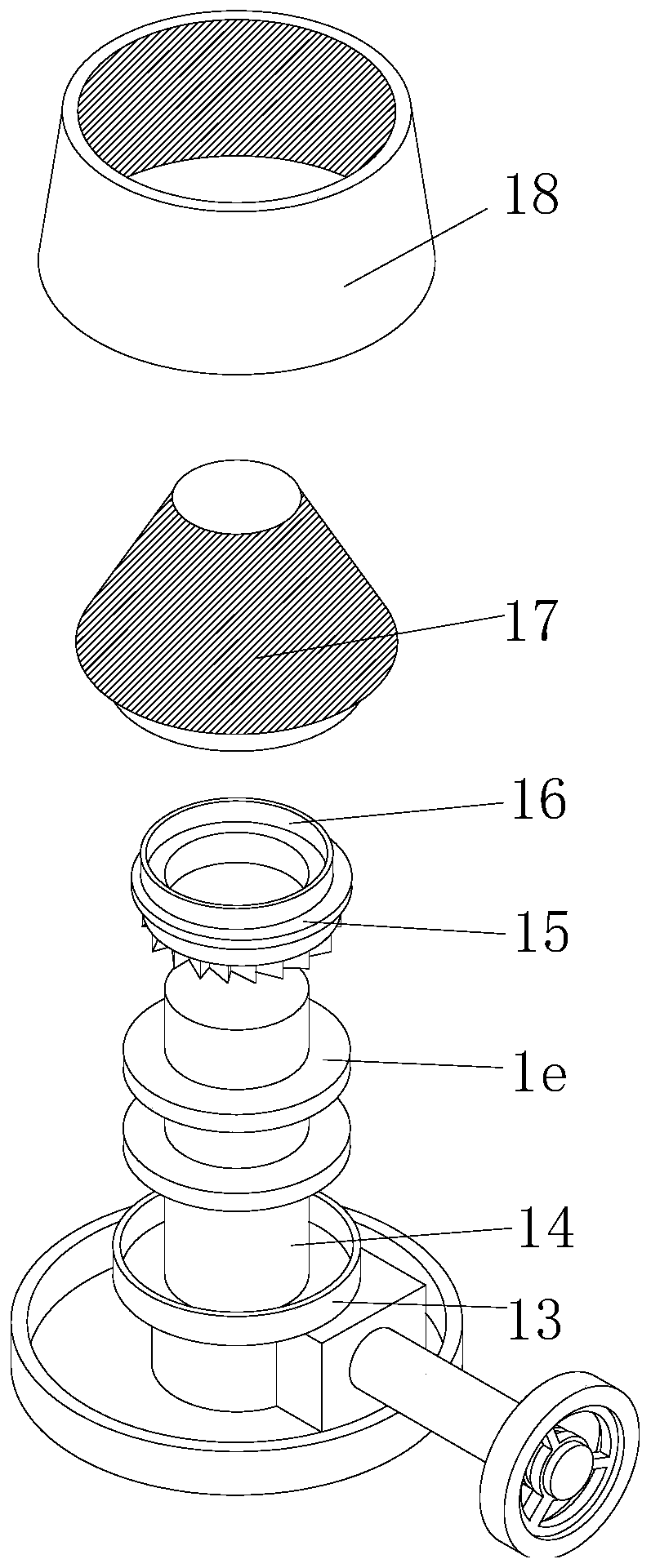

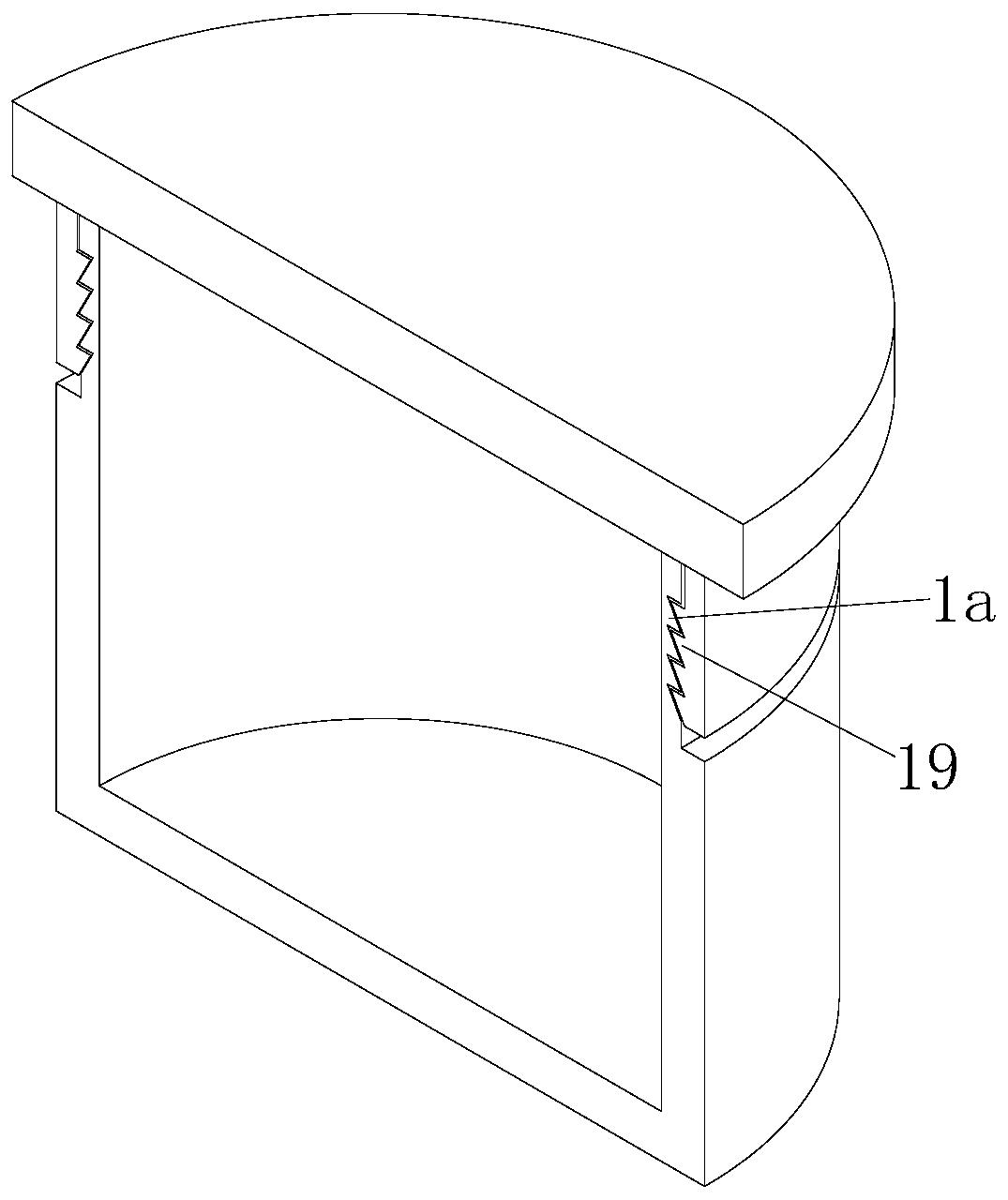

Rotary extrusion waste aluminum recovery device

The invention provides a rotary extrusion waste aluminum recovery device which comprises a waste aluminum extrusion assembly. The waste aluminum extrusion assembly comprises an upper shell and a lowershell, the lower shell is positioned at the bottom end of the upper shell and is connected with the upper shell through an air cylinder, the inner wall of the lower shell is connected with an annularslideway through a bolt, a driving shaft is connected in the annular slideway through a key, the outer periphery of the driving shaft is rotatably connected with a first bevel gear through a bearing,the bottom end of the first bevel gear is slidably connected with the annular slideway through a sliding block, the top end of the first bevel gear is provided with an eccentric slideway, the eccentric slideway and the first bevel gear are integrally formed through a die, the top end of the eccentric slideway is slidably connected with an extrusion cone, and the inner wall of the upper shell is connected with a mortar rolling wall. According to the rotary extrusion waste aluminum recovery device, the extrusion cone can complete the extrusion of the material between the extrusion cone and themortar rolling wall through the matching of the extrusion cone and the mortar rolling wall, so that the extrusion operation is simplified.

Owner:韩峰永

Waste aluminum recycling method

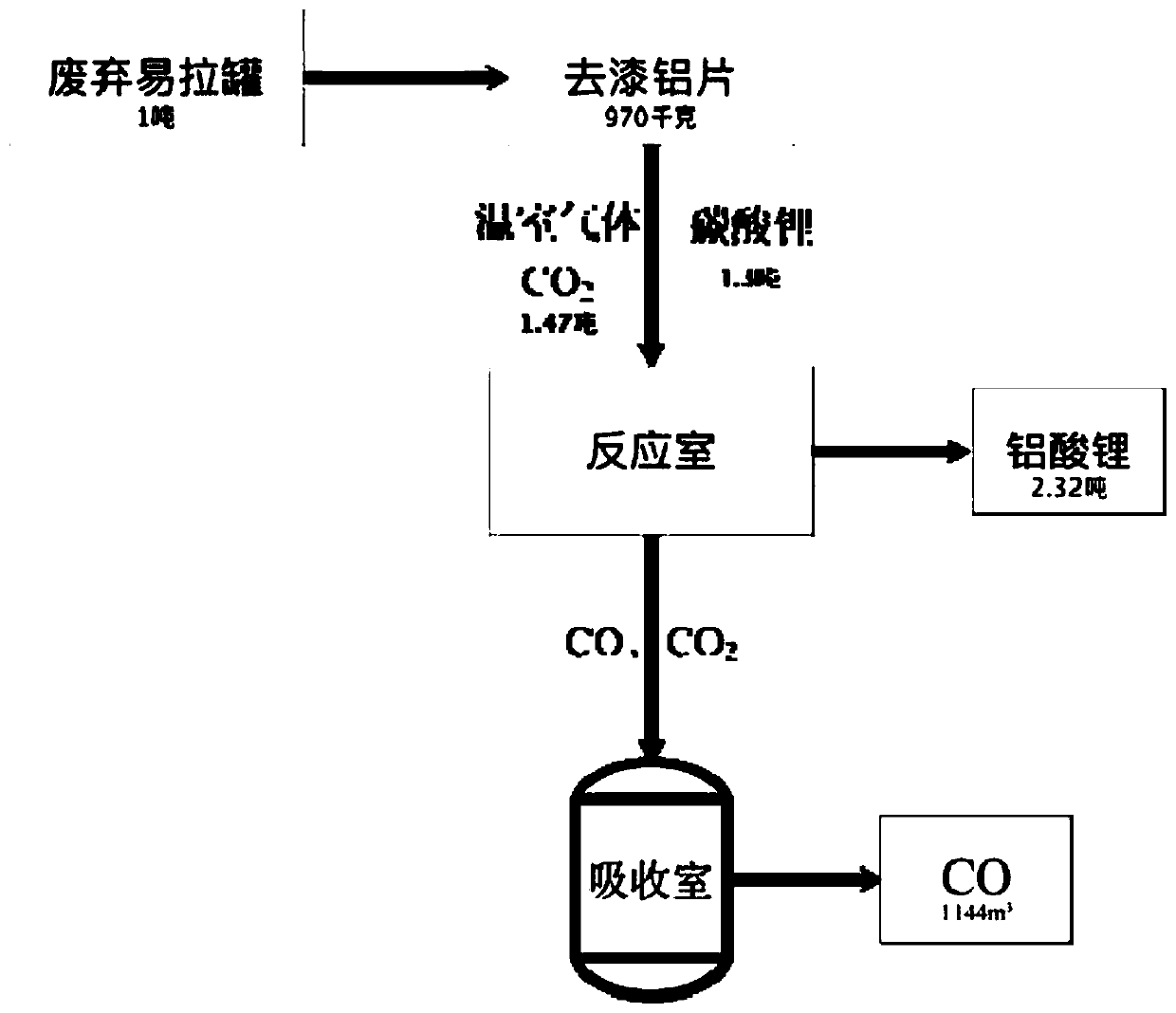

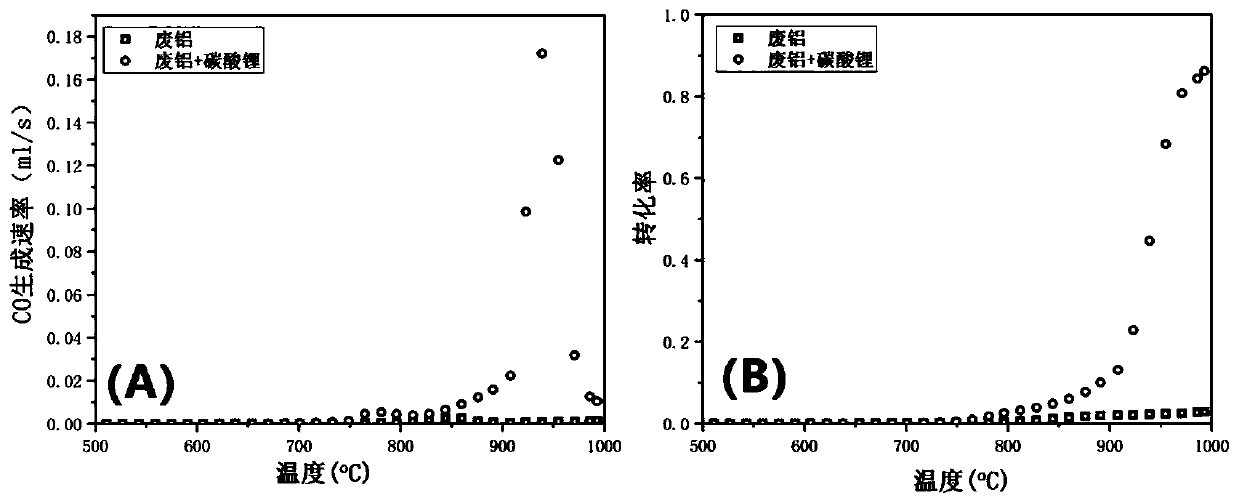

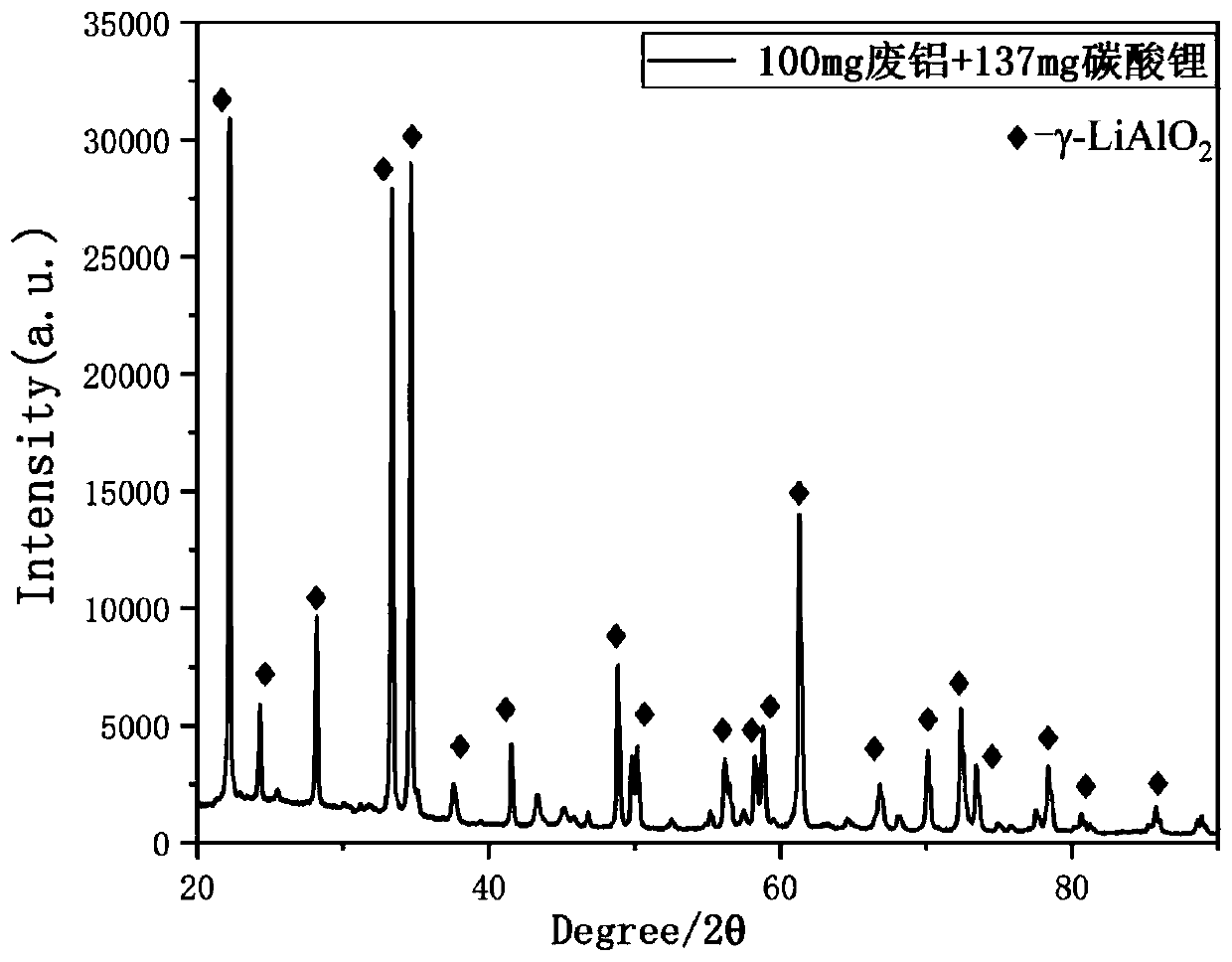

ActiveCN110734082AReduce manufacturing costImprove thermal stabilityWaste processingCarbon monoxideAluminium recyclingLithium carbonate

The invention discloses a waste aluminum recycling method. The waste aluminum recycling method comprises the following steps that waste aluminum is pretreated; mixing the pretreated waste aluminum with lithium carbonate molten salt, then putting the mixture into a crucible, putting the crucible into a reaction furnace, and introducing an inert gas to exhaust air in the reaction furnace; heating toa reaction temperature and introducing carbon dioxide for reaction; and collecting the reacted tail gas and solid products. According to the waste aluminum recycling method, firstly, the generated solid product is gamma-LiAlO2, and the gamma-LiAlO2 material has good thermal stability and molten carbonate corrosion resistance and can be used as an electrolyte substrate material of an MCFC. According to the gamma-LiAlO2 material prepared by the waste aluminum recycling method disclosed by the invention, the waste aluminum is used for replacing primary aluminum, so that the production cost of the gamma-LiAlO2 material can be greatly reduced, and the gamma-LiAlO2 material can be popularized and applied on a large scale. Secondly, the carbon dioxide is consumed in the reaction process and converted into a carbon monoxide fuel, and carbon emission reduction and cyclic utilization are achieved.

Owner:SUZHOU UNIV

Method for processing and preparing high-strength aluminum alloy doors and windows by using recycled aluminum

InactiveCN111893331AImprove mechanical propertiesImprovement ingredientsAluminium recyclingAluminum industry

The invention relates to the technical field of waste aluminum recycling, and discloses a method for processing and preparing high-strength aluminum alloy doors and windows by using recycled aluminum.The invention uses waste aluminum as a raw material to replace part of pure aluminum, adds other alloy elements, and processes and prepares recycled aluminum ingots to be further extruded, processedand formed into aluminum alloy doors and windows. The prepared recycled aluminum ingots are superior in mechanical properties to the widely used aluminum alloys on the market, which have a tensile strength of more than 320MPa, an elongation of more than 15%, and an elongation of more than 228MPa; and the price cost is reduced. The invention obtains the aluminum alloy doors and windows by adoptinga semi-continuous casting process; the added waste aluminum has a high composition, but the aluminum alloy doors and windows with excellent performance can be produced; and therefore, the renewable utilization rate of waste aluminum is improved, the production cost is reduced, and the problems of irrational aluminum industry structure and backward development of the secondary aluminum industry aresolved.

Owner:安徽百圣鑫金属科技有限公司

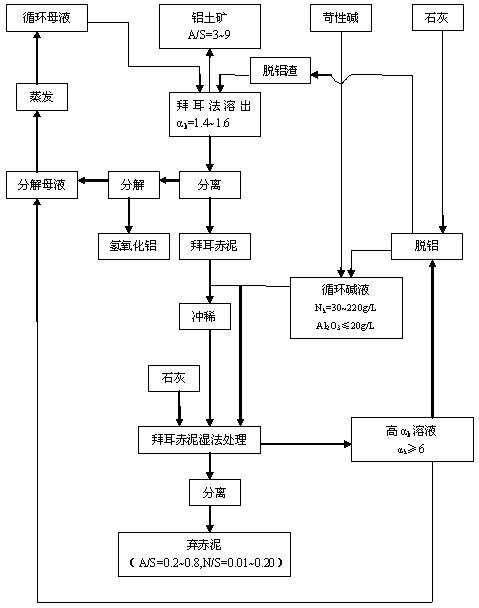

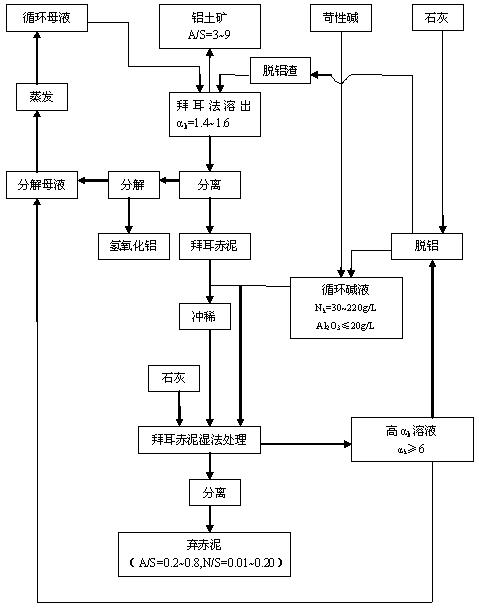

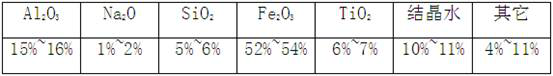

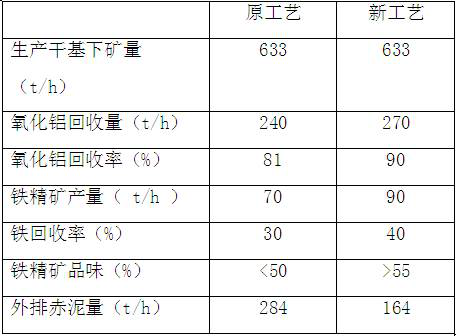

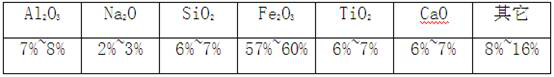

Improved method for producing aluminium oxide by medium-low-grade bauxite

ActiveCN102070166AHigh recovery rateReduce the amount addedAluminium oxides/hydroxidesRed mudAluminium recycling

The invention relates to an improved method for producing aluminium oxide by medium-low-grade bauxite, which is characterized in that the production process comprises two-time dissolution processes, i.e. (1) dealuminizing slag is added into the bauxite for carrying out Bayer-process dissolution, and carrying out Bayer-process production of the aluminium oxide; and (2) adding Bayer-process dissolved red mud obtained in the step (1) into alkali liquor, carrying out wet-process dissolution treatment, recovering alkali and aluminium oxide in the Bayer-process red mud. In the method disclosed by the invention, the process of the Bayer process mainly recovers the aluminium oxide in the bauxite, and a wet-process red mud treatment system mainly recovers alkali in the Bayer-process red mud. Dissolved liquor obtained in the Bayer-process part is diluted and purified to remove seed crystal for decomposition, lime is added into the dissolved liquor by wet-process treatment of the Bayer-process red mud to dealuminize, the obtained high-molecular-proportion dealuminized mother liquor is then used for dissolving the Bayer-process red mud, solid-phase dealuminizing slag replacing the lime is added into a Bayer-process system. In the method disclosed by the invention, the process is simple, the energy consumption is low, alkali consumption is low, the recovery ratio of the aluminium oxide is high, the method is suitable for treating the medium-low-grade bauxite mainly in China, the resource utilization ratio is high, the discharged red mud amount is less, and the red mud is easy to be utilized comprehensively.

Owner:河南华慧有色工程设计有限公司 +1

Novel process for recycling aluminum oxide and iron oxide by dissolving out red mud at low temperature

PendingCN114212809AHigh recovery rateReduce storage costsAluminium compoundsFerric oxidesAluminium recyclingRed mud

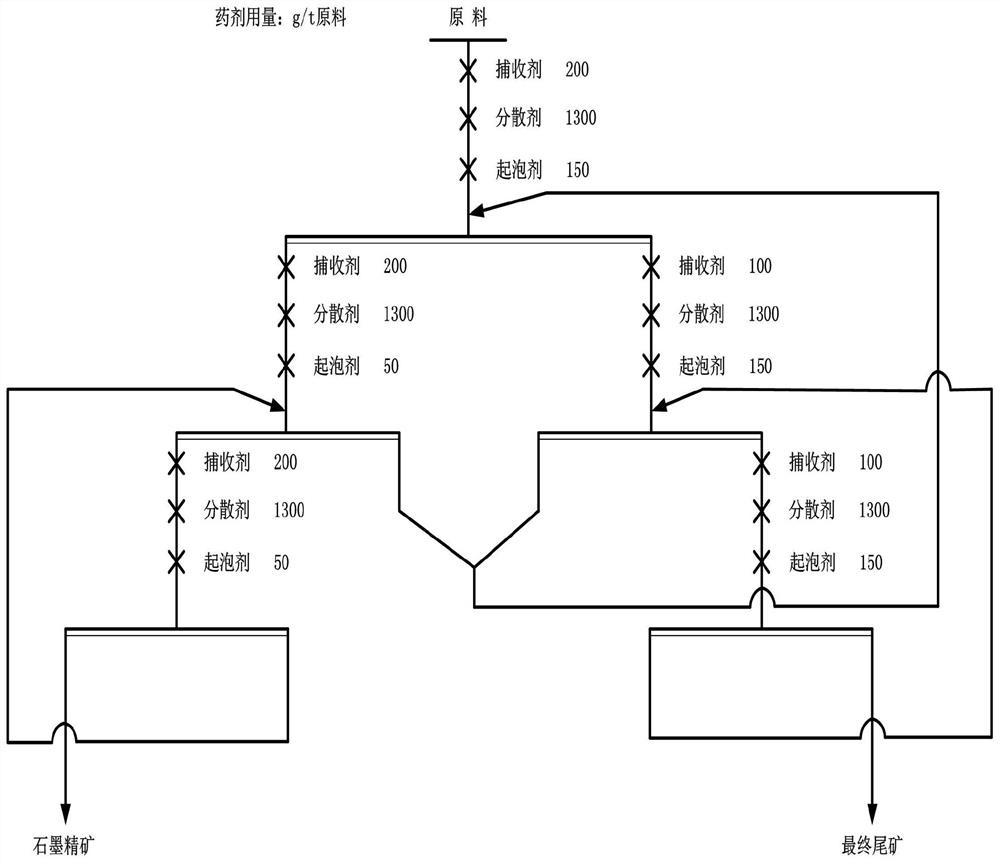

The invention relates to a novel process for recycling aluminum oxide and iron oxide by dissolving out red mud at low temperature. The novel process comprises the following steps: 1) preparing materials; 2) high-temperature dissolution; 3) cooling the slurry; 4) performing liquid-solid separation; the low-temperature dissolved red mud treatment method comprises the following steps of (1) red mud treatment, (2) red mud washing, (3) solid content adjustment, (7) roughing, (8) tailing concentration, (9) roughing concentrate concentration and desliming, (10) concentration, (11) concentrate concentration, (12) concentrate filter pressing, (13) concentration and desliming of concentrated tailings, (14) scavenging, (15) middling concentration and (16) middling filter pressing. The low-temperature dissolved red mud treatment method has the obvious advantages of being high in aluminum oxide recovery rate and iron oxide recovery rate, good in red mud sedimentation performance and large in red mud emission reduction.

Owner:冯圣生

Method for recycling waste aluminum material to manufacture aluminum casting

InactiveCN105274340AReduce harmful hydrogenReduce and control iron contentProcess efficiency improvementAluminium recyclingCasting mold

The invention provides a method for recycling a waste aluminum material to manufacture aluminum casting. The method comprises the following steps: a, screening: magnetically separating the waste aluminum material to remove iron, magnetically separating or manually sorting to remove other impurities; and carrying out dehydration and oil removal on the impurity-removed waste aluminum material at a temperature of 300-400 DEG C; b, smelting: weighing and adding crude aluminum into a smelting furnace for being molten into crude molten aluminum at a temperature of 850-950 DEG C, then, adding the waste aluminum material, which accounts for 5-8% of the total mass of the crude aluminum, obtained in the step a into the crude molten aluminum, and stirring and melting to obtain mixed molten aluminum; and c, casting: casting the mixed molten aluminum obtained in the step b into a casting mould to obtain the aluminum casting. The method has the advantages of being simple in process, high in waste aluminum adaptation, low in cost, high in aluminum recovery rate, and the like.

Owner:LINZHOU LINFENG ALUMINUM & ELECTRICITY

Method and system for preparing high-whiteness and high-purity aluminum hydroxide from solid waste

PendingCN113800544ARealize harmless treatmentRealize resourcesAluminium oxides/hydroxidesAluminium hydroxideSlag

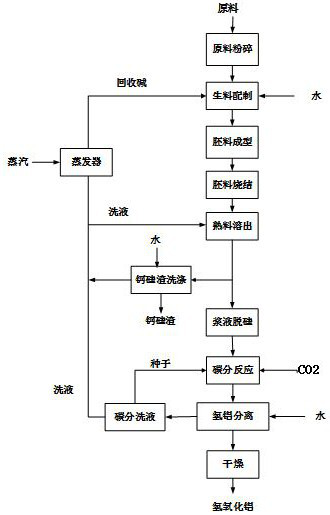

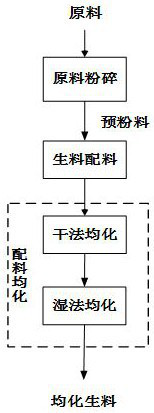

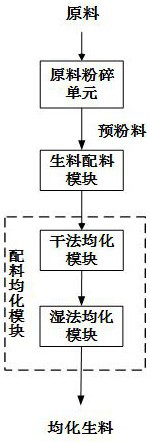

The invention relates to a method and a system for preparing high-whiteness and high-purity aluminum hydroxide from solid waste. The preparation method comprises the following steps: firstly, crushing raw materials to form pre-powder, preparing raw materials from the pre-powder, molding the pre-powder to obtain a blank, sintering the blank to obtain clinker, dissolving out the clinker to obtain slurry, and carrying out slurry desilication, carbon component reaction, hydrogen-aluminum separation and drying on the slurry to prepare the high-whiteness and high-purity aluminum hydroxide. The raw materials comprise aluminum-containing solid waste, calcium-containing solid waste, pulverized coal and sodium carbonate; the raw material crushing comprises the step of crushing the raw materials to process control fineness; and blank sintering refers to temperature programming roasting of the blank, and the roasting temperature ranges from 800 DEG C to 1100 DEG C. According to the invention, solid wastes such as fly ash, coal gangue, carbide slag and the like, pulverized coal and sodium carbonate are crushed into materials with the same fineness, high-whiteness and high-purity aluminum hydroxide can be obtained through alkali-process blank sintering, the recovery rate of aluminum in the solid wastes is 90% or above, and harmless, resource and synergistic utilization of the solid wastes such as fly ash and the like is realized.

Owner:内蒙古茂燊科技有限公司 +1

Method for increasing recycling rate of waste aluminum cans

InactiveCN111893315AImprove recycling rateHigh purityProcess efficiency improvementAluminium recyclingSmelting process

The invention relates to the technical field of waste aluminum recycling, and discloses a method for increasing the recycling rate of waste aluminum cans. The method comprises the steps that firstly the waste aluminum cans are pre-processed, the pre-procession comprises the steps of deironing, cleaning, drying, removing paint, and then pressing the cans into cakes; the cakes of pressed aluminum cans are send into a smelting furnace, a prepared impurity removing solution is added in the smelting process, the additive amount is 0.70%-0.73% of the quality of smelted liquid, the impurity removingsolution can remove most impurities and gases in the process of aluminum cakes smelting, and is beneficial to the separation of slag and aluminum and improve the purity of recovered aluminum. The recovery rate of aluminum in the waste aluminum cans reaches more than 90.5%, and the impurity content is lower than 0.07%. Through the research of waste aluminum regeneration technology, the method realizes the practical application, is conducive to the sustainable development of aluminum resources, reduces the energy consumption, and improves the economic benefits.

Owner:安徽百圣鑫金属科技有限公司

A method for synchronously preparing sodium aluminate through sintering and denitrification of aluminum ash and soda

ActiveCN109928413BPromote oxidative decompositionPromote conversionAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAir atmosphereAluminium recycling

The invention discloses a method for synchronously preparing sodium aluminate through aluminum ash soda sintering denitrification. The method comprises the steps that aluminum ash and mixed sodium salt prepared from sodium carbonate, sodium bicarbonate and sodium peroxide are mixed evenly, and pressed into agglomerates; the agglomerates are dried and sequentially placed in an air atmosphere to besubjected to first-section low-temperature roasting and placed in a strong-oxidizing atmosphere to be subjected to second-section intermediate-temperate roasting, roasted products are cooled and crushed, and then leached out by an alkaline solution, and thus a sodium aluminate solution is obtained. According to the method, industrial waste residue is utilized as a main raw material, the raw material source is wide, the cost is low, the aluminum recovery rate is high, operation is easy, the production cost is low, the environmental friendly effect is achieved, and industrial production requirements are met.

Owner:CENT SOUTH UNIV

Aluminum alloy processing method for improving utilization rate of waste aluminum

InactiveCN111893330AIncrease profitHigh strengthProcess efficiency improvementAluminium recyclingAluminum can

The invention relates to the technical field of waste aluminum recycling, and discloses an aluminum alloy processing method for improving the utilization rate of waste aluminum. The method comprises the following steps of: processing the recycled waste aluminum into an aluminum ingot, mixing the aluminum ingot with pure aluminum according to a mass ratio of (0.33-0.35): (0.60-0.70), adding other alloy elements accounting for 3.5-4.5% of the mixed aluminum material in percentage by mass, and smelting to obtain the aluminum alloy. The binding force between the waste aluminum and new aluminum isenhanced, the processability is upgraded, and the strength of the aluminum alloy is improved. According to the method disclosed by the invention, impurity removal and smelting are performed on the waste aluminum to remove harmful elements in the waste aluminum, so that the quality of the secondary aluminum is guaranteed; when the waste aluminum is used as a pure aluminum substitute for preparing the aluminum alloy, the result shows that the tensile strength of the aluminum alloy profile prepared by adding 30-35% of waste aluminum reaches 345-355MPa, the elongation reaches 11-16%, and the mechanical performance effect is superior to that of the aluminum profile prepared by adding alloy elements into pure aluminum; and moreover, the renewable utilization rate of the waste aluminum is improved, the production cost is reduced, the utilization rate of the waste aluminum can be improved, and the prepared aluminum alloy has extremely high strength and plasticity.

Owner:安徽百圣鑫金属科技有限公司

Recovery system and recovery process for aluminum ash

InactiveCN111375622AReduce recycling costsReduce the proportion of ingredientsSolid waste disposalTransportation and packagingInorganic saltsMicroorganism

The invention provides a recovery system and a recovery process for aluminum ash. The recovery system involves screening equipment for preliminarily screening the recovered aluminum ash, wherein an absorption tower for carrying out deamination treatment on the aluminum ash is connected to the screening equipment; the absorption tower comprises an ammonia gas tank for providing ammonia gas and a reaction kettle; the feeding end of the reaction kettle is connected with the absorption tower, a microbial treatment tank is connected to the discharging end of the reaction kettle, and a calcining device is further connected to the microbial treatment tank. According to the recovery process, a microbial treatment process is added on the basis of a traditional aluminum recovery process so that therecovered aluminum ash can be completely infiltrated in the microbial treatment tank, fluoride in the aluminum ash is decomposed through microorganisms, the content of inorganic salt in treated remaining aluminum slag can be reduced, the proportion of heavy metal components is reduced, and a culture source and a raw material selected for microbial decomposition are cheap and easily available, so that the aluminum ash recovery cost is reduced.

Owner:XINGHUA YONGTAI ALUMINUM IND

Waste aluminum recovery device for easy-to-open cover production line

InactiveCN114260292AEasy to useReduce corner sharpnessSolid waste disposalProduction lineAluminium recycling

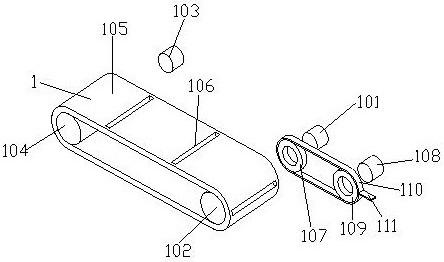

The invention discloses a waste aluminum recovery device for an easy-to-open cover production line, and relates to the technical field of easy-to-open cover production. The waste aluminum recovery device for the easy-open cover production line comprises a device shell, a movement mechanism is arranged in the device shell and comprises a first motor, the rear end of the first motor is fixedly connected with the device shell, a first roller is fixedly connected to an output shaft of the front end of the first motor, a first column is arranged on the left side of the first motor, and the rear end of the first column is fixedly connected with the device shell; the front end of the first column is rotatably connected with a second roller through a bearing, the first roller and the second roller are the same, the outer side of the first roller and the outer side of the second roller are jointly sleeved with a movement belt, six ball column grooves are evenly formed in the outer surface of the movement belt at equal intervals, and clamping mechanisms are evenly arranged on the outer side of the movement belt at equal intervals. According to the waste aluminum recovery device for the easy-to-open cover production line, waste aluminum sheets can be more conveniently used subsequently, meanwhile, the corner sharpness of the waste aluminum sheets is greatly reduced, and the possibility that workers are accidentally injured is reduced.

Owner:英联金属科技(扬州)有限公司

Alumina recovery system and method

PendingCN112811451AEasy dischargeImprove convenienceAluminates/aluminium-oxide/aluminium-hydroxide purificationAmmonia preparation/separationMetallic aluminumAluminium recycling

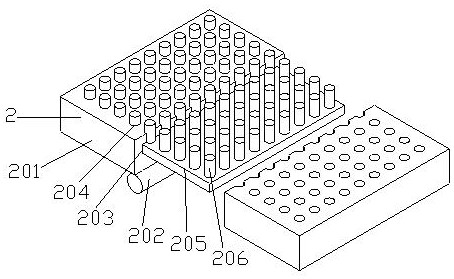

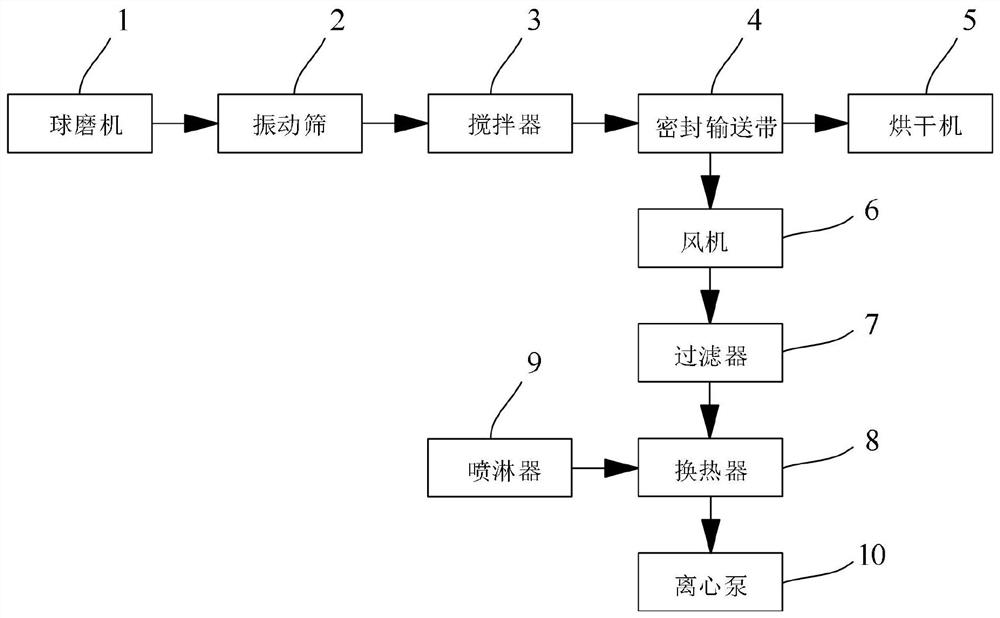

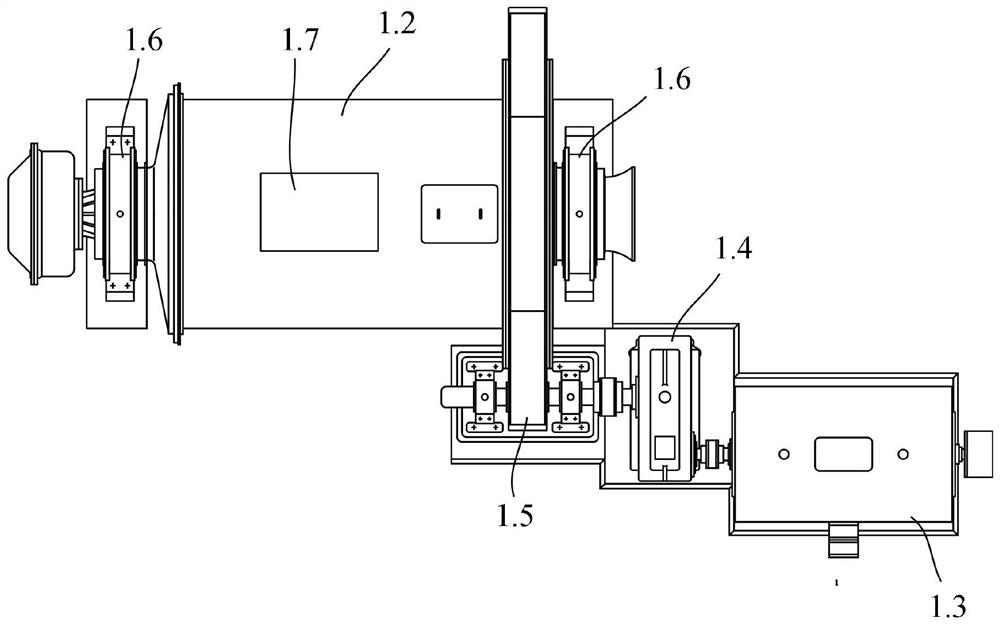

The invention relates to an alumina recovery system and method. The alumina recovery system comprises a ball mill, a vibrating screen, a stirrer, a sealed conveying belt and a dryer; the vibrating screen is arranged at one end of the ball mill, the discharging end of the vibrating screen is communicated with the feeding end of the vibrating screen, and the discharging end of the vibrating screen is communicated with the feeding end of the stirrer; the sealed conveying belt is arranged at one end of the stirrer, the discharging end of the stirrer is communicated with the feeding end of the sealed conveying belt in a sealed mode, and the output end of the sealed conveying belt is communicated with the feeding end of the dryer in a sealed mode. Compared with the prior art, the method has the advantages that the material containing aluminum slag and aluminum ash mixture is treated, metal aluminum, aluminum oxide and ammonia gas are recycled, the effective utilization rate of the aluminum slag and the aluminum ash is increased, the harm of the aluminum ash is solved, and the environmental economy of China is improved; the technology is simple and the cost is low.

Owner:安溪县世荣有色金属有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com