Waste aluminum recycling method

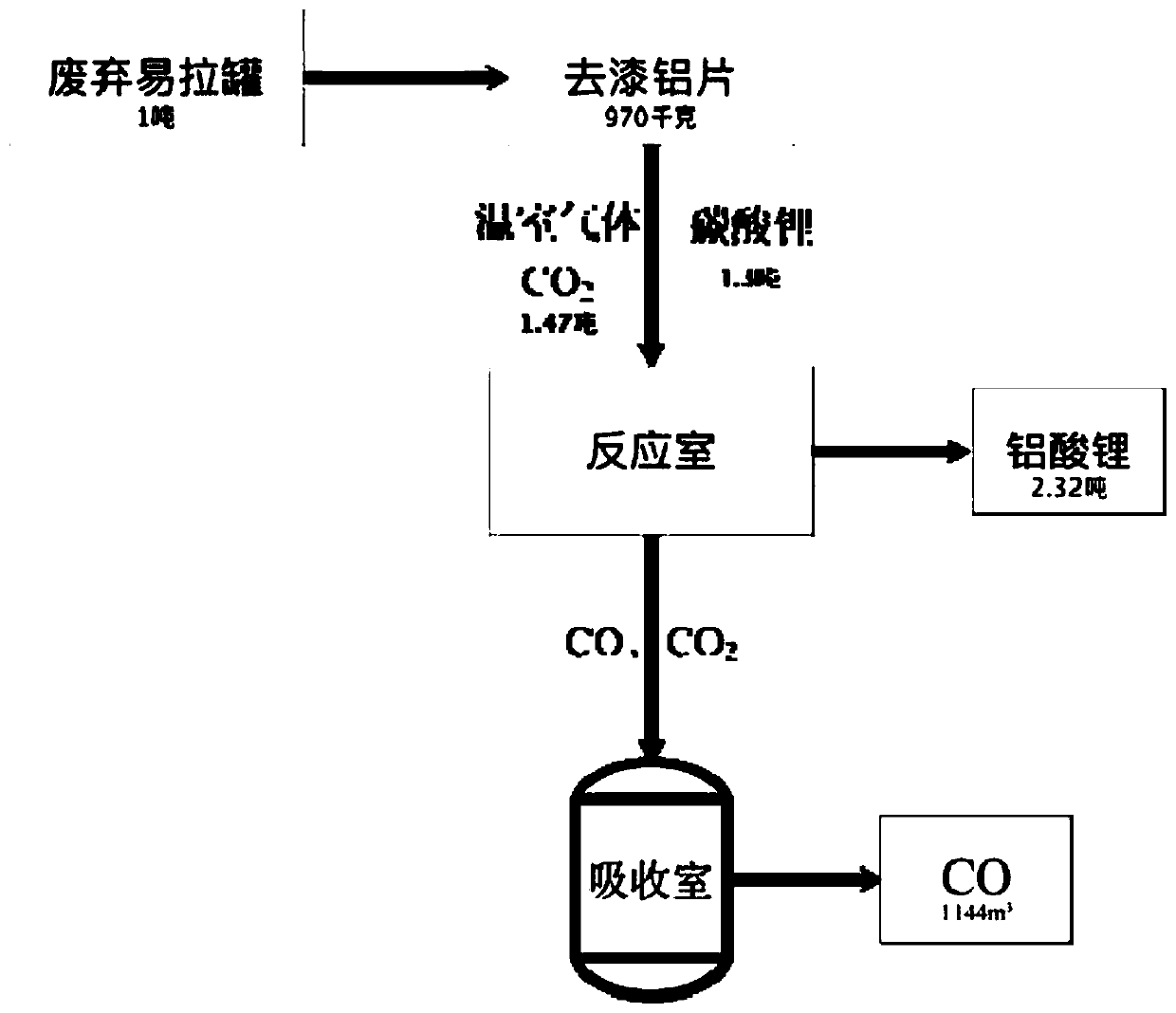

A pretreatment and crucible technology, applied in the field of waste aluminum recycling, can solve the problems of complex process and a large amount of aluminum slag, and achieve the effects of reducing production cost, good thermal stability, and realizing carbon emission reduction and recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The discarded aluminum pop cans were broken into 2mm×2mm aluminum flakes, the aluminum flakes were cleaned and dried, and then treated in a high-temperature furnace at 500°C for 30 minutes for paint removal.

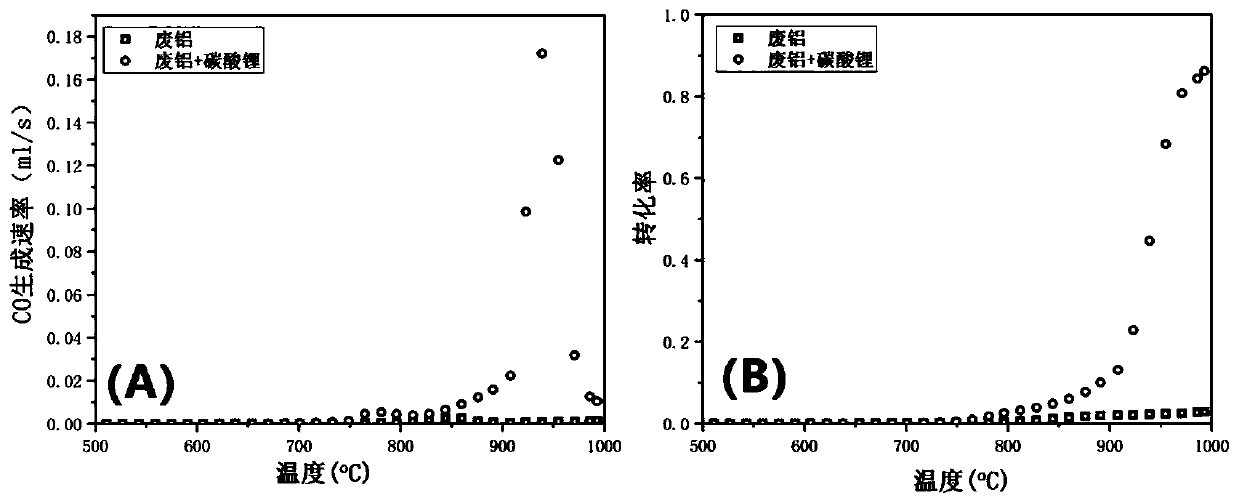

[0059] After mixing the above-mentioned aluminum flakes with lithium carbonate molten salt evenly, place them in the reaction furnace, pass 200ml / min high-purity argon gas for 12 hours, and blow away the remaining air in the reaction furnace and pipeline. Then the reaction furnace was raised to 900°C at a rate of 5°C / min, and 40ml / min CO was introduced at 500°C. 2 The gas reacts.

[0060] The generated tail gas is removed by soda lime and dried by silica gel, and then enters the gas chromatograph to record the change of carbon monoxide concentration.

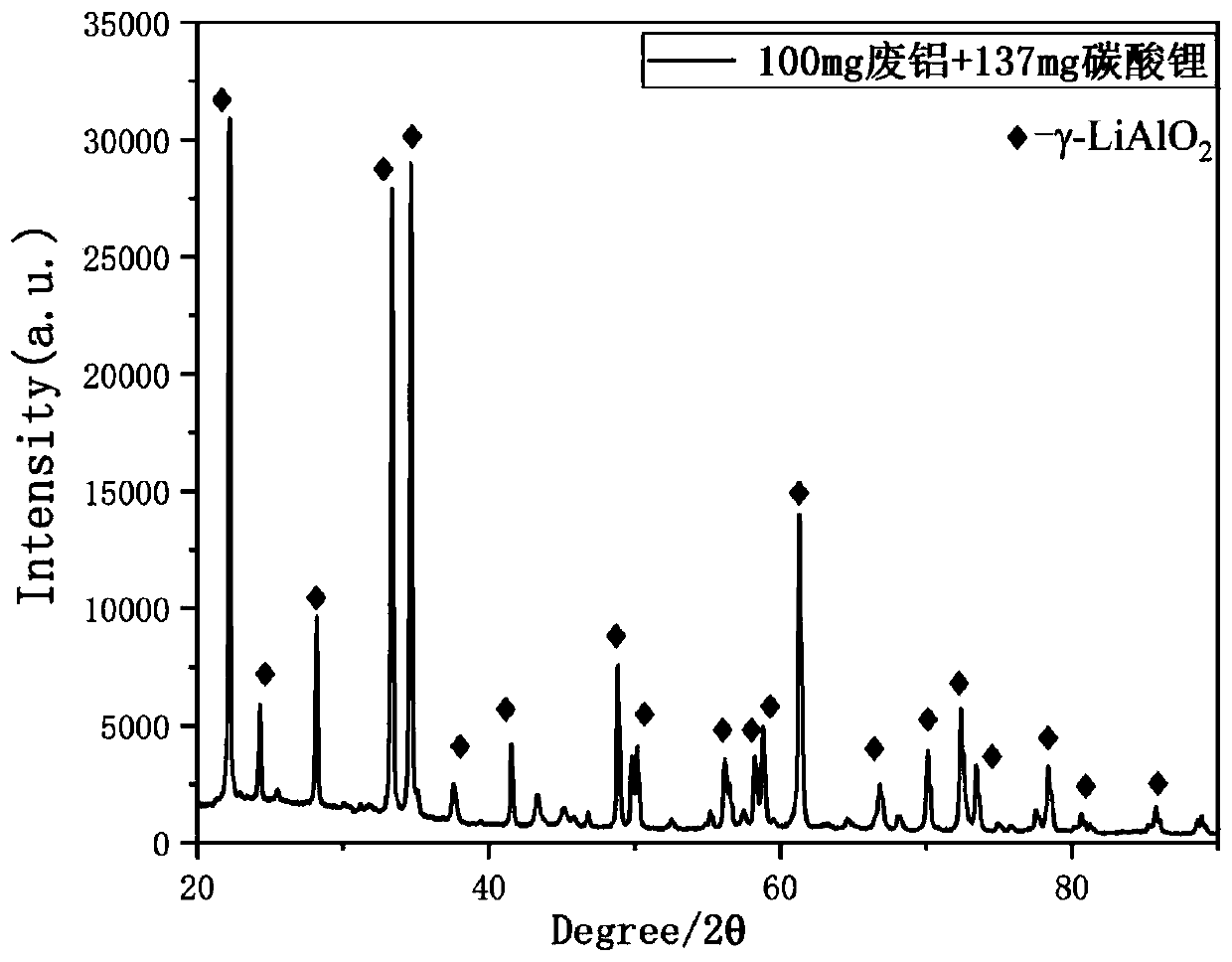

[0061] Collect solid product, and carry out X-ray diffraction phase analysis, the result sees image 3 and using a scanning electron microscope to observe the morphology of the solid product, the results are shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com