Patents

Literature

135results about How to "To achieve the purpose of removing impurities" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

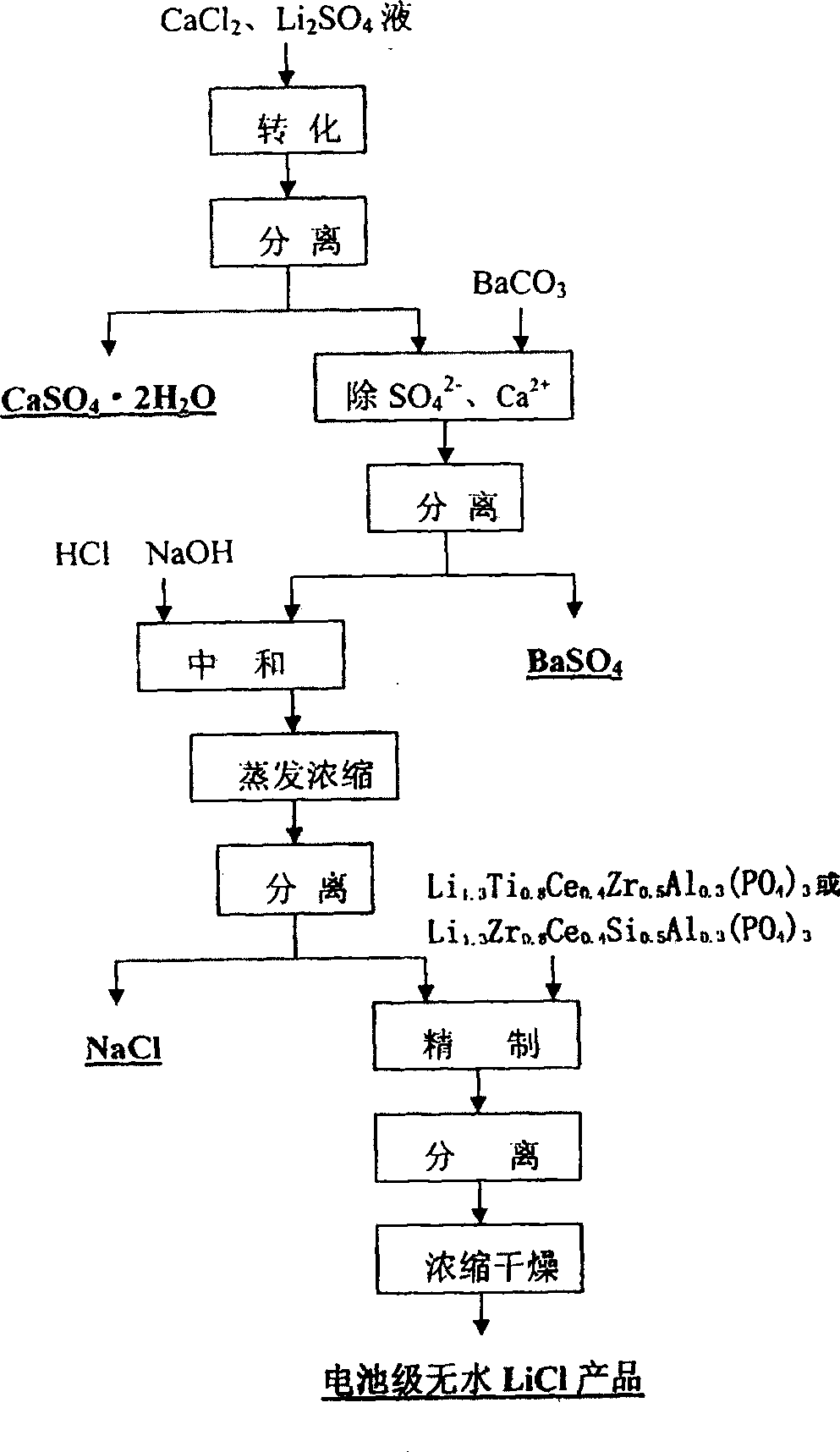

Method for preparing battery-stage anhydrous lithium chloride

ActiveCN101125667AReduce lossesHigh recovery rateAlkali metal chloridesLithium sulphateLithium chloride

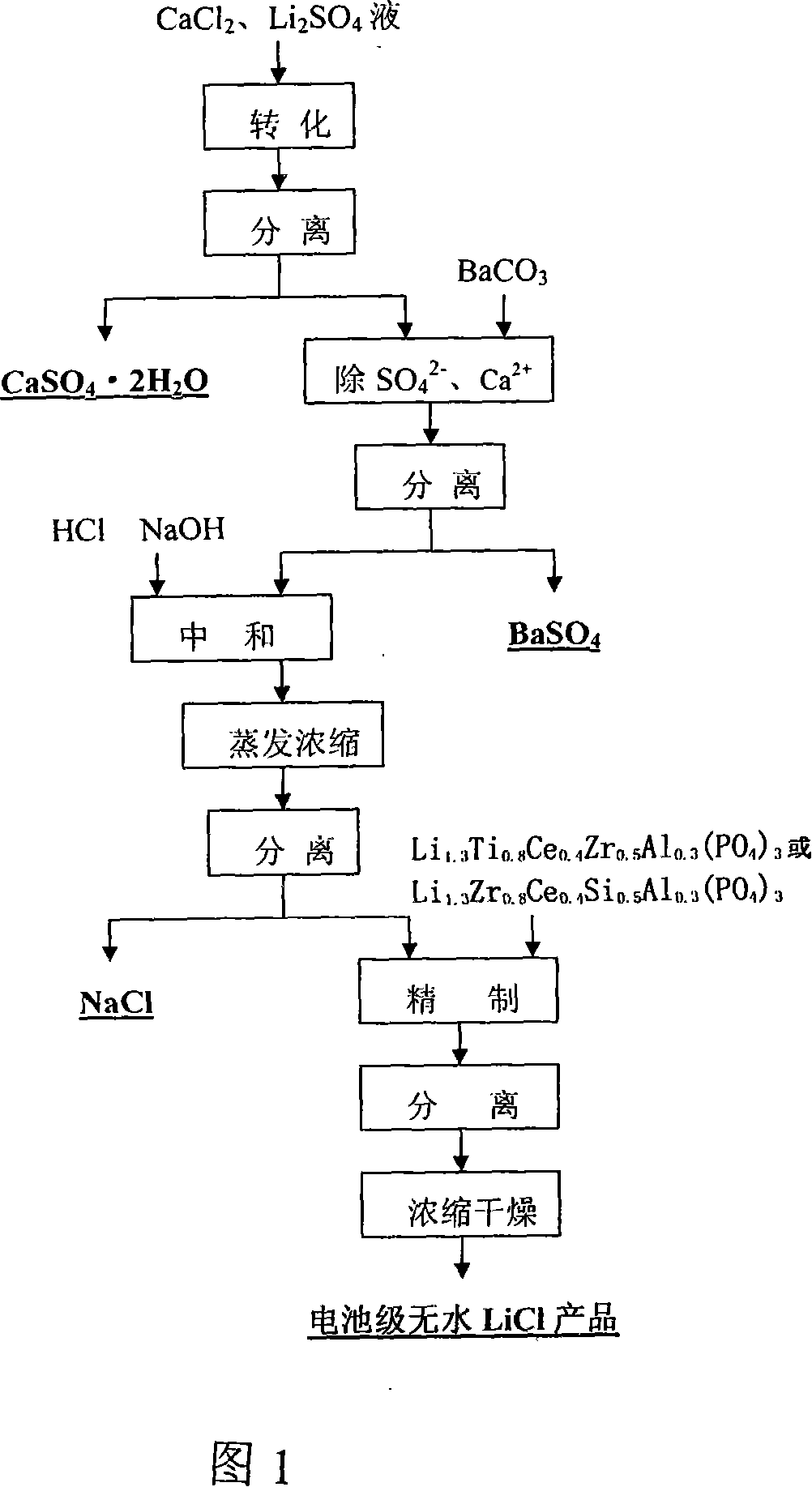

The invention provides a preparation method of a battery grade lithium chloride, comprising: (1) calcium chloride is added into the acid clinker extracting solution of lithium concentrate - lithium sulfate solution, the PH value of the solution is regulated by NaOH to eliminate Fe and Mg, and the precipitation of CaSO4.2H2O, Fe(OH)3 and Mg(OH)2 and lithium chloride solution are obtained after the reaction; (2) the products of step (1) are filtered and cleaned to eliminate the precipitation of CaSO4.2H2O, Fe(OH)3 and Mg(OH)2, and the LiCl solution, i.e. a conversion solution is prepared; (3) the conversion solution is added with BaCO3, and filtered and cleaned after the reaction, to eliminate SO42- and Ca2+, and the LiCl concentrate liquid 1 is prepared; (4) the LiCl concentrate liquid is added with HCL and boiled to eliminate CO32-, and added with NaOH solution to back blend PH, then be evaporated, condensed, cooled, crystallized and separated, and the LiCl concentrate liquid 2 is obtained; (5) the LiCl concentrate liquid is added with refining agent, and filtered and cleaned after the reaction to eliminate Na, and the LiCl finish liquid is prepared, the LiCl finish liquid is condensed and dried, and finally the battery grade LiCl product is prepared. The invention has simple production process and can be easily operated.

Owner:TIANQI LITHIUM CORP

Device and method for preparing high-purity chalcogenide glass

InactiveCN102936090ASimple processEliminates impurity absorptionGlass furnace apparatusEngineeringPollution

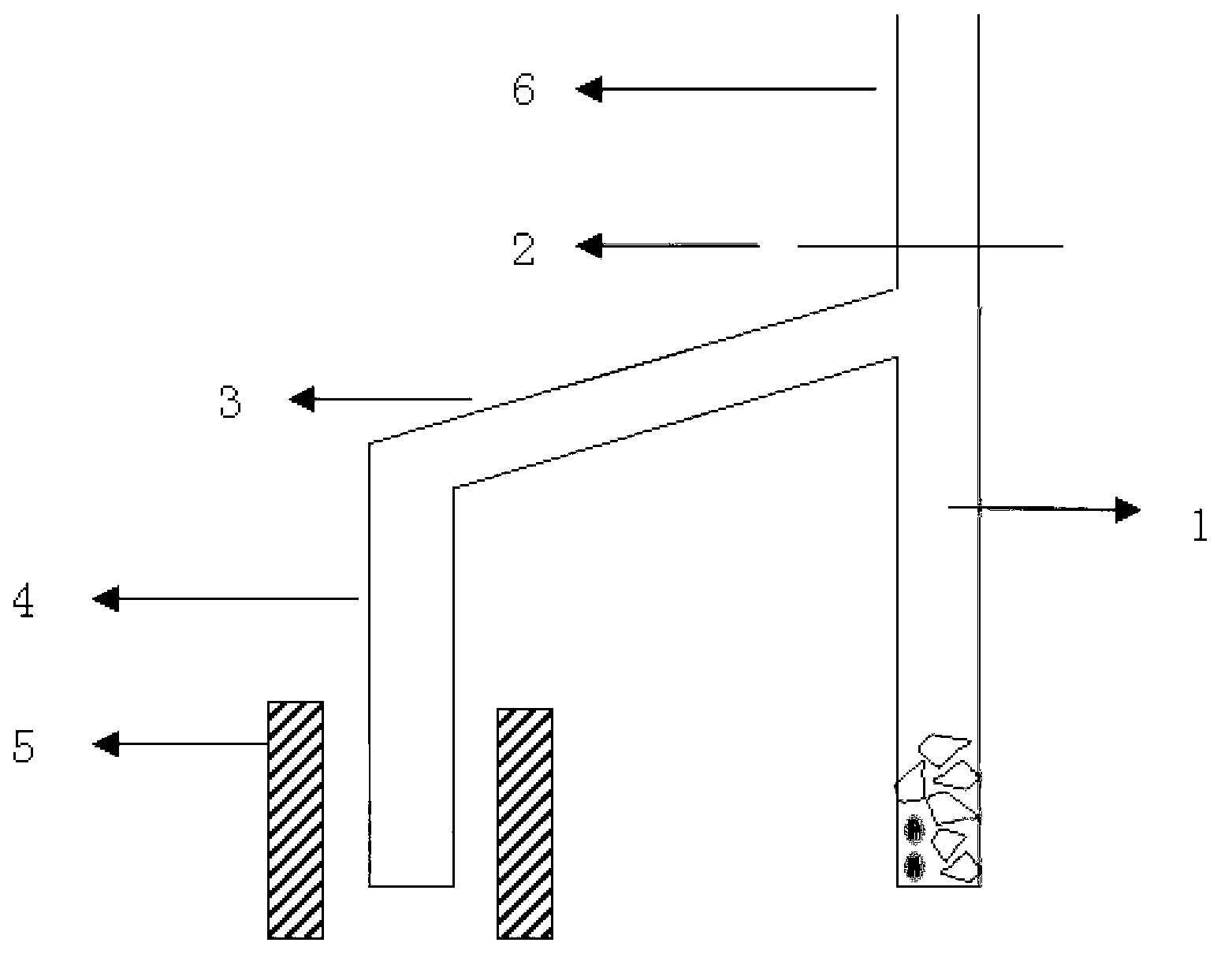

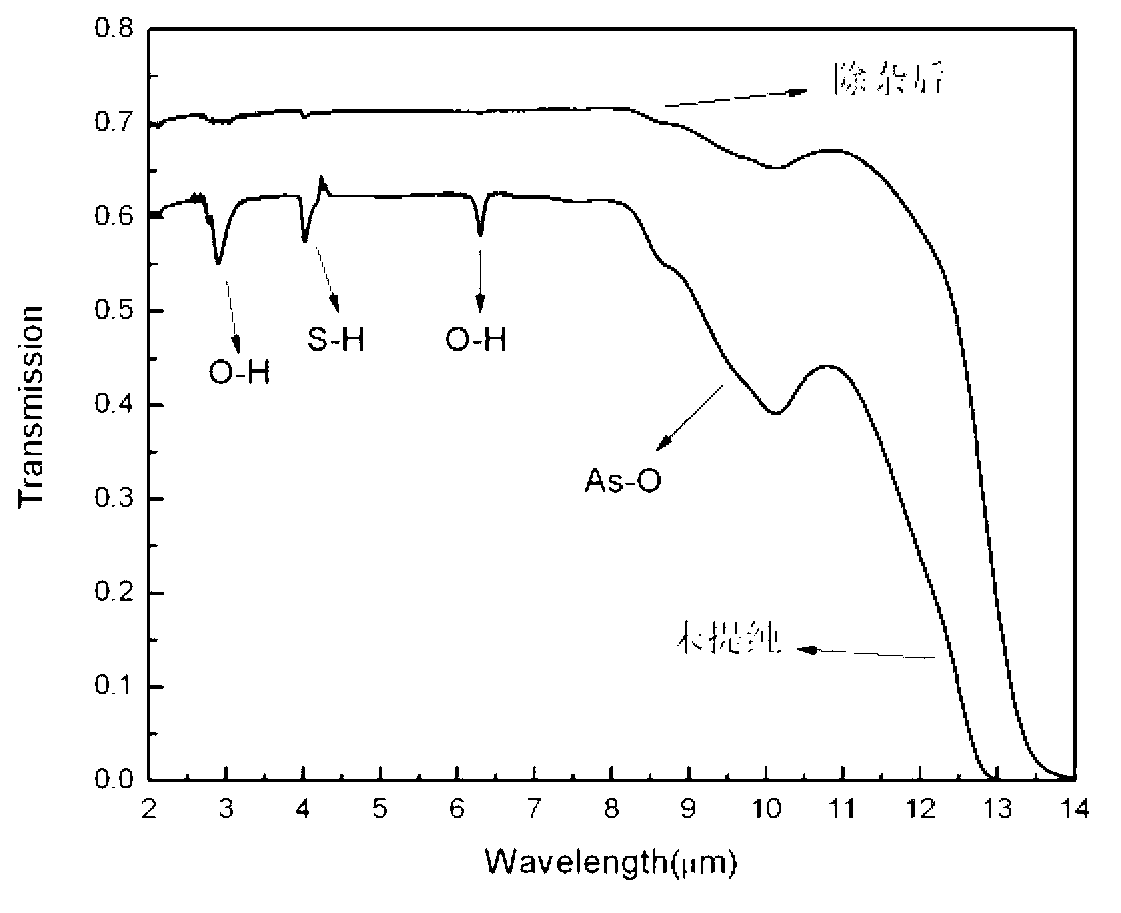

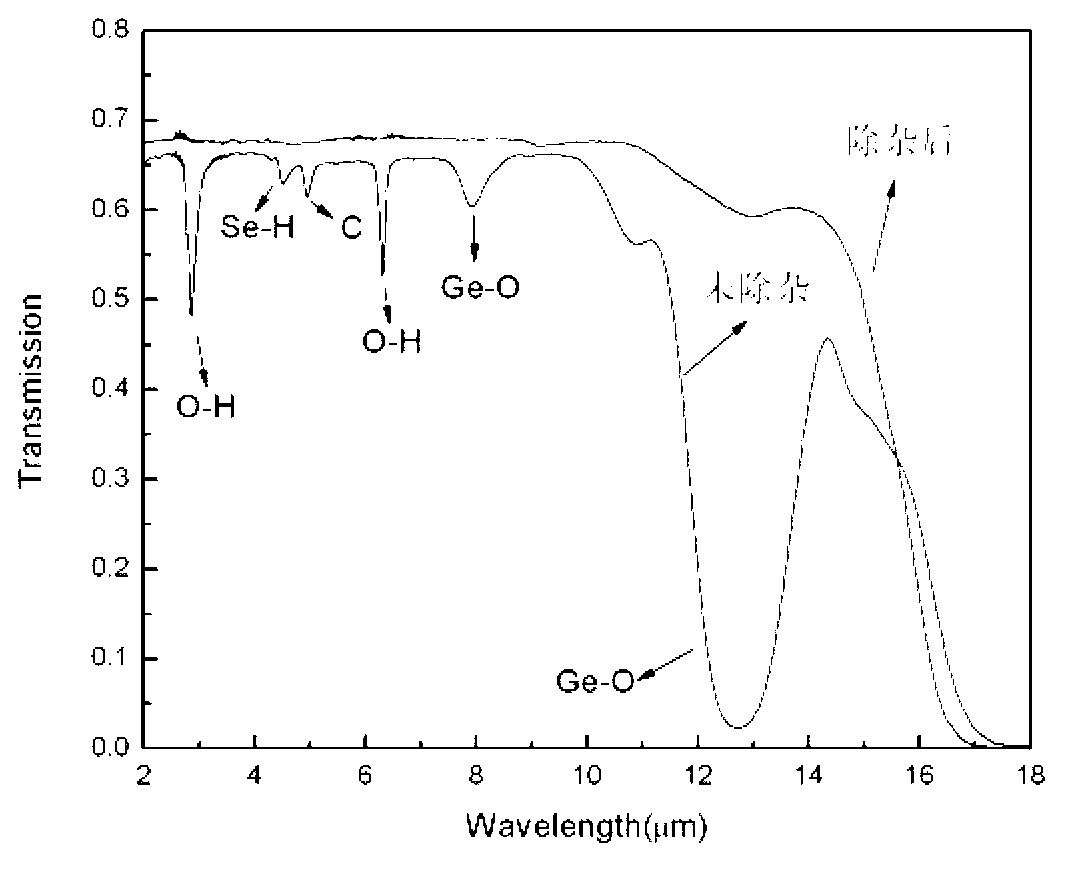

The invention provides a device and a method for preparing high-purity chalcogenide glass. By means of the device and the method, the technical problem that the chalcogenide glass prepared in the prior art is high in purity content, large in absorbing consumption, complex in purification and the like. The device comprises a first vertical pipe, a second vertical pipe, a connection pipe and a third vertical pipe, wherein the upper end of the third vertical pipe is the only opening of the device, the lower ends of the first vertical pipe and the second vertical pipe are both enclosed, and the upper ends of the first vertical pipe and the second vertical pipe are communicated with each other through the connection pipe; the connection pipe is perpendicular to the first vertical pipe and the second vertical pipe, or an included angle formed by the connection pipe and the first vertical pipe is an obtuse angle; and the lower end of the third vertical pipe is communicated with the connection pipe. By means of a process for repeatedly distilling chalcogenide simple substance raw materials, water impurities containted in the chalcogenide simple substance raw materials is eliminated, and the method and the device are simple in process, no secondary pollution can be guided in during preparation, and impurity absorbing of the chalcogenide glass is remarkably eliminated.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

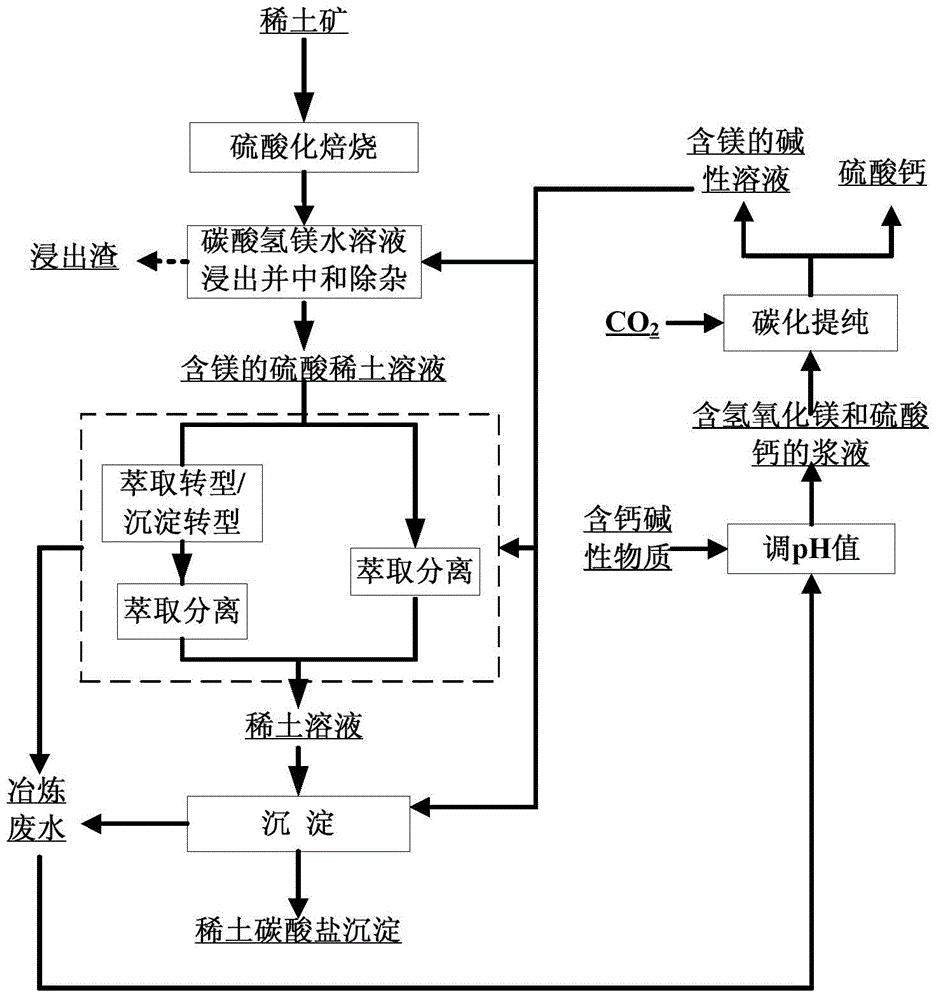

Smelting separation method of rare earth ores

ActiveCN106282553AHigh recovery rateTo achieve the purpose of removing impuritiesProcess efficiency improvementHigh concentrationCarbonization

The invention provides a smelting separation method of rare earth ores. The method comprises the following steps: carrying out leaching, neutralization and impurity removal on sulfuric acid roast ores by using an aqueous solution of magnesium bicarbonate, and carrying out solid-liquid separation to obtain a magnesium-containing rare earth sulfate solution; and carrying out aqueous magnesium bicarbonate solution saponification P507 or P204 extraction transformation or magnesium bicarbonate precipitation transformation enrichment to obtain a high-concentration mixed rare earth chloride solution, carrying out extraction separation, and recovering rare earth from the above obtained aqueous magnesium bicarbonate solution precipitate to obtain various rare earth compound products. Magnesium sulfate-containing wastewater generated in the above process undergoes alkali transformation by cheap alkaline compounds of calcium and magnesium, and CO2 recovered in the smelting separation process is introduced to carry out carbonization purification in order to obtain an aqueous magnesium bicarbonate solution which can be reused in rare earth leaching, transformation, extraction separation and precipitation processes. The method has the advantages of realization of recycling of magnesium and CO2 and zero discharge of ammonia nitrogen and wastewater, great reduction of the production cost, improvement of the recovery rate of rare earths, and realization of green, environmentally-friendly and high-efficient clean production of the rare earths.

Owner:GRIREM ADVANCED MATERIALS CO LTD

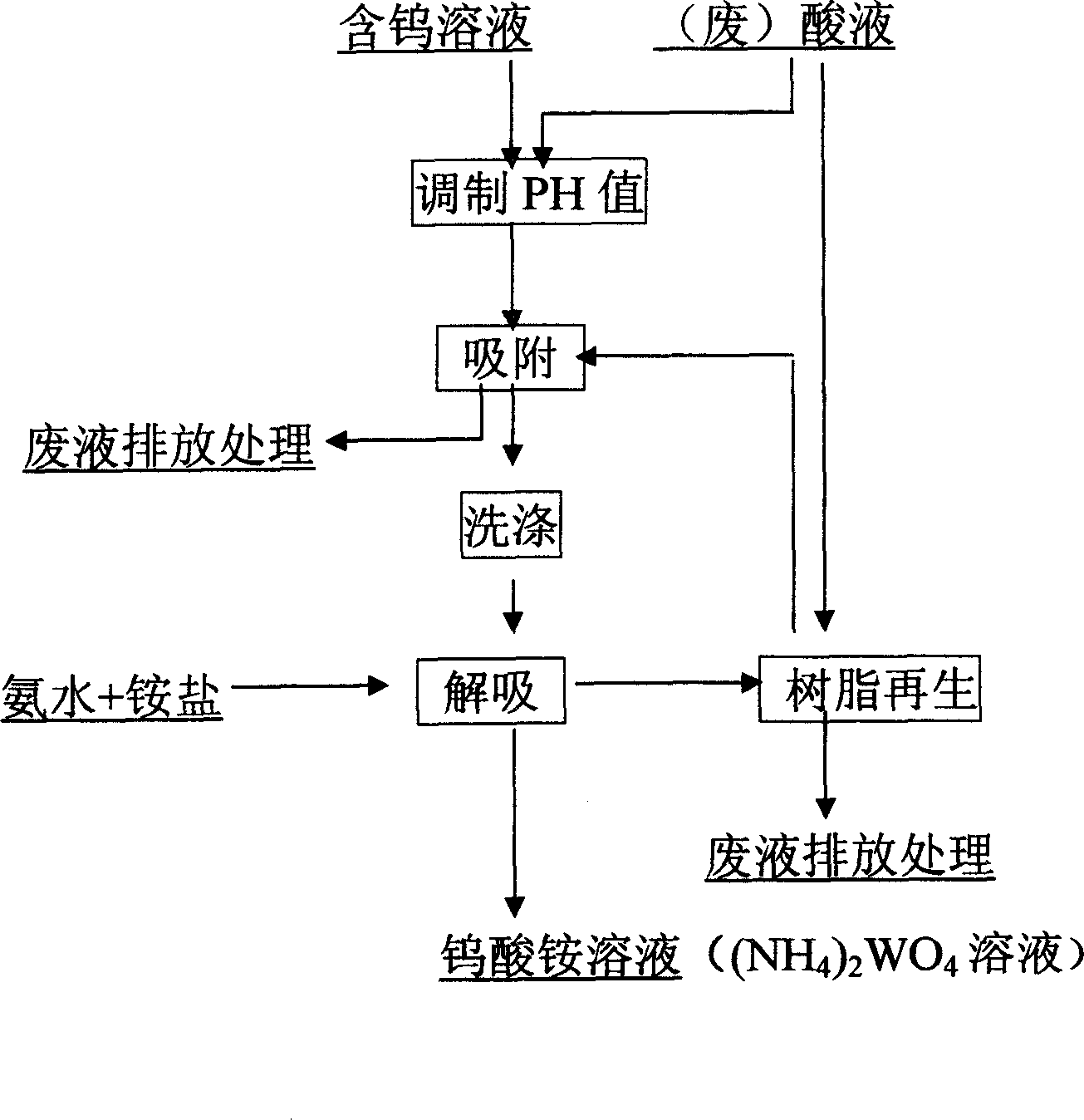

Ion exchange process for preparing ammonium tungstate solution

InactiveCN1865463AReduce crystallizationInhibit crystallizationProcess efficiency improvementIon exchangeIon

The invention discloses an ionic exchanging technology to prepare ammonium tungstate solution, which comprises the following steps: adopting acid solution to regenerate for large-hole faintly alkaline negative resin; adjusting each solution with tungsten at 4-5; proceeding resin adsorption disposal; washing to neutral through negative tungsten resin; blending ammonia and ammonium salt; proceeding adsorption through negative tungsten resin after linear-flow speed from rapid to slow; removing impurity; conversing to produce the product. The invention is simple to operate, which guarantees the quality of ammonium tungstate solution.

Owner:CHENZHOU DIAMOND TUNGSTEN PRODS

Method for preparing rubber accelerator DM (2,2'-dithiobis(benzothiazole)) from 2-mercaptobenzothiazole coarse product as raw material

A method for preparing a rubber accelerator DM (2,2'-dithiobis(benzothiazole)) from 2-mercaptobenzothiazole coarse product as a raw material is provided and is characterized by comprising the steps of adding water and rubber accelerator coarse product M (2-mercaptobenzothiazole) into a reaction kettle with weight ratio of (1-20) to 1, and adding sodium hydroxide with weight ratio of sodium hydroxide to rubber accelerator coarse product M of 100 to (24-60), and reacting to generate M sodium salt liquid; standing solution, collecting supernatant and adding into an oxidation pot, dripping a mixed solution containing hydrogen peroxide with concentration of 1% to 27.5% and dilute sulphuric acid with concentration of 1% to 30% into the oxidation pot with the flow velocity of 1 to 8 m<3> / h under the condition that the temperature is 20 to 60 DEG C and the mixing speed is 50 to 1000rpm, and stopping dripping oxidant solution till the pH value of the solution reaches 4 to 9; and filtrating and washing DM material with the solution, and removing impurities in DM. The process is simple in process, the solvent can be recovered and recycled for use and the loss is small; and the method is nontoxic and harmless to the people, free from the waste gas and high in environmental protection property.

Owner:KEMAI CHEM

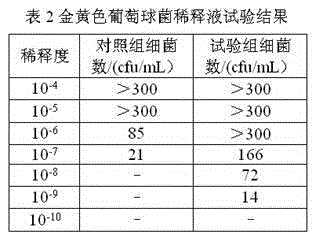

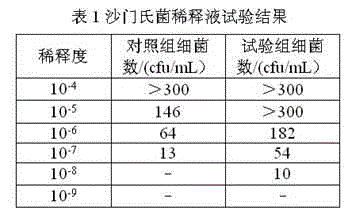

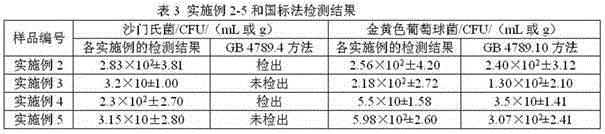

Method for detecting salmonella and staphylococcus aureus in food simultaneously

ActiveCN104894219AAvoid hindranceRapid enrichmentMicrobiological testing/measurementMaterial analysisBiotechnologyMagnetic bead

The invention discloses a method for detecting salmonella and staphylococcus aureus in food simultaneously. The method includes the following steps: 1), diluting a to-be-tested food sample according to GB4789 to obtain sample homogenate of 1:10, adding 50-65wt% of nitrilotriacetic acid solution into the sample homogenate according to the volume ratio of the sample homogenate to the nitrilotriacetic acid solution being (5-7):1, vibrating the mixture, adding phosphate buffer solution or 0.05% tween-20 contained phosphate buffer solution, performing centrifugal layering, and discarding an upper layer; 2), mixing a sample obtained after processing of the step 1) with immunomagnetic beads, vibrating the mixture, subjecting the mixture to standing and layering on a magnetic frame, discarding an upper layer, and washing a lower layer of the sample, wherein the immunomagnetic beads are obtained by modifying salmonella and staphylococcus aureus antibodies, which are labeled by magnetic bead coupled biotin, by streptavidin; 3), adding the phosphate buffer solution to the washed sample, vibrating the mixture, applying the mixture to an LB plate, and performing cultivation and observation. The method is simple and convenient to operate, accurate, efficient and low in cost, two target bacteria are enriched, and detection time can be shorten from 72h to 25h.

Owner:HENAN BUSINESS SCI RES INST

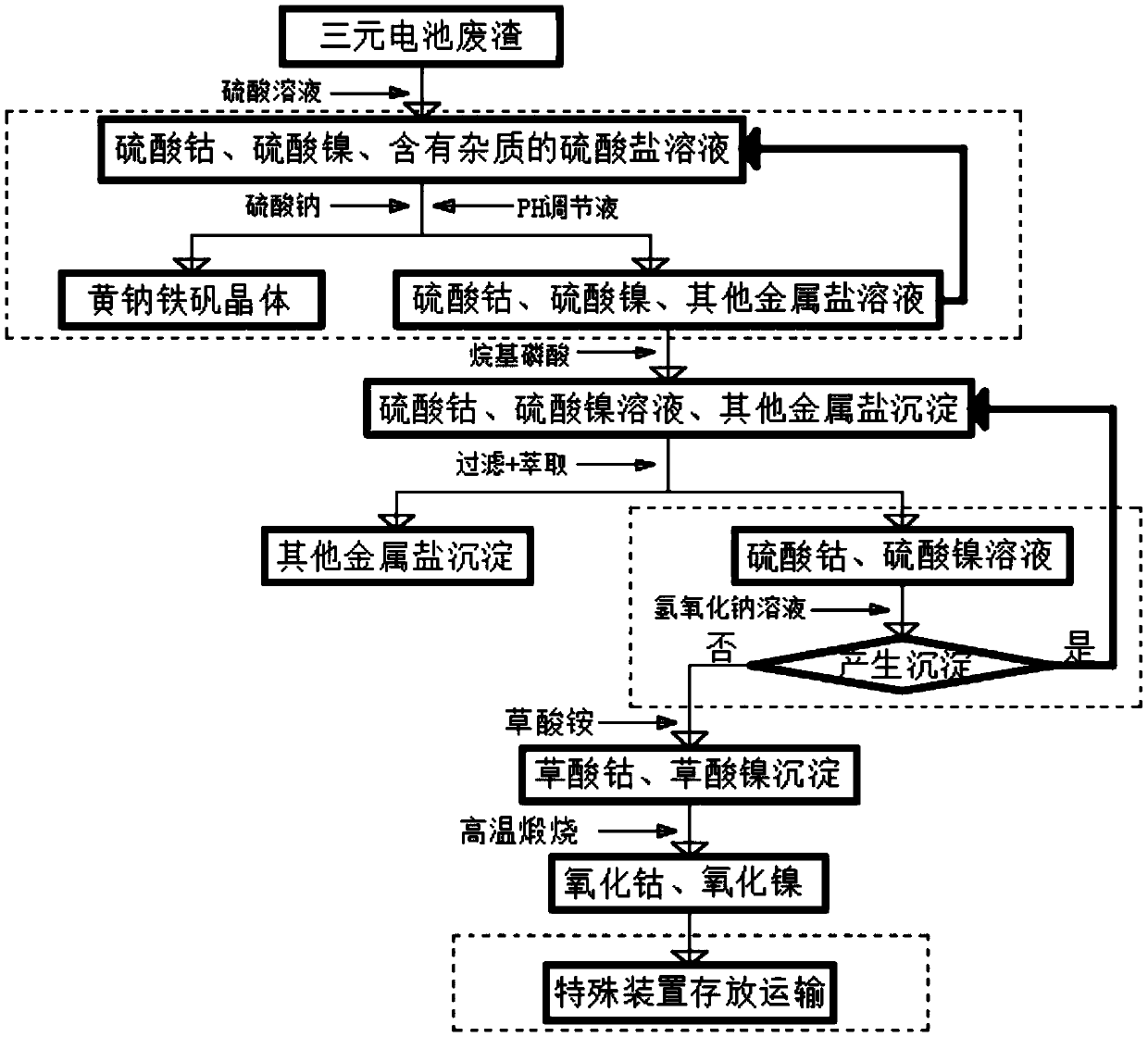

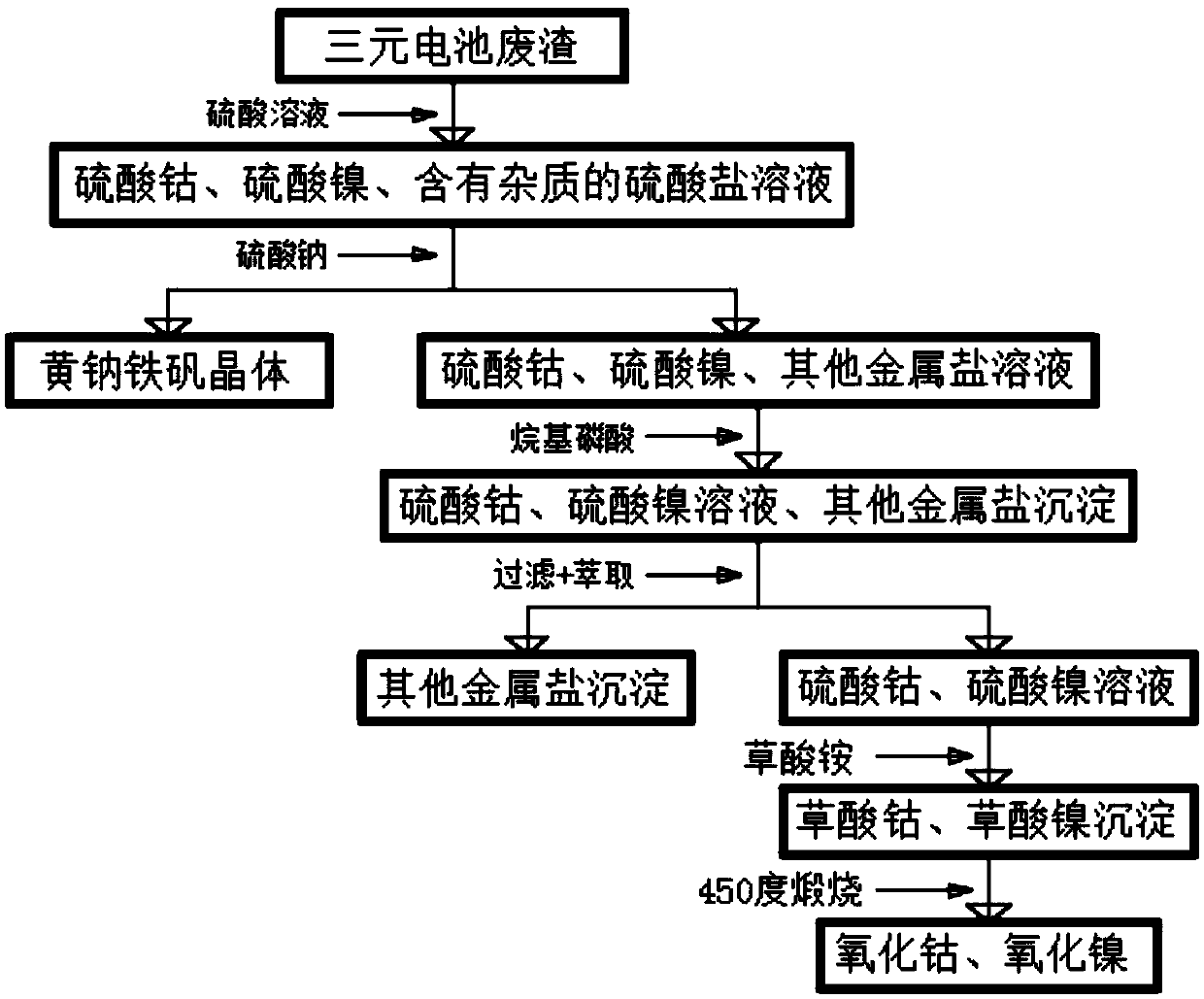

Cobalt and nickel purifying method based on waste battery metal recovery technology

InactiveCN109536724AHigh impurity removal rateImprove the efficiency of impurity removalProcess control/regulationChemical/physical/physico-chemical stationary reactorsFeedback effectMetal impurities

The invention discloses a cobalt and nickel purifying method based on a waste battery metal recovery technology, and belongs to the field of waste battery recovery. The cobalt and nickel purifying method based on the waste battery metal recovery technology comprises the step of recovery of ternary battery waste residues, the original waste battery metal recovery technology is improved, on the onehand, the impurity removal rate for iron ions can be higher than an impurity removal technology for the iron ions in the prior art, meanwhile, the impurity removal efficiency for the iron ions can beimproved, the recovery purity of cobalt and nickel is increased, the progress of the whole technology is accelerated, and the recovery efficiency is improved; on the other hand, compared with the prior art, the method has the advantages that detection of metal impurities in a solution after impurity removal operation is increased, the reaction phenomenon produced in the solution has the feedback effect, impurities can be removed more thoroughly, and the recovery purity of the metal cobalt and the metal nickel is further improved.

Owner:南通北新新能科技股份有限公司

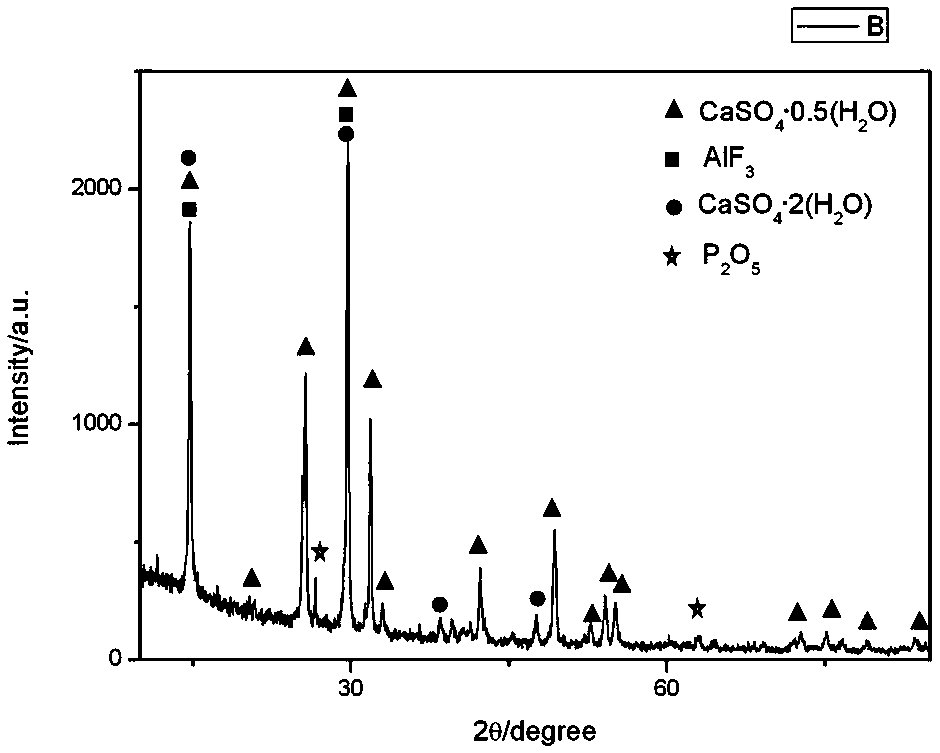

Phosphogypsum putty powder prepared from phosphogypsum

The invention discloses phosphogypsum putty powder prepared from phosphogypsum. The phosphogypsum putty powder is prepared from the following materials: 75-85% of a base material namely decolored phosphogypsum, 10-20% of a filler, 0.3-0.7% of a water retaining agent, 3-7% of a thickener and 0.1-0.5% of a retarder. According to the invention, the whiteness of phosphogypsum is first improved by a method of calcination and acid leaching, and the calcination temperature and the solid-liquid ratio of the method of calcination and acid leaching are determined. The whiteness of the decolored and whitened phosphogypsum can be increased from 25.0% to 80.0% or higher, the decolored phosphogypsum decolored and whitened through the method of calcination and acid leaching is used as the base material for the preparation of the putty powder, and by adding additives, the putty is modified in retarding, water tolerance, crack resistance and other aspects. By the above method, the invention can enablethe putty powder prepared by an industrial waste namely phosphogypsum to obtain the optimum modification effect. Physical properties of the obtained putty powder are in line with the requirements in JG / T298-2010 Putty for Interior.

Owner:HEFEI UNIV OF TECH +1

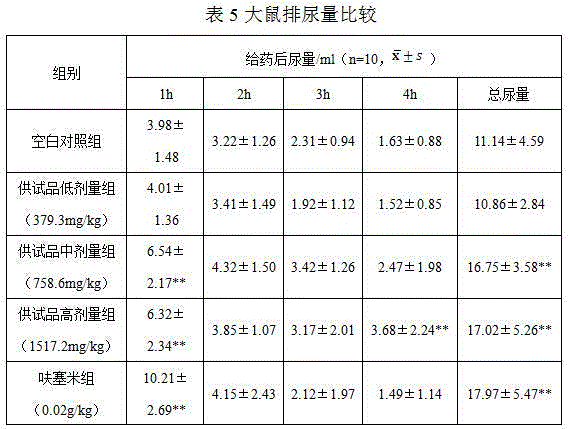

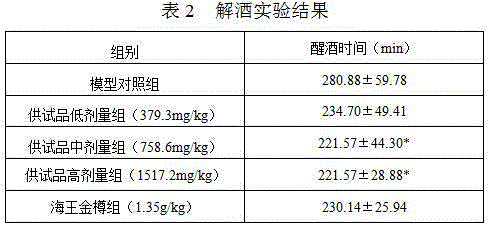

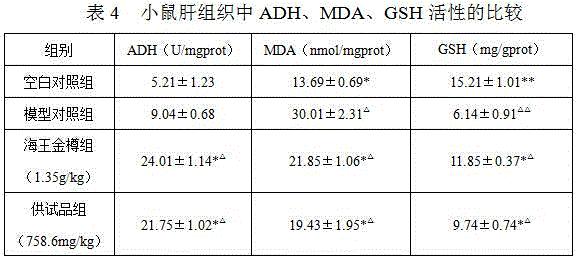

Anti-intoxication, alcohol-expelling and liver-protection preparation and preparation process thereof

InactiveCN104522639AAnti-drunkHangoverNervous disorderDigestive systemPharmacologic actionToxic material

The invention provides an anti-intoxication, alcohol-expelling and liver-protection preparation which has the functions of anti-intoxication, alcohol-expelling and auxiliary protection on alcoholic liver injury. The preparation consists of the following raw materials: 20-50 parts of vine tea, 5-15 parts of galangal, 10-40 parts of mung beans and 10-40 parts of poria cocos. The vine tea contains a great amount of flavonoid substances, and the dihydromyricetin in the vine tea has special effects in removing toxicity in alcohol, preventing alcoholic liver and fatty liver, inhibiting liver cell deteriorate, reducing the morbidity of liver cancer and protecting the liver. The galangal is acrid and hot in property, can enter the spleen and stomach channels, has the functions of eliminating cold to stop pain and warming the middle energy and stopping throwing and has a certain alcohol-expelling function, and moreover the flavonoid substance galangin in the galangal has a protection function on acute alcoholic liver injury. The poria cocos has the effects of clearing damp and promoting dieresis, tonifying spleen and quieting the heart, can promote the alcohol in bodies to discharge out along with urine, and is beneficial to sobering up. The mung beans have the effect of clearing away heat and toxic materials, can effectively relieve the symptoms of dizziness and unclear speaking after drinking alcohol, and furthermore has the pharmacologic action of protecting the liver and the kidney.

Owner:GANSU LONGSHENRONGFA PHARMACEUTICAL INDUSTRY CO LTD

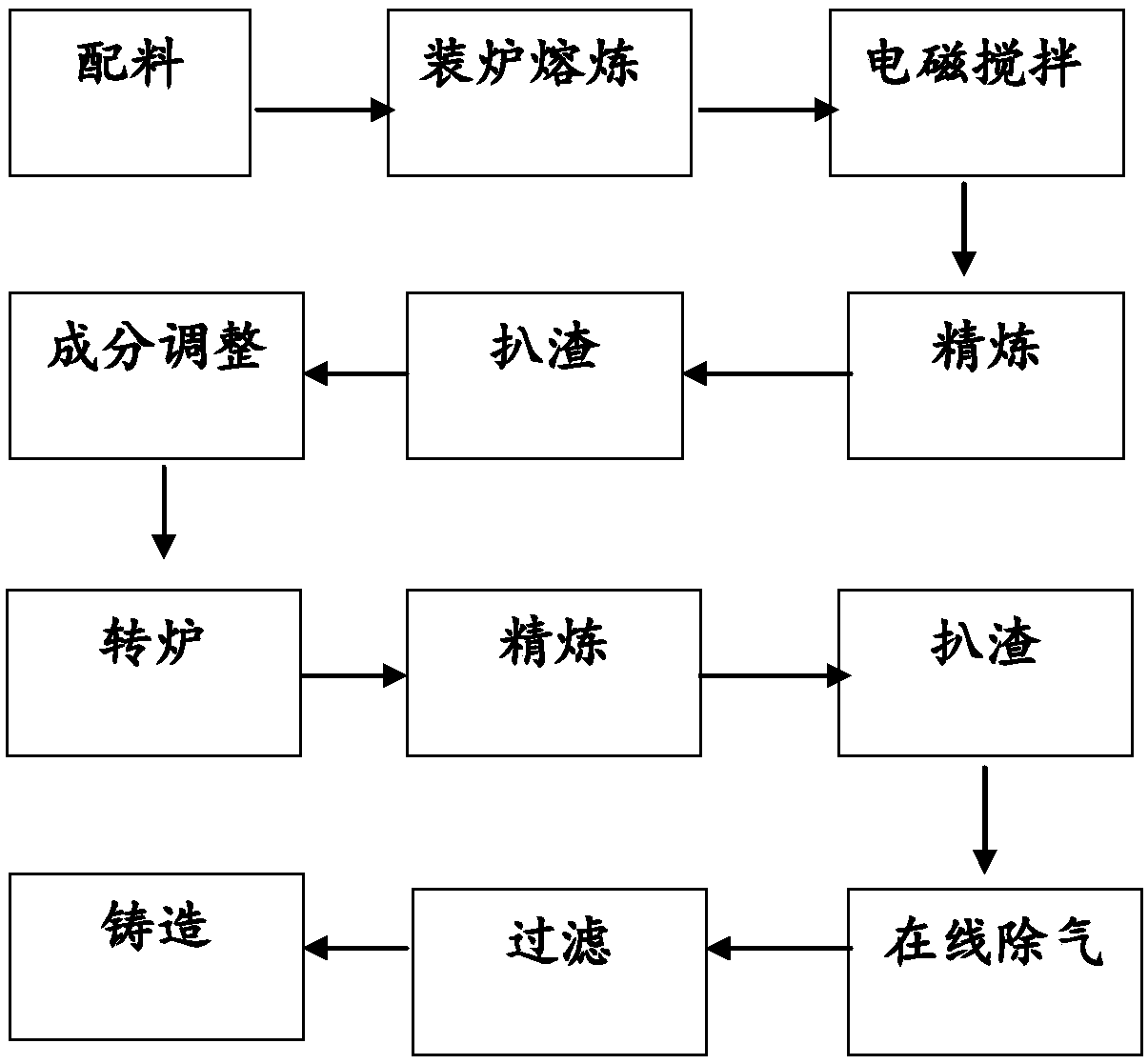

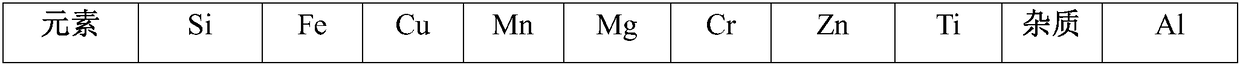

2024 aluminum alloy melting casting method

The invention belongs to the technical field of aluminum alloy, and relates to a 2024 aluminum alloy melting casting method. The aluminum alloy is prepared from the following ingredients in percentageby mass: smaller than or equal to 0.25 percent of Si, smaller than or equal to 0.35 percent of Fe, 4.55 to 4.65 percent of Cu, 0.5 to 0.7 percent of Mn, 1.55 to 1.65 percent of Mg, 0.1 percent of Cr,0.2 percent of Zn, smaller than or equal to 0.12 percent of Ti, impurities (the quantity of single impurities is smaller than or equal to 0.05 percent; the total quantity is smaller than or equal to0.15 percent) and the balance of Al; then, melting, refining, degassing, slag removal and casting are performed; a semi-continuous casting process is used for casting; in the refining process, 23 to 28 percent of NaCl, 20 to 40 percent of KCl and 40 to 60 percent of MgCl2 are added to be used as refining agents; the casting temperature is controlled to be 730 to 740 DEG C; the casting speed is 20to 22 mm / min; the single water flowrate is 300 to 310 L / min; the 2024 aluminum alloy cast ingot is obtained. An aluminum cast rod produced by the 2024 aluminum alloy melting casting method has few defects; the material performance and the finished product rate are improved; the energy consumption is reduced; the production cost is reduced; good economic benefits are realized.

Owner:YINGKOU ZHONGWANG ALUMINUM CO LTD

Process for extracting colistin sulfate through precipitation method

ActiveCN102718842AAccelerated precipitationQuality improvementPolymyxinsPeptide preparation methodsFermentationPotassium permanganate

The invention discloses a process for extracting colistin sulfate through a precipitation method. The process comprises the following steps of: (a) adjusting pH of fermentation liquor containing polymyxin E with oxalic acid or concentrated sulfuric acid, and filtering with a filtering device; (b) adding 0 metal complexing agent and inorganic flocculant to the filtrate, and reacting at normal temperature for 0.5 to 4.0h; (c) heating, cooling, and vacuum-filtering the reactive liquid; (d) adjusting pH of the filtrate above with aqueous alkali, separating the solid from the liquid to obtain a filter cake, dissolving the filter cake with sulfuric acid solution so as to obtain acidizing fluid, adding potassium permanganate and activated carbon to the acidizing fluid respectively, agitating for0.5 to 2.0 hours, and then vacuum-filtering to obtain colistin sulfate liquid; and (e) centrifugally spray-drying the colistin sulfate liquid. With the adoption of the process, the common problems ofthe existing process for purifying fermentation liquor that the steps are complicated, the period is long, the labor intensity is relatively high, and the wastewater is difficult to treat and the like can be overcame.

Owner:HEBEI SHENGXUE DACHENG PHARMA

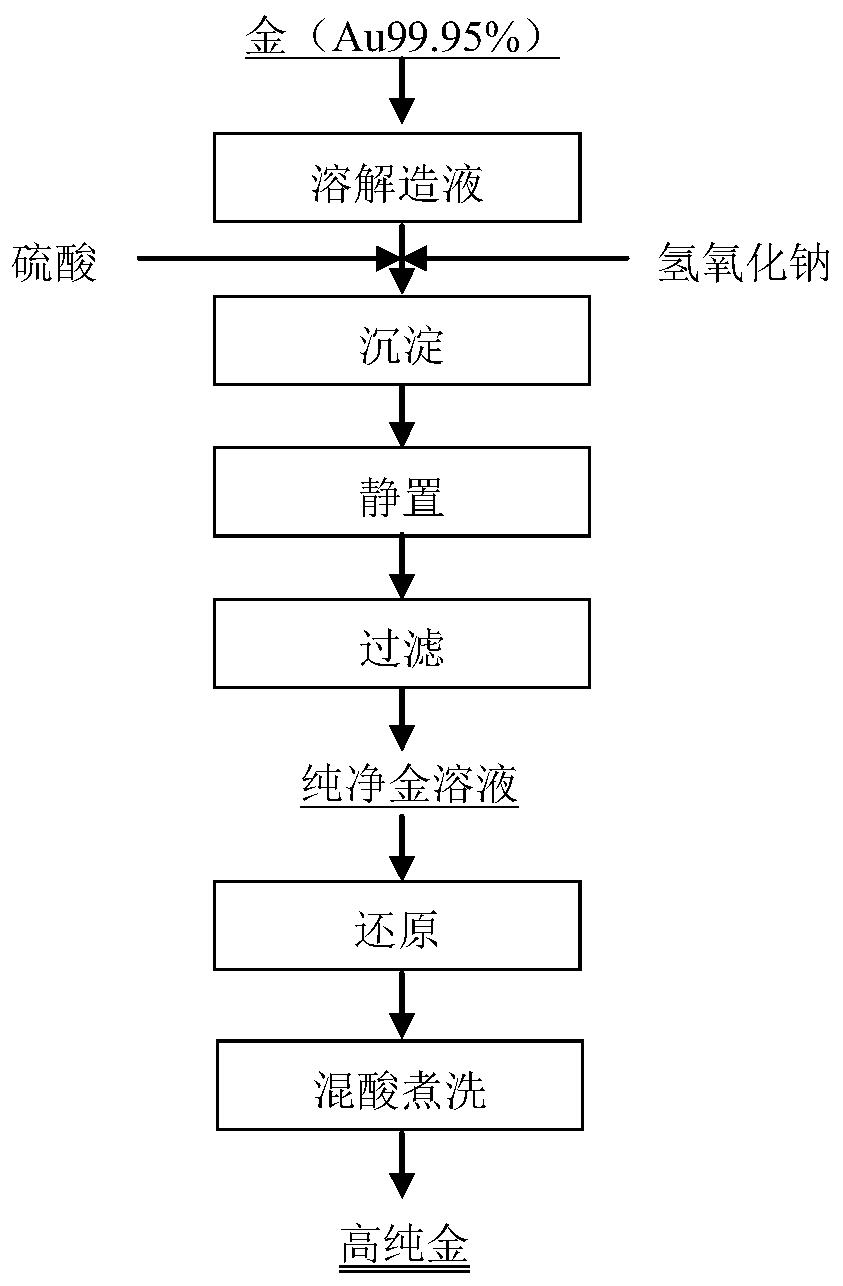

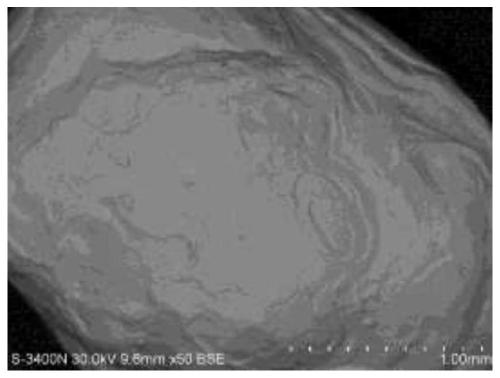

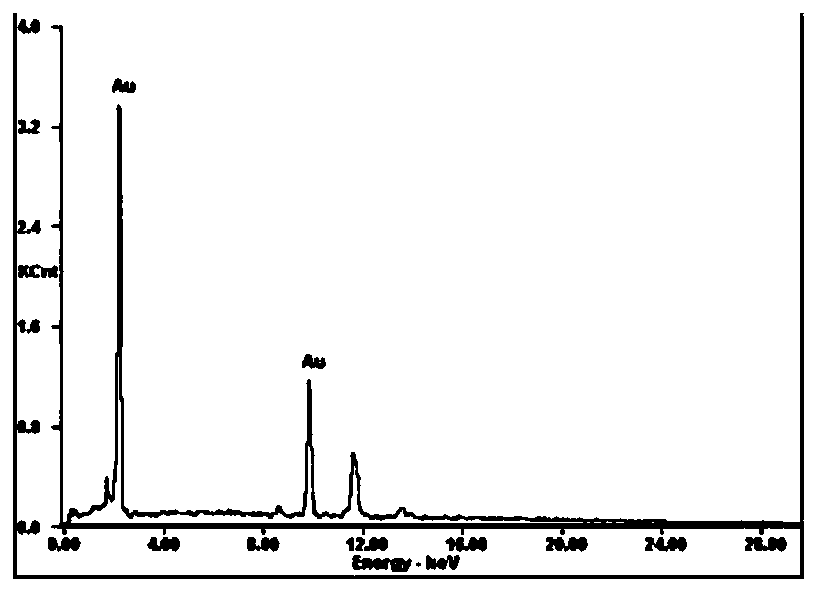

Preparation method of high-purity gold for electron industry

InactiveCN109777968AHigh purityEfficient separationProcess efficiency improvementFiltrationEvaporation

The invention discloses a preparation method of high-purity gold for the electron industry. After gold ingots are rolled into pieces, the pieces are dissolved in aqua regia, a solution is made, nitrate is removed, and a chloroauric acid solution is obtained; sulfuric acid and sodium hydroxide are added to the gold solution, the pH value of the solution is adjusted, the solution is fully stirred and left to stand, and impurities, namely, metal ions, are deposited fully; the solution is subjected to filtration under reduced pressure by the aid of a micro-pore filtering film after being left to stand, and a pure gold solution is obtained; a reducing agent is slowly added to the pure gold solution, the solution is stirred, full reduction, filtration and washing are performed, and gold powder is obtained; the gold powder is placed in a polytetrafluoroethylene container to be boiled and washed with a dilute nitric acid and hydrofluoric acid mixed solution, the solution is filtered and is washed with hot deionized water to be neutral, vacuum drying is performed, and the high-purity gold is obtained. The gold prepared with the method has the purity higher than 99.999%, has the C and S content lower than 1 ppm, has the good smelting cleanliness and can be used as a raw material for high-purity gold evaporation materials for the electron industry.

Owner:SINO PLATINUM METALS CO LTD

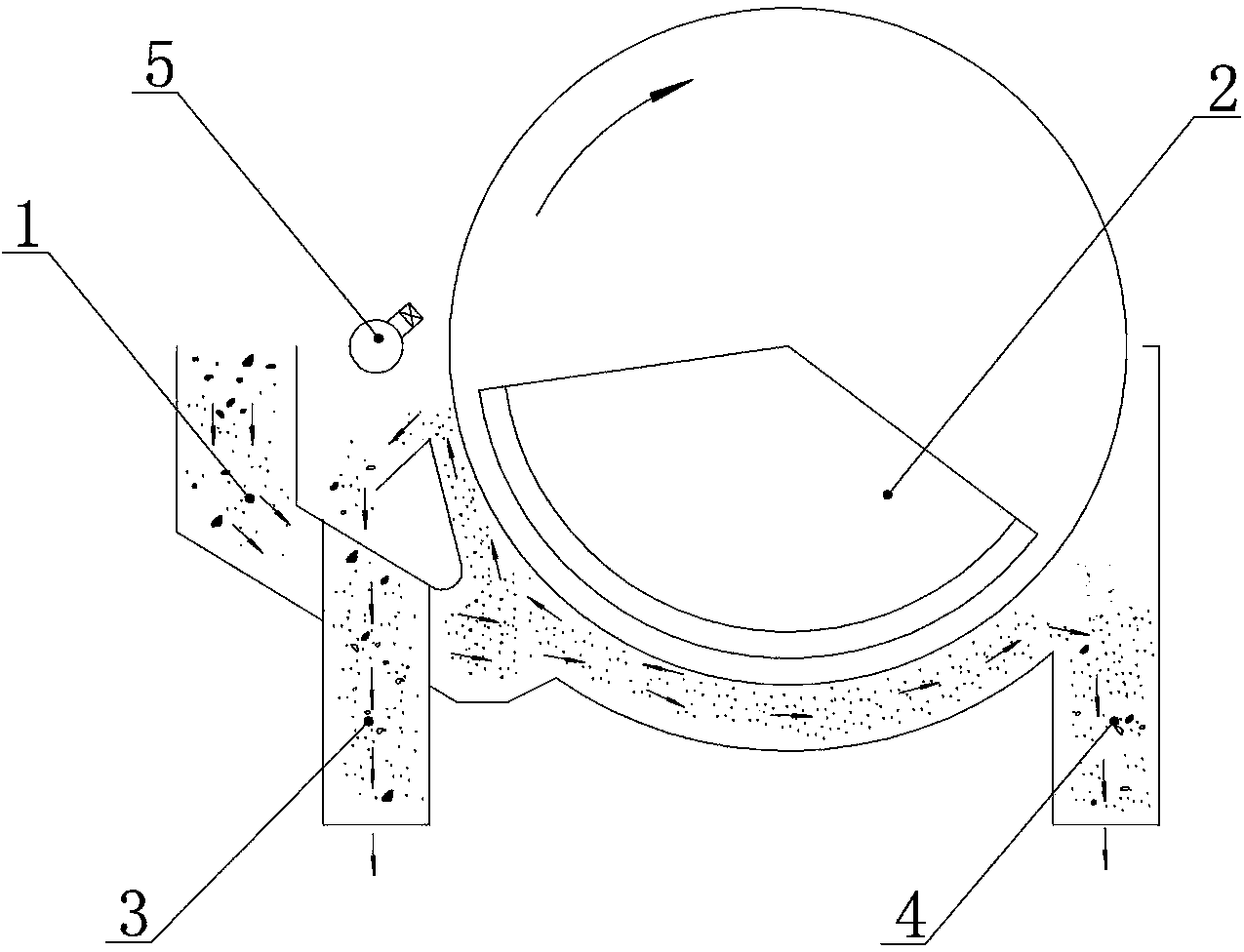

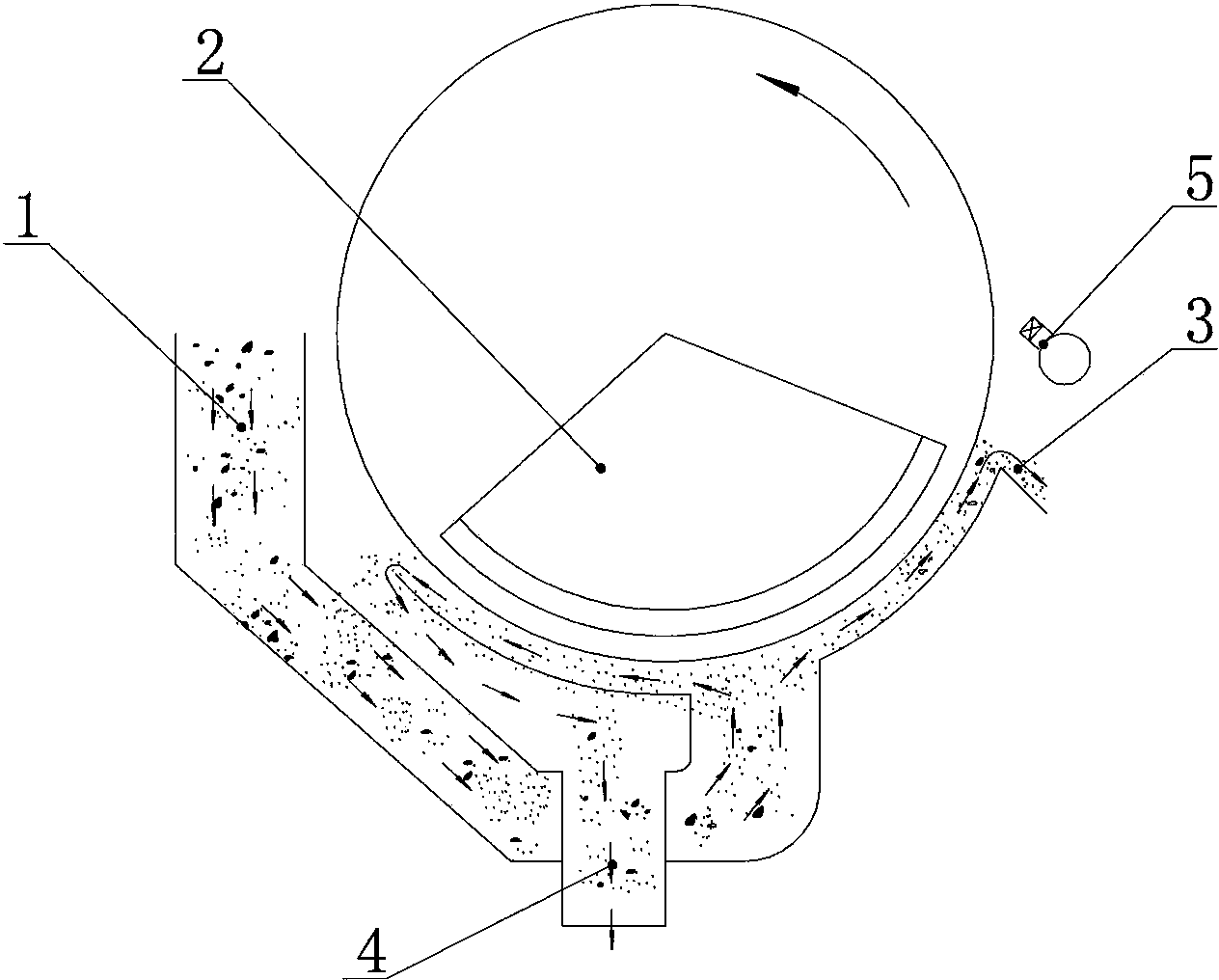

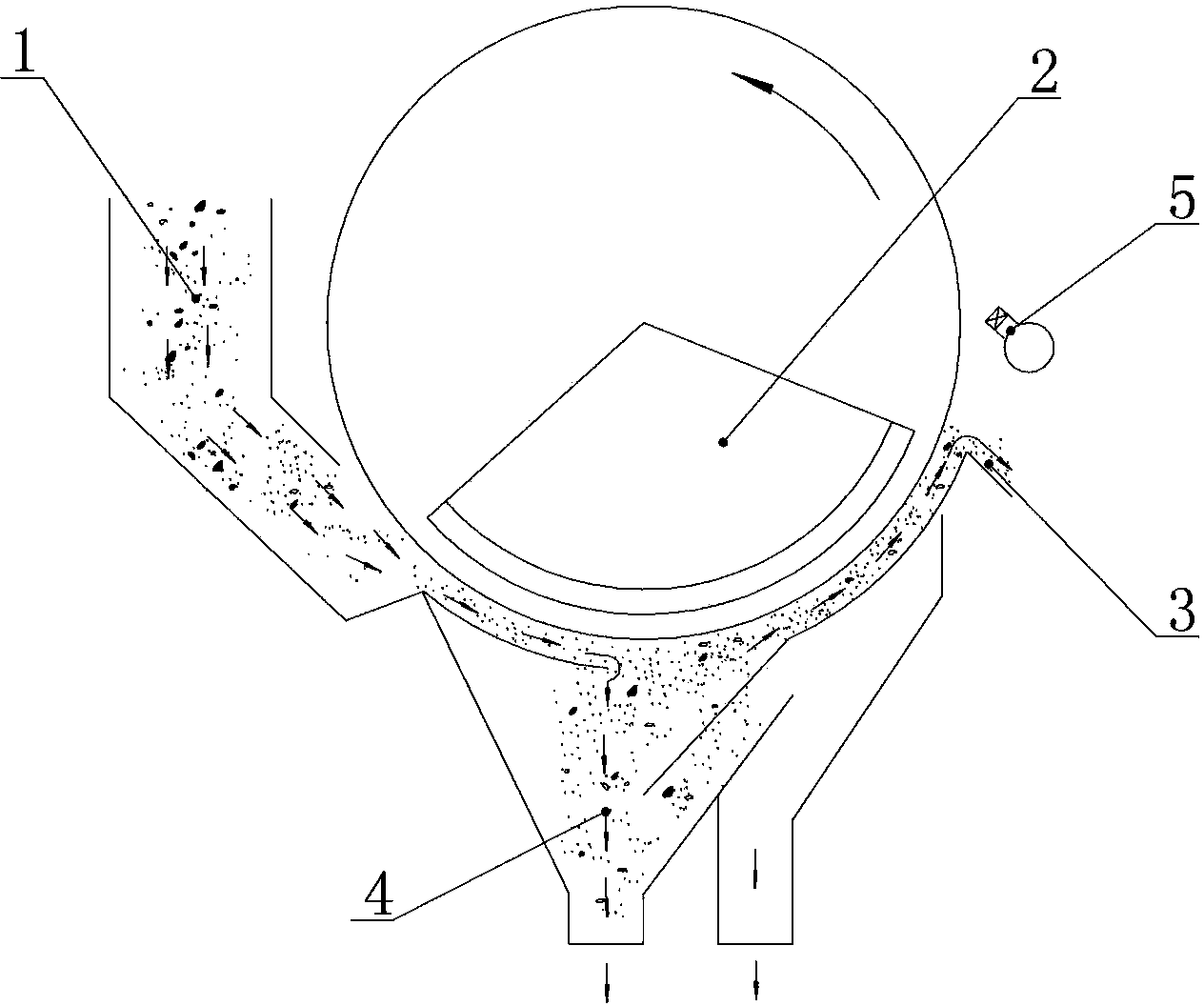

Power magnetic levitation separation and enrichment method and equipment

ActiveCN103846158AGuaranteed field strengthGuaranteed dynamic changeMagnetic separationEnrichment methodsNon magnetic

The invention relates to a separation method and equipment for magnetic matters, in particular to a power magnetic levitation separation and enrichment method and equipment. According to the power magnetic levitation separation and enrichment method and equipment, an alternating power magnetic system changing periodically is arranged in a fixed cylindrical barrel in a manner of rotating around the axis of the barrel for 360 degrees; the alternating power magnetic system does rotary movement around the axis of the barrel at a certain angular speed; magnetic matters in separated minerals on the outer side of the barrel form needle-shaped suspended magnetic polymers which are distributed on the outer surface of the barrel; the needle-shaped suspended magnetic polymers move on the outer surface of the barrel along the rotary direction opposite to that of the power magnetic system to form a magnetic fluid, and are swung and overturned under the effect of the alternating power magnetic system to gradually remove un-magnetized slime and non-magnetic minerals from the needle-shaped suspended magnetic polymers, and further, the magnetic polymers get rid of the acting force of the alternating power magnetic system through a magnetic matter unloading device and are collected. The separation and enrichment method and equipment are unique in design and high in separation and enrichment efficiency.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

Method for reducing impurity element iron in complex multi-element brass alloy

The invention discloses a method for reducing an impurity element iron in a complex multi-element brass alloy, and belongs to the technical field of reclaimed copper melt purification. A main treatment process of the method includes the steps of raw material pretreatment, magnetic separation, melting, refining and casting treatment, specifically, a complex multi-element waste brass raw material isfirstly subjected to raw material pretreatment to separate obvious non-copper impurities, a part of iron is separated by magnetic separation, then copper foil coated elemental boron or a copper-boronalloy is added after induction furnace melting for thermal insulation for 5-20min, then a slag removing agent (dolomite and the like) is added for thermal insulation for 15-30min, and casting into ingots is performed. The iron content of an ingot brass alloy is decreased by 25%-60%, the iron content in a reclaimed brass alloy is reasonably controlled, and the quality of ingot products is improved.

Owner:UNIV OF SCI & TECH BEIJING

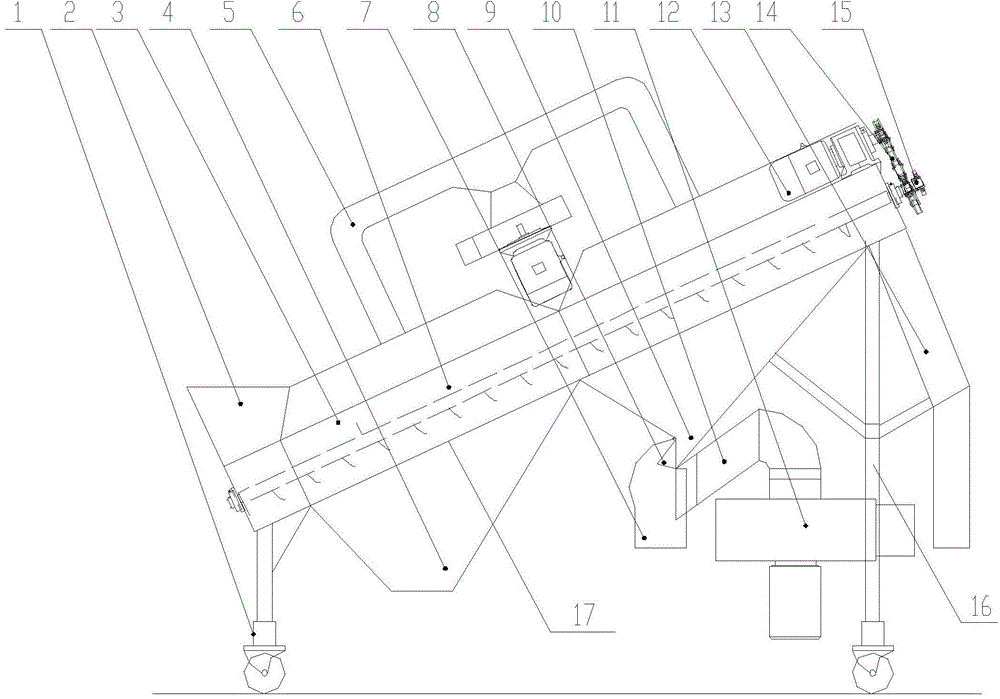

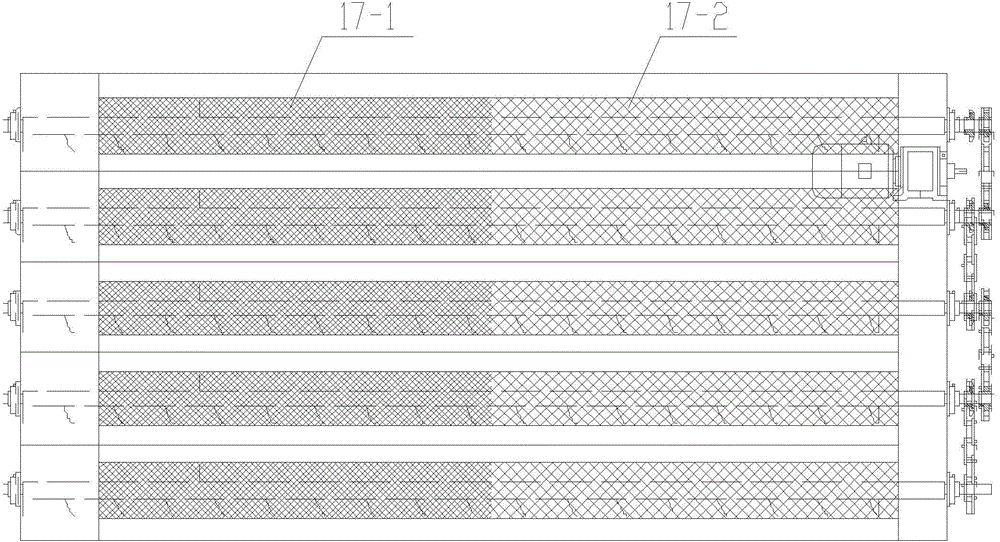

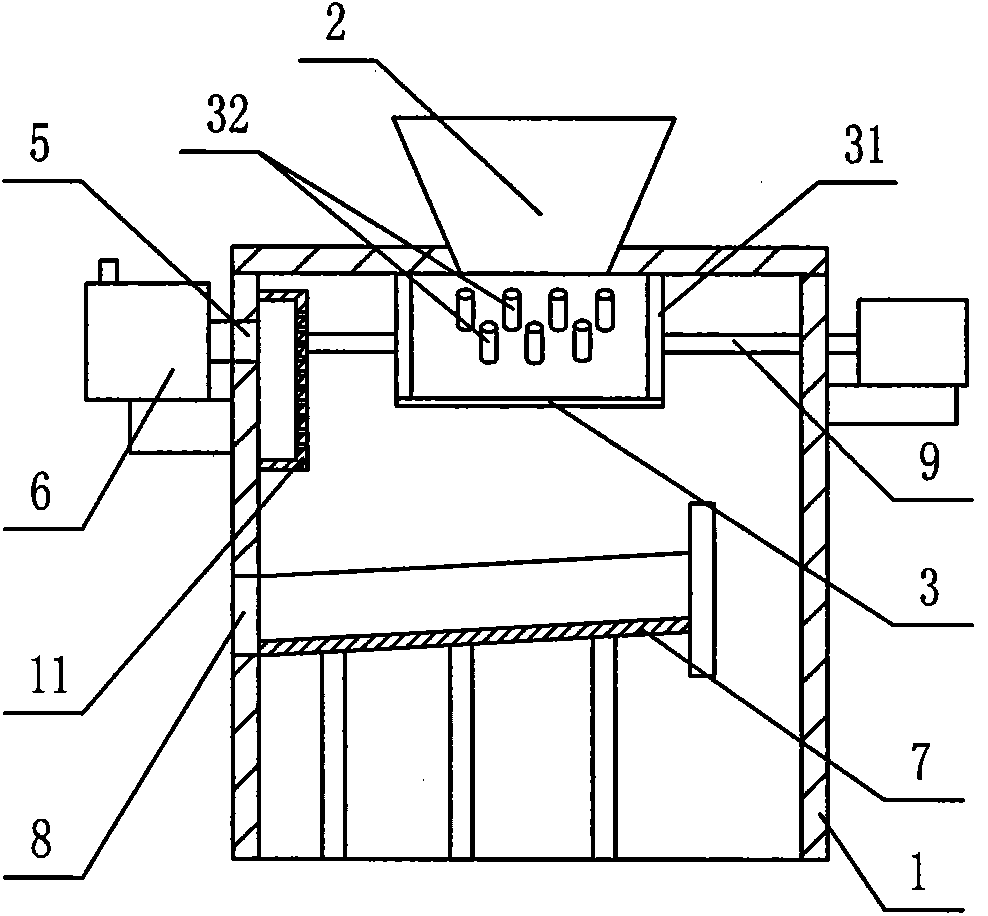

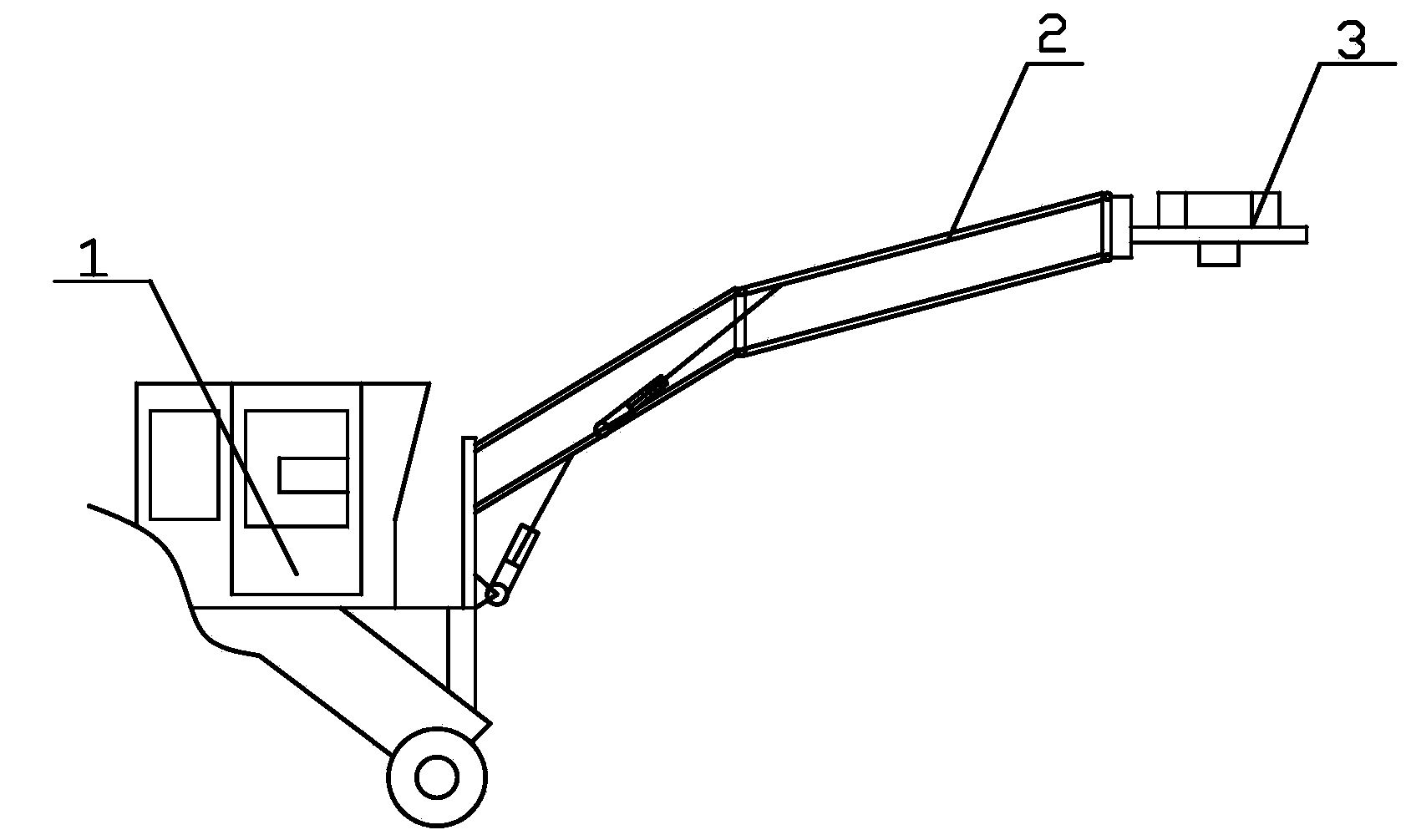

Multi-cylinder combined spiral sieve grain cleaning machine

A multi-cylinder combined spiral sieve grain cleaning machine comprises a machine frame, walking wheels are arranged at the bottom of the machine frame, the grain cleaning machine can move conveniently, a sieve body shell is arranged on the upper portion of the machine frame, at least one sieve drum is obliquely arranged in the sieve body shell, an auger is installed in the sieve drum, one end of an auger shaft in the auger is connected with an auger drive motor through a drive chain, the auger is driven to rotate in the sieve drum through the auger drive motor, the sieve drum is divided into a front part and a rear part, the front part is a thin-hole sieve drum body, the rear part is a thick-hole sieve drum body, the thin-hole sieve drum body is located at the lower end, a feed hopper is arranged on the upper portion of one end of the thin-hole sieve drum body, a small impurity outlet is formed in the lower portion of the thin-hole sieve drum body, a grain outlet is formed in the lower portion of the thick-hole sieve drum body and is provided with a grain outlet baffle, a pure grain outlet is formed in one side of the grain outlet baffle, an air flue is formed in the other side of the grain outlet baffle, one end of the air flue is connected with a draught fan, and a large impurity outlet is formed in the rear end of the thick-hole sieve drum body. The multi-cylinder combined spiral sieve grain cleaning machine is simple in structure and novel in design.

Owner:ANHUI JIESHOUSHI YUNLONG FOOD MACHINE ENG

Process utilizing enzymatic removing impurity to prepare tussah pupa skin chitosan

Owner:JILIN SERICULTURE SCI RES INST

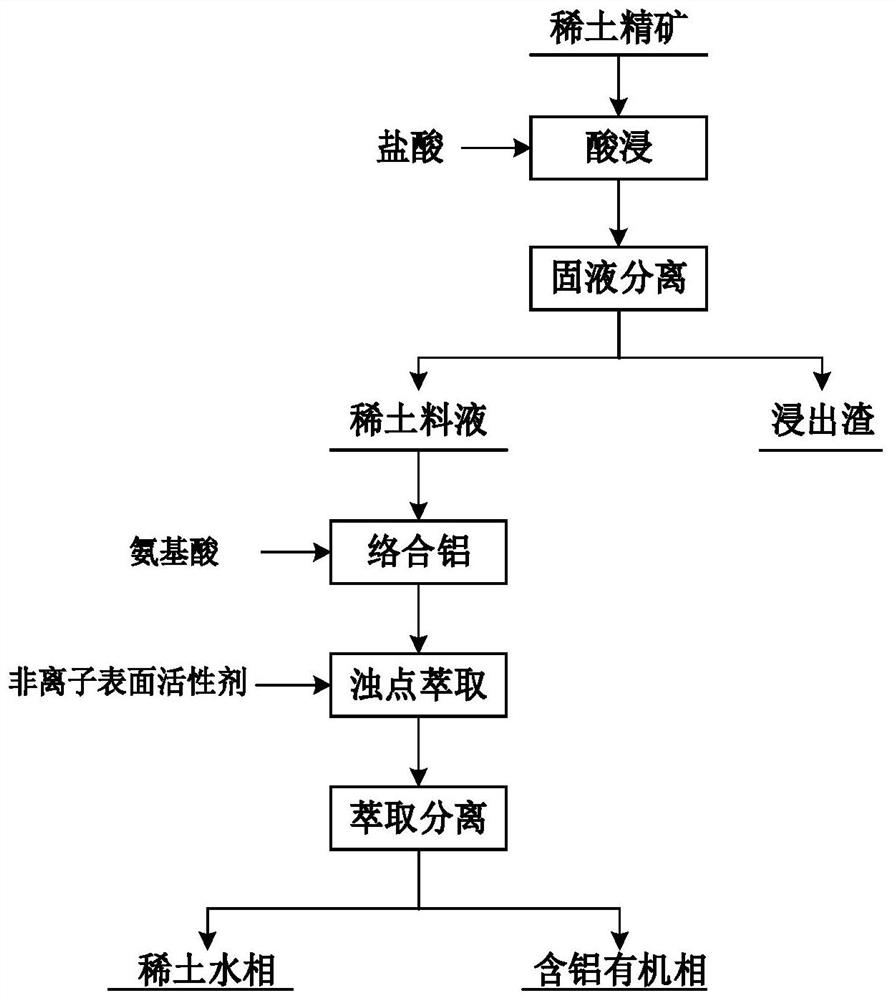

Method for removing aluminum from rare earth feed liquid through complexing-cloud point extraction

ActiveCN113373304AAchieve removalGuaranteed primary extraction rateProcess efficiency improvementAluminum IonPhysical chemistry

The invention discloses a method for removing aluminum from rare earth feed liquid through complexing-cloud point extraction. The method comprises the following steps of carrying out complexing pretreatment on aluminum-containing rare earth feed liquid by adopting glutamic acid and histidine, and carrying out extraction separation on aluminum ions in the rare earth feed liquid by utilizing a cloud point extraction method, so that the aluminum ions are removed from the rare earth feed liquid. A selective complexing-cloud point extraction aluminum removal method can ensure that the one-time extraction rate of the aluminum ions reaches 70% or above, the rare earth extraction rate does not exceed 6%, the concentration of the aluminum ions in the rare earth feed liquid is greatly reduced, and conditions are created for subsequent preparation of high-purity rare earth products. Compared with the prior art, the method has novelty, an extracting agent can be recycled through reverse extraction, the influence on the environment is reduced, and the treatment cost is reduced.

Owner:JIANGXI UNIV OF SCI & TECH

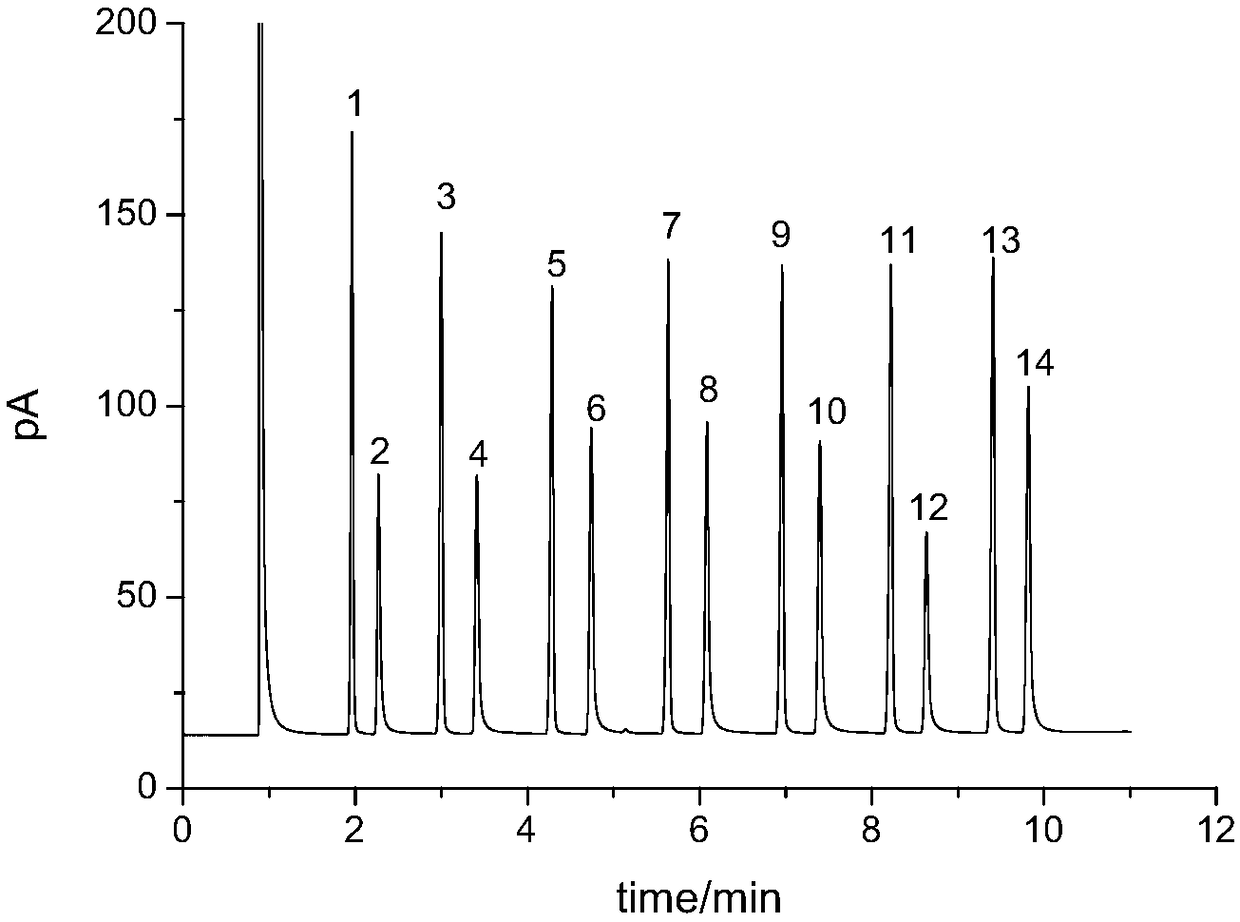

Method for detecting multiple antiseptics in cosmetics

ActiveCN108693262AEfficient extractionEasy to operateComponent separationBenzoic acidDehydroacetic acid

The invention discloses a method for detecting multiple antiseptics in cosmetics. The antiseptics are: benzoic acid, sorbic acid, dehydroacetic acid, methyl paraben, benzyl paraben, benzyl alcohol, phenoxyethanol, o-phenyl phenol, triclosan, triclocarban, methylchloroisothiazolinone, bronopol, chlorphenesin, and iodopropynyl butylcarbamate. The method comprises following steps: tetrahydrofuran liquid-liquid extraction, solid phase extraction column purification, and gas chromatography separation and analysis. The results of tests show that the provided method is suitable for many cosmetics onthe market and can accurately detect antiseptics in the cosmetics.

Owner:伯德创研(广州)生物科技有限公司

Extraction method of nonextractable polyphenol in blueberry

ActiveCN106901359ANo need to collect repeatedlyEasy to operateFood ingredient functionsAcetic acidAlcohol

The invention relates to an extraction method of nonextractable polyphenol in blueberry, and belongs to the technical field of extraction of plant polyphenol. The extraction method comprises the followings steps: preparing blueberry residue, preparing blueberry residue powder, performing acid solution soaking, performing alkali solution soaking, performing enzymolysis, centrifugation, extraction and collecting extractive. The extraction method is simple in operation steps, the operation steps can be performed in one container, and the extractive is not required to be repeatedly collected; weak concentration acid and alkali are adopted to treat materials, ethyl acetate and ethyl alcohol mixed liquor can be utilized for extracting, the method is mild, the bioactivity of the nonextractable polyphenol can be furthest reserved, the extraction ratio is improved, and the environmental pollution is very small.

Owner:TIANJIN AGRICULTURE COLLEGE

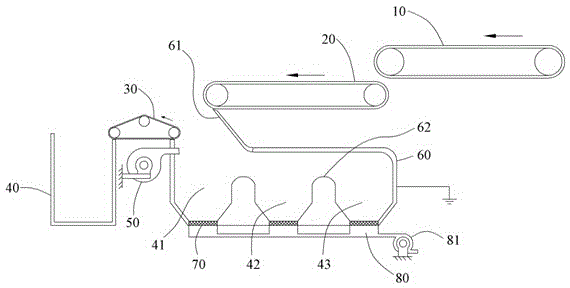

Waste plastic multi-stage sorting system

ActiveCN104998829ATo achieve the purpose of removing impuritiesImprove adsorption capacityPlastic recyclingGradingMechanical engineeringIndustrial engineering

The invention relates to a waste plastic multi-stage sorting system and belongs to the technical field of waste recycling equipment. The system comprises a material conveyer belt, an acceleration conveyer belt, a triangular conveyer belt and at least two storage bins. The first storage bin corresponds to the discharge end of the triangular conveyer belt, and the second storage bin corresponds to the discharge end of the acceleration conveyer belt. A scraper is arranged below the discharge end of the acceleration conveyer belt. A gap is kept between the scraper and the acceleration conveyer belt. The lower end of the scraper is fixedly connected with an air baffle. The first storage bin is in an inverted conical structure, a filtering plate is disposed at the bottom of the first storage bin, an air draft channel is arranged below the filtering plate, and the tail end of the air draft channel is connected with an exhaust fan. By means of the technical scheme, impurities are removed through inertia firstly, a light plastic box is sucked through negative pressure to move at the bottom of the second storage bin, it is guaranteed that the light plastic box smoothly falls into the second storage bin, and the aim of removing plastic impurities is achieved. The system has beneficial technical effects.

Owner:安徽奥生资源利用科技有限公司

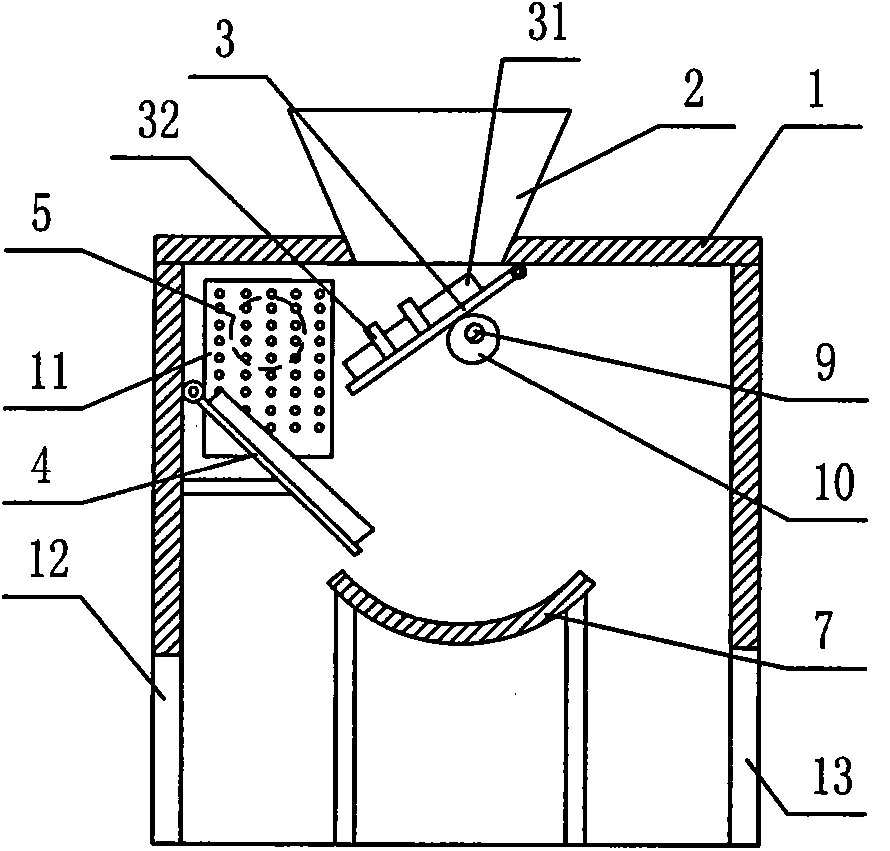

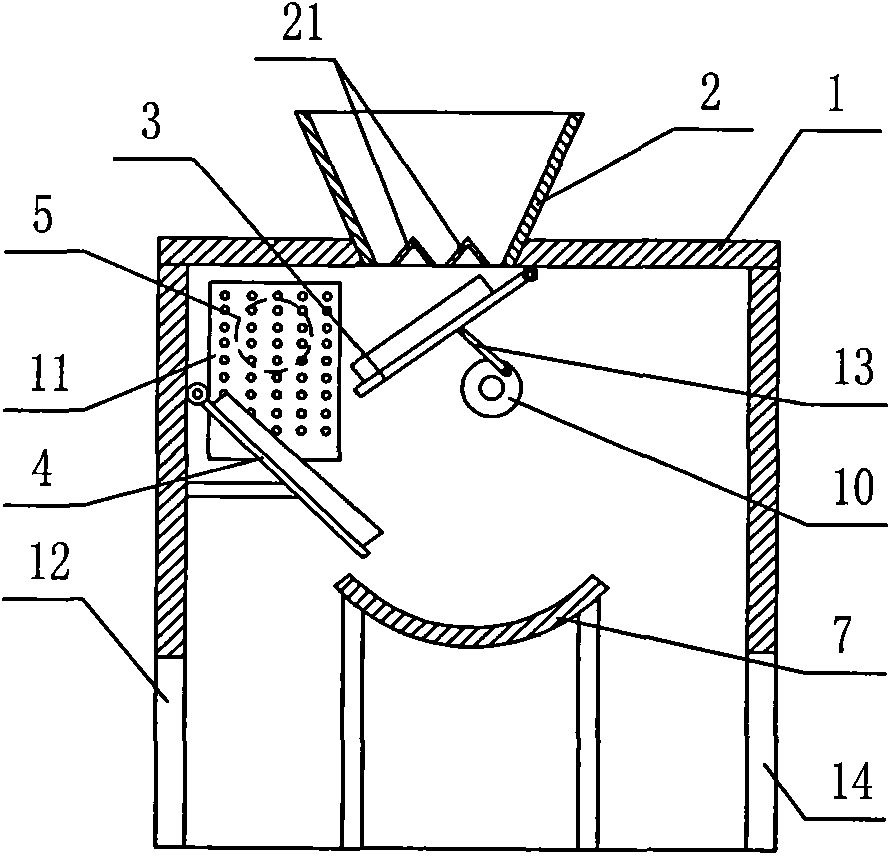

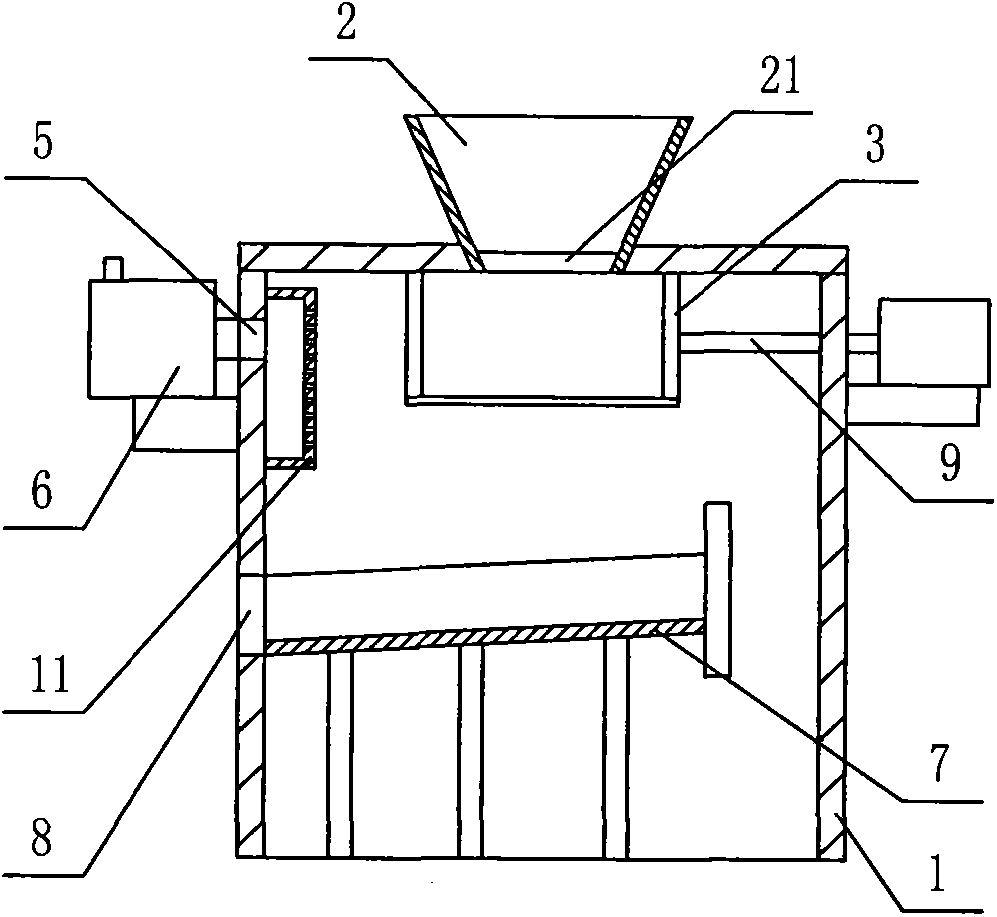

Impurity removing and winnowing machine of wheat

InactiveCN103381406AIncrease cleaning speedTo achieve the purpose of removing impuritiesGas current separationEngineeringImpurity

The invention discloses an impurity removing and winnowing machine of wheat. The impurity removing and winnowing machine comprises a machine case, wherein a material inlet hopper is arranged on the front portion of the top wall of the machine case, a raising board corresponding to the material inlet hopper and driven by a vibration mechanism is hinged to the front portion of the machine case, the rear end portion of the raising board is hinged to the inner top wall of a drying machine case and inclines downwards from rear to front, a flow guiding inclined board on the lower portion of the front part of the raising board is further hinged to the inner wall of the front end of the machine case, an air inlet and an impurity removing fan blowing air into a cavity of the machine case through the air inlet are arranged on the lateral wall of the machine case, a material guiding sieve plate under the material outlet end of the inclined board and downwards inclines to one side of the machine case is arranged in the machine case, and a material outlet corresponding to the lower end of the material guiding sieve plate is arranged on the lateral wall of the machine case. The impurity removing and winnowing machine can automatically remove impurities in wheat and has the advantages of being capable of reducing labor intensity and fast in impurity removing.

Owner:山东鸿源生物科技股份有限公司

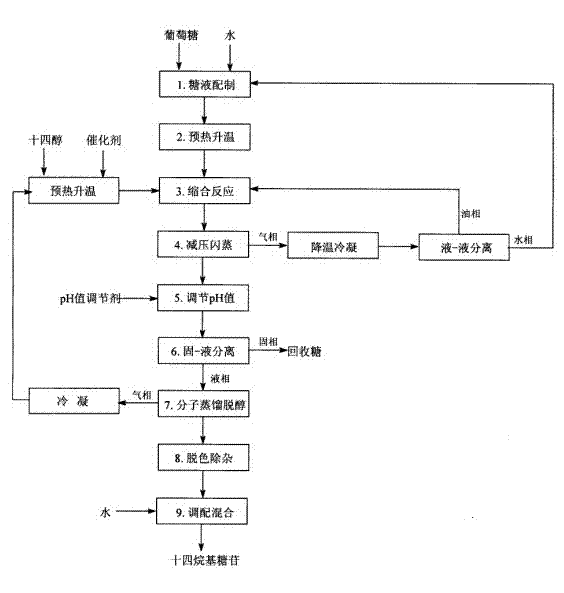

Preparation method of tetradecyl glucopyranoside

ActiveCN102786557AImprove reliabilityGood effect of decolorization and impurity removalSugar derivativesTransportation and packagingAlcoholDistillation

The invention relates to a preparation method of tetradecyl glucopyranoside. Tetradecanol and glucopyranoside as raw materials are prepared into a tetradecyl glucopyranoside aqueous solution. The preparation method comprises the following steps of 1, glucose liquid preparation, 2, pre-heating for temperature increasing, 3, a condensation reaction, 4, reduced pressure flashing, 5, pH value adjustment, 6, solid-liquid separation, 7, molecular distillation alcohol-removal, 8, decoloration purification, and 9, blending. The preparation method has the advantages that a process flow is reasonable and convenient; reaction time is short; a production cost is low; quality is stable; a yield is high; reaction processes are safe and reliable; favorable conditions of separation and refining of chemical reaction products are provided; conditions of process industrialization are provided; and the preparation method is simple, convenient and fast.

Owner:扬州晨化新材料股份有限公司

Wheat impurity removing winnowing machine

InactiveCN103394466AIncrease cleaning speedTo achieve the purpose of removing impuritiesGas current separationEngineeringImpurity

The invention discloses a wheat impurity removing winnowing machine. The wheat impurity removing winnowing machine comprises a machine case, wherein a feed hopper is arranged on the front portion of the top wall of the machine case; an upward winnowing board is hinged to the front portion of the machine case, arranged corresponding to the feed hopper and driven by a swinging mechanism; the rear end portion of the upward winnowing board is hinged to the inner top wall of the drying machine case and inclines downwards from back to front; a guide inclined board located below the front portion of the upward winnowing board is further hinged to the inner wall of the front end of the machine case; the side wall of the machine case is provided with an air inlet and an impurity removing draught fan, and the impurity removing draught fan blows into the inner cavity of the machine case through the air inlet; a guide sieve board which is located below the discharge end of the guide inclined board and inclines downwards to one side of the machine case is installed inside the machine case; a discharge opening is formed in the side wall, corresponding to the lower end of the guide sieve board, of the machine case. The wheat impurity removing winnowing machine can automatically remove impurities in wheat, and has the advantages of relieving labor intensity and being high in impurity removing speed.

Owner:山东鸿源生物科技股份有限公司

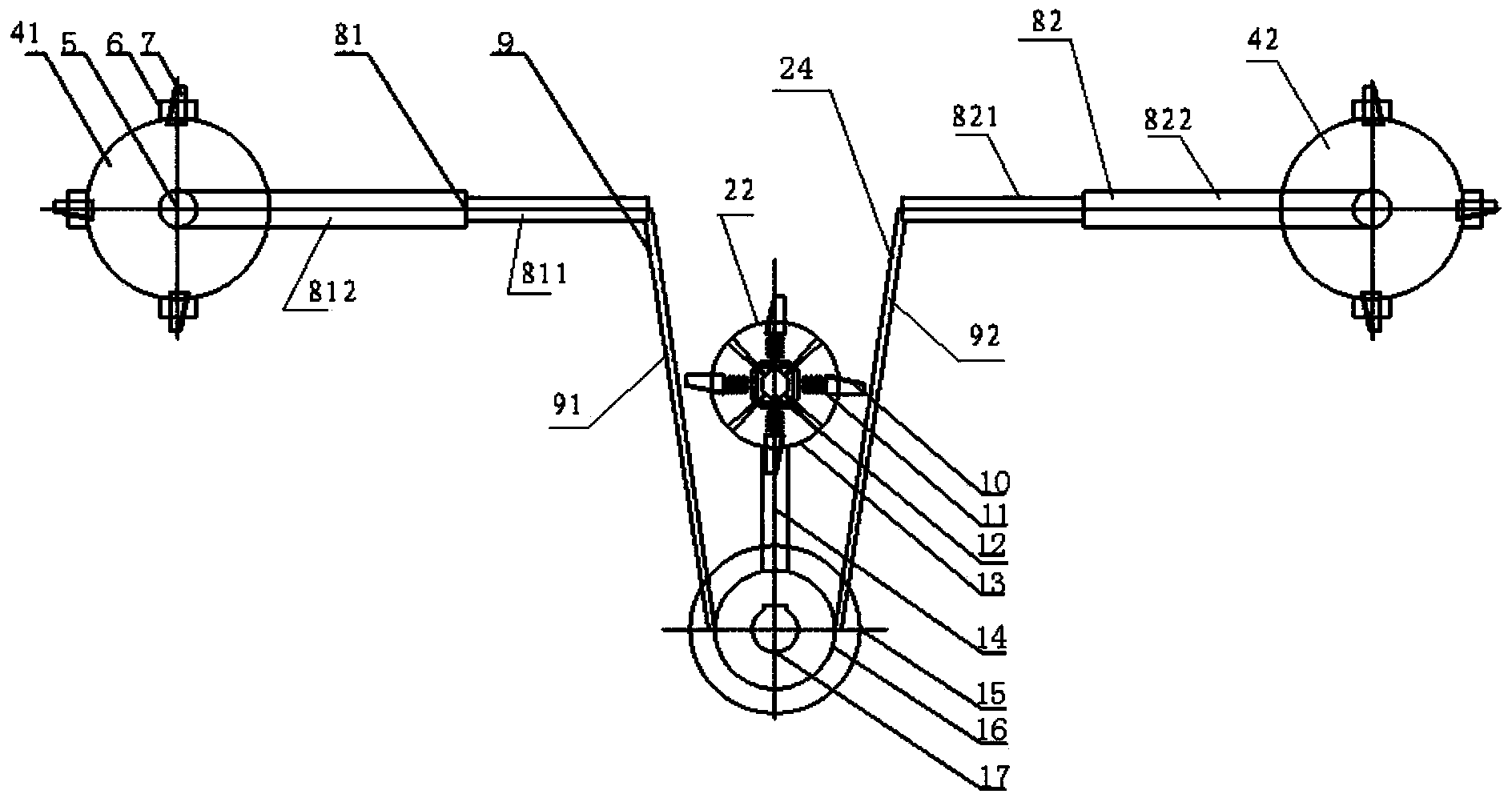

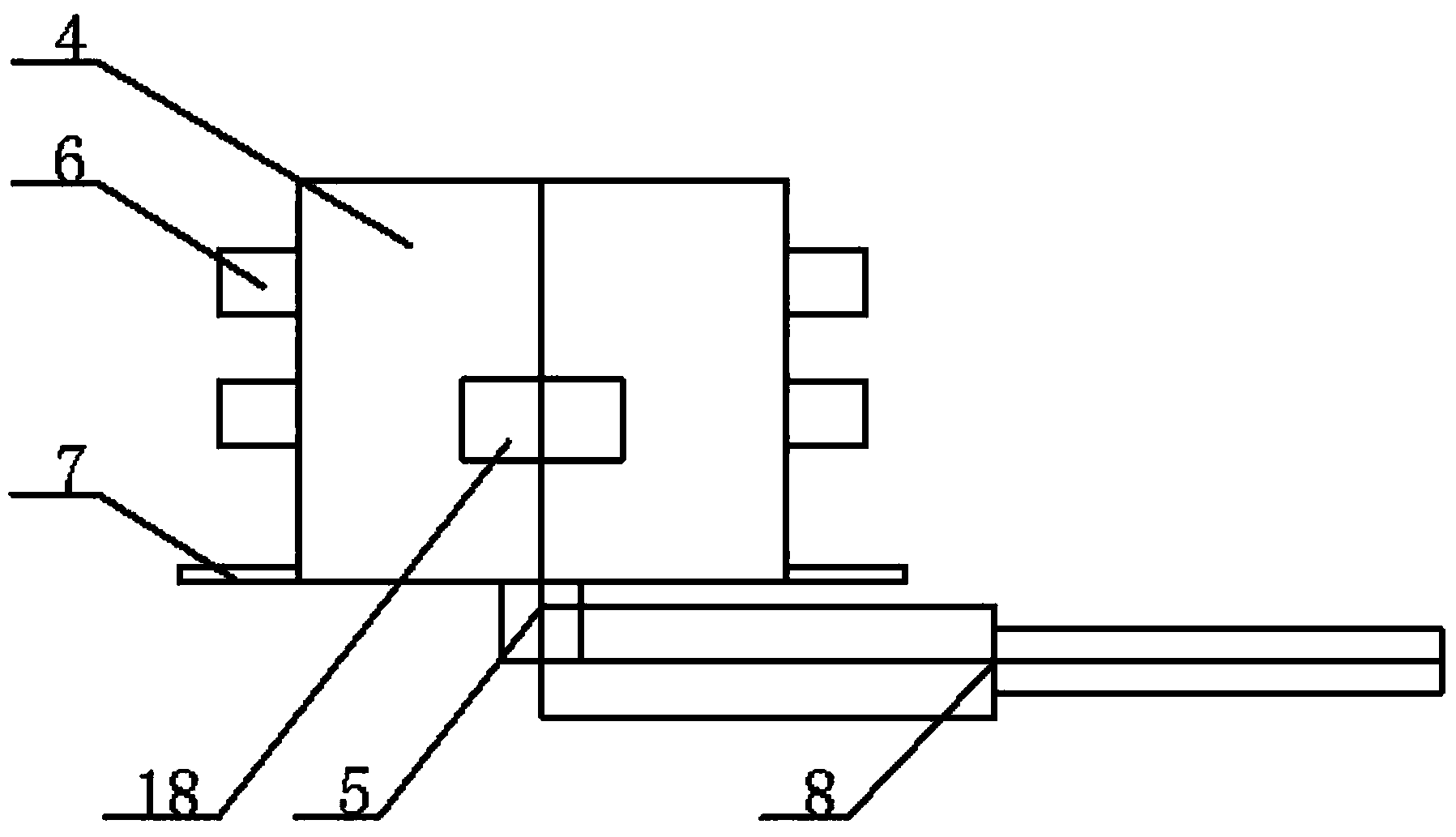

Tip cutting device of sugarcane harvesting machine

ActiveCN103858598AAdapt to the needs of on-site harvestingQuality improvementHarvestersEngineeringMechanical engineering

The invention relates to a tip cutting device of a sugarcane harvesting machine. The tip cutting device comprises guiding barrels, a telescopic drive device and a tip cutting mechanism, wherein the outer wall of each guiding barrel is provided with a plurality of projections and a plurality of first cutting blades, the quantity of the guiding barrels is two, and the first guiding barrel and the second guiding barrel are symmetric to each other; the telescopic drive device comprises a guide rod and a loop bar which is matched with the guide rod and is horizontally arranged, the end part of a first guide rod of a first telescopic drive device and the end part of a second guide rod of a second telescopic drive device are respectively connected with a baffle plate, and the cross section of the arrangement of the two baffle plates is in a V-shaped structure; the tip cutting mechanism is arranged between the two baffle plates, the edge of a tip cutting disc is provided with a plurality of second tip cutting blades, one end of each tip cutting blade is provided with a distance adjusting device and connected with the tip cutting disc, and the tip cutting disc is connected with a longitudinal adjusting device. By adopting the tip cutting device of the sugarcane harvesting machine, the distance between the tip cutting parts is adjusted according to the harvesting situation of a sugarcane field, the impurity content can be effectively reduced, and the sugarcane quality is improved.

Owner:GUANGXI UNIV

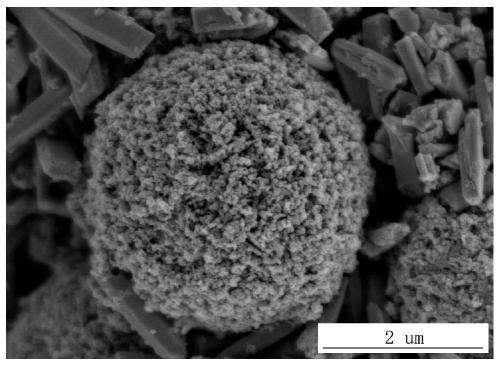

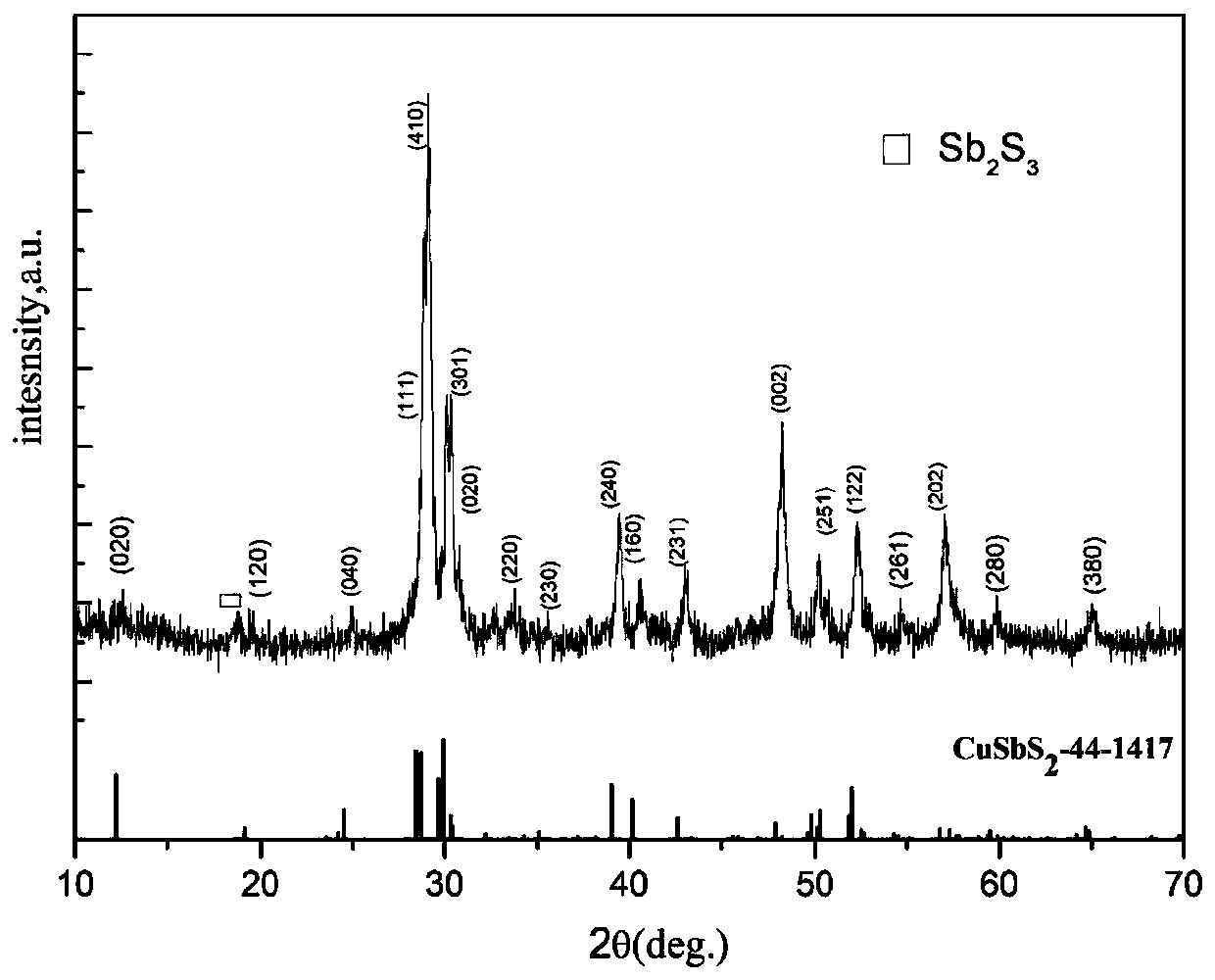

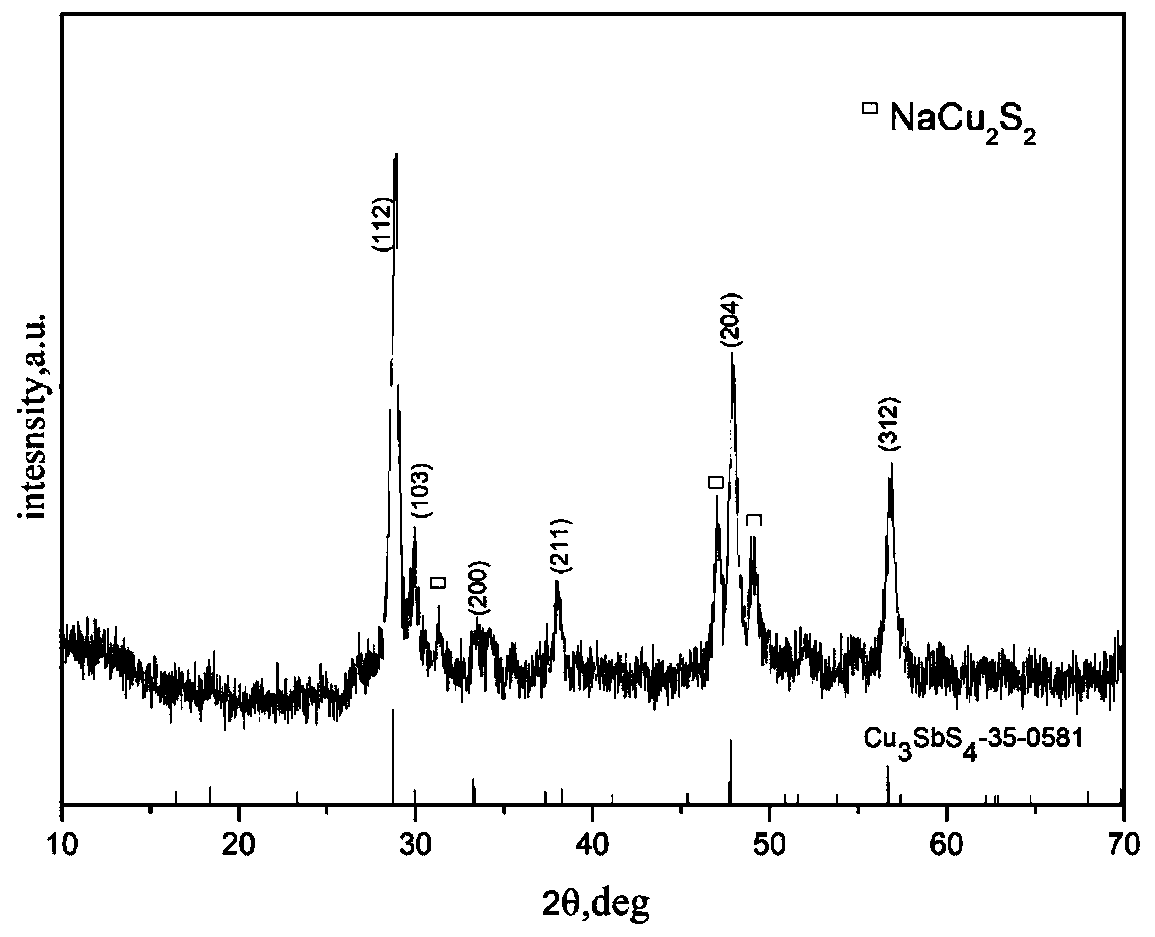

CuSbS2 nanoparticle and preparing method and application thereof

ActiveCN110203971ASingle phaseGood crystallinityPhysical/chemical process catalystsAntimony compoundsSolventNanometre

The invention discloses a preparing method and application of a CuSbS2 nanoparticle. The particle is an agglomerate with a regular square rod-shaped structure. The preparing method comprises the stepsthat copper salt, antimonic salt and a sulfocompound are dissolved in a solvent, and then a precursor solution is prepared after the materials are fully dissolved; a microwave method is adopted for preparing the CuSbS2 nanoparticle; a Na2S solution is added into the obtained CuSbS2 nanoparticle for removing impurity phases. According to the CuSbS2 nanoparticle and the preparing method and application thereof, by regulating preparing technologies and parameters, the purpose of regulating the crystal appearance is achieved, then the ideal crystal surface appearance is prepared, the photocatalytic performance of the CuSbS2 nanoparticle is improved, and the CuSbS2 nanoparticle can increase the degradation rate of rhodamine B under 7 hours of illumination by an xenon lamp of 500 W to 96% from19%.

Owner:JINLING INST OF TECH

Lipopeptid composition with physiological activity and its preparation method and application

InactiveCN101240014AKeep aliveTo achieve the purpose of removing impuritiesPeptide/protein ingredientsPeptide preparation methodsConchMedicine

The invention relates to a natural lipopeptide composite with biological activity extracted from conch, preparation and application in pharmaceutical fields of the same, which pertains to biological and pharmaceutical technical fields. The invention protects a lipopeptide composite with biological activity, preparation and application thereof. The lipopeptide is produced from marine organisms, can be used in treatment and improving hypertension and congestive heart failure.

Owner:BIOLOGY INST OF SHANDONG ACAD OF SCI

Method for preparing battery-stage anhydrous lithium chloride

ActiveCN100469696CReduce lossesHigh recovery rateAlkali metal chloridesLithium sulphateLithium chloride

Owner:TIANQI LITHIUM CORP

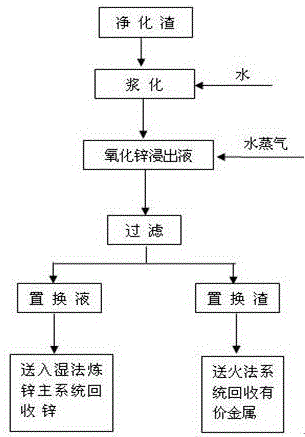

Method for removing impurities from zinc oxide leachate by using zinc hydrometallurgy purification residues

InactiveCN106756025AHigh total replacement rateQuality assuranceProcess efficiency improvementDisplacement reactionsReaction temperature

A method for removing impurities from zinc oxide leachate by using zinc hydrometallurgy purification residues uses an intermediate purification residues as a raw material, and comprises the following steps: 1, slurrying the purification residues; 2, displacing and removing impurities: removing impurities, and carrying out a displacement reaction on simple substance zinc in the purification residues and impurities in zinc oxide leachate at 70-75 DEG C under a pH value of 4.5-5.0 for 1-2 h; and 3, carrying out solid-liquid separation to obtain a displacement liquid and displacement residues. The method has the advantages of realization of open circuit removal of the impurities from the zinc oxide leachate, guaranteeing of the quality of a wet system zinc sulfate solution and increase of the economic benefits of zinc hydrometallurgy under extremely small investment cost and extremely low running cost by using the intermediate produced in the zinc hydrometallurgy system.

Owner:HUNAN SHUI KOU SHAN NONFERROUS METALS GRP

Film coating technology for non-woven fabric

InactiveCN108286192AImproves Strength and ToughnessImprove securityTextiles and paperNonwoven fabricUltimate tensile strength

The invention discloses a film coating technology for non-woven fabric. The technology comprises the steps of selection of film coating raw materials, preparation of a film coating solution additive,treatment of a film coating solution, smelting forming treatment, cooling treatment of the non-woven fabric and reinforcement treatment of the non-woven fabric. According to the method, the film coating raw materials are selected, the film coating solution additive is prepared, the film coating solution is treated, smelting forming treatment is conducted, the non-woven fabric is cooled and reinforced, and a flame retardant, a curing agent and a catalyst are selected as auxiliary materials. By means of the technology, the strength, toughness and uninflammable function of a finished product canbe improved, and the safety of the non-woven fabric is improved.

Owner:浙江德清金乾新材料有限公司

Process for extracting colistin sulfate through precipitation method

ActiveCN102718842BAccelerated precipitationQuality improvementPolymyxinsPeptide preparation methodsFermentationPrecipitation

The invention discloses a process for extracting colistin sulfate through a precipitation method. The process comprises the following steps of: (a) adjusting pH of fermentation liquor containing polymyxin E with oxalic acid or concentrated sulfuric acid, and filtering with a filtering device; (b) adding 0 metal complexing agent and inorganic flocculant to the filtrate, and reacting at normal temperature for 0.5 to 4.0h; (c) heating, cooling, and vacuum-filtering the reactive liquid; (d) adjusting pH of the filtrate above with aqueous alkali, separating the solid from the liquid to obtain a filter cake, dissolving the filter cake with sulfuric acid solution so as to obtain acidizing fluid, adding potassium permanganate and activated carbon to the acidizing fluid respectively, agitating for 0.5 to 2.0 hours, and then vacuum-filtering to obtain colistin sulfate liquid; and (e) centrifugally spray-drying the colistin sulfate liquid. With the adoption of the process, the common problems of the existing process for purifying fermentation liquor that the steps are complicated, the period is long, the labor intensity is relatively high, and the wastewater is difficult to treat and the like can be overcame.

Owner:HEBEI SHENGXUE DACHENG PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com