Method for removing impurities from zinc oxide leachate by using zinc hydrometallurgy purification residues

A technology for hydrometallurgical zinc and zinc oxide, which is applied in the direction of improving process efficiency, can solve problems such as unfavorable economic benefits of enterprises, increased process steps, high operating costs, etc., so as to reduce processing costs, improve economic benefits, and reduce input costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

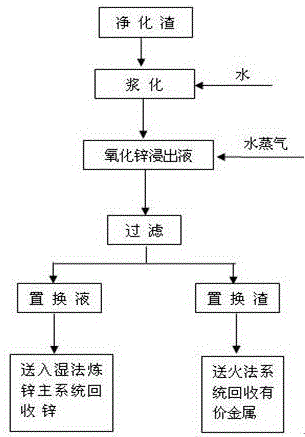

[0033] refer to figure 1 , a kind of method of utilizing the zinc oxide purification slag of the present embodiment to remove the impurity in zinc oxide leaching liquid, this method comprises the following steps:

[0034] A method for removing impurities in zinc oxide leaching solution by using zinc hydrometallurgy purification slag, the method comprises the following steps:

[0035] (1) Slurry purification;

[0036] (2) Replacement and impurity removal: Remove impurities, and the elemental zinc in the purification slag undergoes a replacement reaction with the impurities in the zinc oxide leaching solution. The reaction temperature is 70°C, the pH is 5.0, and the reaction time is 1 hour;

[0037] (3) Solid-liquid separation: to obtain replacement liquid and replacement slag.

[0038] The specific operation of step (1) is: the purification residue is slurried with water at a liquid-solid mass ratio of 3:1, and pumped into the zinc oxide leachate reaction tank.

[0039] The ...

Embodiment 2

[0044] refer to figure 1 , a kind of method that utilizes zinc hydrometallurgy purification slag to remove impurity in the zinc oxide leachate of embodiment 2, compared with embodiment 1, there is following difference:

[0045] Replacement and impurity removal: The impurities are removed, and the elemental zinc in the purification slag undergoes a replacement reaction with the impurities in the zinc oxide leaching solution. The reaction temperature is 73°C, the pH is 4.5, and the reaction time is 1 hour.

[0046] The specific operation of step (1) is: the purification residue is slurried with water at a liquid-solid mass ratio of 4:1, and pumped into the zinc oxide leachate reaction tank.

[0047]6t of purified slag, its chemical composition is: Zn 60%, effective Zn 55%, Cd 5%, Cu 3%, As 1%, Ge1%, Ni1%; the purified slag is 3:1 according to the liquid-solid mass ratio Slurry with water, then pump into zinc oxide leaching solution reaction tank; remove impurities, remove impur...

Embodiment 3

[0049] refer to figure 1 , a kind of method that utilizes the zinc oxide purification slag of embodiment 3 to remove impurity in the zinc oxide leaching solution, compare with embodiment 1, there is following difference:

[0050] Replacement and impurity removal: Remove impurities, and the elemental zinc in the purification slag undergoes a replacement reaction with the impurities in the zinc oxide leaching solution. The reaction temperature is 70°C, the pH is 5.0, and the reaction time is 2 hours.

[0051] The specific operation of step (1) is: the purification residue is slurried with water at a liquid-solid mass ratio of 3:1, and pumped into the zinc oxide leachate reaction tank.

[0052] 6t of purified slag, its chemical composition is: Zn 60%, effective Zn 55%, Cd 5%, Cu 3%, As 1%, Ge1%, Ni1%; the purified slag is 4:1 according to the liquid-solid mass ratio Slurry with water, then pump into zinc oxide leaching solution reaction tank; remove impurities, remove impurities...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com