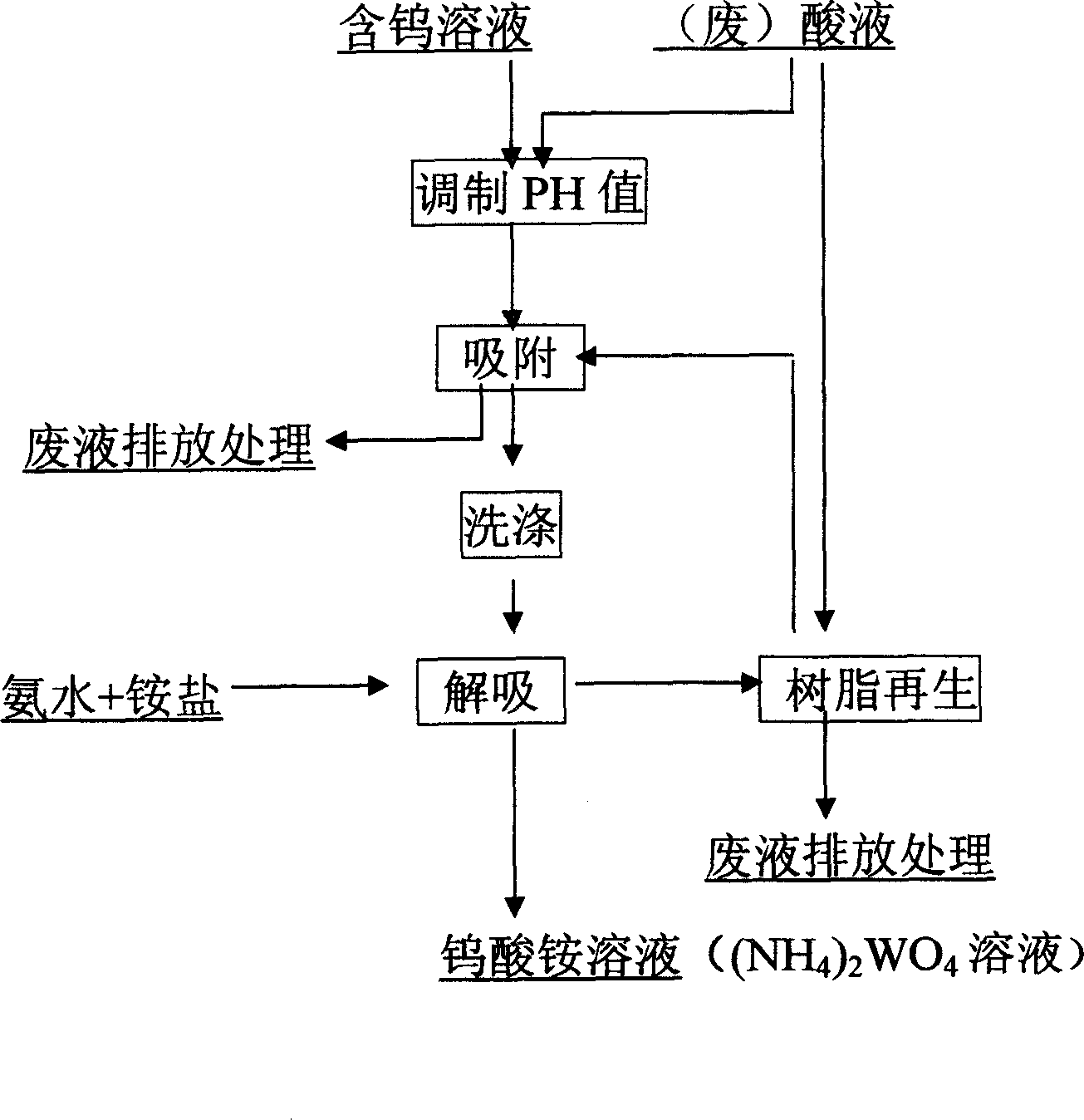

Ion exchange process for preparing ammonium tungstate solution

A technology of ion exchange and ammonium tungstate, applied in the field of ion exchange technology, can solve the problems of slow adsorption speed, complicated operation, and resin damage, and achieve the effects of reducing crystal precipitation, improving impurity removal efficiency, and inhibiting crystal precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: prepare macroporous weakly basic anion resin 600g (dry resin, the same below), adopt the containing SO of PH=2 4 2- acidic solution to regenerate the above resin. Get pure sodium tungstate solution 16L, its WO 3 The content is 69g / l, with SO 4 2- The solution adjusts the acidity of sodium tungstate solution to pH value 4.2, at this time WO 3 The content is 26g / l. Flow the acidic sodium tungstate solution through the regenerated resin for adsorption. The negative tungsten resin after adsorption is washed with pure water until the pH value is neutral; the concentration of ammonia water is 7mol / L and NH 4 With 5L of the mixed solution with a Cl concentration of 2mol / L, the neutral negative tungsten resin is desorbed at a linear flow rate of 15cm / min and then gradually reduced to 3cm / min, and the obtained ammonium tungstate solution is evaporated and crystallized to obtain APT. Its crystallization rate is 94%, and its quality reaches the APT-0 standard....

Embodiment 2

[0018] Embodiment 2: Prepare macroporous weakly basic anion resin 600g, adopt the SO containing SO of PH=1.5 4 2- acidic solution to regenerate the above resin. Get sodium tungstate solution 19L, its WO 3 The content is 69g / l, the mass ratio of tungsten and molybdenum is W: Mo=6500, and the SO4 containing PH=2 2- acidic solution, adjust the pH=4.9 of the above sodium tungstate solution, its WO 3 The content is 26.4 g / l. Flow the acidic sodium tungstate solution through the regenerated resin for adsorption. The negative tungsten resin after adsorption is washed with pure water until the pH value is neutral; the concentration of ammonia water is 8mol / L and NH 4 NO 3 6L of mixed solution with a concentration of 1.5mol / L, desorb the neutral negative tungsten resin at a linear flow rate of 14cm / min and then gradually decrease to 2cm / min, and then evaporate and crystallize the obtained ammonium tungstate solution to obtain APT. Its crystallization rate is 93%, and its quality...

Embodiment 3

[0019] Embodiment 3: Prepare macroporous weakly basic anion resin 600g, adopt the Cl containing Cl of PH=1.0 - hydrochloric acid solution to regenerate the above resin. Take WO 3 APT crystallization mother liquor 15L and WO with a content of 48.58g / l 3 16L of slag washing water with a content of 25g / l, the mass ratio of tungsten and molybdenum in the solution to WO 3 : Mo=3600; adding 0.5% Na with a volume ratio of tungsten-containing solution 2 S solution, with 2mol / L dilute hydrochloric acid and pH 2.5 containing SO4 2- The production waste liquid, adjust the pH=4.21 of above-mentioned solution, this moment WO 3 The content is 27g / l. The acid-adjusted solution is passed through the regenerated resin to perform adsorption. The negative tungsten resin after adsorption is washed with pure water until the pH value is neutral; the concentration of ammonia water is 10mol / L and NH 4 NO 3 5L of the mixed solution with a concentration of 2.2mol / L, desorb the neutral negative ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com