Waste plastic multi-stage sorting system

A technology for waste plastics and fractionation, applied in plastic recycling, grading, solid separation and other directions, can solve problems such as high energy consumption, low product quality, and incompatibility with resource conservation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

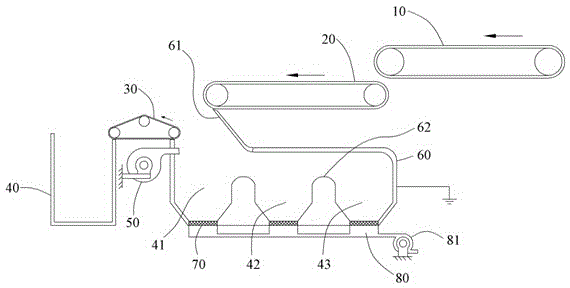

[0011] The present invention provides a multi-stage sorting system for waste plastics, comprising a material conveyor belt 10, an accelerating conveyor belt 20, a triangular conveyor belt 30 and a collection bin, and the material conveying direction of the material conveyor belt 10, the accelerating conveyor belt 20, and the triangular conveyor belt 30 Same, the feed end of described acceleration conveyor belt 20 is correspondingly arranged below the discharge end of material conveyor belt 10, the feed end of described triangular conveyor belt 30 is lower than the discharge end of acceleration conveyor belt 20, and the material conveyor belt 10 The speed of travel is less than the speed of acceleration of the conveyor belt 20, and the collection bins include at least two, the first collection bin 40 corresponds to the discharge end of the triangular conveyor belt 30, and the second collection bin 41 corresponds to the outlet of the acceleration conveyor belt 20. At the material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com