Cobalt and nickel purifying method based on waste battery metal recovery technology

A waste battery and metal technology, which is applied in the field of cobalt and nickel purification based on waste battery metal recycling process, can solve the problems affecting the purity of cobalt and nickel extraction, affecting the reaction and precipitation of iron ions, and iron ions cannot be removed cleanly, so as to improve the purity , improve recovery efficiency, and thoroughly remove impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

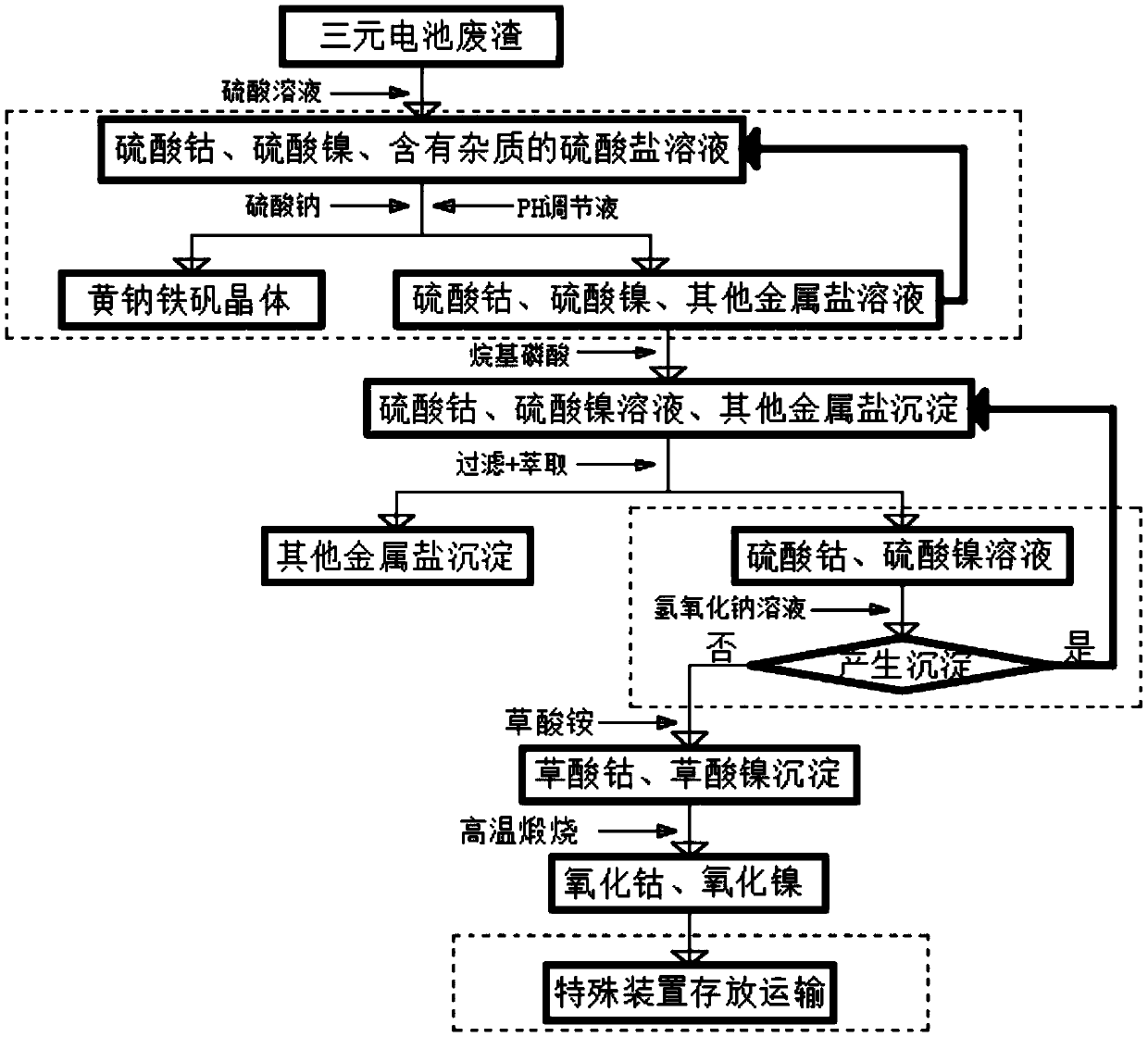

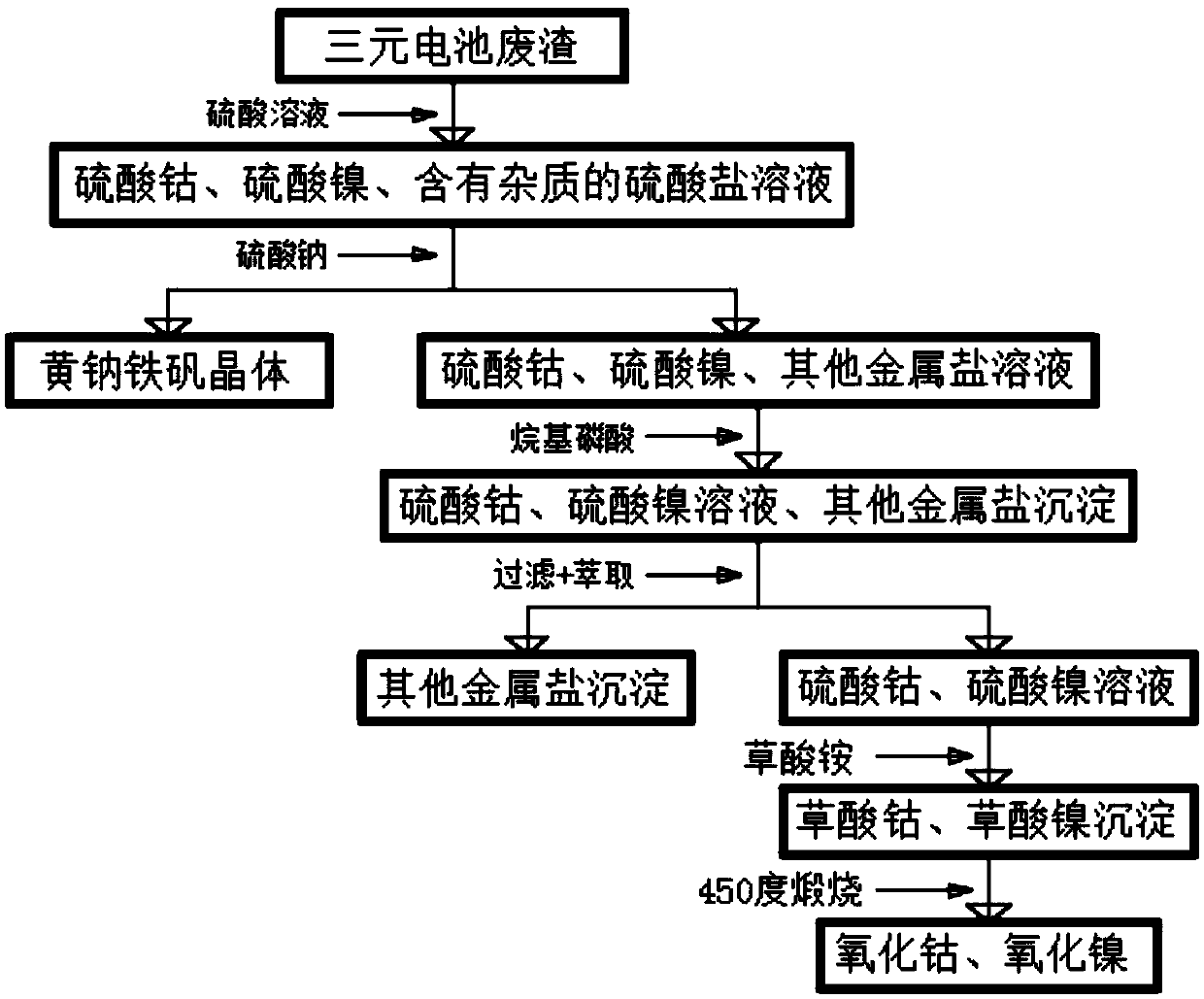

[0049] A method for purifying cobalt and nickel based on waste battery metal recycling process, comprising the following steps:

[0050] Step 1, dissolving waste ternary battery residue in sulfuric acid solution to obtain a solution containing nickel sulfate, cobalt sulfate and a small amount of impurities such as copper, iron, manganese and zinc.

[0051] Step 2. Add the above solution to sodium sulfate. When the reaction is in progress, observe the pH value tester connected to the chemical reaction box 1 in real time to detect the pH value in the solution, and add a weakly alkaline solution to the reaction solution according to the change of the pH value. For neutralization, the ferric ions in the solution react with sodium sulfate to form pale yellow jarosite crystals.

[0052] Step 3, use alkyl phosphoric acid such as: di-2-ethylhexyl phosphoric acid (D-2-EHPA) or other alkyl phosphoric acid ester extractants to extract the remaining copper, iron, manganese, zinc and other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com