Device for detecting and removing foreign matter

A technology for separating out and impurity, which is applied in the field of impurity devices, can solve the problems of adverse effects on optical efficiency and loss, and achieve the effect of high impurity removal rate and high optical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

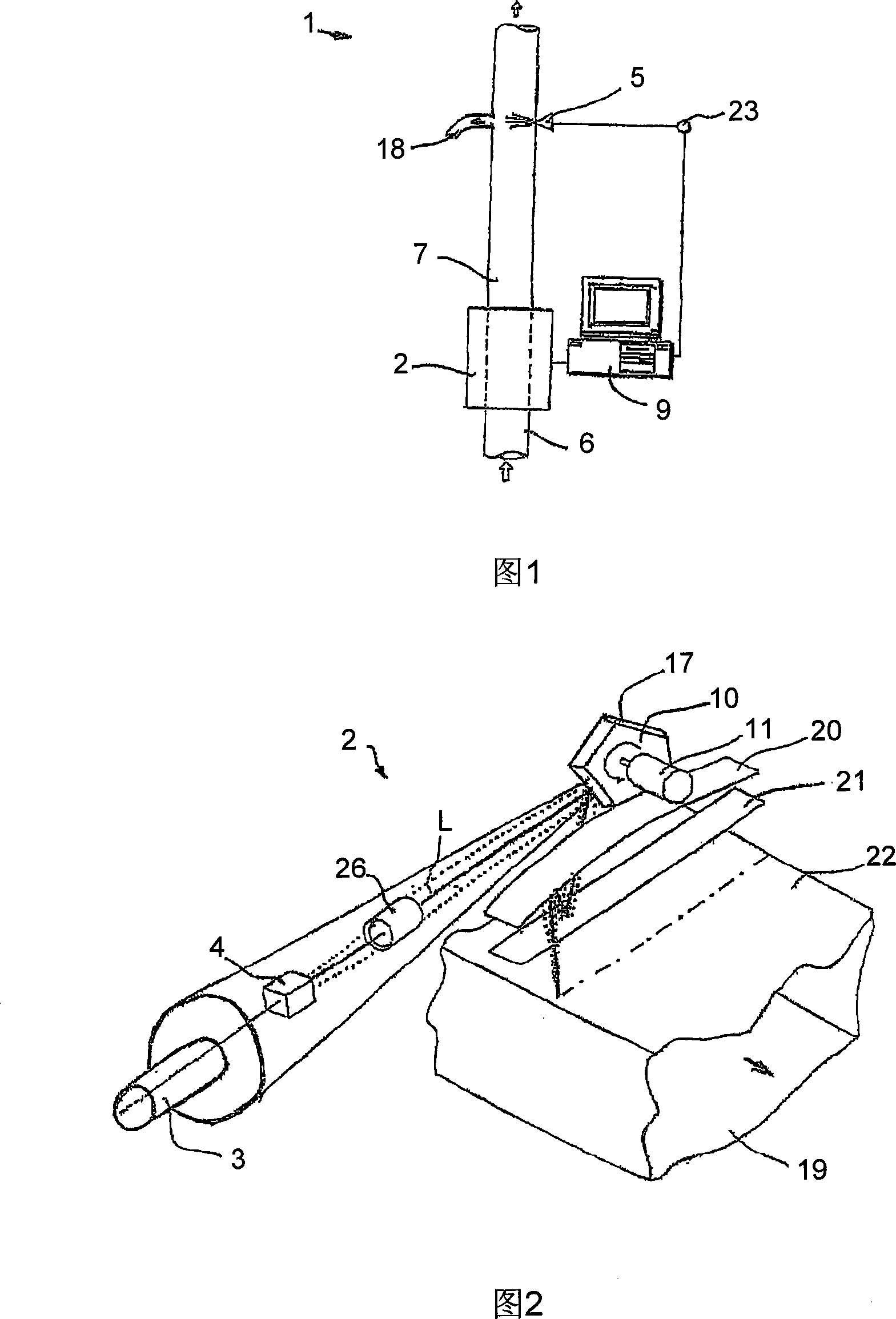

[0042] FIG. 1 shows a device, designated 1 , for detecting and separating impurities in a pneumatically conveyed stream of raw cotton material. The basic structure known per se essentially comprises a detection unit 2 for detecting impurities in a material flow, and a separation device 5 operatively connected to the detection unit. The material flow is conveyed via a conveying line 6 , where a corresponding observation channel 7 is provided in the region of the detection unit 2 .

[0043] When impurities are detected, the corresponding fact is converted by the evaluation unit 9 into a control signal for activating the separating device 5 . The detected impurities are now sent away through the separation pipe 18 or other discharge line until they finally reach a waste container (not shown). In FIG. 1, the separation is accomplished, for example, with compressed air (indicated by compressed air source 23) or directly by blowing out impurities or by operating deflecting shutters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com