Device and method for preparing high-purity chalcogenide glass

A high-purity sulfur and glass technology, applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of complex impurity removal process, large absorption loss, and high impurity content in chalcogenide glass, achieving simple process and eliminating impurities. absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

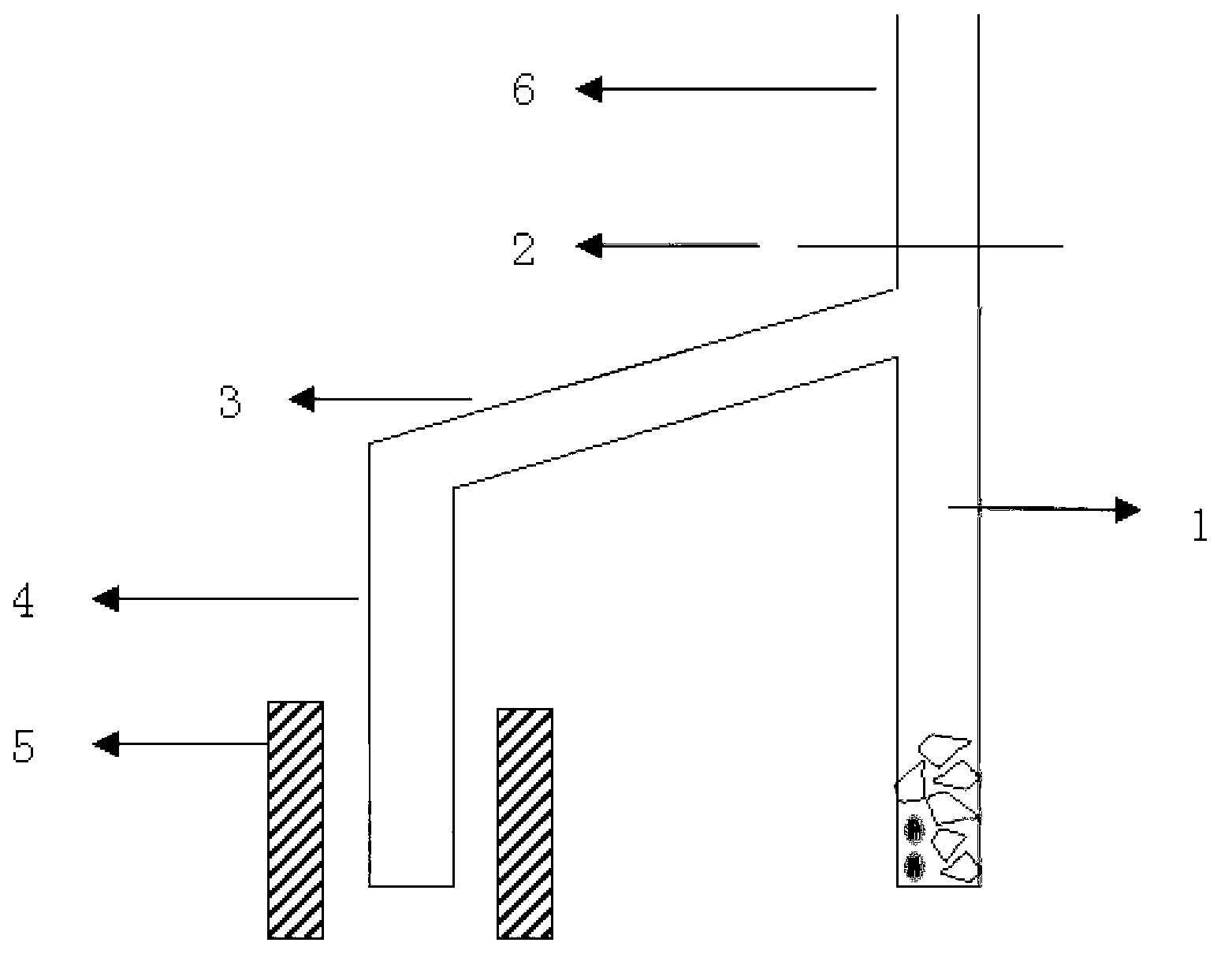

[0034] When using the device of the present invention to prepare high-purity chalcogenide glass, a clean quartz tube with a hydroxyl content lower than 10 ppm is selected, and the angle between the horizontal connecting tube and the first vertical tube is 120 degrees, wherein the first vertical tube is The raw material pipe, the second vertical pipe being the receiving pipe, and the preparation method of high-purity chalcogenide glass specifically include the following steps:

[0035] (1) Weigh the elemental raw materials with a purity of 99.999% or more according to the chalcogenide glass production formula, wherein the sulfuric elemental raw materials are placed in the raw material tube, and the other elemental raw materials are placed in the receiving tube, and 50-500ppm of distillate is added to the receiving tube. Oxygen agent, add 200-500ppm of dehydration agent into the raw material pipe; among them, the oxygen scavenger is aluminum or magnesium, and the dehydration agen...

Embodiment 1

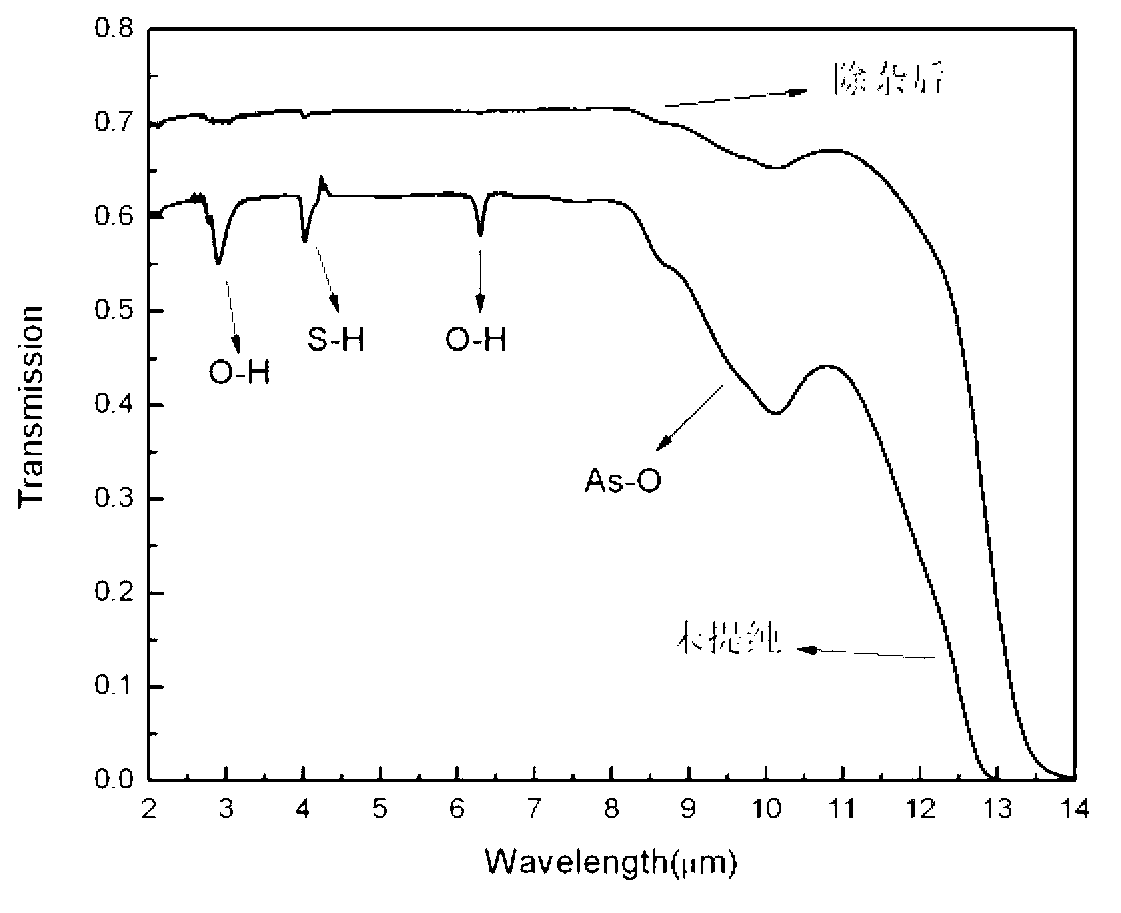

[0045] Example 1: Taking the component as As 2 S 3 Take the high-purity chalcogenide glass as an example, including the following specific steps:

[0046] (1) Clean the device with ultrasonic waves for 30 minutes to remove particles and impurities attached to the inner wall, then soak it in hydrofluoric acid for 2 minutes to remove other harmful ions attached to the inner wall, rinse it with deionized water, and place it in a high temperature protected by nitrogen In the furnace, bake at 1000°C for 10 hours to remove the free water and part of the structural water attached to the inner wall, and then slowly cool down to room temperature;

[0047] (2) select elemental raw materials arsenic and sulfur with a purity of 99.999%, and accurately weigh the raw materials according to the formula, wherein the sulfur is placed in the raw material tube, the arsenic is placed in the receiving tube, and 50 ppm of aluminum is placed in the receiving tube, and 500 ppm of arsenic is placed i...

Embodiment 2

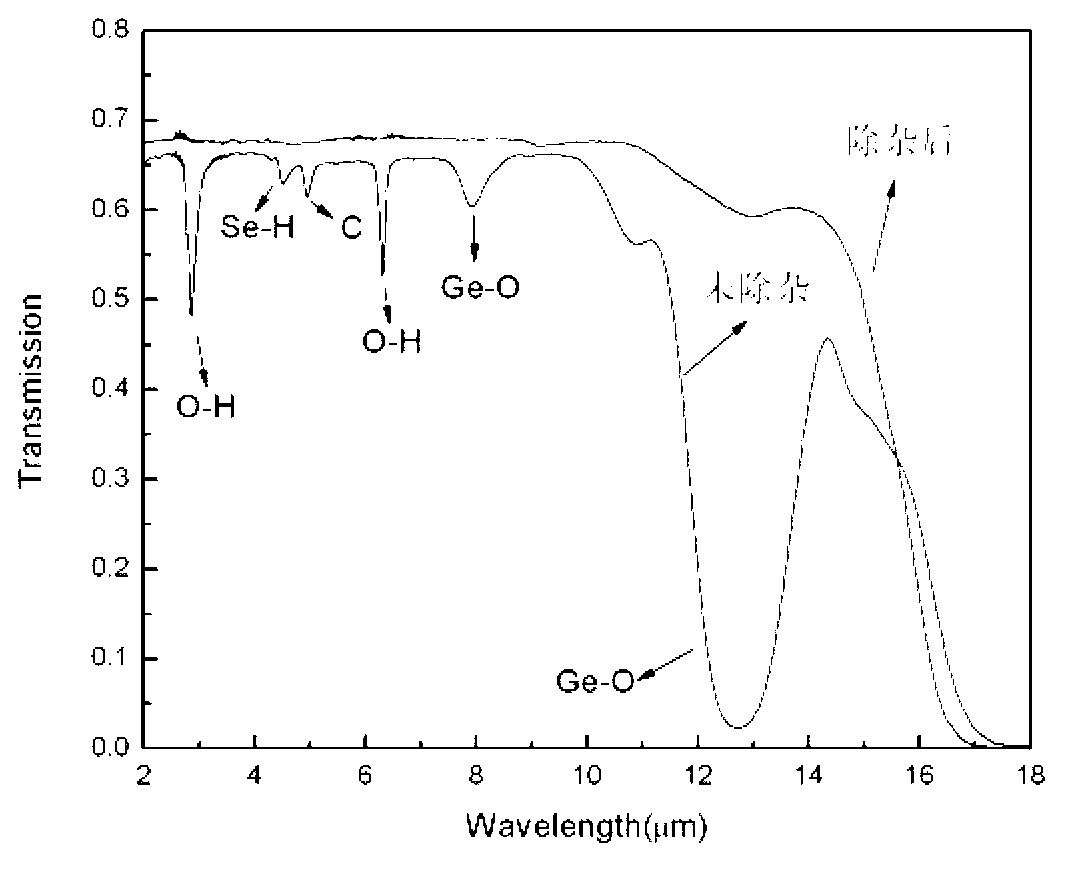

[0053] Embodiment two: take component as Ge 28 Sb 12 Se 60 Take the high-purity chalcogenide glass as an example, including the following specific steps:

[0054] (1) Clean the device with ultrasonic waves for 30 minutes to remove particles and impurities attached to the inner wall, then soak it in hydrofluoric acid for 2 minutes to remove other harmful ions attached to the inner wall, rinse it with deionized water, and place it in a high temperature protected by nitrogen In the furnace, bake at 1000°C for 10 hours to remove the free water and part of the structural water attached to the inner wall, and then slowly cool down to room temperature;

[0055] (2) select elemental raw materials germanium, antimony and selenium with a purity of 99.999% for use, accurately weigh the raw materials according to the formula, wherein the selenium is placed in the raw material tube, the germanium and antimony are placed in the receiving tube, and the aluminum introduced into 300ppm is pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com