Smelting separation method of rare earth ores

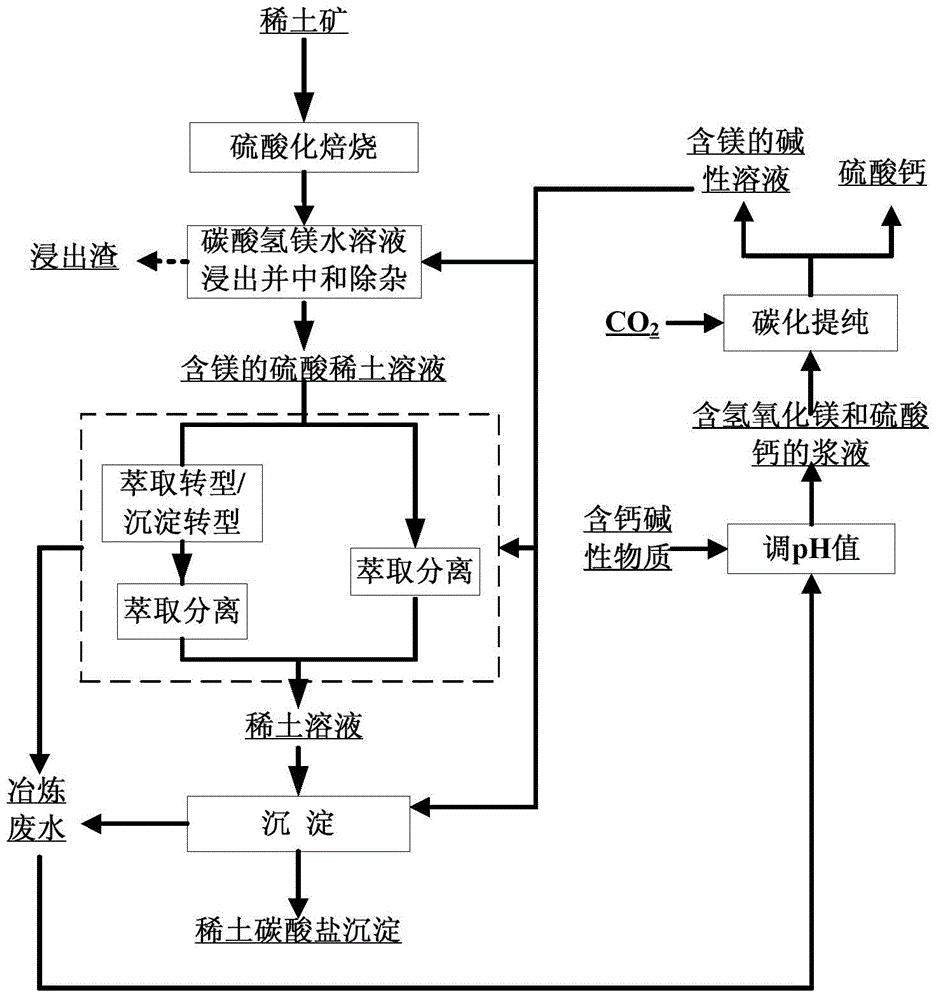

A separation method and rare earth ore technology are applied in the field of smelting and separation of rare earth ore, which can solve the problems of high operating cost, large investment cost and limited application, and achieve the effects of improving recovery rate, improving recovery and reducing production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] After roasting 1Kg Baotou mixed rare earth concentrate (REO 50.4%) with sulfuric acid, leaching and neutralizing and removing impurities with a concentration of 2g / L magnesium bicarbonate aqueous solution (calculated as MgO), control the end point of pH to 4.5, Iron, phosphorus, thorium and other impurities are precipitated and removed, and 48.9L of magnesium-containing rare earth sulfate solution and leaching residue are obtained by solid-liquid separation; the content of rare earth in the magnesium-containing rare earth sulfate solution is 10.0g / L (calculated as REO), and the recovery rate of rare earth is 97.0%.

Embodiment 2

[0066] After roasting 1Kg Baotou mixed rare earth concentrate (REO 53.0%) with sulfuric acid, it is leached and neutralized with an aqueous solution of magnesium bicarbonate (calculated as MgO) with a concentration of 18g / L. The pH value at the end is controlled to be 4.3. Iron, phosphorus, thorium and other impurities are removed by precipitation and solid-liquid separation to obtain 12.64L of magnesium-containing rare earth sulfate solution and leaching residue; the content of rare earth in the magnesium-containing rare earth sulfate solution is 41.0g / L (calculated as REO), and the recovery rate of rare earth is 97.5%.

Embodiment 3

[0068] Baotou mixed rare earth concentrate (REO 51.6%) is mixed with 93wt% concentrated sulfuric acid at a speed of 1t / h into a rotary kiln with a mineral acid ratio of 1:1.4 (weight ratio) and continuous roasting at 350°C. Use 10g / L magnesium bicarbonate aqueous solution to leaching and neutralize the roasted rare earth ore after sulfuric acid acidification and roasting, control the pH at the end point to 4.2, and obtain a magnesium-containing rare earth sulfate solution 14.6m by solid-liquid separation 3 / h and leaching residue; the content of rare earth in the magnesium-containing rare earth sulfate solution is 34.5g / L (calculated as REO), the recovery rate of rare earth is 97.6%, and impurity ions such as iron, phosphorus, and thorium form precipitation into the leaching residue.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com