Recovery method of aluminum oxide in hydrated garnet

A technology of hydrated garnet and a recovery method, which is applied in the field of recovery of alumina in hydrated garnet, can solve the problems of unfavorable industrial promotion, complicated process, and low recovery efficiency of alumina, and achieves low economic cost, simple steps, Conducive to the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

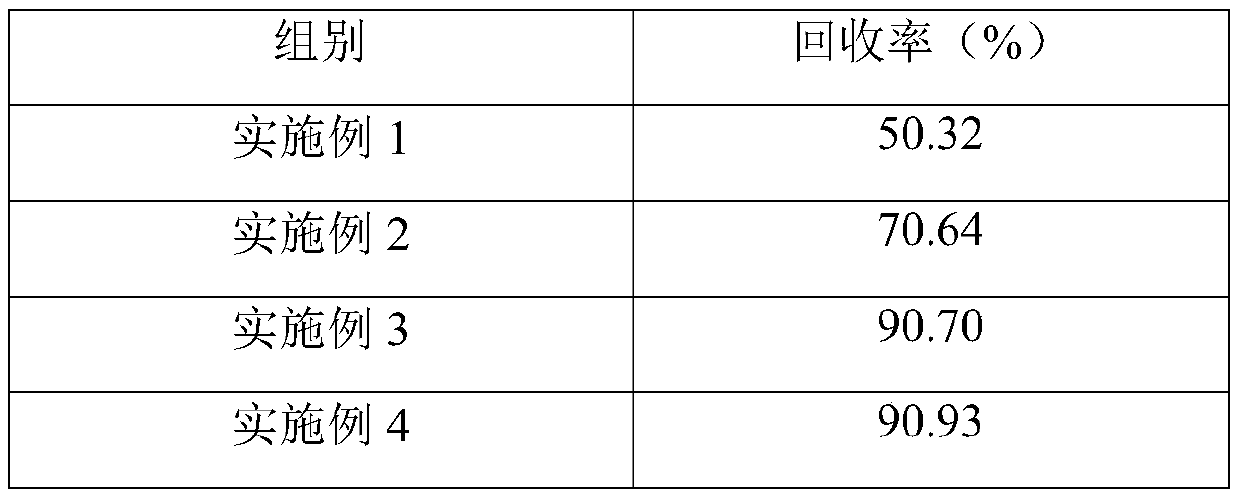

Embodiment 1

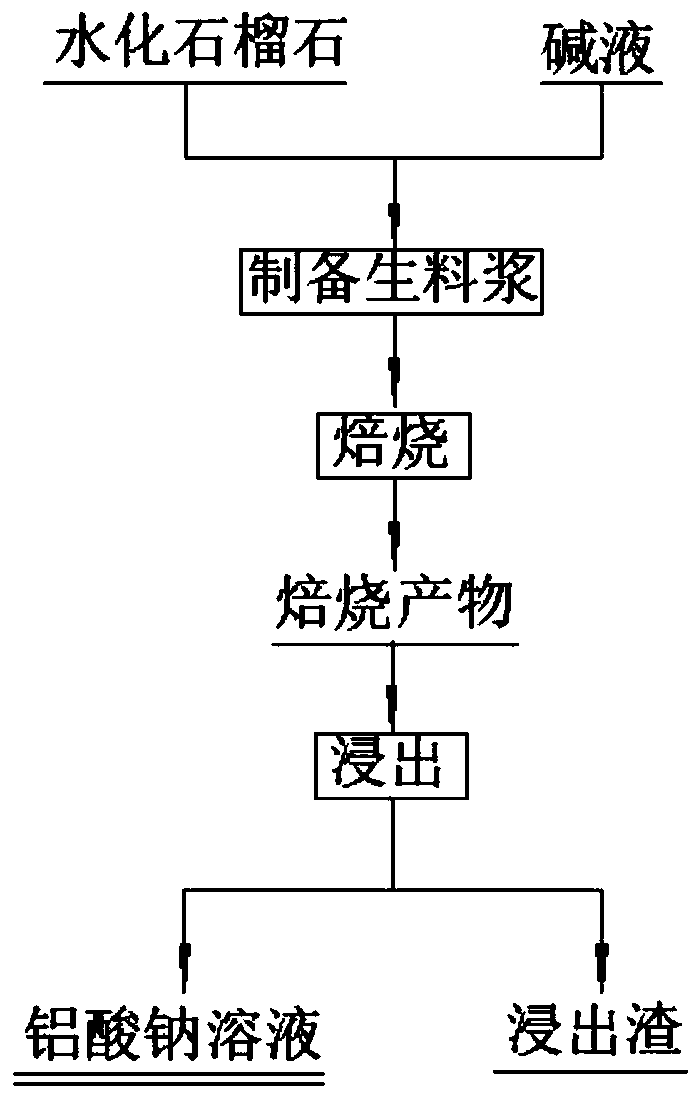

[0033] The method for recovering alumina in hydrated garnet of the present invention, the specific process is as follows figure 1 As shown, the steps are as follows:

[0034] (1) Mix hydrated garnet and lye uniformly to prepare raw slurry, make the molar ratio of sodium oxide to alumina of 0.5, liquid-solid ratio of 0.5mL / g, and roast at 200℃ for 0.5h, The roasting is carried out in an air atmosphere, the roasting temperature is lower, the energy consumption is reduced, and the cost is lower.

[0035] (2) Put the roasted product in a sodium carbonate solution with an alkali concentration of 5g / L for leaching operation, the leaching temperature is 25℃, the leaching time is 0.2h, and then the solid-liquid separation is carried out. The sodium aluminate solution and the leaching residue are easier Separation, simple operation.

Embodiment 2

[0037] The content of this embodiment is basically the same as that of embodiment 1, except that the molar ratio of sodium oxide to aluminum oxide in the raw slurry is 1.1, the liquid-to-solid ratio is 1.2 mL / g, and it is calcined at 350°C for 1.6 hours. The roasted product was placed in 79g / L sodium hydroxide solution for leaching operation.

Embodiment 3

[0039] The content of this embodiment is basically the same as that of embodiment 1, except that the molar ratio of sodium oxide to aluminum oxide in the raw slurry is 1.7, the liquid-to-solid ratio is 2 mL / g, and it is calcined at a temperature of 500°C for 2.7 hours. The roasted product is leached in 153g / L sodium hydroxide solution, the leaching temperature is 50°C, and the leaching time is 2h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com