Alumina recovery system and method

A recovery system, alumina technology, applied in chemical instruments and methods, aluminate/alumina/aluminum hydroxide purification, inorganic chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

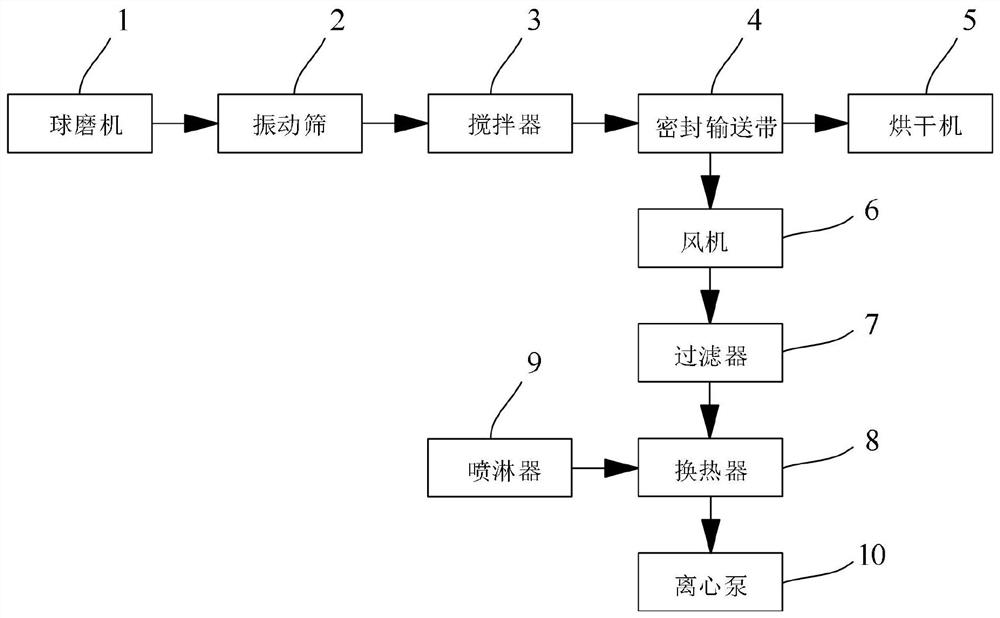

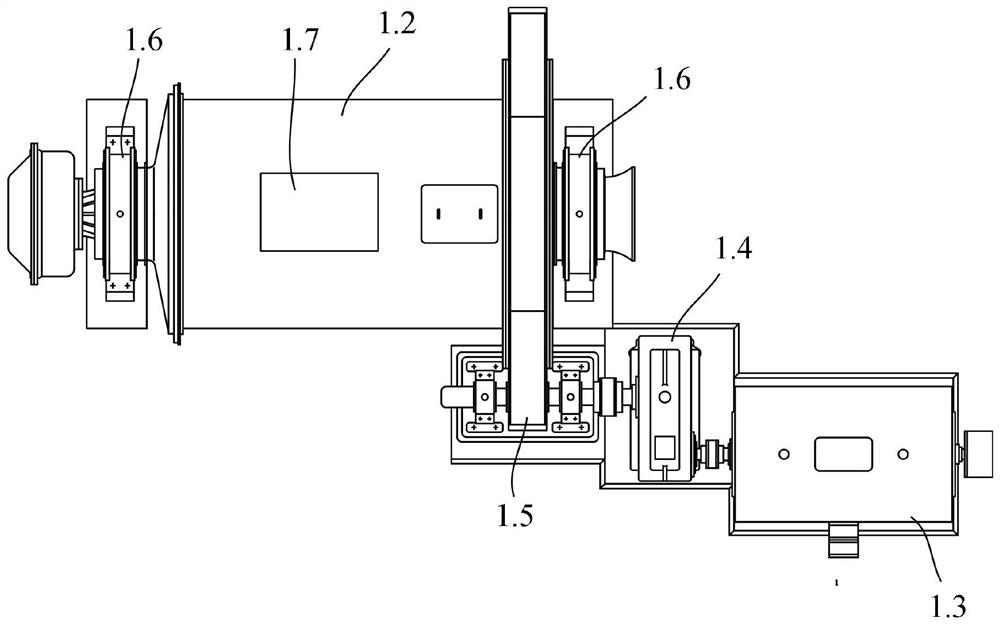

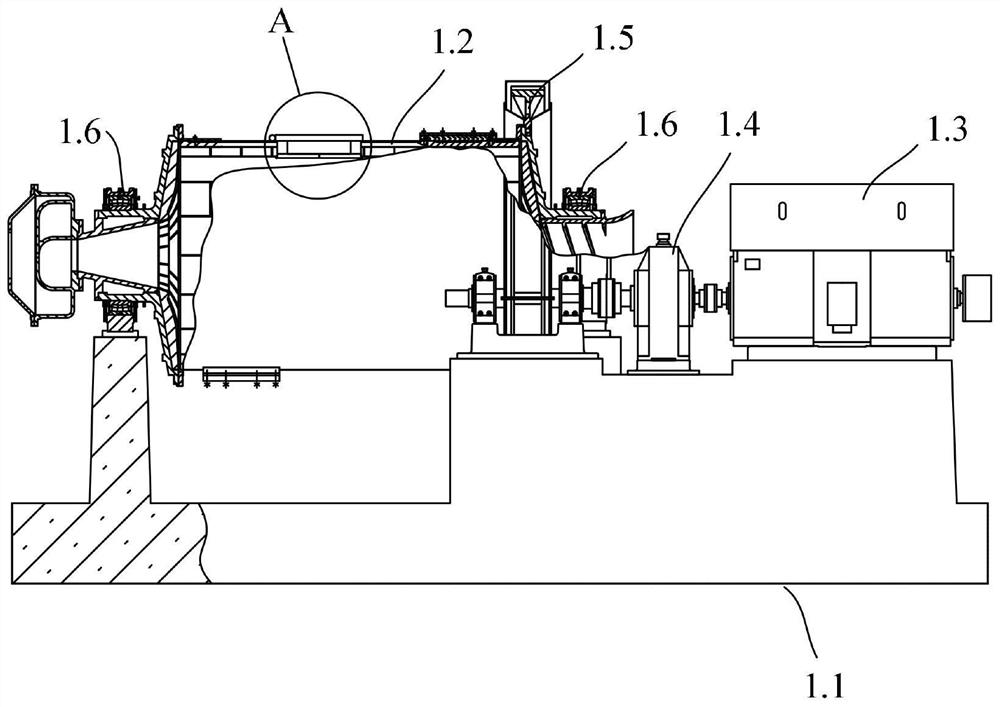

[0057] Such as Figure 1 to Figure 8 As shown, the alumina recovery system includes a ball mill 1, a vibrating screen 2, an agitator 3, a sealed conveyor belt 4 and a dryer 5; the vibrating screen 2 is placed at one end of the ball mill 1, and the vibrating screen 2 The discharge end is communicated with the feed end of the vibrating screen 2, and the discharge end of the vibrating screen 2 is communicated with the feed end of the agitator 3; the sealing conveyor belt 4 is placed in the agitator 3 At one end, the discharge end of the agitator 3 is in sealing communication with the feeding end of the sealing conveyor belt 4 , and the output end of the sealing conveyor belt 4 is in sealing communication with the feeding end of the dryer 5 .

[0058] Add aluminum-containing materials to the ball mill 1, use the ball mill 1 to crush the aluminum-containing materials, and import the obtained aluminum-containing crushed materials into the vibrating screen 2; the vibrating screen 2 p...

Embodiment 2

[0089] Such as figure 1 Shown, a kind of alumina recycling method comprises the following steps:

[0090] Add aluminum-containing slag and aluminum ash mixture materials to the ball mill 1, use the ball mill 1 to pulverize the aluminum-containing slag and aluminum ash mixture materials, and import the obtained aluminum-containing pulverized materials into the vibrating screen 2; Vibration screening to obtain metal aluminum and aluminum ash, and recycling of metal aluminum;

[0091] Then aluminum ash is introduced into the agitator 3, and water is added to the agitator 3 at the same time, and the aluminum ash and water are stirred and mixed to obtain alumina and ammonia; the alumina and ammonia are introduced into the sealing conveyor belt 4, and the sealing conveyor belt The ammonia gas in 4 is introduced into the filter 7 by the fan 6 for filtering, and the filtered ammonia gas enters the heat exchanger 8, and the ammonia gas is sprayed with pure water at the same time, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com