Cutting and crushing equipment for waste aluminum recovery

A technology of cutting and crushing and aluminum recovery, which is applied in the field of cutting and crushing equipment for aluminum waste recycling, which can solve problems such as blockage and inability to quickly crush round aluminum waste, and achieve the effect of reducing workload and ensuring dryness and cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

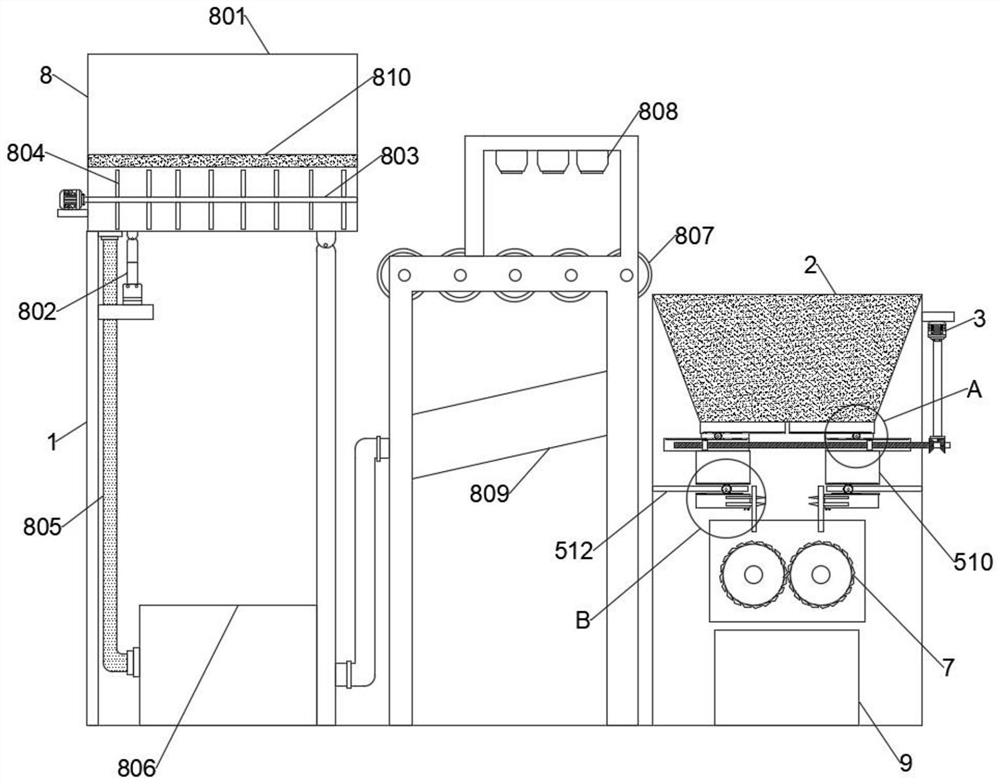

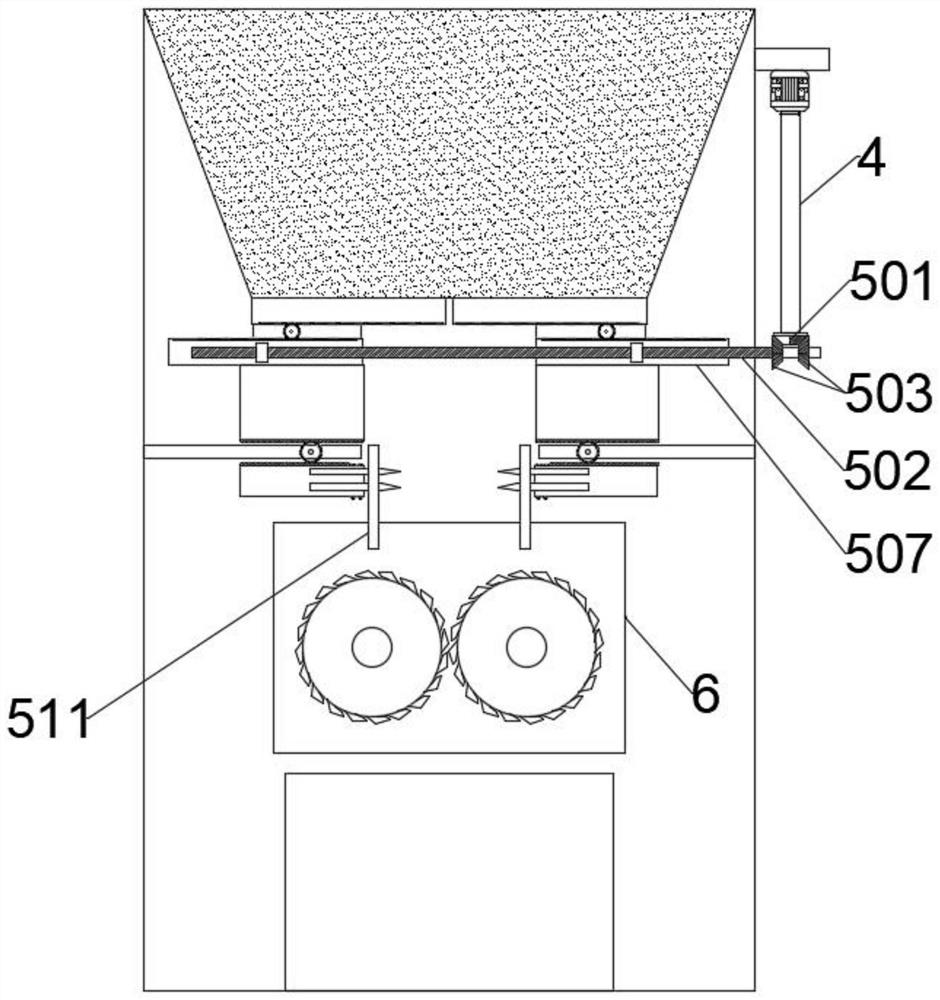

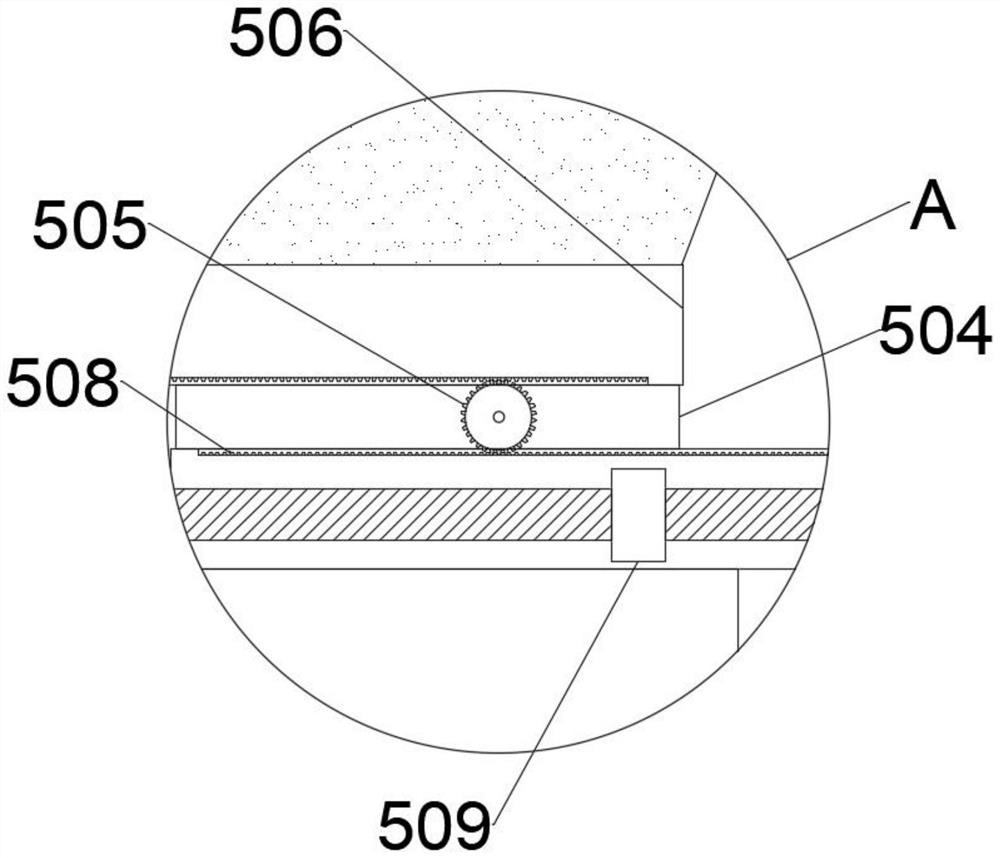

[0030] Due to the different shapes of some existing scrap aluminum materials, when the crushing device crushes the scrap aluminum, the hob of the existing device cannot grab the scrap aluminum for crushing due to the radian angle of the scrap aluminum shape, so that the scrap aluminum is always Rolling above the hob creates a blockage at the outlet. To solve this problem, the specific operations are as follows:

[0031] A collection box 2 is installed on the top of the frame 1, aluminum scrap is poured into the collection box 2, the first motor 3 is turned on, the first motor 3 drives the rotating rod 4 to rotate, and the rotating rod 4 drives the first bevel gear 501 Rotate, and then make the first bevel gear 501 drive the second bevel gear 503 to rotate, because the bevel tooth of the first bevel gear 501 has only half, and then make the first bevel gear 501 can intermittently drive two second bevel gears 503 to carry out Rotate, the second bevel gear 503 drives the threaded...

Embodiment 2

[0036] There are a lot of oil stains and other stains attached to the surface of the existing scrap aluminum, but the existing scrap aluminum is not cleaned when it is crushed, which leads to a large amount of stains remaining in the crushed scrap aluminum particles, which affects the use. In order to solve this problem, the specific operation as follows:

[0037] The operator pours the waste aluminum into the cleaning box 801 included in the cleaning assembly 8 and adds cleaning liquid, starts the third motor, the third motor drives the stirring rod 803 to rotate, the stirring rod 803 drives the stirring blade 804 to rotate, and the stirring blade 804 stirs Cleaning liquid, make the cleaning liquid fully mix with the waste aluminum, and then clean the stains on the surface of the waste aluminum, and then open the switch on the outside of the conduit 805, the waste cleaning liquid flows into the recovery box 806 through the conduit 805, due to the internal setting of the cleani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com