Waste aluminum recycling and direct forming device and method

A kind of aluminum recycling and direct technology, applied in the direction of workpiece cooling device, workpiece surface treatment equipment, coating, etc., can solve the problem of non-implementation, and achieve the effect of reducing cost, improving interface bonding strength, and reasonable equipment structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

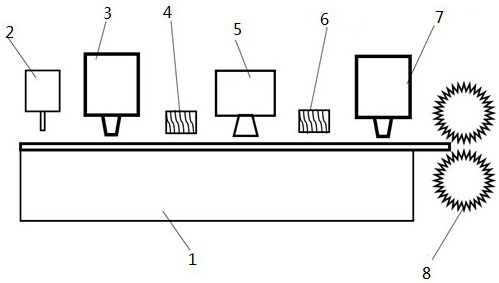

[0033] Such as figure 1 As shown, a waste aluminum recycling direct forming device includes a conveying device 1, a heating system 2, a melting furnace I3, a temperature regulating device I4, a composite material stirring device 5, a temperature regulating device II6, a melting furnace II7 and a twin-roll rolling device 8; Heating system 2, melting furnace I3, temperature regulating device I4, composite material stirring device 5, temperature regulating device II6, melting furnace II7, and twin-roll rolling device 8 are all placed around the conveying device 1.

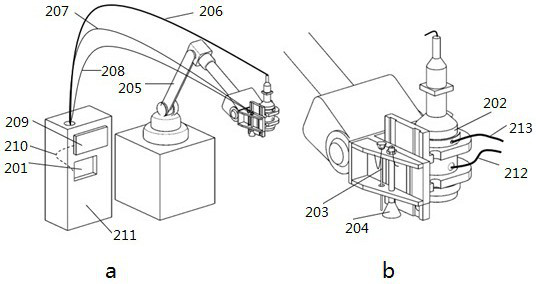

[0034] Such as figure 2 As shown, the heating system 2 includes a laser 201, a focusing mirror 202, a temperature sensor 203 and a distance sensor 204, and the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com