A degradable bone rod implantation device and its preparation method

A technology for bone rods and devices, applied in the field of degradable bone rod implantation devices and its preparation, can solve problems such as the degradation of implant materials, implant failure, metal ion diffusion, etc., and achieve good regenerative function and repair Effects of bone damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present application also provides a preparation method of the degradable bone rod implantation device, comprising the following steps:

[0035] In-situ growth of Ca-P-Ag coating on the surface of degradable medical bone rod by micro-arc oxidation process;

[0036] The degradable medical bone-setting rod is a pure magnesium material or a magnesium alloy material, and the magnesium alloy material includes: Fe greater than 0 and less than or equal to 0.5wt%, Zn greater than 0 and less than or equal to 1wt%, greater than 0 and less than or equal to 0.6wt% of Mn, greater than 0 and less than or equal to 0.05wt% of Cu, 0.8wt% of Sr and the balance of Mg;

[0037] The coating is a Ca-P-Ag coating.

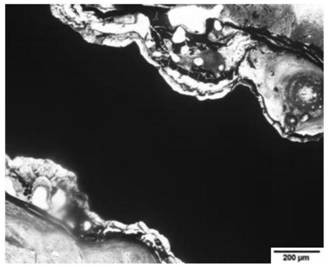

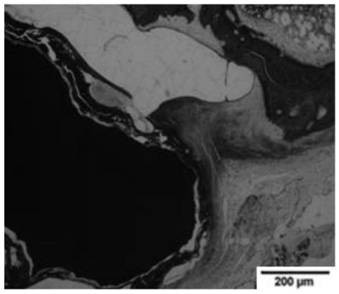

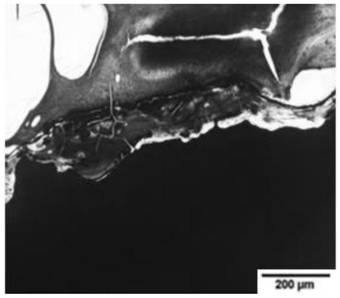

[0038] In the process of preparing the degradable bone rod implantation device, the present application prepared a Ca-P-Ag coating on the surface of the medical bone rod through a micro-arc oxidation process; the medical bone rod was prepared according to a method well known to ...

Embodiment 1

[0042] provide as figure 2 The medical bone-synthesizing rod shown, the diameter D of the bone-synthesized rod connected by the coaxial is 8mm, the height h 0 A base of 10mm with a diameter d of 4mm and a height h 1 The length W of the groove in the center of the bottom of the base is 6mm, and the height h 2 3mm; meanwhile, the bone bonding rod is a magnesium alloy material, which consists of 0.1wt% Fe, 0.6wt% Zn, 0.6wt% Mn, 0.02wt% Cu, 0.8wt% Sr and the rest of Mg;

[0043] The micro-arc oxidation process is used to in-situ grow Ca-P-Ag coating on the surface of the medical bone rod to obtain a degradable magnesium alloy bone rod implant device; the specific composition of the electrolyte in the micro-arc oxidation process is sodium silicate 40wt%+nano Hydroxyapatite powder 50wt% + sodium fluoride 5wt% + glycerin 2wt% + sodium hydroxide 2wt% + 1wt% nano-Ag powder + deionized water 2000mL, the specific process parameters are constant voltage 300V; pulse frequency 350Hz; Ra...

Embodiment 2

[0047] provide as figure 2 As shown in the medical bone rod, the bone rod is coaxially connected with a diameter D of 6 mm and a height h 0 A base of 8mm with a diameter d of 3mm and a height h 1 The length W of the groove in the center of the bottom of the base is 4mm, and the height h 2 2mm; meanwhile, the bone bonding rod is a magnesium alloy material, which consists of 0.4wt% Fe, 0.8wt% Zn, 0.4wt% Mn, 0.03wt% Cu, 0.8wt% Sr and the rest of Mg;

[0048] The Ca-P-Ag coating is grown in situ on the surface of the medical bone rod by using the micro-arc oxidation process to obtain a degradable magnesium alloy bone rod implant device; the specific composition of the electrolyte in the micro-arc oxidation process is sodium silicate 50wt%+nano HA powder 40wt% + sodium fluoride 5wt% + glycerin 2wt% + sodium hydroxide 2wt% + 1wt% nano-Ag powder + deionized water 2000mL, the specific process parameters are constant voltage 400V; pulse frequency 250Hz; duty cycle 10% , oxidation t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com