Separation method for pyrolysis and hydrogenation of butanol and octanol waste liquid

A separation method and technology of butanol and octanol, applied in the field of obtaining butanol and octanol products, can solve the problems of high catalyst activity at low temperature, complex catalyst composition, and low utilization rate of raw materials, so as to improve stability, reduce composition complexity, reduce effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

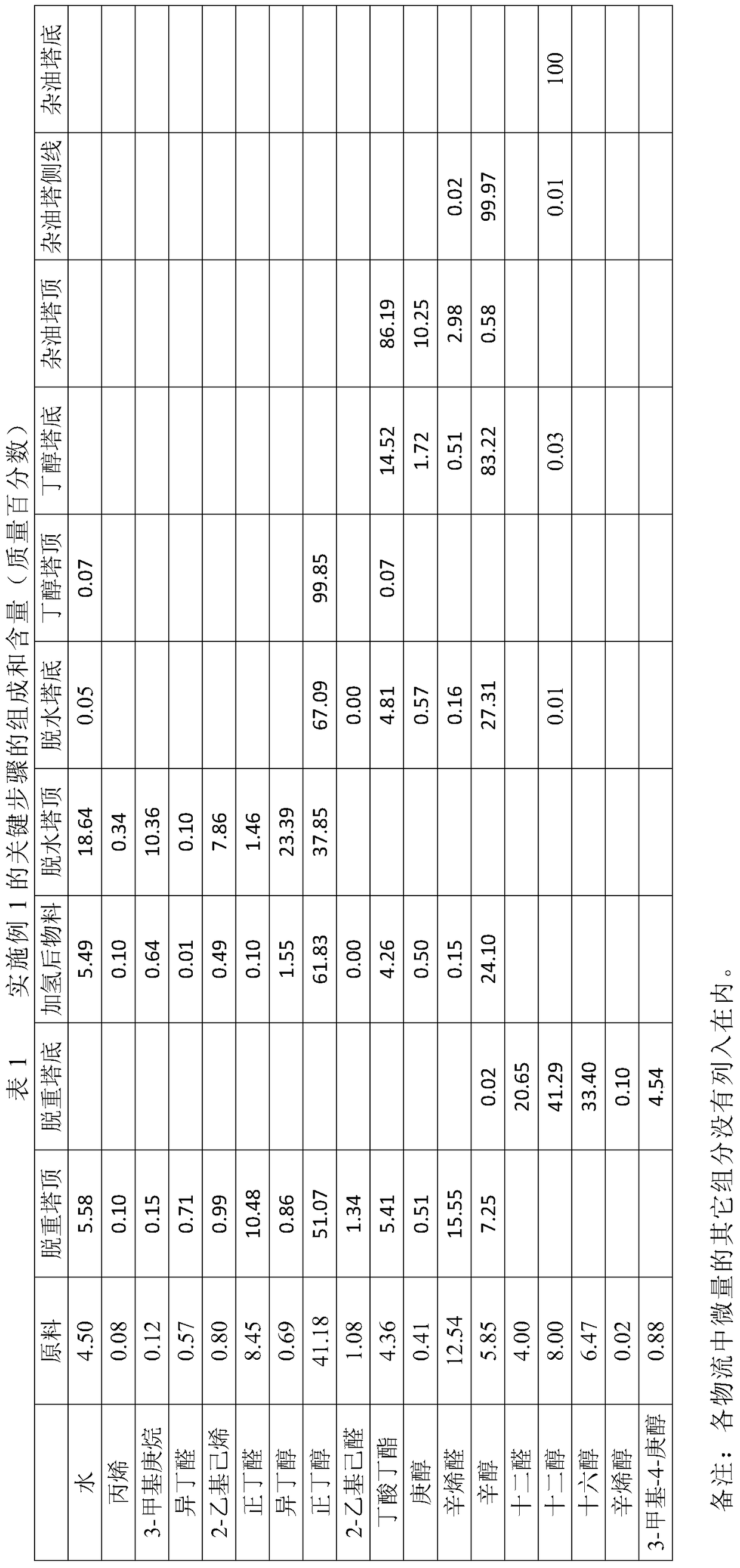

Embodiment 1

[0031] The separation method of cracking and hydrogenation of butanol waste liquid of the present invention specifically comprises hydrogenation unit and rectification unit, comprises the following steps:

[0032] (1) Weight removal: the butanol waste liquid is passed into the weight removal tower, and through the rectification process, water, hydrocarbons, isobutyraldehyde, n-butyraldehyde and butanol, octenal and octane are distilled from the top of the weight removal tower Alcohol, which contains heavy components containing twelve carbon atoms and sixteen carbon atoms from the bottom of the tower; the top temperature of the weight removal tower is 40 ° C, the top pressure is 0.07 MPa, and the temperature of the bottom of the tower is 199 ° C ;

[0033] (2) Cracking: The heavy component stream from the bottom of the de-weighting tower enters the cracking furnace for cracking, and the cracked stream is passed into the flash tank, and the light component stream steamed from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com