Crude octanol liquid phase hydrogenation catalyst and preparation method thereof

A liquid-phase hydrogenation and catalyst technology, which is applied in the directions of heterogeneous catalyst chemical elements, chemical instruments and methods, and hydroxyl compound preparation, can solve problems such as the treatment of waste catalysts for catalytic cracking that is not mentioned, and achieve good economic benefits and social benefits. Benefit, improved purity and color, high hydrogenation activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

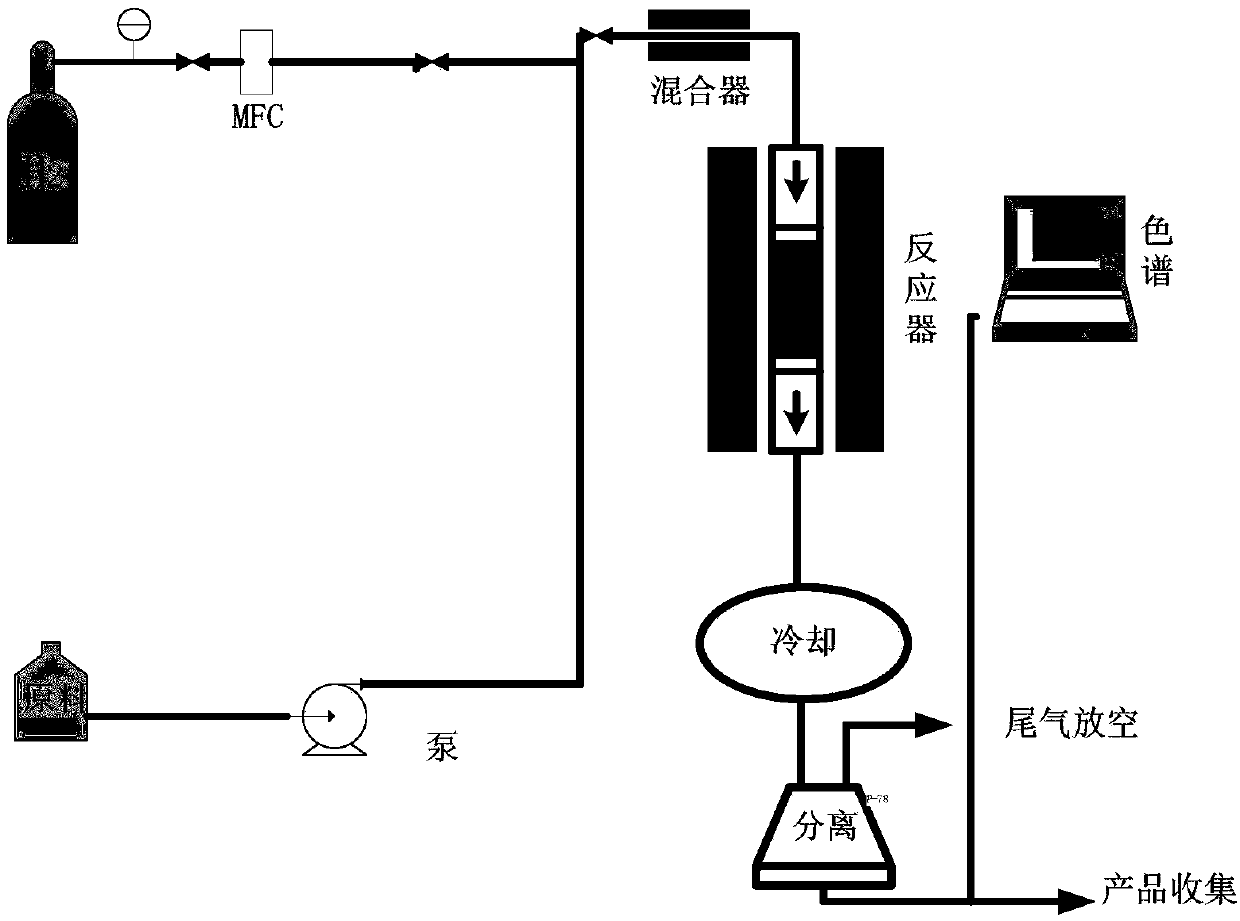

Method used

Image

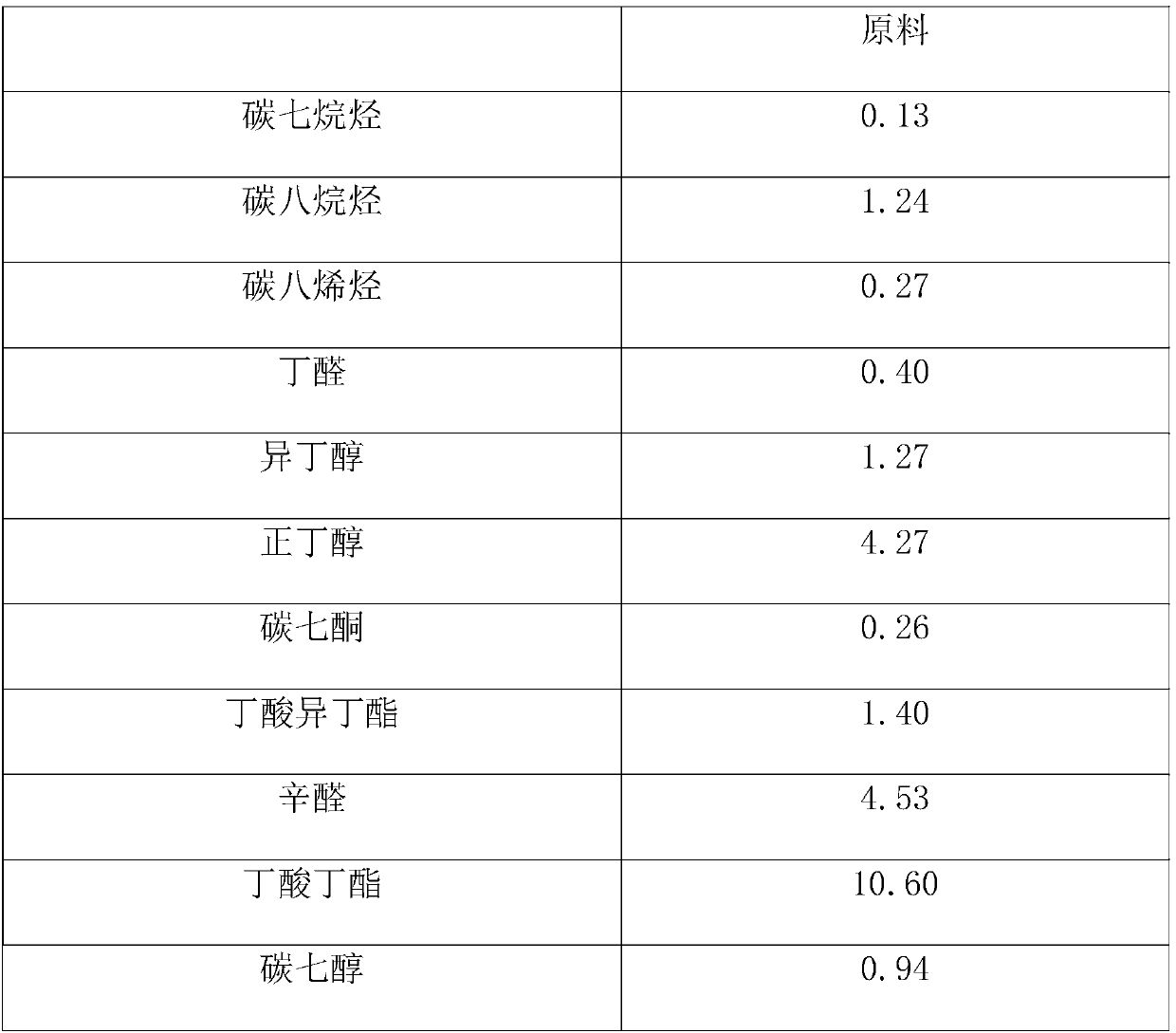

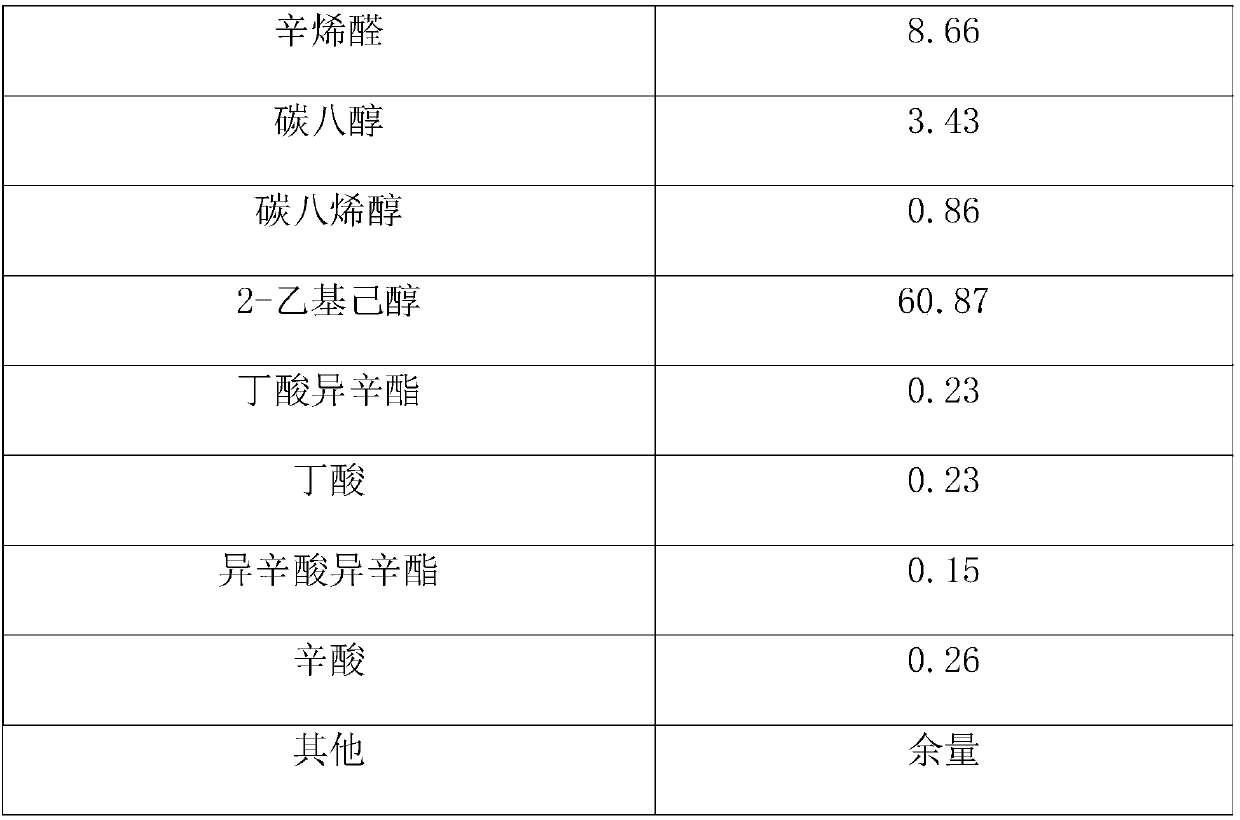

Examples

Embodiment 1

[0032] CD002 (taken from Sinopec Catalyst Qilu Branch in 2017, containing about 37% (m / m) SiO 2 , about 53% (m / m) Al 2 o 3 , the balance is iron, nickel, vanadium, sodium, etc., which can be washed off by acid) The waste agent is soaked and washed with 30% nitric acid for 2 hours, taken out and drained, and roasted to remove carbon deposits. The roasting temperature is 500 ° C, and the roasting time is 2 hours. The final waste agent is crushed through a 140 mesh sieve.

[0033] Weigh a certain amount of nickel nitrate, add water to dissolve, and adjust the pH value with nitric acid to configure a 3.7mol / L nickel nitrate solution with a pH value of 1.2.

[0034] Vector preparation:

[0035]Mix 35g of the roasted waste catalytic cracking catalyst, 8.75g of alumina glue, 1.2g of turnip powder and 1mL of nitric acid, the pH value of the mixed material is measured as 4, add 10mL of water and knead evenly; then extrude into strips, Dry at 120°C for 6 hours, and then roast. The r...

Embodiment 2

[0040] Soak and wash CD002 waste agent (taken from Sinopec Catalyst Qilu Branch in 2017) with 35% nitric acid for 10 hours, take it out and drain, and roast to remove carbon deposits. The roasting temperature is 700°C and the roasting time is 10 hours. The powder was crushed through a 160 mesh sieve.

[0041] Weigh a certain amount of nickel nitrate, add water to dissolve, and adjust the pH value with nitric acid to prepare a 0.5 mol / L nickel nitrate solution with a pH value of 2.5.

[0042] Vector preparation:

[0043] Mix 78g of roasted waste catalytic cracking catalyst, 17g of alumina glue, 1.5g of scallop powder and 1mL of nitric acid, the pH value of the mixed material is measured as 3, add 29mL of water and knead evenly; Dry at 120°C for 4h, and bake at 1100°C for 2h to prepare the carrier. The alumina glue used has a specific surface area of 305m 2 / g.

[0044] Catalyst preparation:

[0045] Spray 68mL of the above-mentioned nickel nitrate solution on the carrier...

Embodiment 3

[0048] Soak CD002 waste agent (taken from Sinopec Catalyst Qilu Branch in 2017) with nitric acid with a concentration of 10% for 10 hours, take it out and drain, and roast to remove carbon deposits. The roasting temperature is 550 ° C and the roasting time is 4 hours. The agent was crushed through a 120 mesh sieve.

[0049] Weigh a certain amount of nickel nitrate, add water to dissolve, and adjust the pH value with nitric acid to prepare a 2 mol / L nickel nitrate solution with a pH value of 2.5.

[0050] Vector preparation:

[0051] Mix 62g of the roasted waste catalytic cracking catalyst, 13g of alumina glue, 1.5g of turnip powder and 0.8mL of nitric acid, the pH value of the mixed material is measured to be 3.5, add 22mL of water and knead evenly; then extrude into strips, The carrier was obtained after drying at 120°C for 4h and calcining at 1050°C for 3h. The alumina glue used has a specific surface area of 315m 2 / g.

[0052] Catalyst preparation:

[0053] Spray 85...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com